Tip self-heating type anti-freezing self-repairing cable

A self-repairing and self-heating technology, applied in the direction of insulated cables, power cables, cables, etc., can solve the problems that the protective layer of the wire core is easy to become brittle, reduce the service life of the cable, and cause safety hazards, so as to reduce the probability of cracking, The effect of prolonging the service life and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

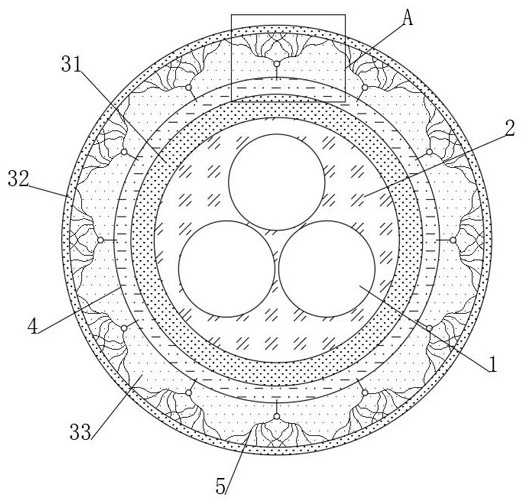

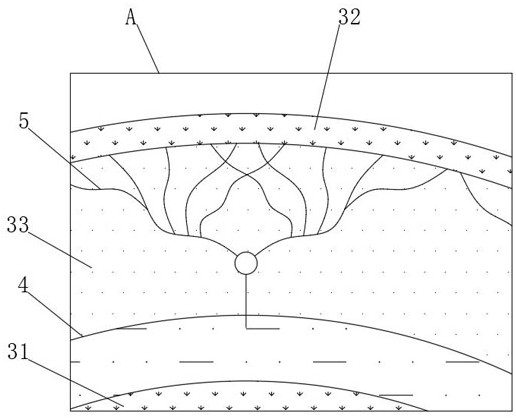

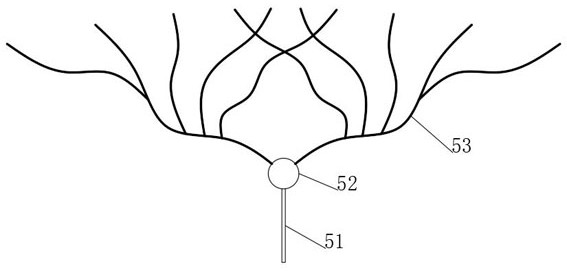

[0038] see figure 1 , a terminal self-heating type freeze-resistant self-repairing cable, comprising a plurality of wire cores 1, the outer ends of the plurality of wire cores 1 are wrapped with an inner insulating layer 2, and the outer ends of the inner insulating layer 2 are wrapped with an outer protective layer, and the outer protective layer includes The inner protection layer 31 wrapped outside the inner insulation layer 2, the outer insulation protection layer 32 located at the outermost layer, and the repair interlayer 33 arranged between the inner protection layer 31 and the outer insulation protection layer 32, the repair interlayer 33 is near the inner end A ring-shaped repair cavity 4 is excavated, and the ring-shaped repair cavity 4 is filled with repair glue, which can be a rubber repair agent. The repair interlayer 33 is inlaid with a plurality of evenly distributed capillary dispersion bundles 5, and the outer ends of the capillary dispersion bundles 5 are one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com