Waterborne bicomponent fluorocarbon conductive anticorrosion paint and preparation method and application method thereof

A conductive anti-corrosion, water-based fluorocarbon resin technology, used in anti-corrosion coatings, conductive coatings, devices for coating liquids on surfaces, etc. The effect of improving the functional performance of the paint film, excellent electrical conductivity and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

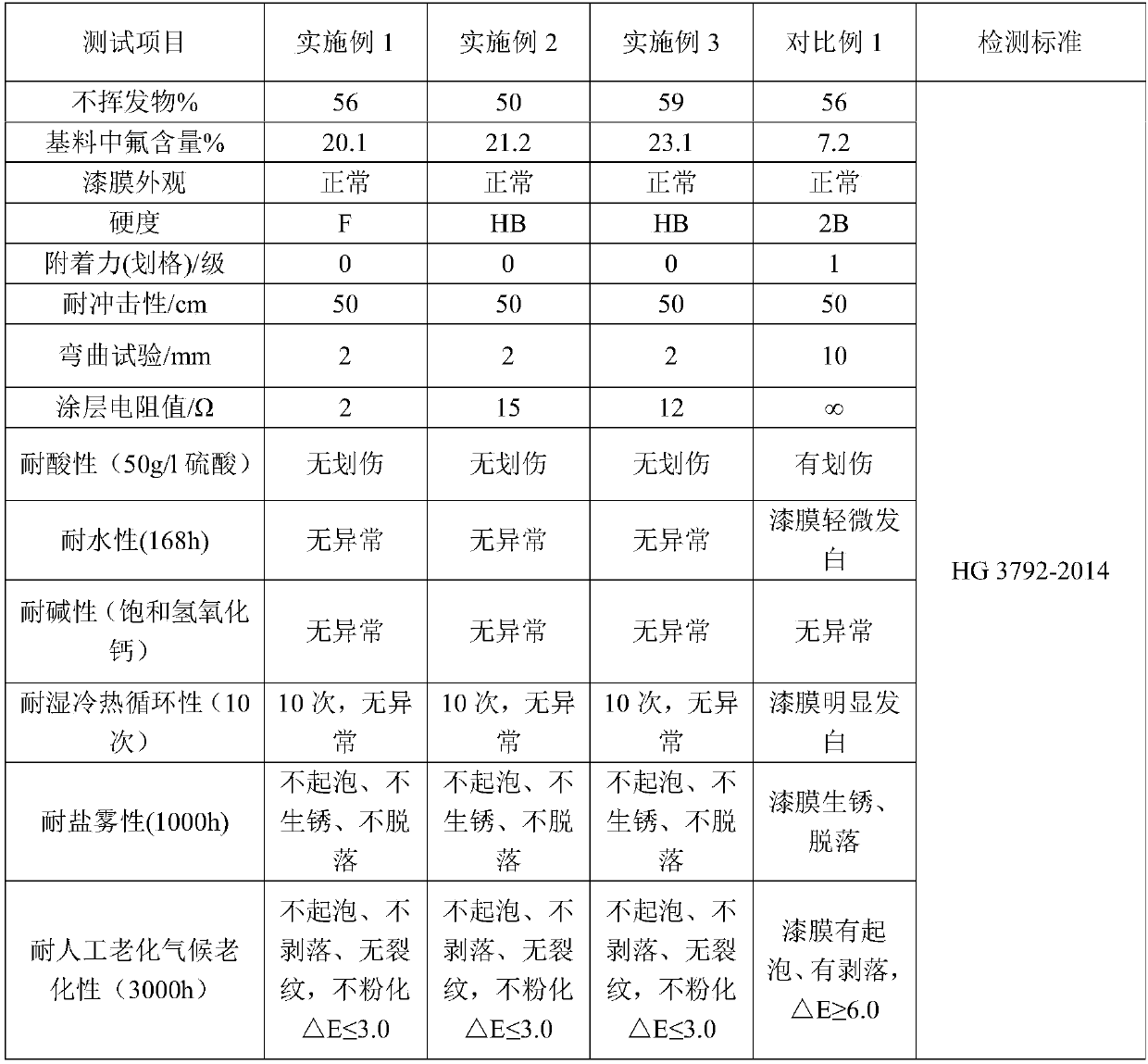

Examples

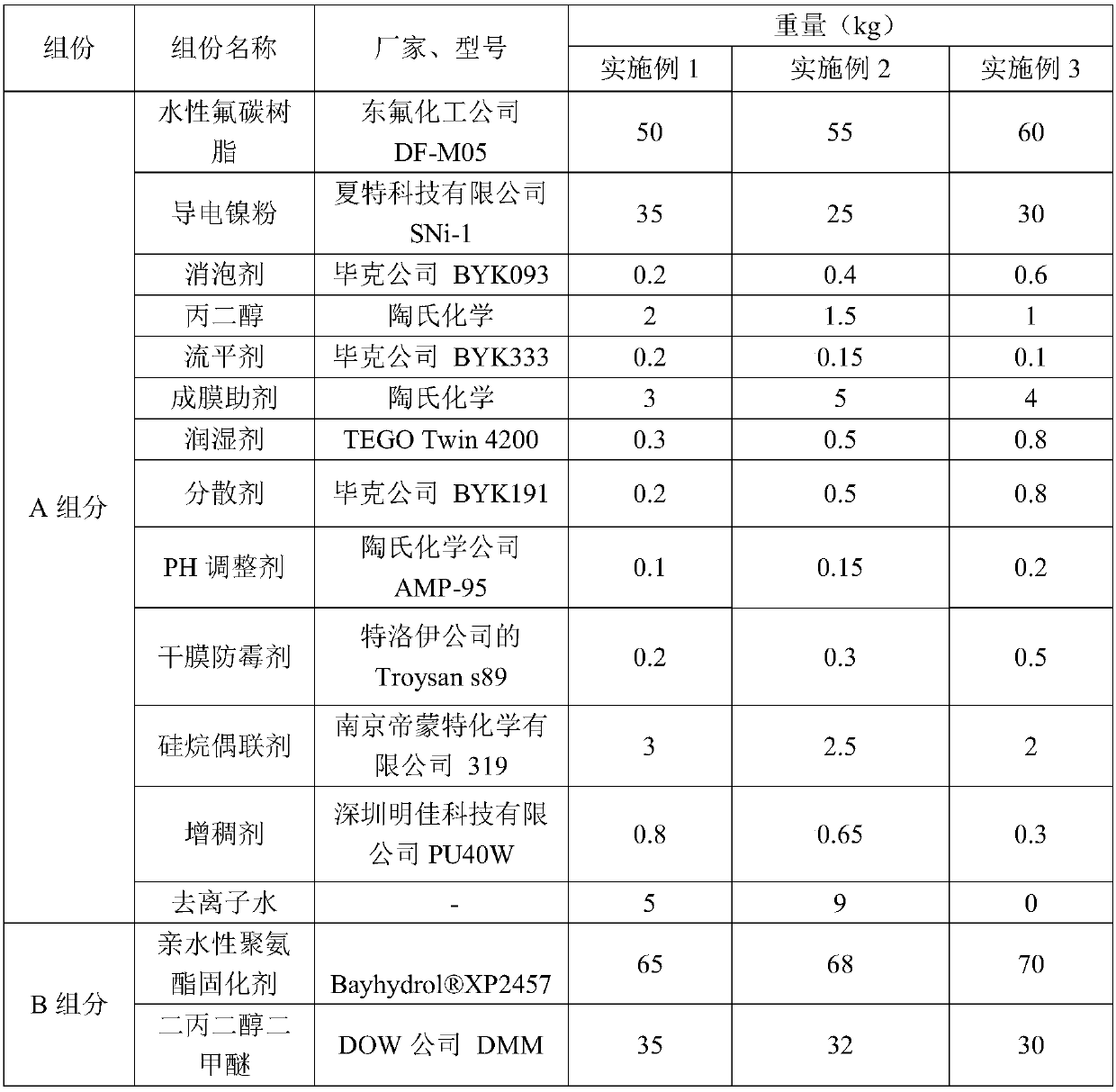

Embodiment 1

[0044] (1) Preparation of component A:

[0045] Step 1. Add 50kg of water-based fluorocarbon resin into the paint mixing container;

[0046] Step 2. Slowly add 35kg of conductive nickel powder, 0.2kg of defoamer, 2kg of propylene glycol, 3kg of silane coupling agent, and 0.2kg of dispersant under low-speed stirring at 400-500rpm / min, and then high-speed at 1000-1200rpm / min. Disperse for 45 minutes;

[0047] Step 3. Slowly add 0.3kg of wetting agent, 0.2kg of leveling agent, 0.1kg of PH regulator, and 0.2kg of dry film antifungal agent into the paint mixing container under low-speed stirring at 400rpm / min. Stirring at a medium speed at a speed of 10 min.

[0048] Step 4: After premixing 3kg of film-forming aid and deionized water at a ratio of 1:1, slowly add it to the paint mixing container at a speed of 400-500rpm / min while stirring at a low speed;

[0049] Step 5. Slowly add the remaining deionized water into the paint mixing container under low-speed stirring at 400-500r...

Embodiment 2

[0058] (1) Preparation of component A:

[0059] Step 1. Add 55kg of water-based fluorocarbon resin into the paint mixing container;

