Graphene-glass fiber composite material and preparation method thereof

A glass fiber and composite material technology, applied in glass manufacturing equipment, manufacturing tools, yarns, etc., can solve the problems of poor glass fiber bonding, unsatisfactory processing performance, poor clustering, etc., and achieve great application value and distribution. Uniform, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

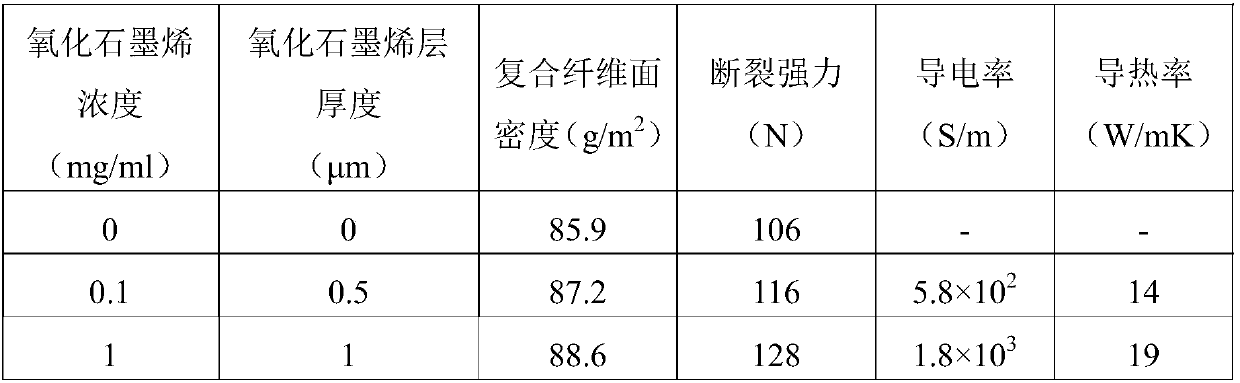

Embodiment 1

[0028] (1) The glass fiber is ultrasonically cleaned in acetone to remove oil stains on the surface and dried;

[0029] (2) Using an aqueous dispersion of graphene oxide to coat and dry the surface of the glass fiber obtained in step (1) repeatedly, the number of cycles is 15 to obtain a glass fiber coated with graphene oxide. The thickness of the graphene oxide layer is 3μm;

[0030] (3) Put the graphene oxide-coated glass fiber obtained in step (2) into water for surface swelling, and then overlap the fibers to form a non-woven fabric after drying, and the drying temperature is lower than 100 degrees Celsius.

[0031] (4) The graphene oxide crosslinked glass fiber obtained in step (3) is placed in a closed kettle containing hydrazine hydrate, and reduced at 80°C for 12 hours.

