Patents

Literature

48results about How to "Avoid cutting errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

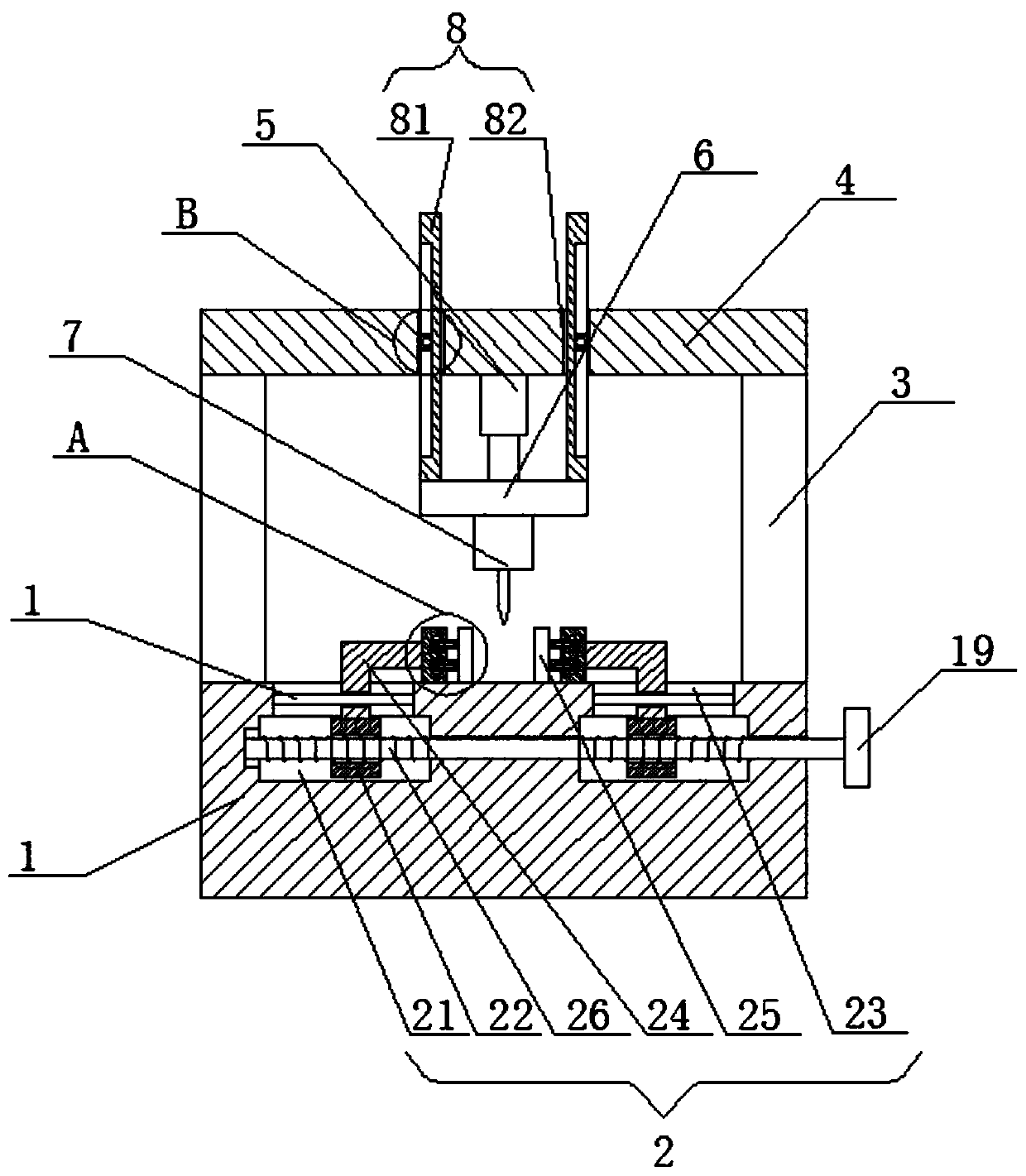

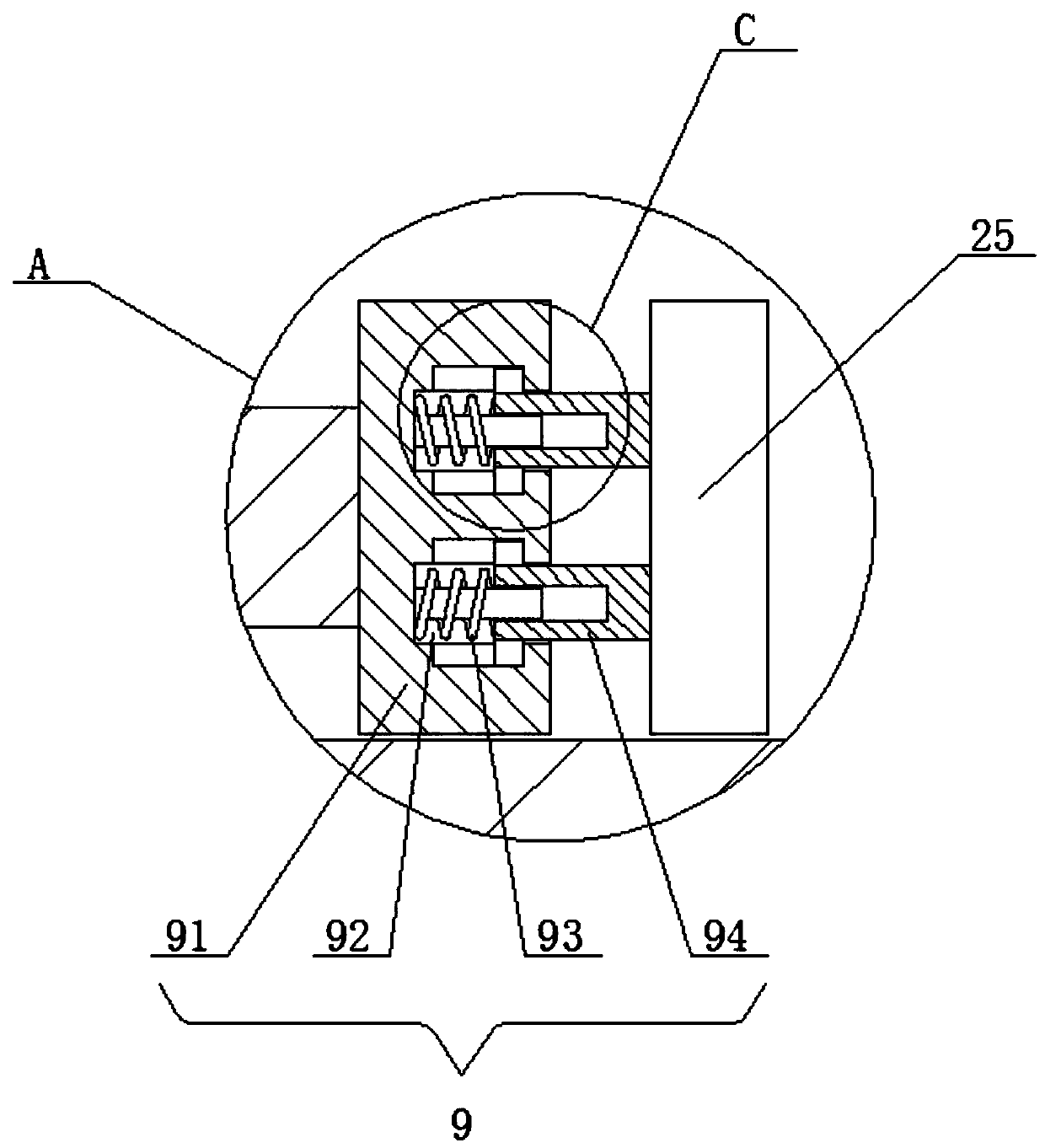

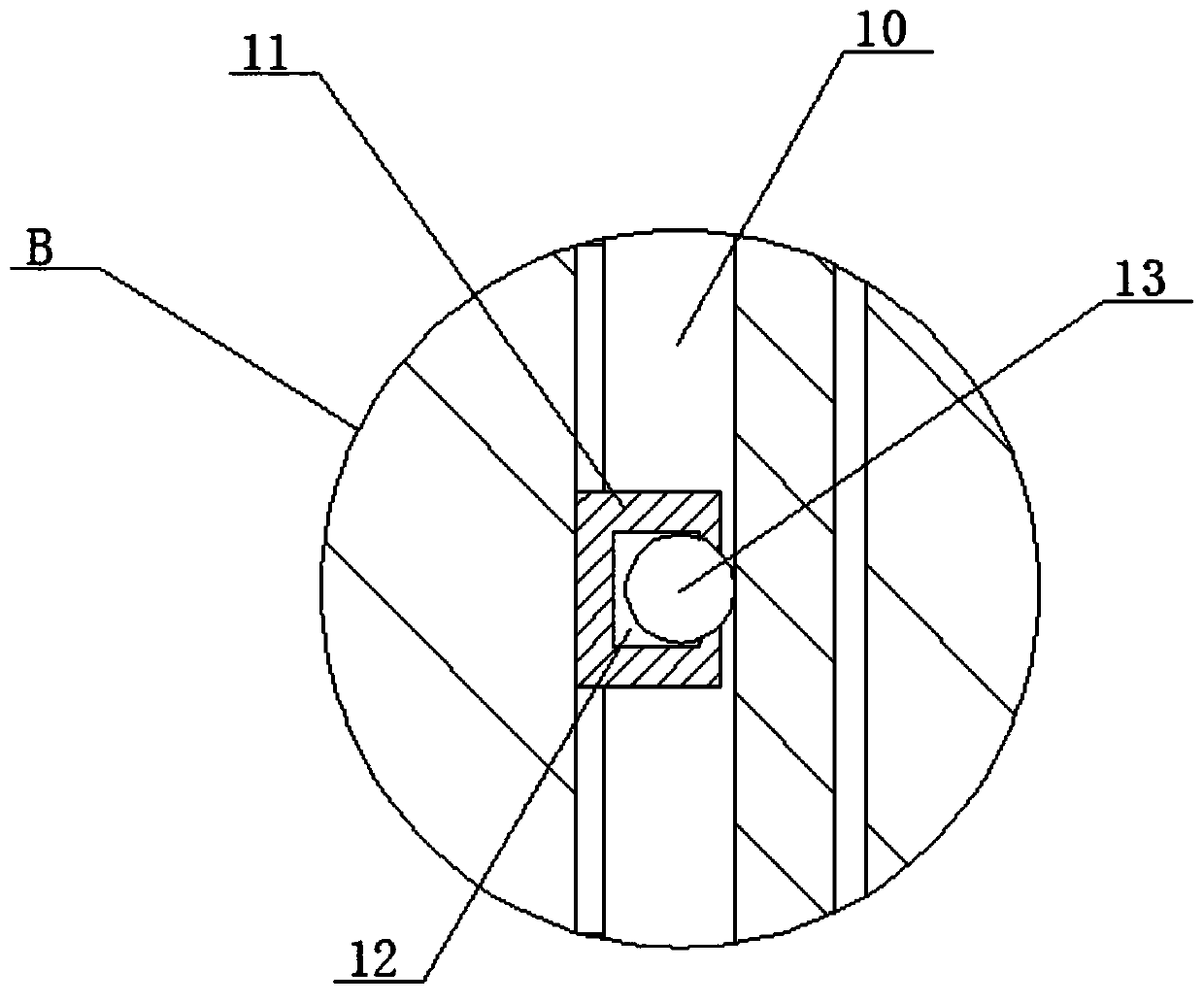

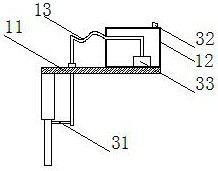

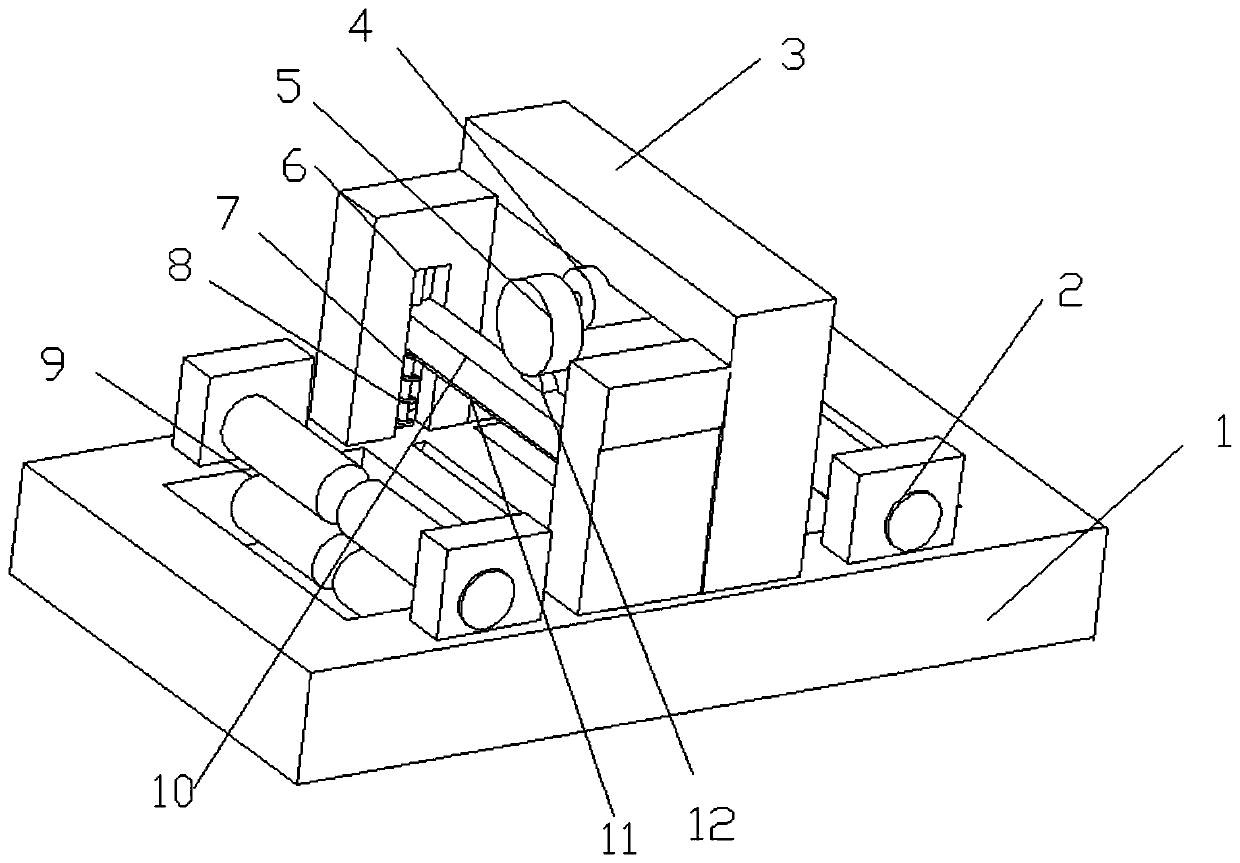

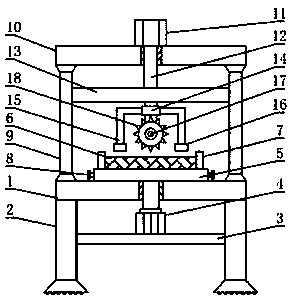

