Polyurethane sponge loaded with hybridized graphene coating and preparation method of polyurethane sponge

A technology of polyurethane sponge and graphite coating, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve problems such as hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] For the preparation method of the micron zinc oxide used in the present invention, please refer to: Segovia M., Lemus K., Moreno M., Ana M.A.S., Gonzalez G., Ballesteros B., Sotomayor C., Benavente E. Zinc oxide / carboxylic acid lamellar structures . Mater. Res. Bull. 2011, 46(11): 2191-2195.

[0030] The preparation method of graphite oxide adopted in the present invention please refer to: Singh, E., Chen, Z., Houshmand, F., Ren, W., Peles, Y., Cheng, H. M. and Koratkar, N. Superhydrophobic graphene foams. Small . 2013, 9(1): 75-80.

Embodiment 1

[0031] Example 1: (please add the specific preparation process of polyurethane sponge loaded with hybrid graphite coating)

[0032] 1) Preparation of graphene oxide (GO). The main method is to add 2g of graphite to a 500ml beaker, then add 50ml of concentrated H 2 SO 4 added to it and cooled to 0 in an ice bath o C; followed by 6g KMnO 4 Add slowly, allow it to warm to room temperature, and place the suspension at 35 oC Continue to stir for 2h under ice water; add 350ml deionized water to dilute after cooling under ice water; add 30% H 2 o 2 to reduce the manganese ions until the gas volatilization is complete; finally the resulting suspension is filtered, washed once with 1mol / L HCl, washed twice with deionized water, and then at 60 oC Dry for 24 h to obtain brown GO powder.

[0033] 2) Low-temperature synthesis of micron ZnO. at 60 oC 2.97g Zn(CH 3 COO) 2 ·H 2 O was added to 125ml of methanol, also at 60 oC Dissolve 1.5g KOH in 65ml methanol, and add it to Z...

Embodiment 2

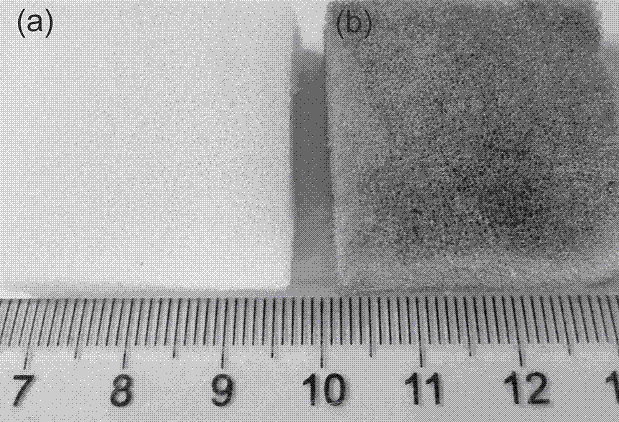

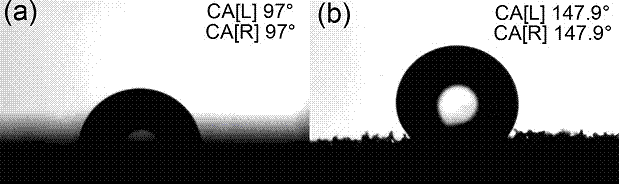

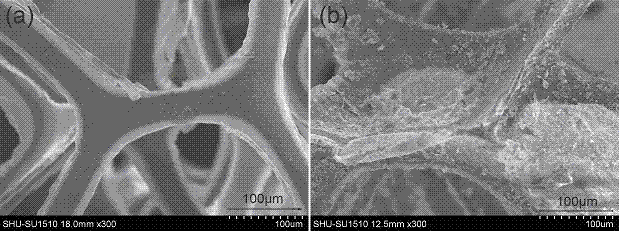

[0035] Example 2: Determination of Hydrophobic and Lipophilic Effects of Hybrid Graphene Loaded Polyurethane Sponge

[0036] 1) Measurement of contact angle - the measurement of contact angle of materials can be used to show the affinity and repellency of materials to water and oil. Cut the material into a flat section, put it on a glass slide, then place the slide on the contact angle measuring instrument, adjust the position of the sample and the focal length of the microscope lens to make the surface of the material clearly visible, and control the injection needle to drop a drop of water / oil , and then through the shape image of the droplet obtained by the microscope lens and the camera, the contact angle value is calculated by using the built-in software of the instrument for fitting. The affinity of the material to water and oil can be judged by the value of the contact angle: when the contact angle of the material to water reaches 150°, it means that the material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com