A kind of preparation method of biological glue for fracturing

A bio-glue and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor salt resistance, high construction friction, high gel-breaking residue, etc., achieve good temperature resistance, construction friction Low resistance and good sand-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

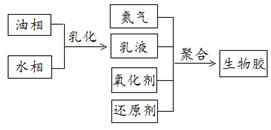

[0039] A kind of preparation method of bioglue for fracturing comprises following realization steps (see figure 1 ):

[0040] Step 1: preparation of the water phase, the proportion of which is: 40-88 parts of water, 2-10 parts of polyoxyethylene succinic monoester sodium rosin acid, and 10-50 parts of acrylamide;

[0041] Described water is pure water, demineralized water.

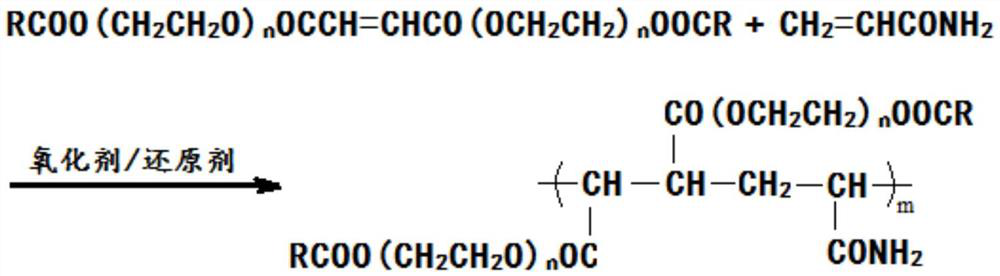

[0042] The sodium abietic acid polyoxyethylene succinic acid monoester sulfonate is a biosurfactant prepared from natural rosin, which is widely used in washing and cosmetic industries, and the commercially available purity is greater than 95%. Its molecular structural formula is:

[0043] RCOO (CH 2 CH 2 O) n OCCH=CHCO(OCH 2 CH 2 ) n OOCR

[0044] Wherein: n=5-20; R is rosin skeleton, namely

[0045] According to the above proportion, add sodium polyoxyethylene succinic acid monoester sulfonate and acrylamide successively into water, stir until completely dissolved, and then mix evenly to form...

Embodiment 1

[0063] Add 50 parts of water into container A with agitator, start the agitator, then add 8 parts of abietic acid polyoxyethylene succinic acid monoester sodium sulfonate and 42 parts of acrylamide respectively, stir until completely dissolved, and prepare an aqueous phase.

[0064] Add 95 parts of white oil and 80 5 parts of Span into container B with agitator, stir for more than 15 minutes until the mixture is uniform, and prepare the oil phase.

[0065] In the container C with agitator, first add 50 parts of the above-prepared oil phase, start the agitator, then add 50 parts of the above-prepared water phase at a uniform speed, and continue stirring for 30 minutes to form an emulsion.

[0066] Start the agitator of reactor D, and when container C continues to stir, use the homogeneous emulsification pump to pump the emulsion into reactor D; The pump is pumped to container C; after the addition, the emulsion in container C is pumped to reactor D by a homogeneous emulsificati...

Embodiment 2

[0069] Add 60 parts of water into container A with agitator, start the agitator, then add 5 parts of abietic acid polyoxyethylene succinic acid monoester sodium sulfonate and 40 parts of acrylamide respectively, stir until completely dissolved, and prepare an aqueous phase.

[0070] Add 96 parts of white oil and 4 parts of Span 80 into container B with a stirrer, stir for more than 15 minutes until the mixture is even, and prepare an oil phase.

[0071] In container C with a stirrer, first add 60 parts of the above-prepared oil phase, start the agitator, then add 40 parts of the above-prepared water phase at a constant speed, and continue stirring for 30 minutes after the addition is complete to form an emulsion.

[0072] Start the agitator of reactor D, and when container C continues to stir, use the homogeneous emulsification pump to pump the emulsion into reactor D; The pump is pumped to container C; after the addition, the emulsion in container C is pumped to reactor D by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com