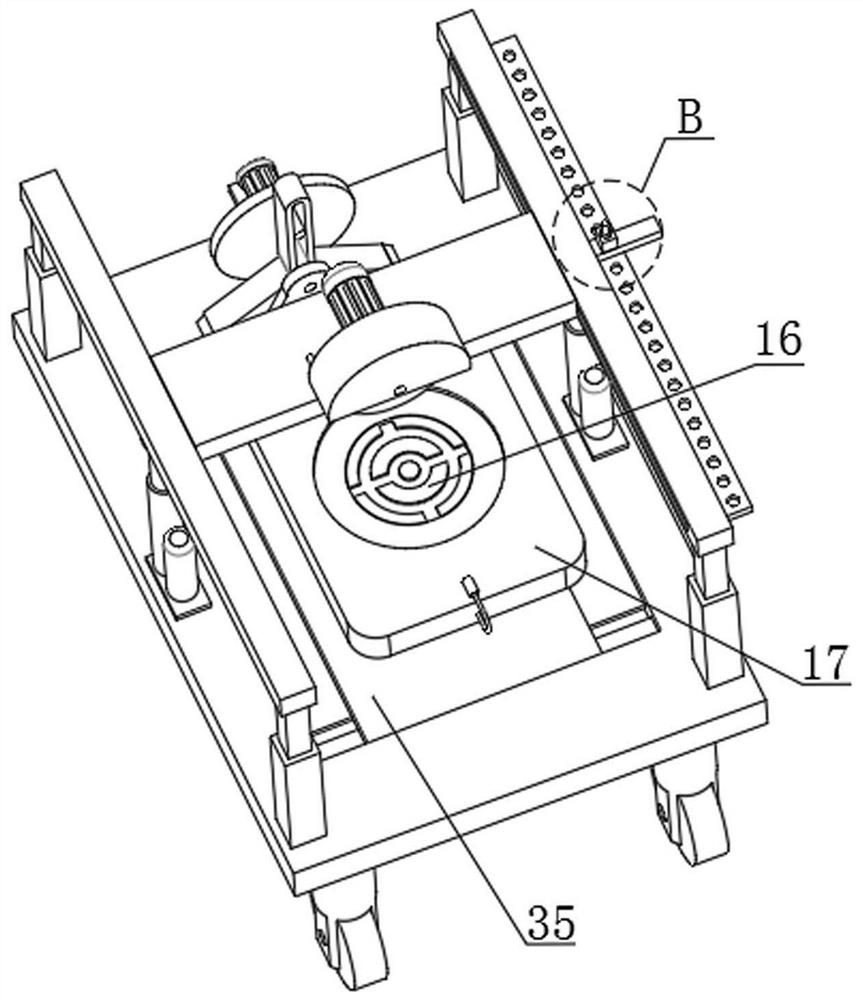

Cutting device for novel macromolecule jade slab

InactiveCN110900672AEasy to holdEasy to processMetal working apparatusClassical mechanicsEngineering

The invention relates to the technical field of jade cutting, and discloses a cutting device for a novel macromolecule jade slab. The cutting device comprises a base, wherein a clamping device is arranged at the upper end of the base, supporting plates are symmetrically and fixedly connected with the two sides of the upper end of the base, the upper ends of the two supporting plates are fixedly connected with a cross plate together, a cylinder is fixedly connected with the center of the lower end of the cross plate, the output end of the cylinder is fixedly connected with a moving plate, the lower end of the moving plate is fixedly connected with a cutting machine main body, and a stabilizing mechanism is arranged on the moving plate; the clamping device comprises two sliding slots, two sliding blocks, two channels, two connecting rods, two clamping plates, two threaded holes and screws, the two sliding slots are symmetrically arranged in the base, the two sliding blocks are respectively and slidingly connected with the two sliding slots, and the two channels are respectively formed on the upper end of the base and arranged through the two sliding slots. The cutting device for thenovel macromolecule jade slab can clamp the jade very conveniently, is stable and reliable, and does not generate large cutting errors.

