Automatic double-sided gelatin sponge pasting machine

A technology of sponge glue and sticking machine, applied in the field of sponge glue sticking, can solve the problems of hand fatigue, affect product quality, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

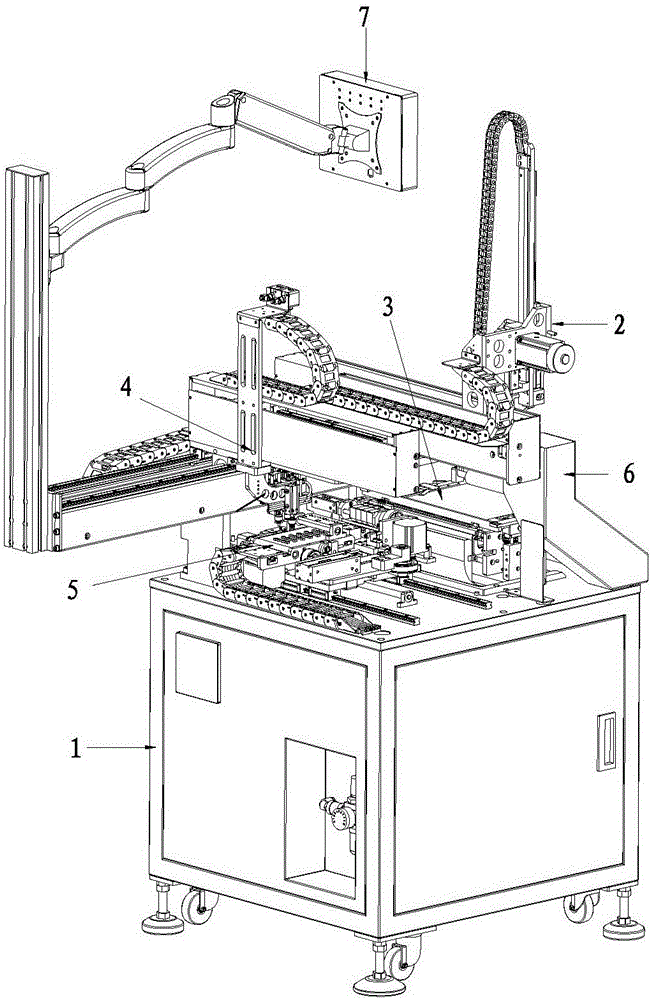

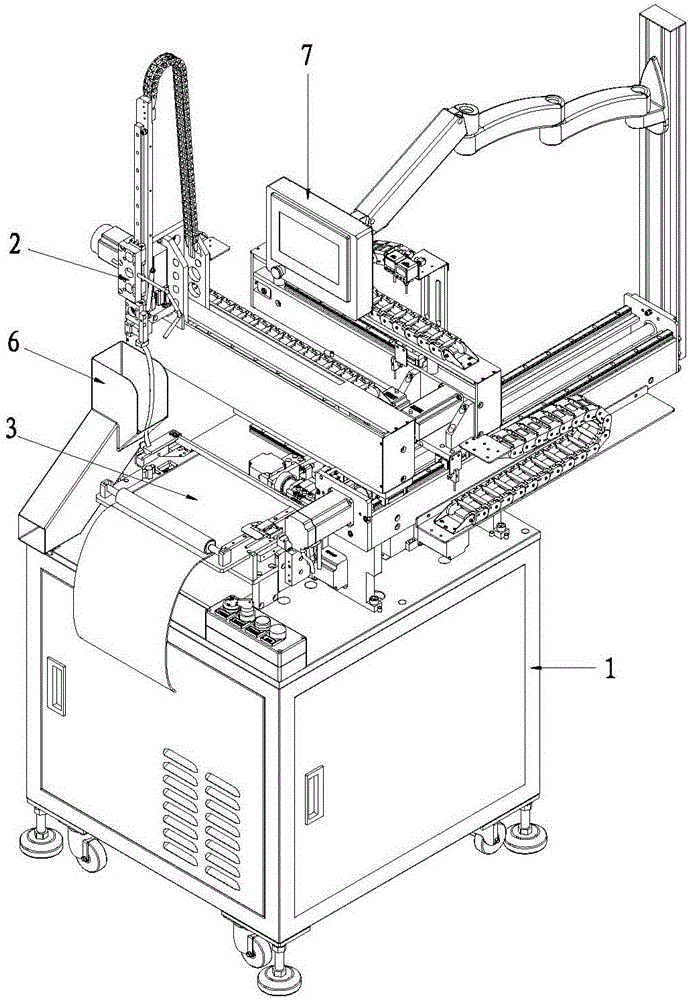

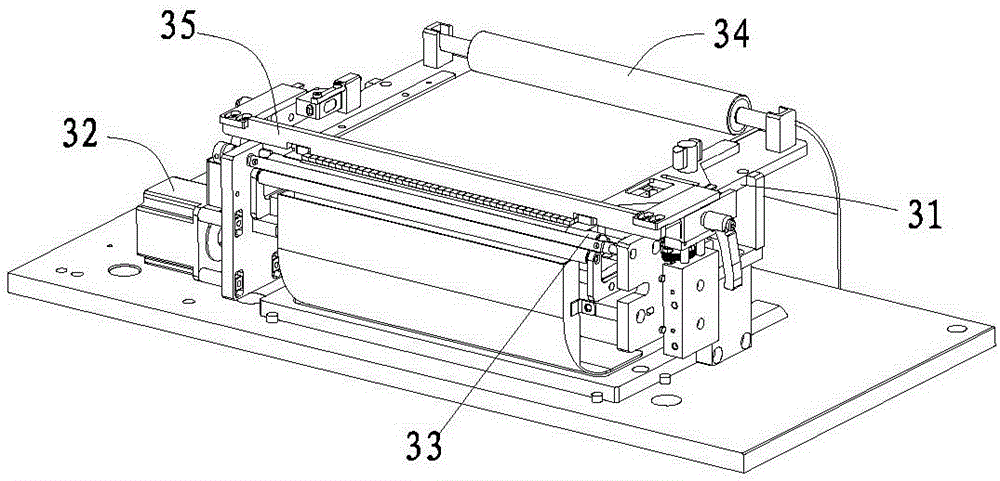

[0023] Examples, see Figure 1 to Figure 5 , a kind of automatic double-sided sponge adhesive sticking machine that the present embodiment provides, and it comprises frame 1, release paper stripping manipulator 2, sponge pasting feeding platform 3, sponge picking and placing manipulator 4, sponge stripping arrangement mechanism 5 and The waste discharge flow channel 6, the sponge sticker feeding platform 3 and the sponge peeling arrangement mechanism 5 are sequentially arranged on the frame 1, and the waste discharge flow channel 6 is arranged on one side of the sponge sticker feed platform 3, so that The release paper cleaning manipulator 2 is arranged on the upper position of the sponge paste feeding platform 3, and can tear the release paper on the sponge paste and move to the waste discharge channel 6, and the sponge pick-and-place manipulator 4 It is arranged at the upper position of the sponge peeling arrangement mechanism 5, and the sponge paste on the sponge peeling ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com