Guar gum derivative and preparation method and application thereof

A guar gum derivative, guar gum technology, applied in the field of petroleum fracturing, can solve the problem of low cross-linking strength, and achieve the effect of high cross-linking strength and stable jelly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides the preparation method of the guar gum derivative described in above-mentioned technical scheme, comprises the following steps:

[0039] After mixing guar gum, borax and a solvent, they are mixed with an alkaline reagent under a protective atmosphere for alkalization to obtain a guar gum suspension;

[0040] The guar gum suspension is subjected to a two-step etherification reaction with a first etherification agent and a second etherification agent to obtain the guar gum derivative, and the first etherification agent is C1-C5 epoxy Alkanes, the second etherifying agent is halogenated dicarboxylic acid sodium salt or halogenated dicarboxylic acid ester; the sequence of etherification reaction between the first etherifying agent and the second etherifying agent is not limited.

[0041] In the invention, the guar gum, borax and solvent are mixed, and then mixed with an alkaline reagent in a protective atmosphere to carry out alkalization...

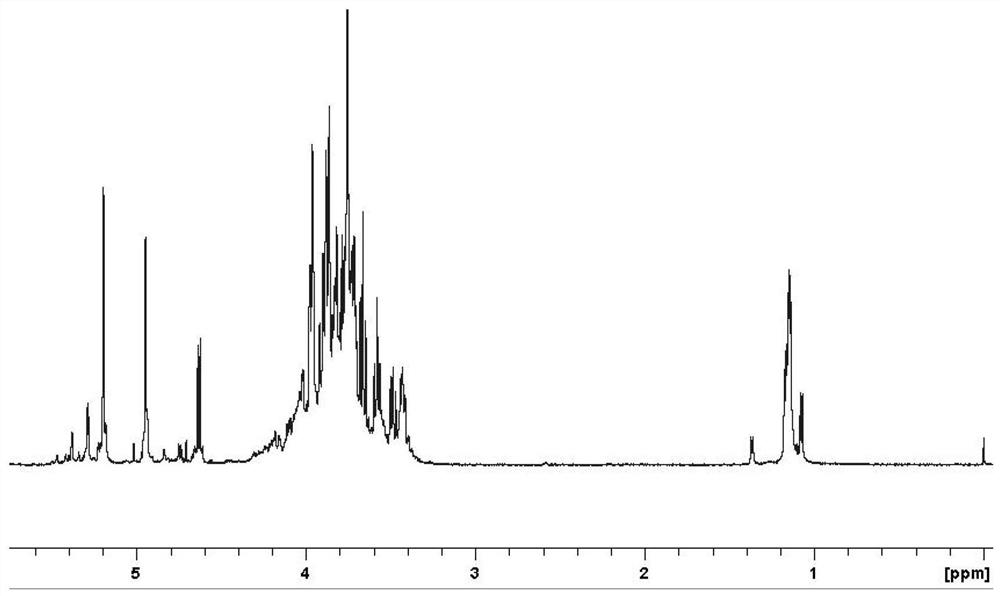

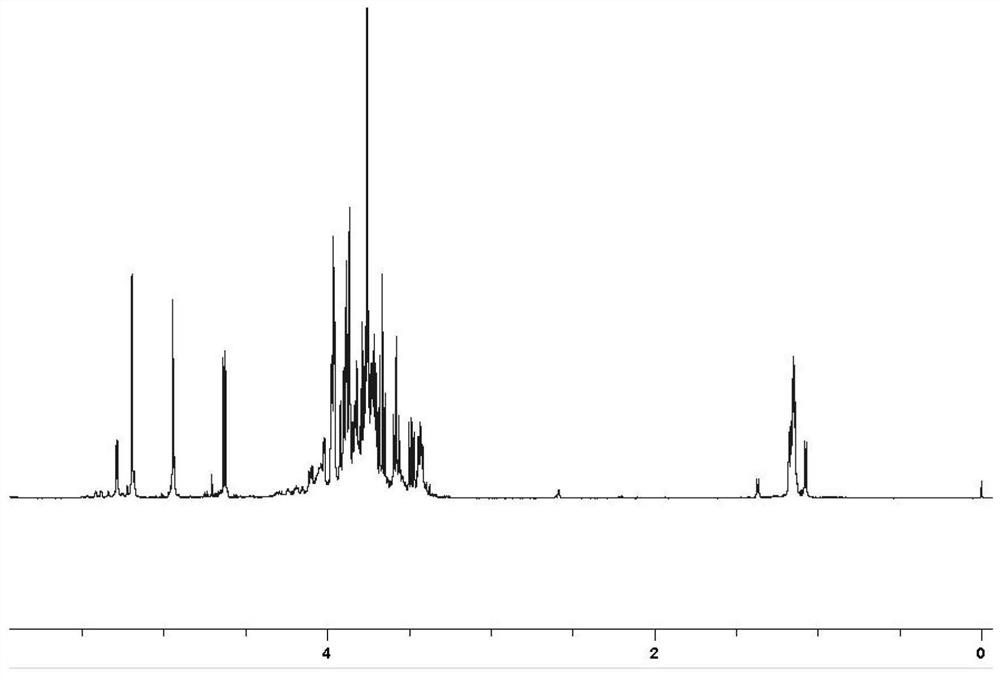

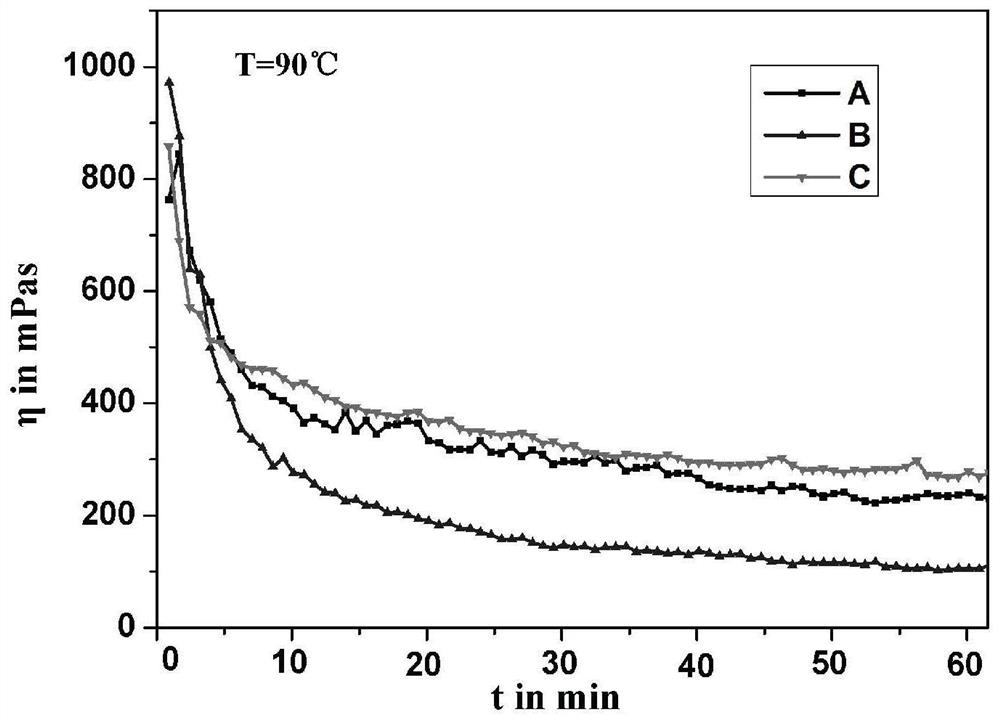

Embodiment 1

[0075] Add 100g of guar gum, 1.5g of borax and 200g of isopropanol into a three-necked flask, stir with nitrogen gas at room temperature for 30min, add dropwise 50wt% sodium hydroxide solution 35g under nitrogen protection, dropwise for 30min, and directly raise the temperature to 70 ℃, add 10g of propylene oxide