High-elasticity foamed rubber

A technology of foaming rubber and high elasticity, which is applied in the field of rubber, and can solve the problems of poor foaming effect, uneven foaming, and decreased performance of foamed rubber, so as to achieve uniform and fine foaming holes, reduce vulcanization shrinkage, and improve Effects of Toughness and Plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

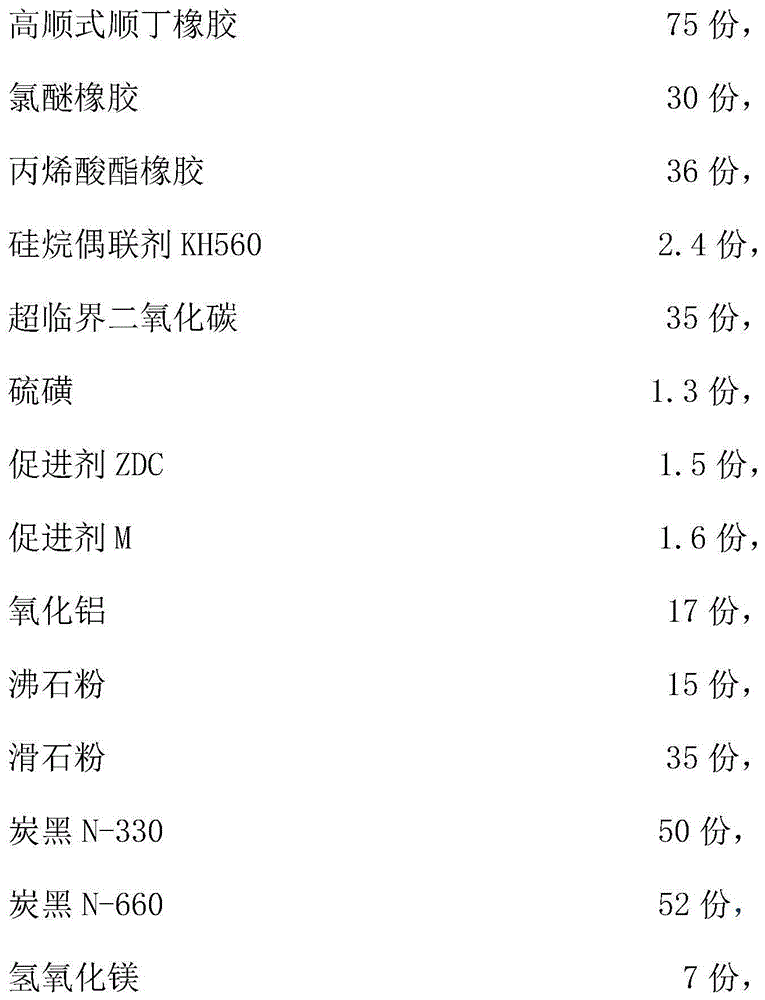

[0013] A kind of high elasticity foam rubber that the present invention proposes, its raw material comprises by weight:

[0014]

[0015]

[0016] Among them, zeolite powder and talcum powder are 400 mesh.

