White carbon black with dyeing groups on surface and preparation method of white carbon black

A technology of white carbon black and radicals, which is applied in the field of colorant modified white carbon black, can solve the problems of rubber product performance failure, etc., and achieve the effect of low cost, simple process and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

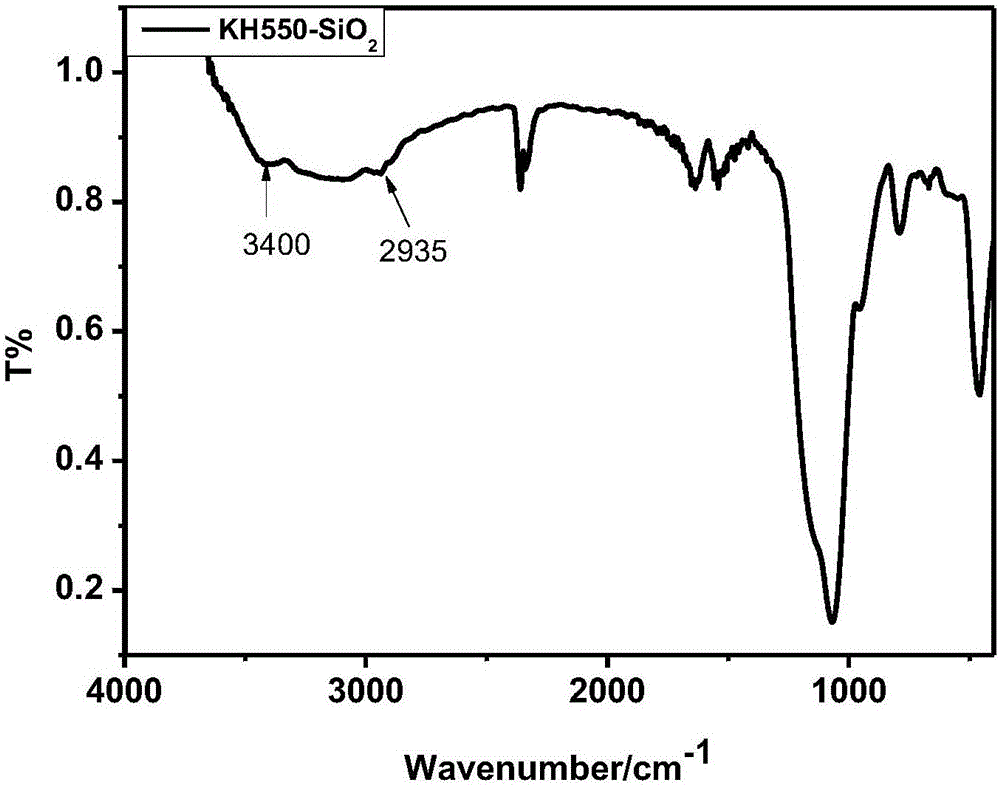

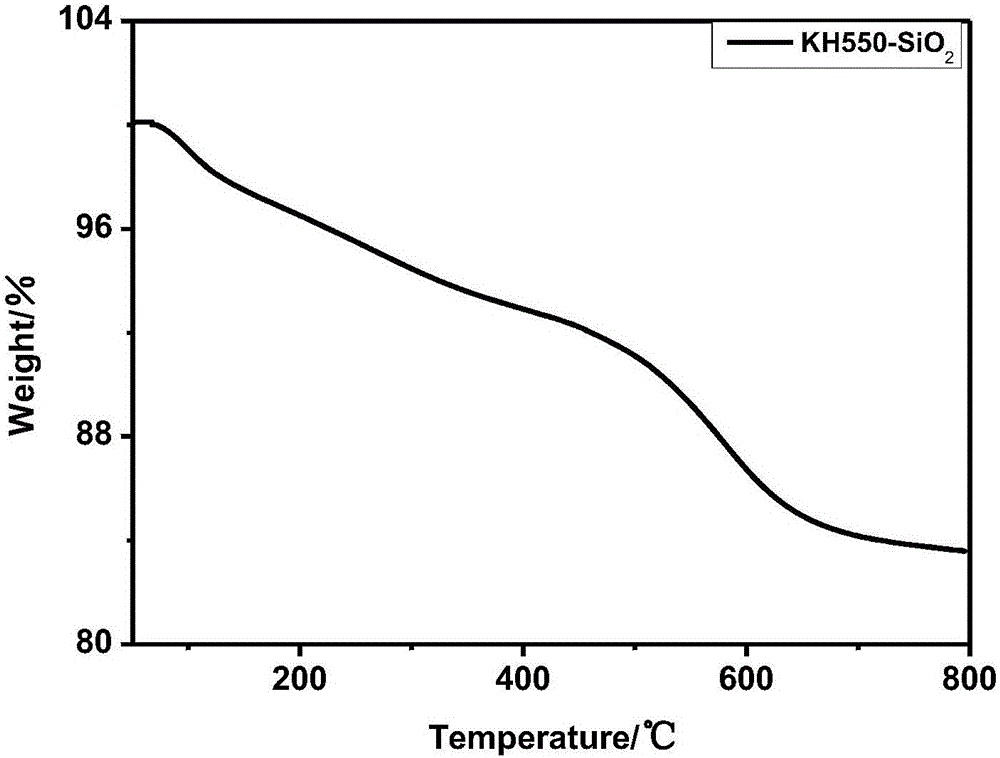

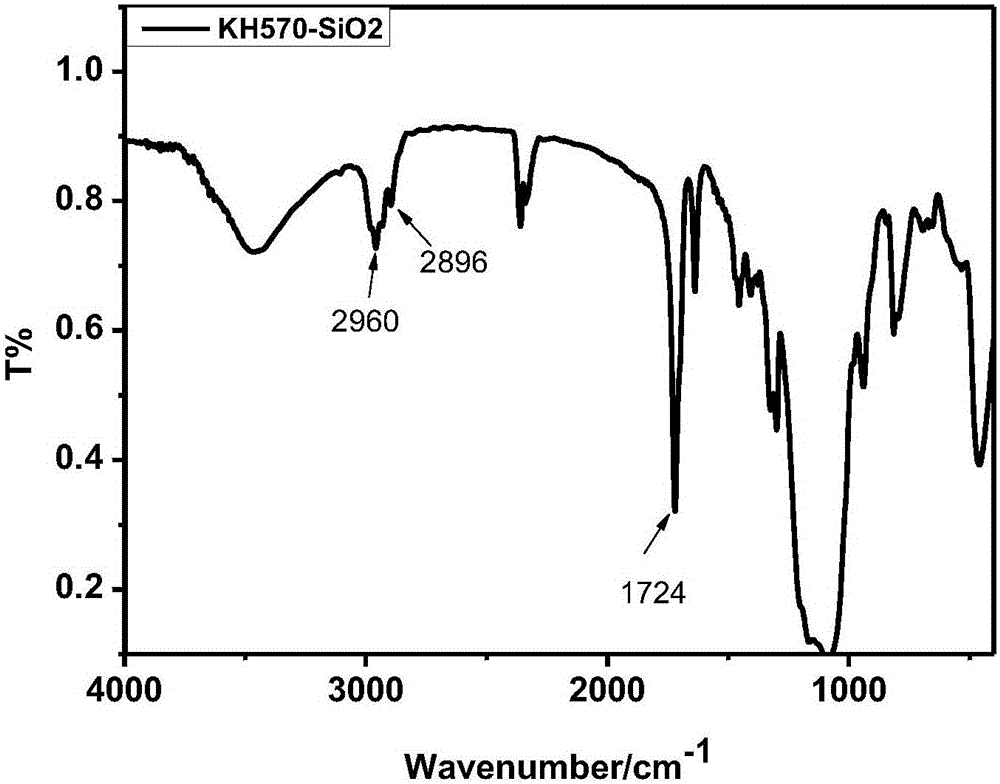

[0035]1) 5.0 grams of industrial grade granular white carbon black (the density of white carbon black is 175g / L, and the specific surface area is 160-200m 2 / g) is ultrasonically dispersed in a mixed solution of 100ml water and 100ml ethanol to form a suspension. After stirring for 0.5h, add 2ml ammonia water as a catalyst, and add silane coupling agent 3-aminopropyltriethoxysilane (KH-550 ) 10ml, reacted for 12 hours, filtered and dried to obtain modified white carbon black with amino modification on the surface.

[0036] 2) Adding 5g of modified silica containing amino groups on the surface to the specific experimental process is to mix the modified silica with 2g of dyeing agent (3,4,9,10-perylenetetracarboxylic dianhydride) in a flask, Add 50ml of toluene and heat in an oil bath at 100°C. After stirring and reacting for 5 hours, the product was washed, centrifuged and dried to obtain dyed functional white carbon black.

Embodiment 2

[0038] 1) Stir and mix 5ml of ammonia water and 100ml of alcohol in the flask for about half an hour to create an alkaline environment. Use a syringe to drop 20ml of TEOS reagent into the flask. TEOS decomposes in an alkaline environment to obtain nano-scale silica