Ultrathin magnetic field shielding sheet excellent in heat dissipation performance and preparation method of ultrathin magnetic field shielding sheet excellent in heat dissipation performance

A technology of heat dissipation performance and shielding sheet, which is applied in the fields of magnetic field/electric field shielding, cooling/ventilation/heating transformation, electrical components, etc. It can solve the problems that the thickness and heat dissipation performance cannot meet the growing requirements of customers, and achieve optimal heat dissipation effect. Good magnetic field shielding performance and guaranteed mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of an ultra-thin magnetic field shielding sheet with excellent heat dissipation performance in this embodiment, the specific preparation steps are as follows:

[0035] (1) The amorphous and nanocrystalline strips (composed of Fe 75-90wt.%, Si 5-10wt.%, B 1-10wt.%, Cu 1-5wt.%, Nb 3-10wt.%, other 0-5wt.%) at 560° C. for 30 minutes to obtain nanocrystalline strips with a thickness of 18 μm.

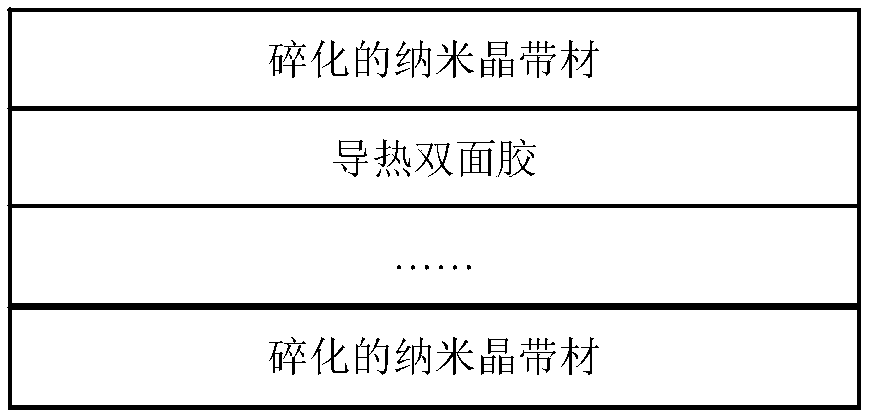

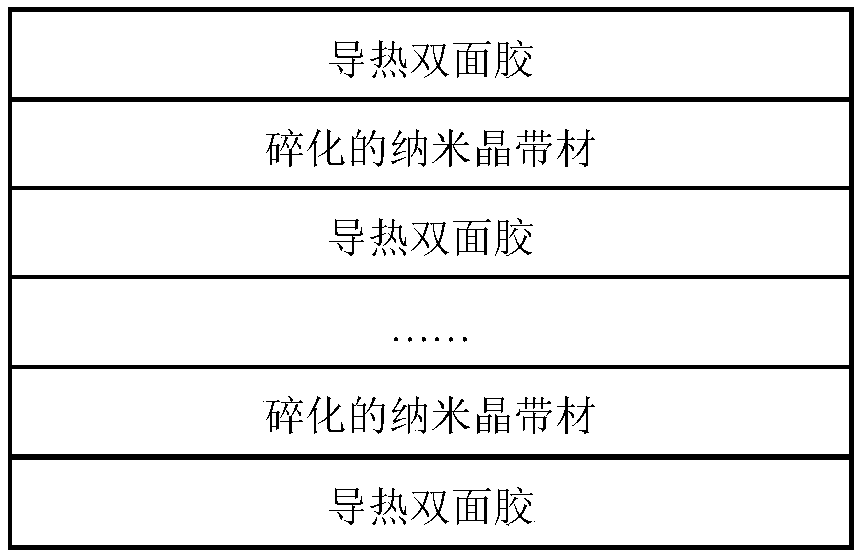

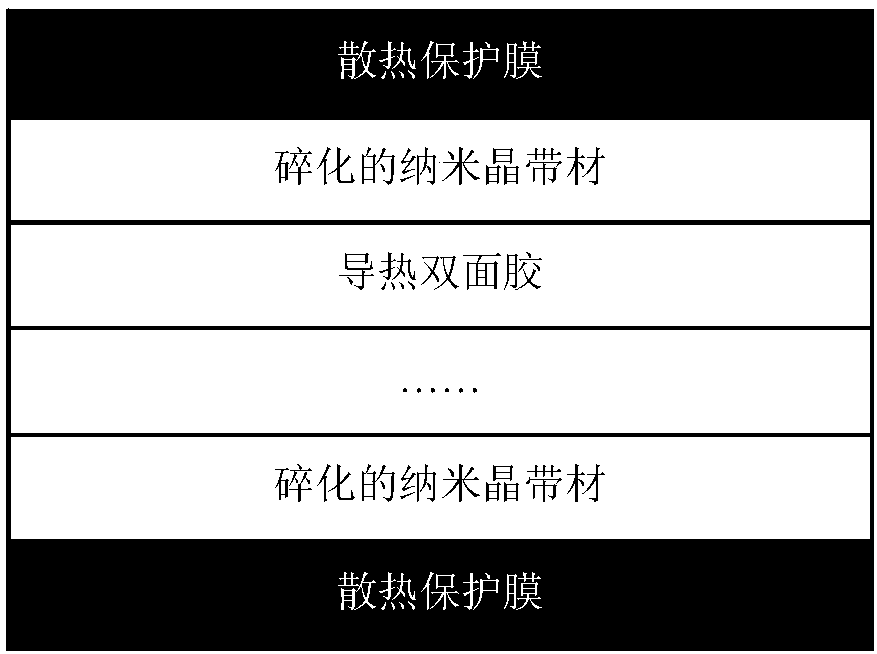

[0036] (2) On one side of the nanocrystalline strip obtained in step (1), use a thermally conductive double-sided adhesive with a thickness of 3 μm (composed of adding ceramic powder, aluminum oxide and other thermally conductive fillers to ordinary PET double-sided adhesive) for compounding treatment.

[0037] (3) The nanocrystalline strip after the regluing treatment obtained in step (2) is subjected to crushing treatment, and the crushing process is completed by dislocation rolling of the upper and lower flower rollers: through a group of patterned steel bars...

Embodiment 2

[0045] The preparation method of an ultra-thin magnetic field shielding sheet with excellent heat dissipation performance in this embodiment, the specific preparation steps are as follows:

[0046] (1) The amorphous and nanocrystalline strips (composed of Fe 75-90wt.%, Si 5-10wt.%, B 1-10wt.%, Cu 1-5wt.%, Nb 3-10wt.%, other 0-5wt.%) at 650° C. for 100 minutes to obtain nanocrystalline strips with a thickness of 20 μm.

[0047] (2) On one side of the nanocrystalline strip obtained in step (1), use a thermally conductive double-sided adhesive with a thickness of 5 μm (composed of adding ceramic powder, aluminum oxide and other thermally conductive fillers to ordinary PET double-sided adhesive) for compounding treatment.

[0048] (3) The nanocrystalline strip after the regluing treatment obtained in step (2) is subjected to crushing treatment, and the crushing process is completed by dislocation rolling of the upper and lower flower rollers: through a group of patterned steel bar...

Embodiment 3

[0056] The preparation method of an ultra-thin magnetic field shielding sheet with excellent heat dissipation performance in this embodiment, the specific preparation steps are as follows:

[0057] (1) The amorphous and nanocrystalline strips (composed of Fe 75-90wt.%, Si 5-10wt.%, B 1-10wt.%, Cu 1-5wt.%, Nb 3-10wt.%, other 0-5wt.%) at 580° C. for 60 minutes to obtain a nanocrystalline ribbon with a thickness of 22 μm.

[0058] (2) On one side of the nanocrystalline strip obtained in step (1), use a thermally conductive double-sided adhesive with a thickness of 5 μm (composed of adding ceramic powder, aluminum oxide and other thermally conductive fillers to ordinary PET double-sided adhesive) for compounding treatment.

[0059] (3) The nanocrystalline strip after the regluing treatment obtained in step (2) is crushed, and the crushing process is completed by dislocation rolling of the upper and lower flower rollers: through a group of two mirror steel rods up and down, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com