Organosilicon compound modified hydrophobic polyurethane foam and preparation method thereof

A technology of organosilicon compound and polyurethane foam, which is used in the preparation and application of oil-water separation materials, and can solve the problems of poor oil-water selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

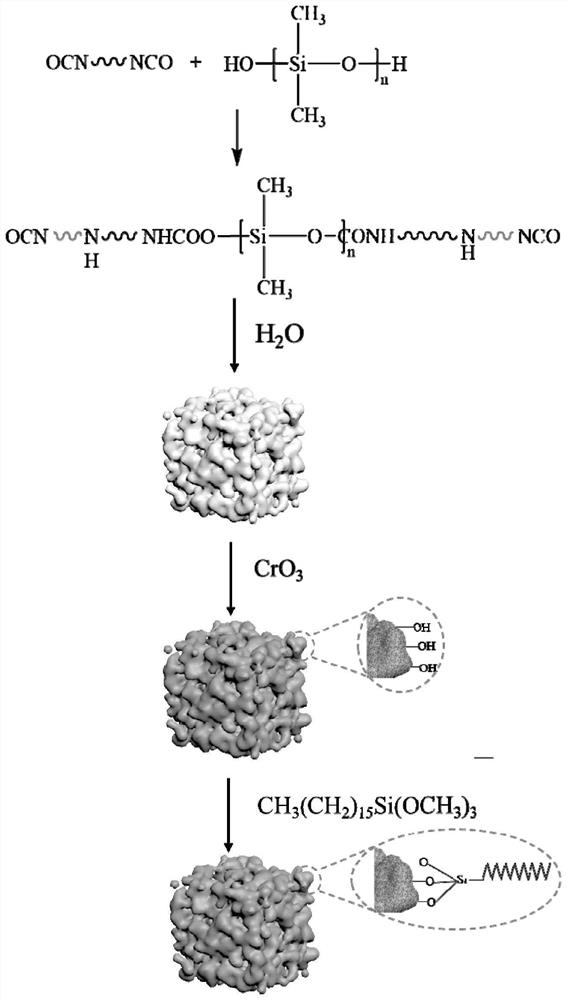

[0045] A kind of preparation method of the hydrophobic polyurethane foam modified by organosilicon compound, synthetic route is as follows figure 1 shown, including the following steps:

[0046] Step 1: Accurately weigh 20.0g of isocyanate-terminated polyurethane prepolymer in a three-necked flask, add 1.0g (5% of the mass fraction of isocyanate-terminated polyurethane prepolymer) of hydroxyl-terminated polydimethylsiloxane, and place at 75°C Under stirring for 40min; then cooled to room temperature. During this period, acetone was added dropwise to adjust the viscosity of the system.

[0047] Step 2: Add 40.0 g of distilled water to the above reaction system, set the mechanical stirrer at a speed of 900 rpm at room temperature, and stir the mixture rapidly for 40 seconds to obtain a mixed solution. The mixed solution was quickly transferred to an evaporating dish, and foamed and solidified at room temperature for 10 minutes to obtain a polyurethane foam. Then cut it into 2...

Embodiment 2

[0052] A kind of preparation method of the hydrophobic polyurethane foam modified by organosilicon compound, synthetic route is as follows figure 1 shown, including the following steps:

[0053] Step 1: Accurately weigh 20.0g of isocyanate-terminated polyurethane prepolymer in a three-necked flask, add 2.0g (10% of the mass fraction of isocyanate-terminated polyurethane prepolymer) of hydroxyl-terminated polydimethylsiloxane, at 70°C Next, stir for 50min; then cool to room temperature. During this period, acetone was added dropwise to adjust the viscosity of the system.

[0054] Step 2: 35.0 g of distilled water was added to the above reaction system, and the mixture was stirred rapidly for 40 s at room temperature with a mechanical stirrer at a speed of 900 rpm to obtain a mixed solution. The mixed solution was quickly transferred to an evaporating dish, and foamed and solidified at room temperature for 10 minutes to obtain a polyurethane foam. Then cut it into 2×2×2cm 3 ...

Embodiment 3

[0059] A kind of preparation method of the hydrophobic polyurethane foam modified by organosilicon compound, synthetic route is as follows figure 1 shown, including the following steps:

[0060] Step 1: Accurately weigh 20.0g of isocyanate-terminated polyurethane prepolymer in a three-necked flask, add 3.0g (15% of the mass fraction of isocyanate-terminated polyurethane prepolymer) of aminopropyl-terminated polydimethylsiloxane, and Stir at room temperature for 50 min, during which acetone is added dropwise to adjust the viscosity of the system.

[0061] Step 2: 30.0 g of distilled water was added to the above reaction system, and the mixture was rapidly stirred at room temperature at 850 rpm for 40 s to obtain a mixed solution. The mixed solution was quickly transferred to an evaporating dish, and foamed and solidified at room temperature for 10 minutes to obtain a polyurethane foam. Then cut it into 2×2×2cm 3 After washing three times with distilled water and absolute eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com