required for the reaction. The reaction temperature is 40°C. About three hours after the Stober method reaction vessel started to react, 5ml TEOS and 2ml silane coupling agent KH-550 were added dropwise into the vessel using a syringe, and the reaction was continued for about 24h after the addition was completed. Use a high-speed centrifuge for centrifugal washing. The specific operation is to use a centrifugal tube to divide the sample, and then centrifuge in a high-speed centrifuge. After centrifugation, pour out the supernatant, take out the solids for washing, and centrifuge again after washing. A total of three washes were performed using distilled water (to remove NH3), distilled water and alcohol (to remove H ...

Embodiment 3

[0041] 1) 5.0 grams of industrial grade granular white carbon black (the density of white carbon black is 175g / L, and the specific surface area is 160-200m 2 / g) is ultrasonically dispersed in a mixed solution of 100ml water and 100ml acetone to form a suspension, after stirring for 0.5h, add 2ml ammonia water as a catalyst, and add silane coupling agent 3-aminopropyltriethoxysilane (KH-550 ) 10ml, reacted for 12 hours, filtered and dried to obtain modified white carbon black with amino modification on the surface.

[0042] 2) Adding 5g of modified silica containing amino groups on the surface to the specific experimental process is to mix the modified silica with 2g of dyeing agent (3,4,9,10-perylenetetracarboxylic dianhydride) in a flask, Add 50ml of toluene and heat in an oil bath at 100°C. After stirring and reacting for 5 hours, the product was washed, centrifuged and dried to obtain dyed functional white carbon black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com