[0060] Step 2. Slowly add 25kg of conductive nickel powder, 0.4kg of defoamer, 1.5kg of propylene glycol, 2.5kg of silane coupling agent, and 0.5kg of dispersant under low-speed stirring at 400-500rpm / min, and then rotate at 1000-1200rpm / min Disperse at high speed for 45 minutes;

[0061] Step 3: Slowly add 0.5kg of wetting agent, 0.15kg of leveling agent, 0.15kg of PH regulator, and 0.3kg of dry film antifungal agent into the paint mixing container in sequence under low-speed stirring at 400rpm / min, and then Stirring at a medium speed at a speed of 10 min.

[0062] Step 4. After pre-mixing 5kg of film-forming aid and deionized water at a ratio of 1:1, slowly add it to the paint mixing container at a speed of 400-500rpm / min under low-speed stirring;

[0063] Step 5. Slowly add the remaining deionized water into the paint mixing container unde...

Embodiment 3

[0072] (1) Preparation of component A:

[0073] Step 1. Add 60kg of water-based fluorocarbon resin into the paint mixing container;

[0074] Step 2. Slowly add 25kg of conductive nickel powder, 0.6kg of defoamer, 1kg of propylene glycol, 2kg of silane coupling agent, and 0.8kg of dispersant under low-speed stirring at 400-500rpm / min, and then high-speed at 1000-1200rpm / min. Disperse for 45 minutes;

[0075] Step 3. Slowly add 0.8kg of wetting agent, 0.1kg of leveling agent, 0.21kg of PH regulator, and 0.5kg of dry film antifungal agent into the paint mixing container under low-speed stirring at 400rpm / min, and then mix at 600-800rpm Stirring at a medium speed at a speed of 10 min.

[0076] Step 4. After pre-mixing 4kg of film-forming aids and deionized water at a ratio of 1:1, slowly add them into the paint mixing container at a speed of 400-500rpm / min while stirring at a low speed;

[0077] Step 5. Slowly add the remaining deionized water into the paint mixing container un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com