3D polypyrrole chitosan gelatin composite electric conduction material and preparation method thereof

A technology of polypyrrole chitosan gelatin and chitosan polymer, which is applied in the field of materials, can solve the few researches on the feasibility of 3D composite conductive patch materials, achieve good biocompatibility, high conductivity, and accelerate The effect of signaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

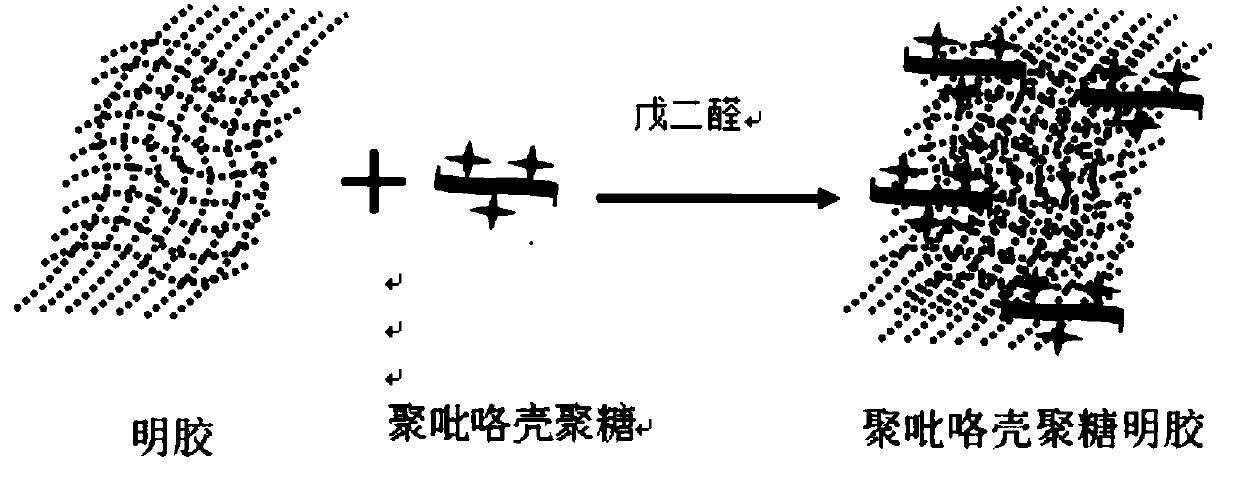

[0044] This embodiment provides a preparation method of a 3D polypyrrole chitosan gelatin composite conductive material, comprising the following steps:

[0045] (1) preparation concentration is the acetic acid solution of 0.172mol / L, adds chitosan in described acetic acid solution, and controls the ratio of the mass of acetic acid and chitosan in described acetic acid solution to be 0.525:1, under 400rpm stirring condition Stir for 4h to fully mix to obtain chitosan acidic solution;

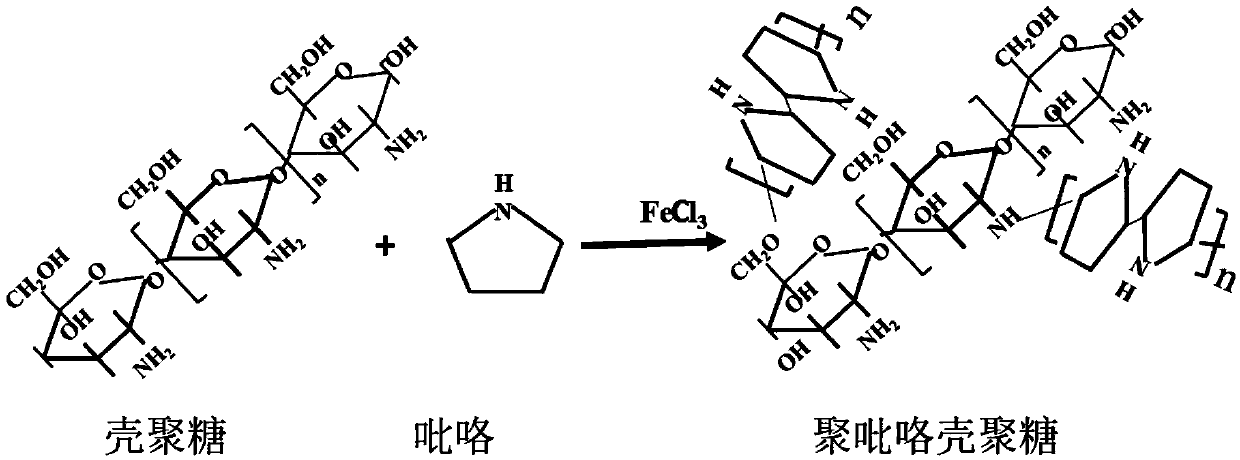

[0046] (2) adding pyrrole in the chitosan acidic solution described in step (1), and controlling the mass ratio of chitosan and pyrrole in the chitosan acidic solution is 1:0.294, stirred for 12h under 400rpm stirring condition Fully mix evenly to obtain chitosan-pyrrole mixed solution;

[0047] (3) Prepare a ferric chloride solution with a concentration of 0.67mol / L, slowly add the ferric chloride solution dropwise to the In the chitosan-pyrrole mixed solution, control the mass ratio of ferri...

Embodiment 2

[0051] This embodiment provides a preparation method of a 3D polypyrrole chitosan gelatin composite conductive material, comprising the following steps:

[0052] (1) preparation concentration is the acetic acid solution of 0.17mol / L, adds chitosan in described acetic acid solution, and controls the ratio of the mass of acetic acid and chitosan in described acetic acid solution to be 0.4:1, under 300rpm stirring condition Stir for 4h to fully mix to obtain chitosan acidic solution;

[0053] (2) adding pyrrole in the chitosan acidic solution described in step (1), and controlling the mass ratio of chitosan and pyrrole in the chitosan acidic solution to be 1:0.03, stirring for 12h under 300rpm stirring conditions Fully mix evenly to obtain chitosan-pyrrole mixed solution;

[0054] (3) Prepare a ferric chloride solution with a concentration of 0.067mol / L, slowly add the ferric chloride solution dropwise at a rate of 0.3ml / h to the In the chitosan-pyrrole mixed solution, control ...

Embodiment 3

[0058] This embodiment provides a preparation method of a 3D polypyrrole chitosan gelatin composite conductive material, comprising the following steps:

[0059] (1) preparation concentration is the acetic acid solution of 0.18mol / L, adds chitosan in described acetic acid solution, and controls the ratio of the mass of acetic acid and chitosan in described acetic acid solution to be 0.6:1, under 500rpm stirring condition Stir for 2h to fully mix to obtain chitosan acidic solution;

[0060] (2) adding pyrrole in the chitosan acidic solution described in step (1), and controlling the mass ratio of chitosan and pyrrole in the chitosan acidic solution to be 1:0.04, stirring for 8h under 500rpm stirring conditions Fully mix evenly to obtain chitosan-pyrrole mixed solution;

[0061] (3) Prepare a ferric chloride solution with a concentration of 0.67mol / L, slowly add the ferric chloride solution dropwise to the In the chitosan-pyrrole mixed solution, control the mass ratio of ferri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com