Organic bentonite for white oil-based drilling fluid and preparation method thereof

A technology of white oil-based drilling fluid and bentonite, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as poor high temperature resistance, high product cost, and poor hydrophobicity and lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

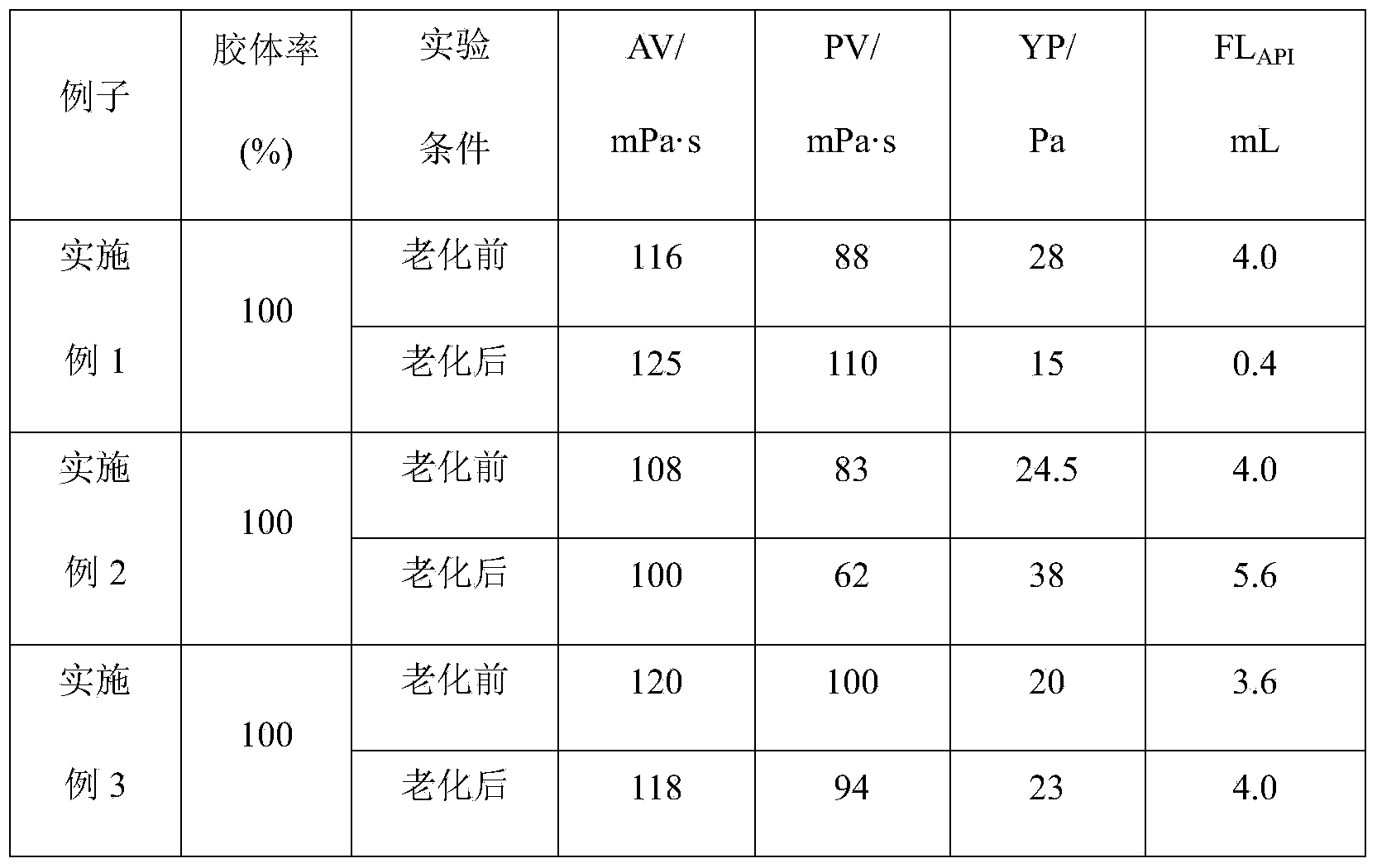

Embodiment 1

[0007] Example 1: Put 30 g of sodium bentonite through a 200-mesh sieve into the reactor, then add 800 mL of deionized water, and stir with an electric mixer for 1 hour at a temperature of 80 ° C to disperse the bentonite in deionized water to form Suspension; then weigh 9g cetyltrimethylammonium chloride, add 40mL deionized water to be mixed with cetyltrimethylammonium chloride solution, the cetyltrimethylammonium chloride solution Add it to the above-mentioned bentonite suspension, and in a water bath at 80°C, ion exchange reaction occurs under stirring conditions for 3 hours to obtain a modified suspension; then weigh 1.8g of sodium dodecylsulfonate, add 40mL Prepare sodium dodecylsulfonate solution with deionized water, add the sodium dodecylsulfonate solution to the above-mentioned primary modified suspension, and react in a water bath at a temperature of 80°C for 1 hour to obtain a secondary Modified suspension; finally put the above secondary modified suspension in a co...

Embodiment 2

[0008] Example 2: Put 20 g of sodium bentonite through a 200-mesh sieve into the reactor, then add 600 mL of deionized water, and stir with an electric mixer for 1 hour at a temperature of 90 ° C to disperse the bentonite in deionized water to form Suspension; Then take by weighing 6g tetradecyl trimethyl ammonium chloride, add 20mL deionized water and be mixed with tetradecyl trimethyl ammonium chloride solution, this tetradecyl trimethyl ammonium chloride solution Add it to the above bentonite suspension, and in a water bath at a temperature of 80°C, an ion exchange reaction occurs under stirring conditions for 2 hours to obtain a primary modified suspension; then weigh 1.2g of sodium lauryl sulfate, add 40mL to remove Ionized water is prepared into a sodium lauryl sulfate solution, and the sodium lauryl sulfate solution is added to the above-mentioned primary modified suspension, and reacted in a water bath at a temperature of 80°C for 2 hours to obtain a secondary modified ...

Embodiment 3

[0009] Example 3: first put 25g of sodium bentonite through a 200-mesh sieve into the reactor, then add 700mL of deionized water, and stir with an electric mixer for 1 hour at a temperature of 70°C to disperse the bentonite in deionized water to form Suspension; Then take by weighing 7.5g octadecyltrimethylammonium chloride, add 30mL deionized water and be mixed with octadecyltrimethylammonium chloride solution, the octadecyltrimethylammonium chloride The solution was added to the above-mentioned bentonite suspension, and the ion exchange reaction occurred under stirring conditions for 1 hour in a water bath at a temperature of 80°C to obtain a primary modified suspension; then weigh 1.5g of sodium dodecylbenzenesulfonate, Add 40mL of deionized water to prepare a sodium dodecylbenzenesulfonate solution, add the sodium dodecylbenzenesulfonate solution to the above-mentioned primary modified suspension, and react in a water bath at a temperature of 80°C for 3 hours. Obtain a sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com