Self-suspension proppant and preparation method thereof

A proppant and self-suspension technology, applied in chemical instruments and methods, earth square drilling, mining fluids, etc., can solve problems such as easy consolidation of products, increased viscosity of aqueous solution, and influence on settlement time, etc., to achieve good viscosity increase Effect, good self-suspension ability, effect of good suspension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Coupling agent alcohol solution preparation: measure 900mL of absolute ethanol, 50g of isobutyltrimethoxysilane, and 10mL of hydrolysis accelerator acetic acid, stir at 400r / min for 10 minutes and set aside.

[0041] Preparation of water-soluble viscosity-increasing polymer emulsion: Weigh 250g polyethylacrylate (weight average molecular weight 3 million, Mw / Mn is 2.56) polymer material, 10g emulsifier OP-10, measure 30mL acetic acid as hydrolysis accelerator The solution was poured into 1500mL water in turn, stirred at a speed of 1000r / min for 10 minutes and then set aside.

[0042] Preparation of self-suspension proppant: take a certain amount of 50kg ceramsite proppant (particle size 40-70 mesh) and put it into the fluidized bed; turn on the fan and heating device of the fluidized bed, and the air volume of the fan can make the fluidized bed Keep the proppant fully boiling and flowing, and set the temperature of the hot air at 150°C; when the temperature in the bed i...

Embodiment 2

[0044] Embodiment 2 (contrast):

[0045] The preparation of the water-soluble viscosity-increasing polymer emulsion is the same as in Example 1.

[0046] Self-suspension proppant preparation: Weigh a certain amount of 50kg ceramsite proppant (particle size 40-70 mesh), put it into a container for standby; add the prepared viscosity-increasing polymer emulsion into the container, stir evenly, and mix the obtained mixture After natural drying, sieving, the self-suspension proppant is obtained. See Table 1 and Table 2 for the test data of self-suspension ability and temperature resistance ability.

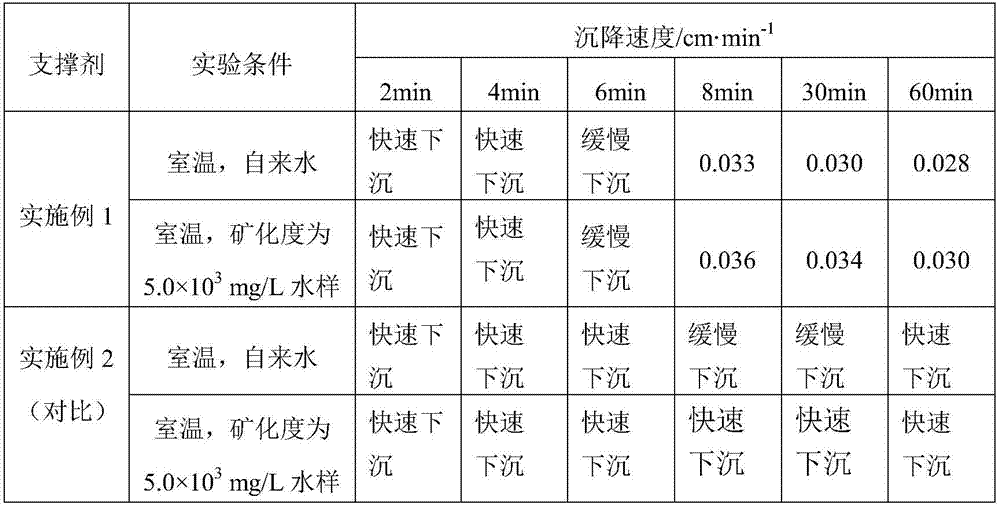

[0047] Table 1 Suspension capacity of self-suspending proppant

[0048]

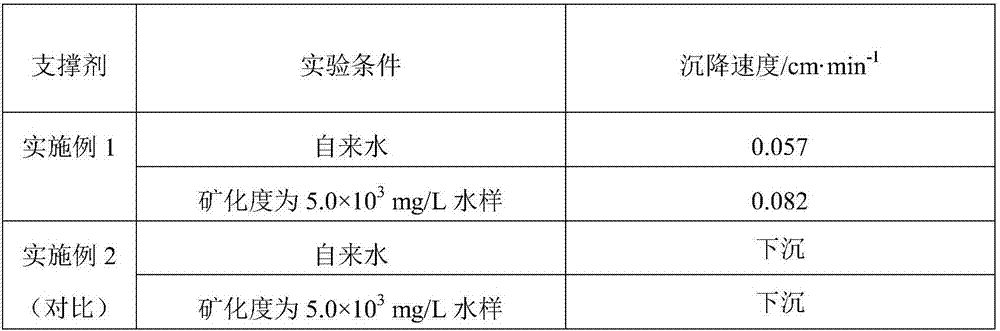

[0049] Table 2 Temperature resistance test of self-suspending proppants (100°C)

[0050]

Embodiment 3

[0052] Coupling agent alcohol solution preparation: Measure 1700mL of absolute ethanol, 100g of dodecyltrimethoxysilane, 50mL of acetic acid, stir at 400r / min for 10 minutes and set aside.

[0053] Preparation of water-soluble viscosity-increasing polymer emulsion: Weigh 300g poly ethyl 2-acrylamido-2-methyl-propanesulfonate (weight average molecular weight 6 million, Mw / Mn is 1.75) polymer material, emulsifier OP-10 20g, measure 50mL of acetic acid hydrolysis accelerator, pour into 2000mL water in turn, stir at 1000r / min for 10 minutes and set aside.

[0054] Self-suspension proppant preparation: take a certain amount of 50kg ceramsite proppant (particle size 40-70 mesh), put it into the fluidized bed; turn on the fan and heating device of the fluidized bed, the air volume of the fan can make the fluidized bed Keep the proppant fully boiling and flowing, and set the temperature of the hot air at 150°C; when the temperature in the bed is constant, spray the prepared coupling a...

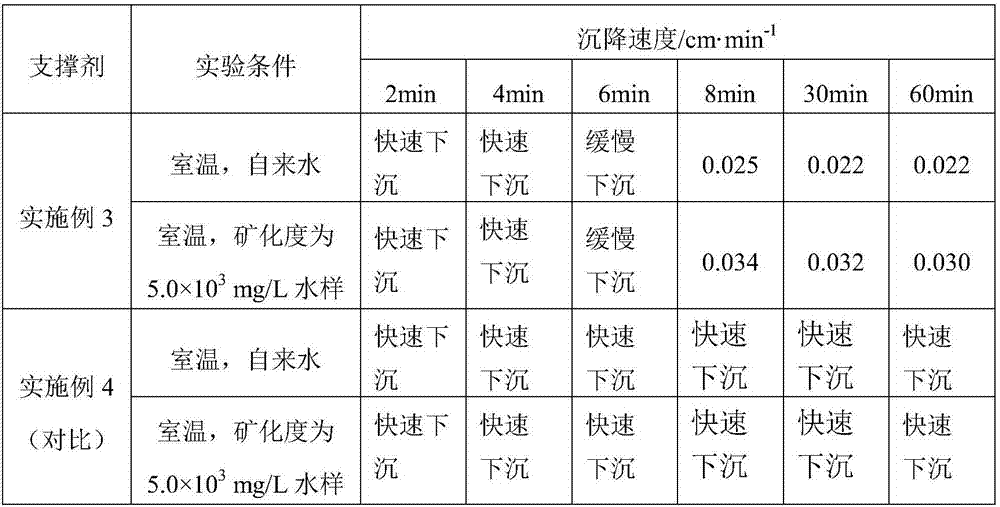

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com