Glass tube cutting equipment

A technology for cutting equipment and glass tubes, used in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

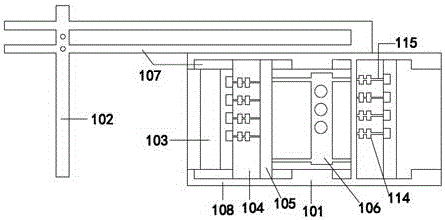

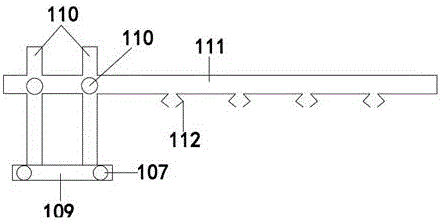

[0016] Such as figure 1 As shown, a glass tube cutting device includes a support 101 , a mechanical arm 102 , a net 103 , two rotators 104 , a cutter 105 , and a heating device 106 . Wherein said support comprises 6 support guide rails 107, support side platform 108, and described support is the cuboid of hollow out, has 2 in described support guide rail 107 and is positioned at the upper surface of support side platform 108, and 2 are welded on described support side platform 108 outer sides, 2 embedded in the support and parallel to the support side platform 108; the bottom end of the mechanical arm 102 is penetrated by the support table side guide rail and suspended above the support; the mechanical arm 102 includes a platform 109, two support bars 110, a support arm 111, three machine fingers 112, and two knobs 113; the platform 109 is arranged at the lowermost end of the mechanical arm 102, and the platform 109 is covered by the support The side guide rail runs through; ...

Embodiment 2

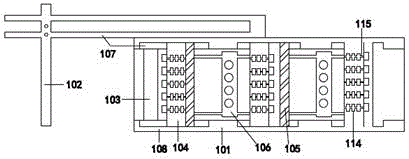

[0019] Such as Figure IIAs shown, a glass tube cutting device includes a support 101 , a mechanical arm 102 , a connecting net 103 , three rotators 104 , two cutters 105 , and two heating devices 106 . Wherein said support comprises 6 support guide rails 107, support side platform 108, and described support is the cuboid of hollow out, has 2 in described support guide rail 107 and is positioned at the upper surface of support side platform 108, and 2 are welded on described support side platform 108 outer sides, 2 embedded in the support and parallel to the support side platform 108; the bottom end of the mechanical arm 102 is penetrated by the support table side guide rail and suspended above the support; the mechanical arm 102 includes a platform 109, 2 support rods 110, a support arm 111, 4 machine fingers 112, and 2 knobs 113; The side guide rail runs through; the support rod 110 is inserted on the platform 109 and is perpendicular to the platform 109; Parallel in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com