Antibacterial-hemostatic material with non-woven fabric fiber fabric structure and production method of antibacterial-hemostatic material

A fiber fabric and hemostatic material technology, which is applied in the field of electrospun fiber antibacterial-hemostatic material and its preparation, can solve the problems of high electric charge, difficult spinning, high viscosity, etc., achieves simple operation, improves hemostatic performance, and saves the amount of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

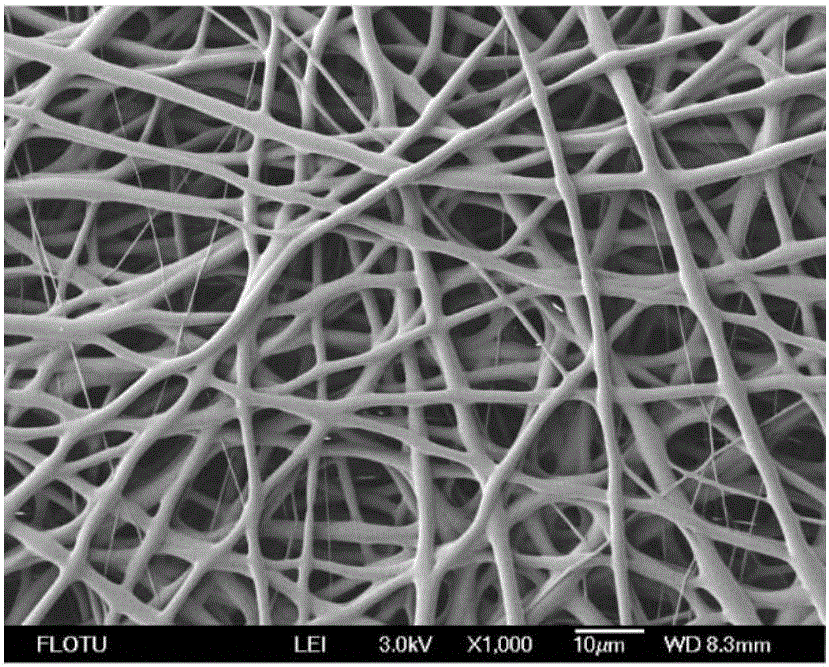

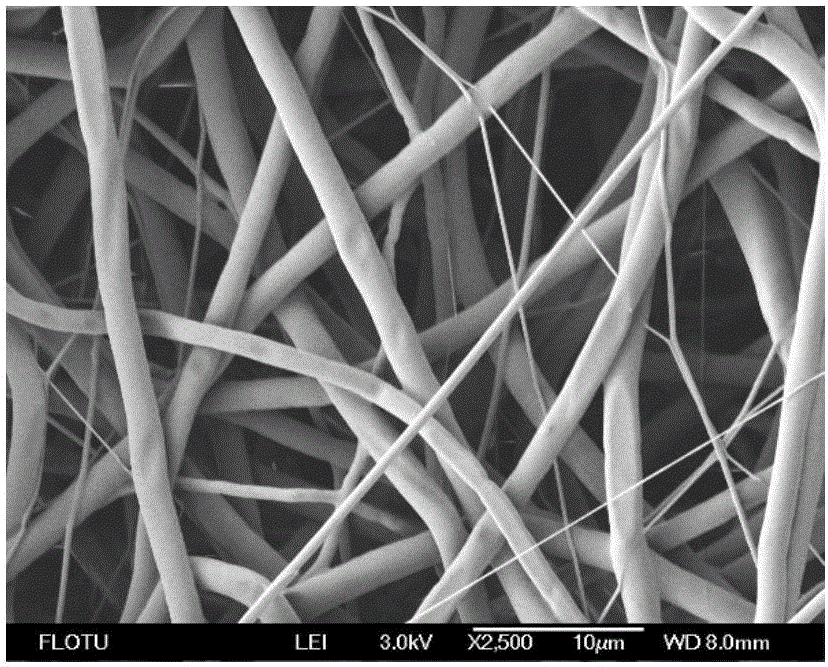

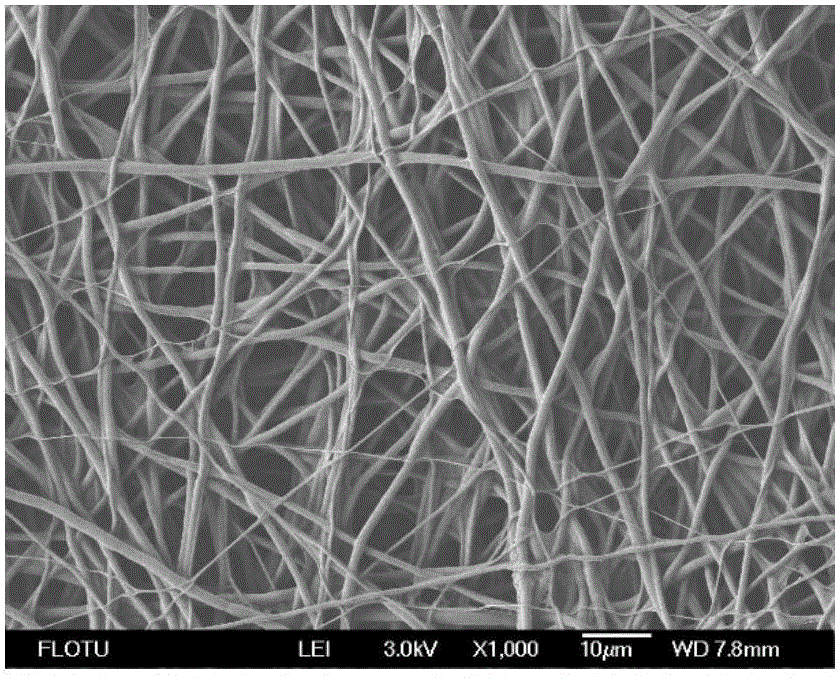

Image

Examples

Embodiment 1

[0027]Example 1: Preparation of electrospun fiber membrane: Add 9 grams of hexafluoroisopropanol to a beaker, add 1 g of polybutylene succinate (PBS) (molecular weight Mw=65000), stir at room temperature to make it Dissolving to obtain a spinning solution with a mass percentage concentration of 10 wt%. The prepared spinning solution is subjected to electrospinning to obtain an electrospun fiber membrane, and the prepared electrospun fiber membrane is desolventized in a vacuum oven for 24 hours.

[0028] Preparation of chitosan solution: dissolving glacial acetic acid in deionized water to prepare a concentration of 5 wt% acetic acid solution, weighing 1.5g of chitosan powder (deacetylation degree>90%, molecular weight 200000) was dissolved in 100g of the above-mentioned acetic acid solution A chitosan solution with a mass fraction of 1.5wt% was obtained.

[0029] A certain area of the electrospun fiber membrane was cut and dipped into the chitosan solution, soaked for 30 min...

Embodiment 2

[0040] Example 2: Change the molecular weight of polybutylene succinate in Example 1 to Mw=100000, the preparation method is the same as Example 1, and the hemostatic time of the electrospun fiber membrane is shorter than that of gelatin sponge. The 2h contact sterilization rate of E.coli(DH5α) reached 83%.

Embodiment 3

[0041] Embodiment 3: change polybutylene succinate into polycaprolactone in embodiment 1, use amount is 0.6g, preparation method is the same as embodiment 1, but change the thrombin solution concentration into 5U / mL, electric The hemostasis time of the spun fiber membrane is shorter than that of the gelatin sponge. The 2h contact sterilization rate of E.coli(DH5α) reached 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com