Fusion splicing devices and methods of photon crystal optical fiber

A technology of photonic crystal fiber and fusion splicing, which is applied in the coupling of optical waveguide, program control in sequence/logic controller, electrical program control, etc. Distribution control, it is difficult to control the collapse degree of cladding air holes, etc., to achieve the effect of simple structure, strong anti-vibration interference ability, and avoid brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

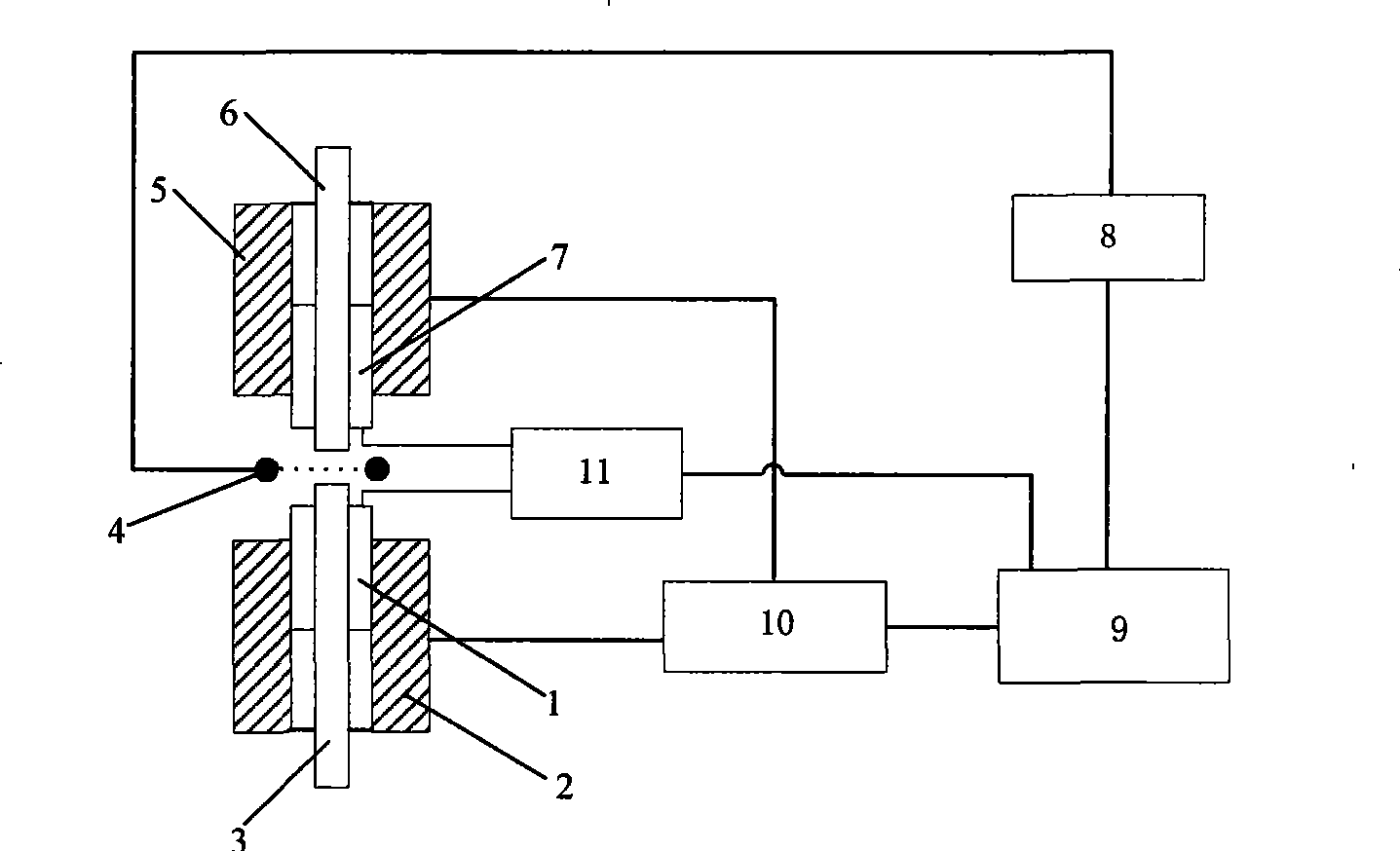

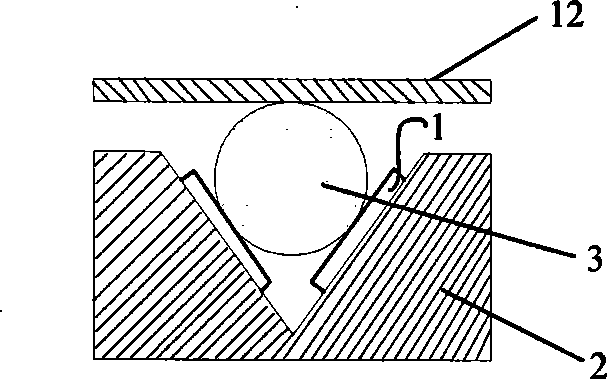

[0019] 1. The specifications of the fusion-spliced lower and upper photonic crystal fibers (3, 6) are: the mode field radius is 7.5 μm, the core diameter is 10.9 μm, the hole spacing is 3 μm, the air hole diameter is 2 μm, and the number of air hole layers is 6 layers . Install the fused lower and upper photonic crystal fibers (3, 6) on the lower and upper three-dimensional motion V-groove devices (2, 5).

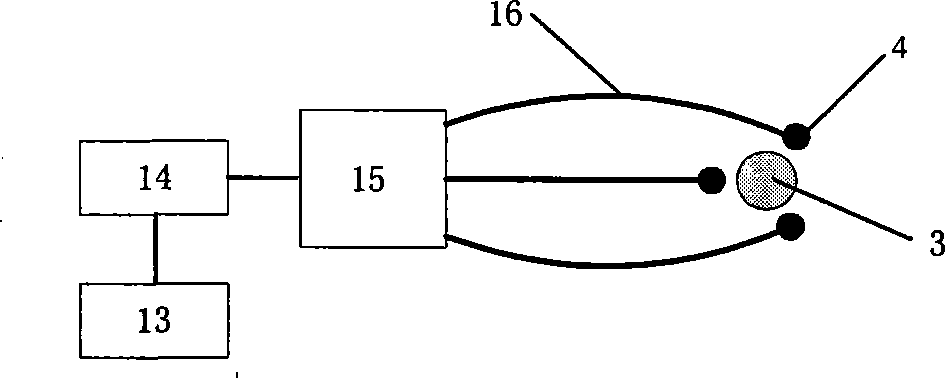

[0020] 2. According to the structural parameters of the lower and upper photonic crystal fibers (3, 6), pass through the lower and upper stress sensors (1, 7), the stress sensor demodulation unit 11, the three-dimensional alignment controller and the fixture control unit of the fixture control unit 10 The feedback control of the optical fiber clamp 12 automatically adjusts the clamping force of the lower and upper photonic crystal fibers (3, 6). The maximum pressure that this kind of photonic crystal fiber can withstand is 0.09N / μm. The clamping force used in the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com