Articular cartilage graft and preparation method thereof

A technology for articular cartilage and grafts, applied in joint implants, joint implants, medical science and other directions, can solve the problems of affecting the integration effect, poor biocompatibility, difficult cell migration, etc., and achieve the promotion of extracellular matrix. Secretion, good compression and abrasion resistance, improved long-term efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

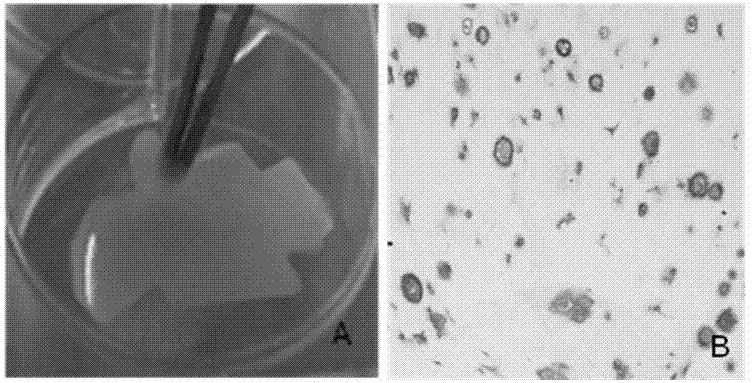

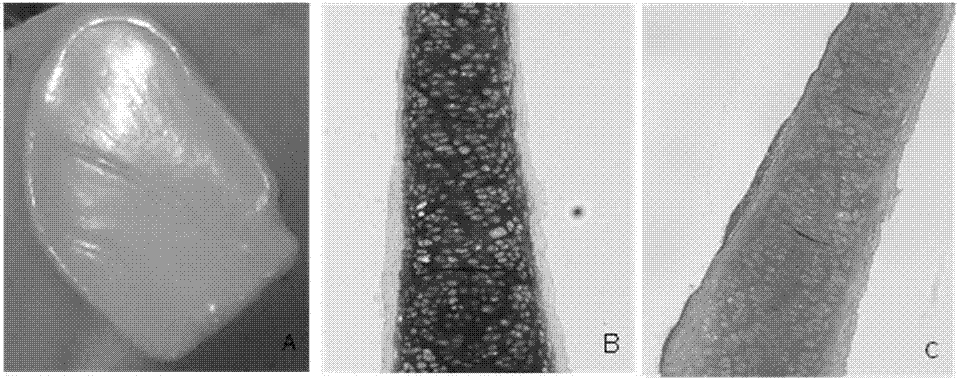

[0030] Step 1. Obtain chondrocytes: cut the rabbit superficial cartilage tissue into 0.5~3mm 3 Size, first digest with 10 times volume of 0.1% (w / v) hyaluronidase solution for 30 minutes, shake once every 15 minutes, rinse with PBS twice after digestion; then add 10 times volume of 0.2% (w / v) ) Digestion with type II collagenase solution for 4 hours, stop the digestion with PBS and fully pipette the cells, filter with a 200-mesh sieve, and wash twice with PBS to isolate the primary superficial chondrocytes at a cell density of 1×10 5 Pcs / cm 2 Inoculate in culture flask, add culture solution A, 37℃, 5% CO 2 After culturing in the incubator for 3 days, when the superficial chondrocytes reach 80% confluence, they are subcultured. Add 10 times the volume of 0.25% (w / v) trypsin solution to digest for 3 minutes, stop with PBS and wash twice, according to the cell density of 1×10 4 Pcs / cm 2 Inoculate, add culture medium A, and subculture once every 3 days;

[0031] Cut the rabbit middle c...

Embodiment 2

[0043] Step 1. Obtain chondrocytes: cut the superficial layer of porcine cartilage into 0.5~3mm 3 Size, first digest with 10 times volume of 0.15% (w / v) hyaluronidase solution for 45 minutes, shake once every 15 minutes, rinse with PBS twice after digestion; then add 10 times volume of 0.25% (w / v) v) Digestion with type II collagenase solution for 8 hours, stop the digestion with PBS and fully pipette, filter with 200 mesh screen and wash twice with PBS to isolate primary superficial chondrocytes at a cell density of 5×10 5 Pcs / cm 2 Inoculate in culture flask, add culture solution A, 37℃, 5% CO 2 After 7 days of culture in the incubator, when chondrocytes reach more than 90% confluence, pass them down, digest with 10 times the volume of 0.5% (w / v) trypsin solution for 8 minutes, stop with PBS and wash twice, according to cell density 1×10 5 Pcs / cm 2 Inoculate, add culture medium A, passage once every 7 days, and change the medium every 3 days;

[0044] Cut the porcine middle cartil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com