Owner:江苏德丰新建材科技有限公司

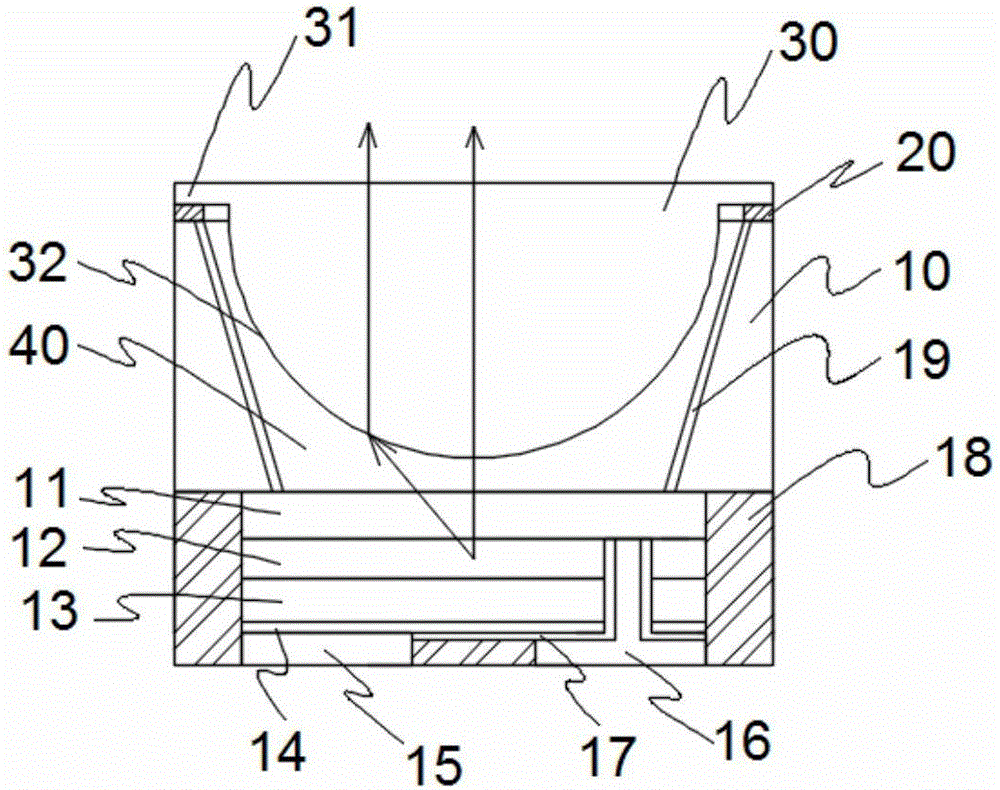

