Hydrophobic modification method of sodium alginate sponge as well as product and application thereof

A technology of sodium alginate and hydrophobic modification, applied in the field of hydrophobic modification of sodium alginate sponge, can solve the problem of not having oil-water selective separation and the like, achieve good stability and durability, easy operation, and simple modification method Inexpensive and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

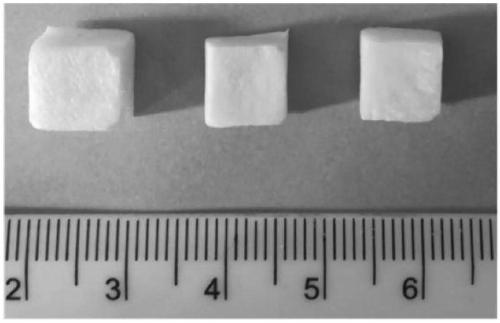

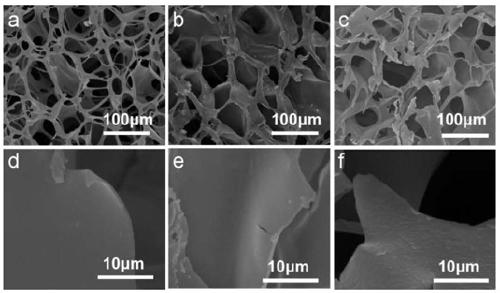

[0031] Dissolve 1g sodium alginate in 25mL water, pour the solution into 1.0×1.0×1.0cm 3 Sodium alginate sponge is prepared in the module, soak 1g sodium alginate sponge in 200mL 5wt% CaCl 2 Sodium alginate-calcium sponge was prepared after 4h in the solution, washed and soaked in 200mL 3wt% ZrOCl 2 ·8H 2 0 solution for 4 hours, freeze-dried after washing, and dried at 80°C to obtain a sodium alginate-calcium-zirconium sponge.

[0032] The modified sodium alginate sponge, sodium alginate-calcium-zirconium sponge, has a water wetting angle of 138.2°-143.8°. Sodium alginate-calcium-zirconium has a porosity of 81.8%.

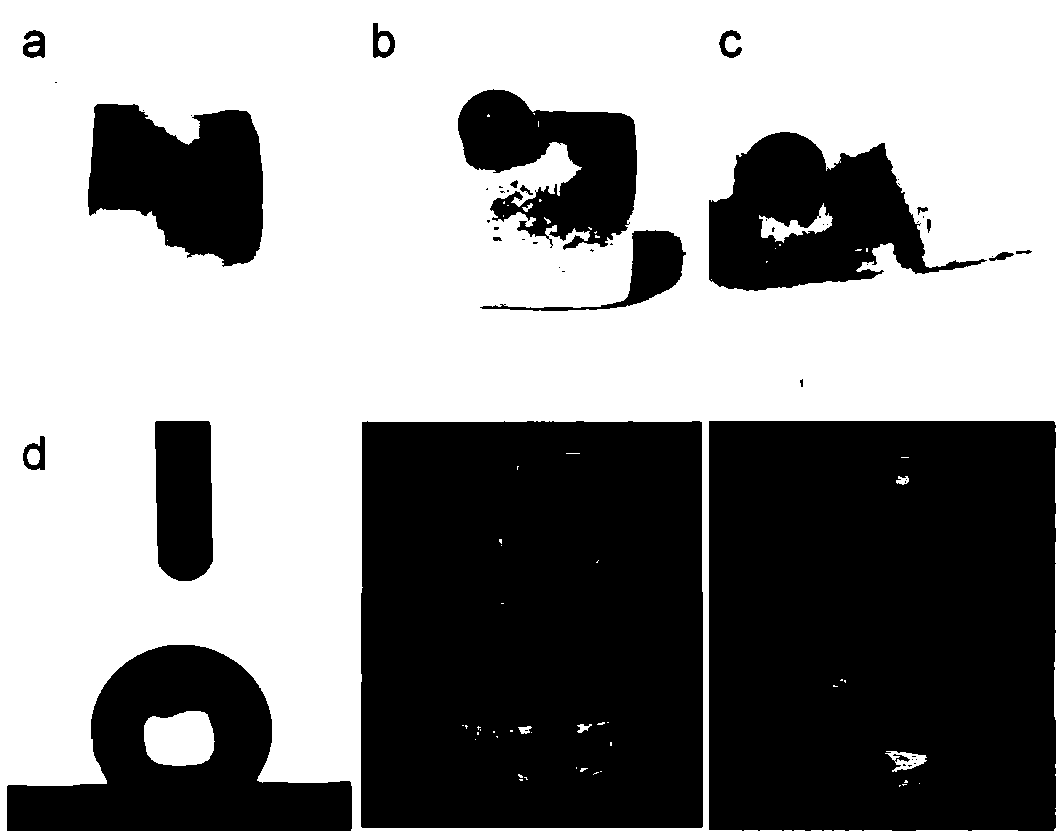

[0033] Surface observation of hydrophobic and lipophilic properties before and after modification, see figure 2 . figure 2 It is the observation of sodium alginate sponge to oil-water adsorption before and after the modification of embodiment 1, wherein, figure 2 (a) Sodium alginate-calcium sponge before modification, drip water and soybean oil on its surf...

Embodiment 2

[0036]Taking n-hexane as an example, soak the sodium alginate-calcium-zirconium sponge sample in Example 1 in n-hexane for 1-2 minutes, then take it out and weigh it. The oil absorption is calculated by comparing the mass difference before and after oil absorption with the initial mass is the oil absorption of the sample. After each oil absorption, elute with ethanol by gently squeezing several times, and dry at 80°C for later use. The adsorption capacity of the first five times were 10.21, 7.3, 7.1, 6.5, 6.9g / g, showing excellent cycle performance.

[0037] Taking chloroform as an example, soak the sodium alginate-calcium-zirconium sponge sample in Example 1 in chloroform for 1-2 minutes, then take it out and weigh it, and calculate the oil absorption by comparing the mass difference before and after oil absorption with the initial mass. of oil absorption. After each oil absorption, elute with ethanol by gently squeezing several times, and dry at 80°C for later use. The ad...

Embodiment 3

[0039] Taking light soybean oil / water as an example, the application of modified sodium alginate-calcium-zirconium sponge in oil-water separation was tested ( Figure 4 a). For the convenience of observation, soybean oil was stained with Oil Red O. The sodium alginate-calcium-zirconium sponge sample in Example 1 was placed on the oily water surface. From the beginning to the end of the adsorption, it only took 30 seconds to completely remove the oil slick on the water surface. Exhibits excellent oil-water separation properties.

[0040] Taking heavy oil chloroform / water as an example, the application of modified sodium alginate-calcium-zirconium sponge in oil-water separation was tested ( Figure 4 b). In order to facilitate the observation of chloroform stained with Oil Red O, the sodium alginate-calcium-zirconium sponge sample in Example 1 was immersed in the bottom of the water with tweezers. From the beginning to the end of the adsorption, it only took 10 seconds to comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com