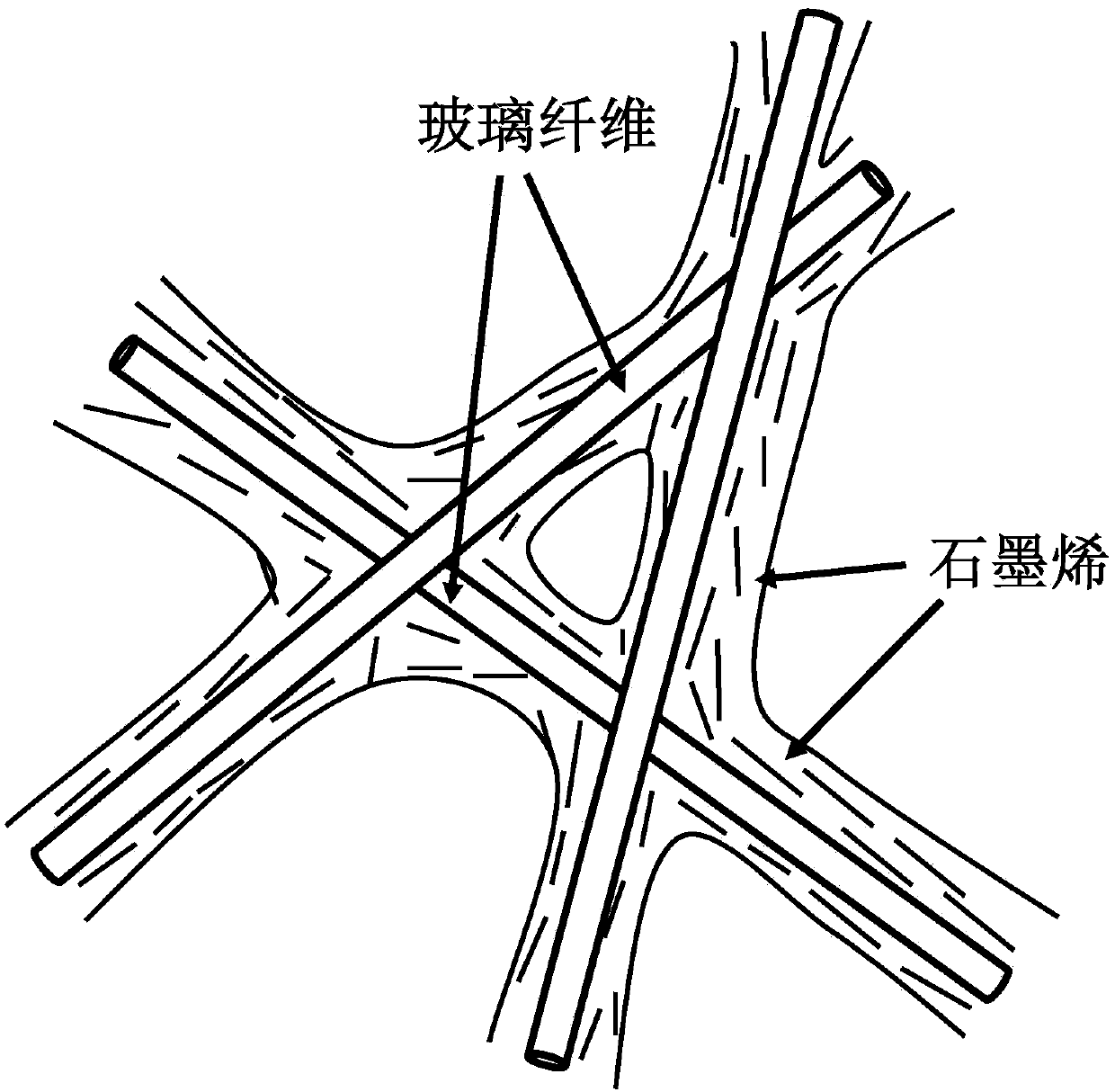

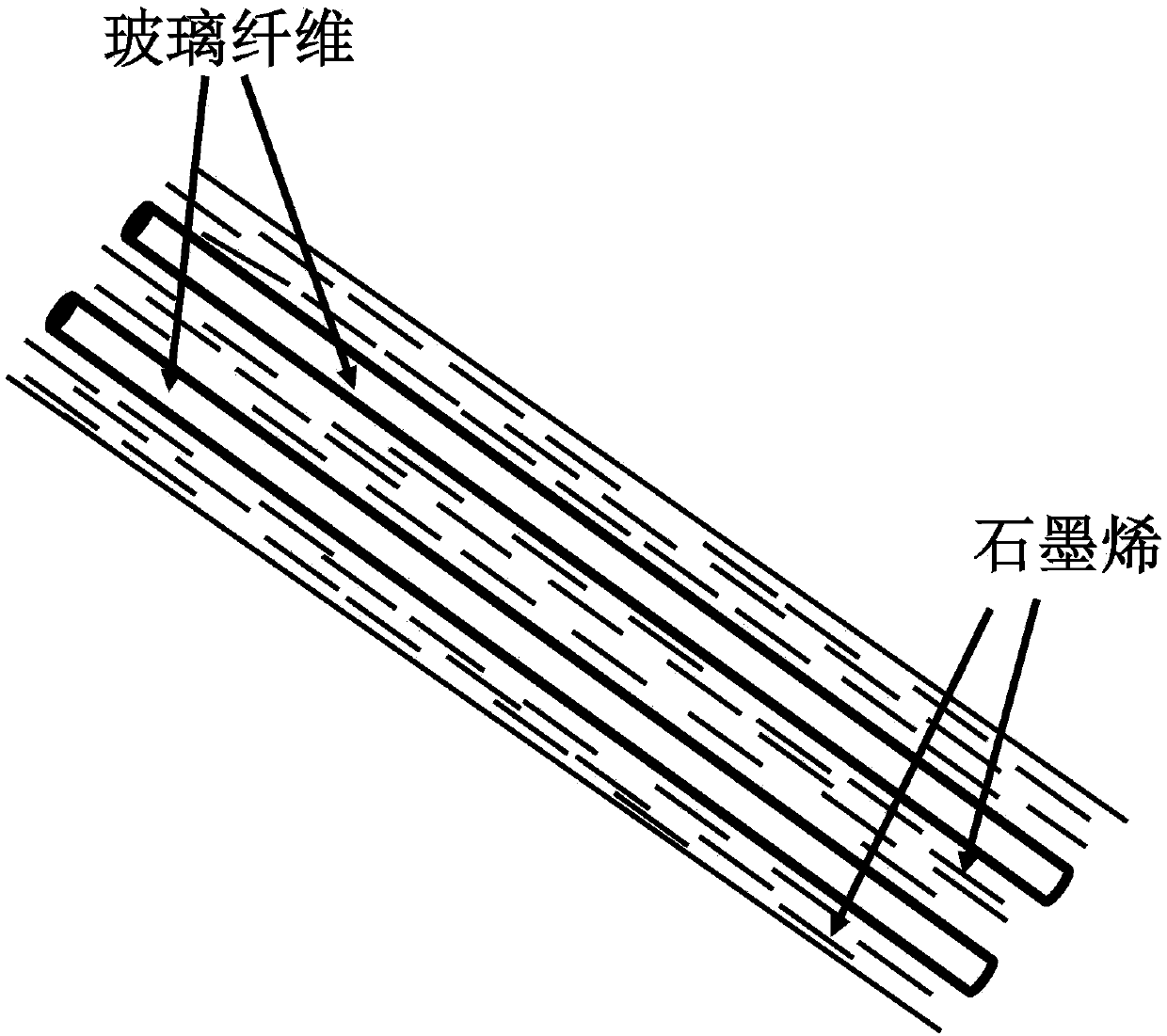

[0032] After the above steps, the graphene is coated on the surface of the glass fiber, the surface of the glass fiber and the graphene sheet are connected by van der Waals force and hydrogen bond, the glass ...

Embodiment 2

[0037] (1) The glass fiber is ultrasonically cleaned in acetone to remove oil stains on the surface and dried;

[0038] (2) Using graphene oxide dispersion in N,N-dimethylformamide to coat and dry the glass fiber surface obtained in step (1) repeatedly, the number of cycles is 13 to obtain a graphene oxide coated surface glass fiber. The thickness of the graphene oxide layer is 3μm;

[0039] (3) Put the graphene oxide-coated glass fiber obtained in step (2) into water for surface swelling, and then overlap the fibers to form a non-woven fabric after drying, and the drying temperature is lower than 100 degrees Celsius.

[0040] (4) The graphene oxide crosslinked glass fiber obtained in step (3) is placed in a closed kettle containing hydrazine hydrate, and reduced at 80°C for 12 hours.

[0041] After the above steps, the graphene is coated on the surface of the glass fiber, the surface of the glass fiber and the graphene sheet are connected by van der Waals force and hydrogen bond, th...

Embodiment 3

[0043] (1) The glass fiber is ultrasonically cleaned in acetone to remove oil stains on the surface and dried;

[0044] (2) Using an ethanol dispersion of graphene oxide to coat and dry the surface of the glass fiber obtained in step (1) repeatedly, the number of cycles is 16 to obtain a glass fiber coated with graphene oxide. The thickness of the graphene oxide layer is 3μm;

[0045] (3) Put the graphene oxide-coated glass fiber obtained in step (2) into water for surface swelling, and then overlap the fibers to form a non-woven fabric after drying, and the drying temperature is lower than 100 degrees Celsius.

[0046] (4) The graphene oxide crosslinked glass fiber obtained in step (3) is placed in a closed kettle containing hydroiodic acid, and reduced at 90°C for 18 hours.

[0047] After the above steps, the graphene is coated on the surface of the glass fiber, the surface of the glass fiber and the graphene sheet are connected by van der Waals force and hydrogen bond, the glass fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com