A kind of preparation method and application of nanometer calcium carbonate modified by mma in-situ polymerization

A technology of nano-calcium carbonate and polymerization reaction, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of affecting and reducing the mechanical properties of polymer composite materials, so as to improve durability and improve hydrophobicity The effect of lipophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

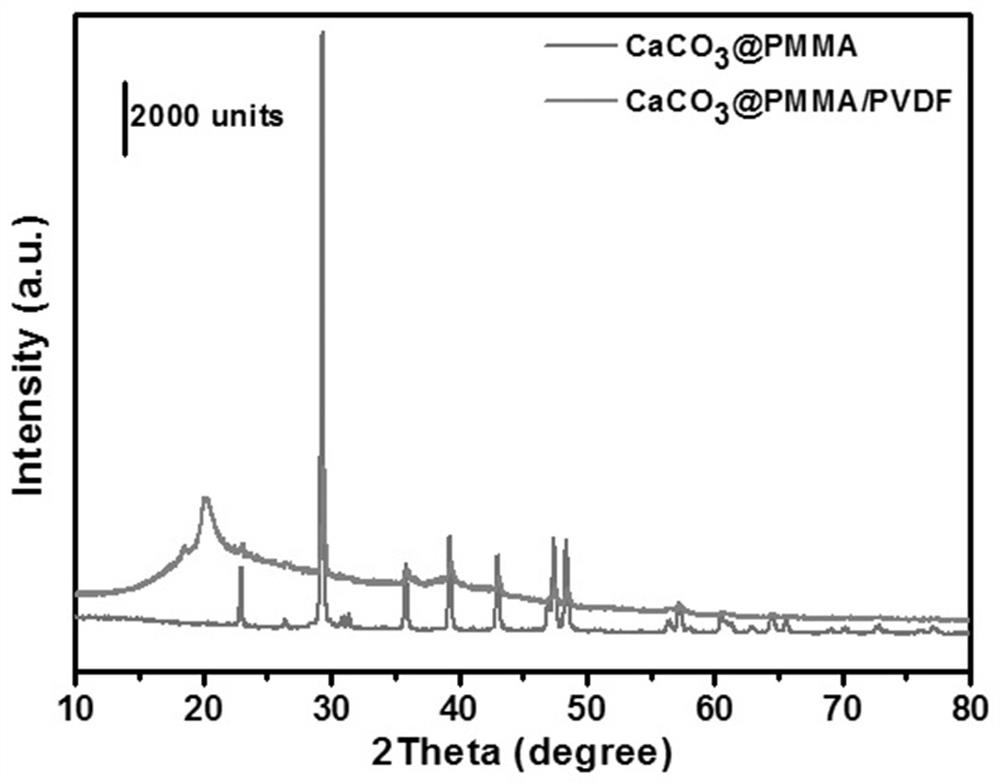

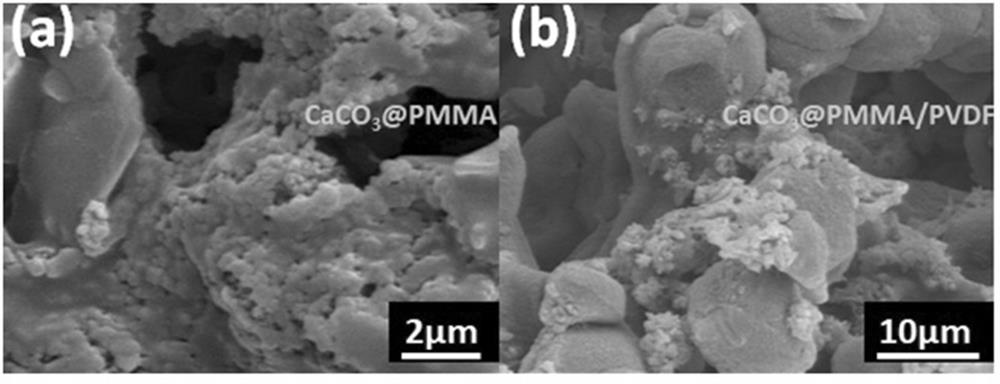

Image

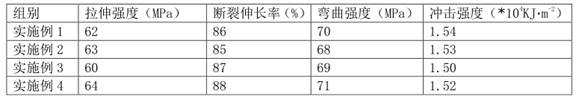

Examples

Embodiment 1

[0029] 1. Ingredients: PVDF 94.5wt%; powdered CaCO 3 @PMMA composite 5.5wt%.

