Blocked double-component, solvent-free, waterproof and moisture-permeable polyurethane resin and preparation method thereof

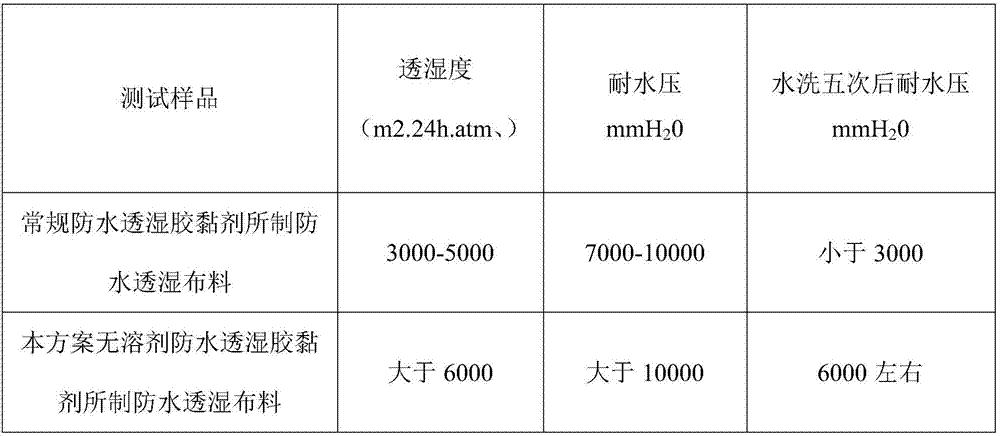

A polyurethane resin, waterproof and moisture-permeable technology, which is applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesives, etc., can solve the problems of short storage time of mixtures and unstable performance of finished products, and achieve long storage time, Excellent washing resistance and the effect of improving moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Preparation of component A: in parts by weight, put 60 parts of toluene isocyanate (TDI-80), 90 parts of 4,4-diphenylmethane diisocyanate MDI, and 0.1 parts of antioxidant into the reaction kettle at 40 °C Stir evenly, put 140 parts of neopentyl glycol polyester polyol with a molecular weight of 2000 into the reactor and react at 60-70°C for 2 hours, then put 100 parts of polytetrahydrofuran polyol with a molecular weight of 1500 into the reactor. React at 60-70°C for 2 hours, then put 300 parts of polyoxyethylene polyol with a molecular weight of 2000 into the reactor and react at 60-70°C for 4 hours, after the reaction until the residual NCO reaches the theoretical value, add 65 parts of butanone oxime React with 0.1 part of organic bismuth catalyst at 70-80°C until no residual NCO is present, and then discharge. (2) Preparation of component B: in parts by weight, 40 parts of diethylenetriamine and 60 parts of isophoronediamine were uniformly mixed. (3) Mix compo...

Embodiment 2

[0018] (1) Preparation of Component A: In parts by weight, 70 parts of toluene isocyanate (TDI-80), 85 parts of 4,4-diphenylmethane diisocyanate MDI, and 0.15 parts of antioxidant were put into the reactor at 45°C Stir evenly, put 110 parts of neopentyl glycol polyester polyol with a molecular weight of 1500 into the reactor and react at 60-70°C for 2.5 hours, then put 150 parts of polytetrahydrofuran polyol with a molecular weight of 2000 into the reactor. React at 60-70°C for 2.5 hours, then put 380 parts of polyoxyethylene polyol with a molecular weight of 2500 into the reactor and react at 60-70°C for 5 hours, and add 70 parts of butanone oxime after the reaction until the residual NCO reaches the theoretical value React with 0.12 parts of organic bismuth catalyst at 70-80°C until no residual NCO is present, and then discharge. (2) Preparation of component B: in parts by weight, 60 parts of diethylenetriamine and 40 parts of isophoronediamine were uniformly mixed. (3) Mix...

Embodiment 3

[0020] (1) Preparation of component A: in parts by weight, put 80 parts of toluene isocyanate (TDI-80), 90 parts of 4,4-diphenylmethane diisocyanate MDI, and 0.2 parts of antioxidant into the reactor at 50°C Stir evenly, put 250 parts of neopentyl glycol polyester polyol with a molecular weight of 3000 into the reactor and react at 60-70°C for 3 hours, then put 300 parts of polytetrahydrofuran polyol with a molecular weight of 3000 into the reactor. React at 60-70°C for 3 hours, then put 900 parts of polyoxyethylene polyol with a molecular weight of 3000 into the reactor and react at 60-70°C for 6 hours, add 80 parts of butanone oxime after the reaction until the residual NCO reaches the theoretical value React with 0.3 parts of organic bismuth catalyst at 70-80°C until no residual NCO is present, and then discharge. (2) Preparation of component B: in parts by weight, 70 parts of diethylenetriamine and 30 parts of isophoronediamine were uniformly mixed. (3) Mix component A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com