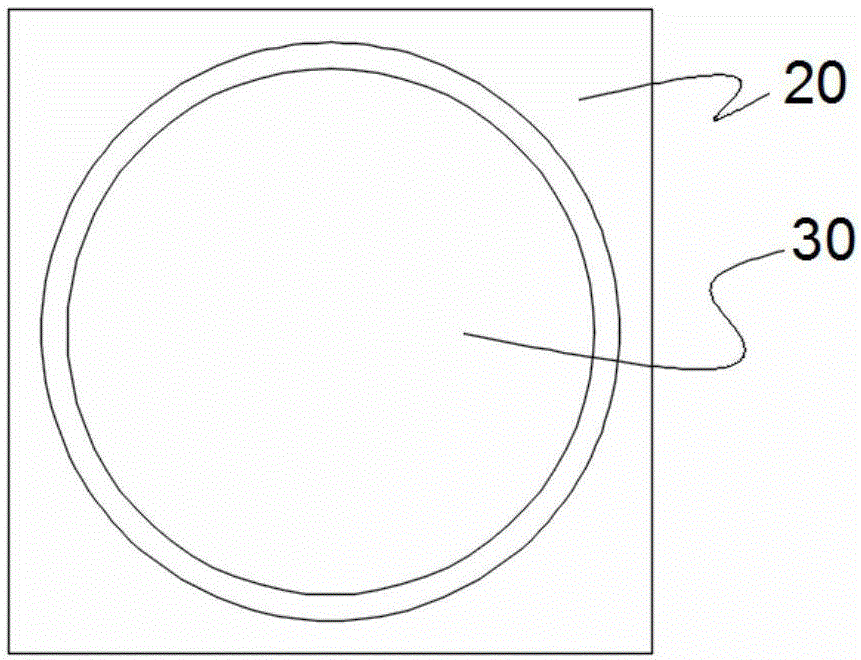

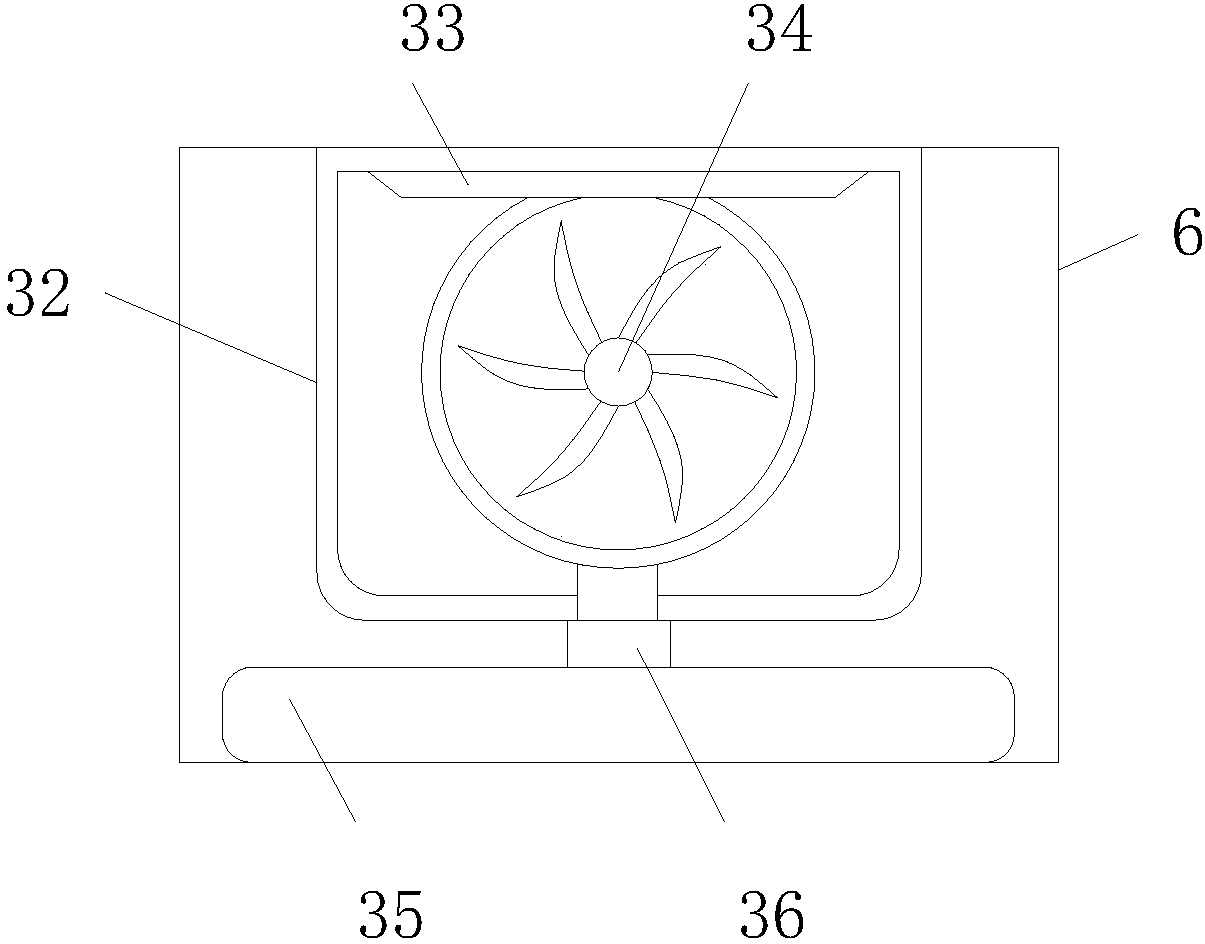

