Enteric hollow capsule and preparation method thereof

A hollow capsule, enteric-coated technology, applied in the directions of capsule delivery, pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve the problems of affecting the sealing, affecting the efficacy, and breaking the gastric juice, so as to improve the sealing and slow down the water. The effect of reducing the loss of parts and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

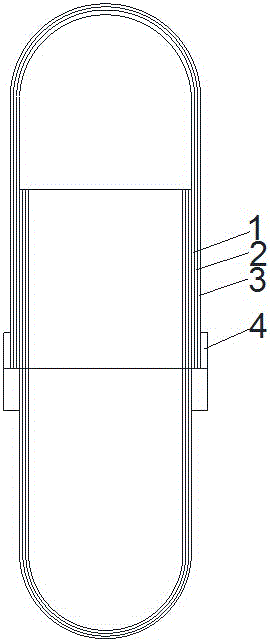

[0024] Such as figure 1 As shown, an enteric hollow capsule includes a capsule shell 1 and an enteric coating 3, the enteric coating 3 is coated on the outer surface of the capsule shell 1, and the capsule shell 1 includes a capsule cap inserted into one body and the capsule body, the capsule cap and the capsule body are sealed by a layer of sealing film 4, and the sealing film 4 is arranged at the position where the opening end of the capsule cap and the capsule body are inserted. An isolation layer 2 is provided between the capsule shell 1 and the enteric coating 3 . The thickness of the isolation layer 2 is 7 μm, and the thickness of the enteric coating 3 is 10 μm.

[0025] A method for preparing an enteric-coated hollow capsule, comprising the following steps: using gelatin, cellulose, or pullulan to prepare a capsule liquid according to a known method, dipping the capsule liquid into a rubber mold to form a capsule shell, and The capsule shell includes a capsule cap and...

Embodiment 2

[0030] An enteric hollow capsule, comprising a capsule shell 1 and an enteric coating 3, the enteric coating 3 is coated on the outer surface of the capsule shell 1, and the capsule shell 1 includes a capsule cap and a capsule body inserted in one , the capsule cap and the capsule body are sealed by two layers of sealing film 4, and the sealing film 4 is arranged at the position where the opening end of the capsule cap and the capsule body are inserted. An isolation layer 2 is provided between the capsule shell 1 and the enteric coating 3 . The thickness of the isolation layer 2 is 10 μm, and the thickness of the enteric coating 3 is 15 μm.

[0031] A method for preparing an enteric-coated hollow capsule, comprising the following steps: using gelatin, cellulose, or pullulan to prepare a capsule liquid according to a known method, dipping the capsule liquid into a rubber mold to form a capsule shell, and The capsule shell includes a capsule cap and a capsule body; the capsule ...

Embodiment 3

[0036] An enteric hollow capsule, comprising a capsule shell 1 and an enteric coating 3, the enteric coating 3 is coated on the outer surface of the capsule shell 1, and the capsule shell 1 includes a capsule cap and a capsule body inserted in one , the capsule cap and the capsule body are sealed by two layers of sealing film 4, and the sealing film 4 is arranged at the position where the opening end of the capsule cap and the capsule body are inserted. An isolation layer 2 is provided between the capsule shell 1 and the enteric coating 3 . The thickness of the isolation layer 2 is 8 μm, and the thickness of the enteric coating 3 is 12 μm.

[0037] A method for preparing an enteric-coated hollow capsule, comprising the following steps: using gelatin, cellulose, or pullulan to prepare a capsule liquid according to a known method, dipping the capsule liquid into a rubber mold to form a capsule shell, and The capsule shell includes a capsule cap and a capsule body; then the caps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com