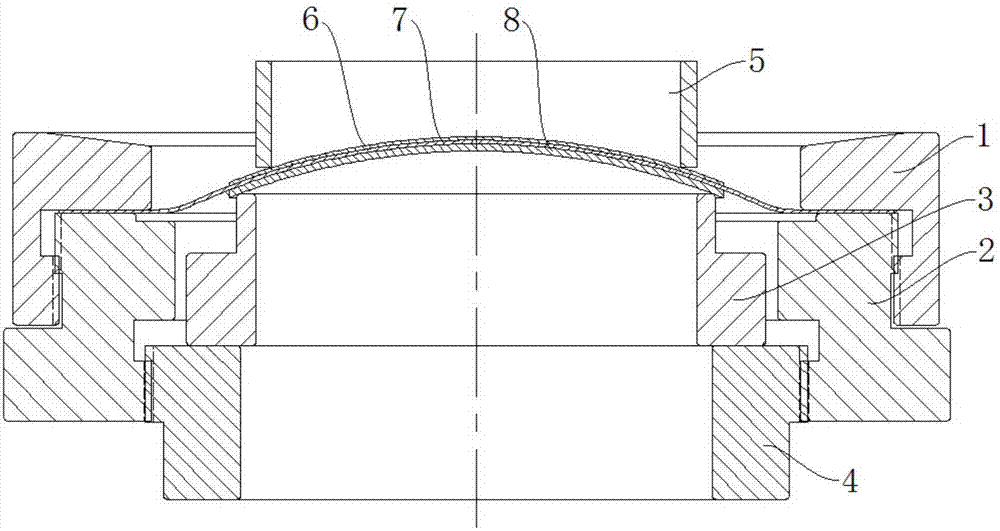

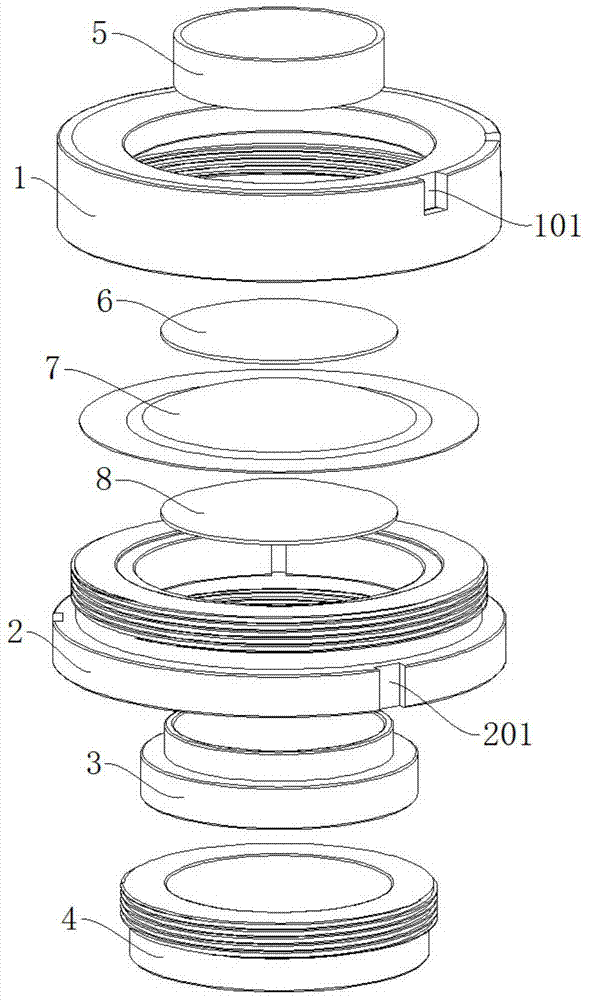

Method and die for manufacturing glass polarizing lens

A technology for polarizing lenses and a manufacturing method, applied in optics, optical elements, polarizing elements, etc., can solve the problems of complex molding equipment, difficult operation, cumbersome molding process, etc., achieve high operating efficiency and accuracy, simplify the molding process, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of manufacturing method of glass polarizing lens of the present embodiment, its steps are:

[0048] (1) Clamp the cut polarizing film flat sheet, heat and humidify the polarizing film flat sheet until the polarizing film flat sheet softens. Specifically, firstly, place the clamped flat polarizing film above the heating device, and shake it back and forth, so that the flat polarizing film is heated evenly, and the heating temperature is 40°C to 100°C. In this embodiment, according to the polarizing The properties of the film flat sheet are selected at a heating temperature of 70°C, and the heating device is a heating furnace; then, the heated polarizing film flat sheet is placed above the steam generating device to fully soften the polarizing film flat sheet, and the method is heated and humidified. The softening speed of the polarizing film is improved, and the softening time is saved. Compared with the prior art, the humidification step is added, which effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com