Embodiment 2

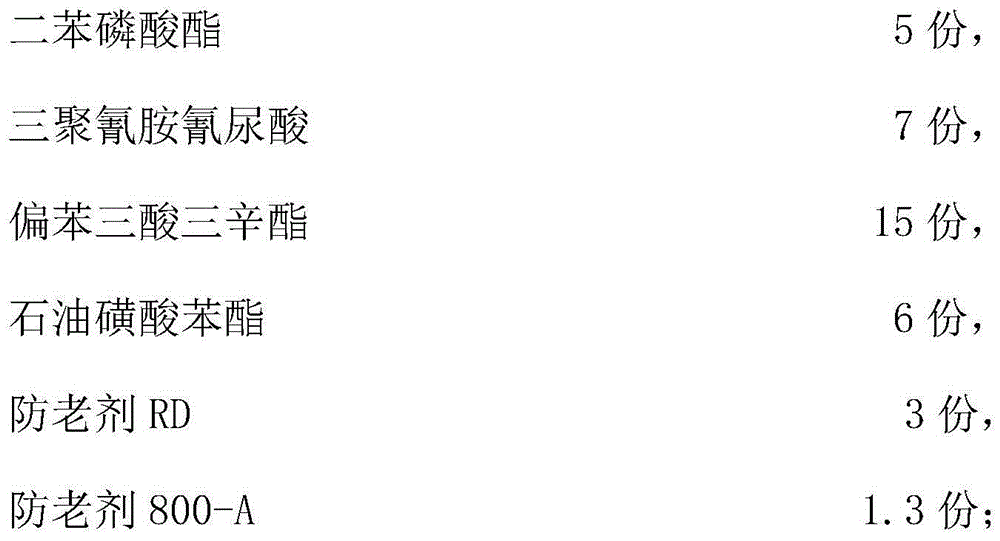

[0018] A kind of high elasticity foam rubber that the present invention proposes, its raw material comprises by weight:

[0019]

[0020]

[0021] Among them, zeolite powder and talcum powder are 500 mesh.

Embodiment 3

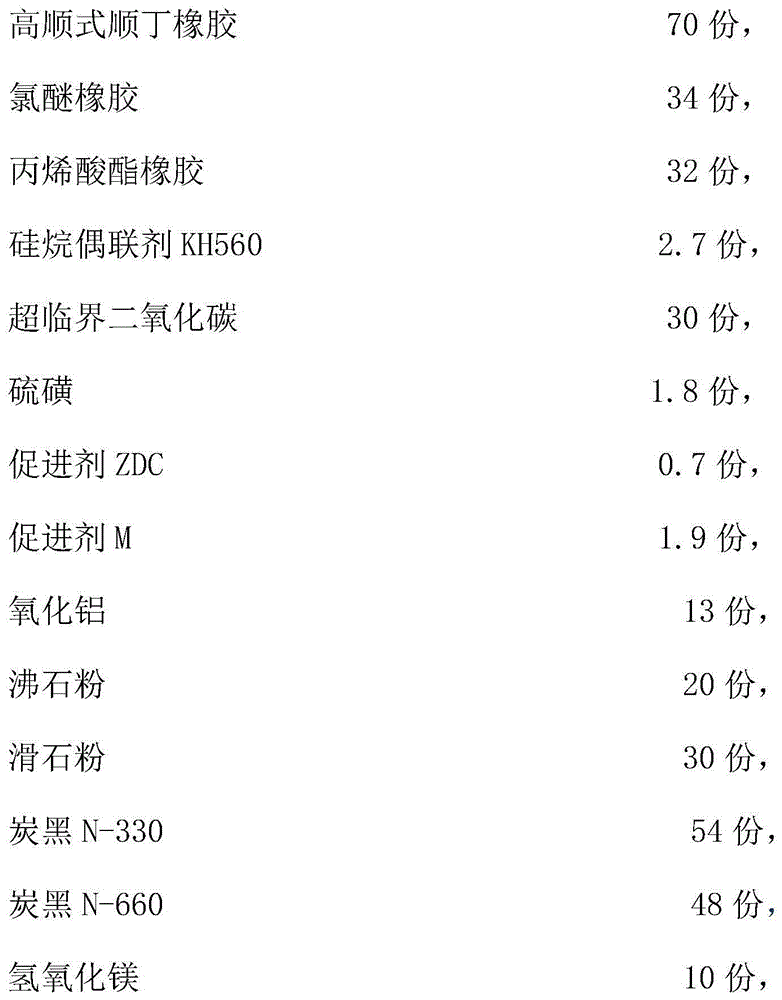

[0023] A kind of high elasticity foam rubber that the present invention proposes, its raw material comprises by weight:

[0024]

[0025]

[0026] Among them, zeolite powder and talcum powder are 460 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com