dropwise, stir and react for 2h, discharge the material, wash once with suction filtration water, wash twice with alcohol water, and dry to obtain the reaction intermediate. Take 50g reaction intermediate, 45g sodium chloromalonate, 0.8g Add borax into a three-necked flask, pour 100g of isopropanol, and pass through nitrogen to stir and disperse for 30 minutes to make the mixture uniform, raise the temperature to 50°C, and add 30g of 50wt% sodium hydroxide solution dropwise in a nitrogen-protected environment. After the dropwise addition, the material was discharged after 1 hour of reaction, washed once with suction filtration water, washed twice with alcohol water and...

Embodiment 2

[0081] Add 100g of guar gum, 1.5g of borax and 200g of isopropanol into a three-necked flask, stir with nitrogen gas at room temperature for 30min, add dropwise 50wt% sodium hydroxide solution 35g under nitrogen protection, dropwise for 30min, and directly raise the temperature to 70 ℃, add 10g of propylene oxide dropwise, stir and react for 2h, discharge the material, wash once with suction filtration water, wash twice with alcohol water, and dry to obtain the reaction intermediate. Take 50g reaction intermediate, 28g sodium chloromalonate, 0.8g Add borax into a three-necked flask, pour 100g of isopropanol, and stir and disperse for 30 minutes with nitrogen gas to make the mixture uniform. Heat up to 50°C. Under nitrogen protection environment, add 20g of 50wt% sodium hydroxide solution dropwise, drop slowly, and add time After the dropwise addition, the material was discharged after 1 hour of reaction, washed once with suction filtration water, washed twice with alcohol water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com