[0030]2. Preparation:

[0031] (1) Sodium benzenesulfonate (NaSS), polyvinylpyrrolidone (PVP), azobisisobutyronitrile (AlBN), and methyl methacrylate (MMA) were added to the two mixed phase solvents at 70 o Mixture A was obtained by stirring at C for 3h;

[0032] (2) Add nano calcium carbonate slurry and stearic acid reagent to mixture A, continue at 70 o Mixture B was obtained by stirring at C for 5h;

[0033] (3) Pour the mixture B cooled to room temperature into a centrifuge tube and centrifugally filter to obtain the precipitate as CaCO 3 Composites of @PMMA, followed at 60 o Dry at C for 18h to obtain powdery CaCO 3 @PMMA composite;

[0034] (4) The dried powdered CaCO 3 @PMMA composites, polyvinylidene fluoride (PVDF) particles were added to organic solvents, and CaCO was prepared by water-gas phase separations (WVIPs) 3 @PMMA / PVDF composite material;

[0035] (5) The CaCO 3 The @PM...

Embodiment 2

[0046] 1. Ingredients: PVDF 90wt%; powdered CaCO 3 @PMMA composite 10wt%.

[0047] 2. Preparation:

[0048] (1) Sodium benzenesulfonate (NaSS), polyvinylpyrrolidone (PVP), azobisisobutyronitrile (AlBN), and methyl methacrylate (MMA) were added to the two mixed phase solvents at 75 o Mixture A was obtained by stirring at C for 3h;

[0049] (2) Add nano calcium carbonate slurry and stearic acid reagent to mixture A, continue at 75 o Mixture B was obtained by stirring at C for 5h;

[0050] (3) Pour the mixture B cooled to room temperature into a centrifuge tube and centrifugally filter to obtain the precipitate as CaCO 3 Composites of @PMMA, followed at 65 o Dry at C for 18h to obtain powdery CaCO 3 @PMMA composite;

[0051] (4) The dried powdered CaCO 3 @PMMA composites, polyvinylidene fluoride (PVDF) particles were added to organic solvents, and CaCO was prepared by water-gas phase separations (WVIPs) 3 @PMMA / PVDF composite material;

[0052] (5) The CaCO 3 The @PMMA...

Embodiment 3

[0063] 1. Ingredients: PVDF 85.5wt%; powdered CaCO 3 @PMMA composite 14.5wt%.

[0064] 2. Preparation:

[0065] (1) Sodium benzenesulfonate (NaSS), polyvinylpyrrolidone (PVP), azobisisobutyronitrile (AlBN), and methyl methacrylate (MMA) were added to the two mixed phase solvents at 80 o Mixture A was obtained by stirring at C for 3h;

[0066] (2) Add nano calcium carbonate slurry and stearic acid reagent to mixture A, continue at 80 o Mixture B was obtained by stirring at C for 5h;

[0067] (3) Pour the mixture B cooled to room temperature into a centrifuge tube and centrifugally filter to obtain the precipitate as CaCO 3 Composites of @PMMA, followed at 70 o Dry at C for 18h to obtain powdery CaCO 3 @PMMA composite;

[0068] (4) The dried powdered CaCO 3 @PMMA composites, polyvinylidene fluoride (PVDF) particles were added to organic solvents, and CaCO was prepared by water-gas phase separations (WVIPs) 3 @PMMA / PVDF composite material;

[0069] (5) The CaCO 3 The @...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com