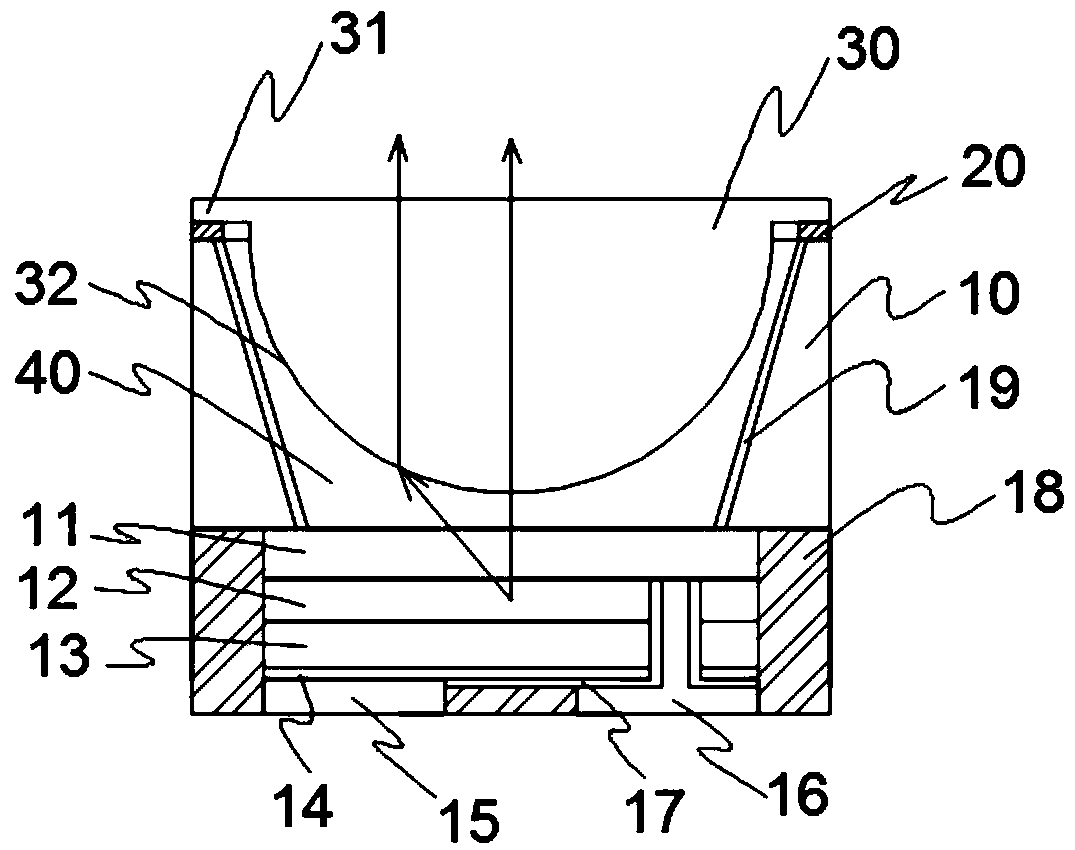

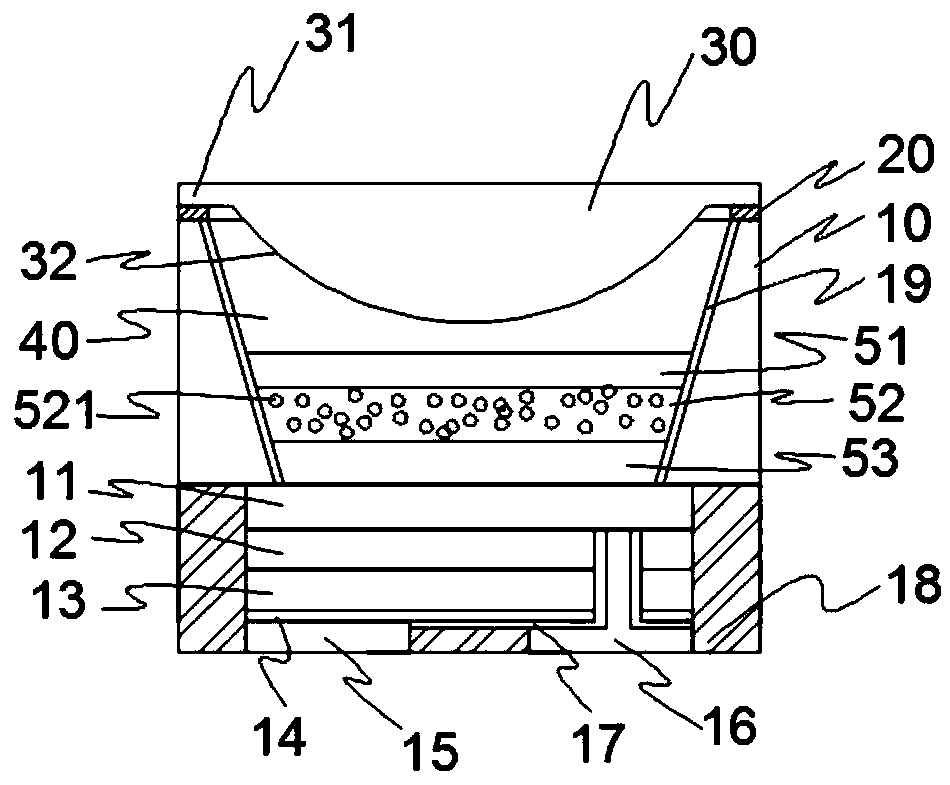

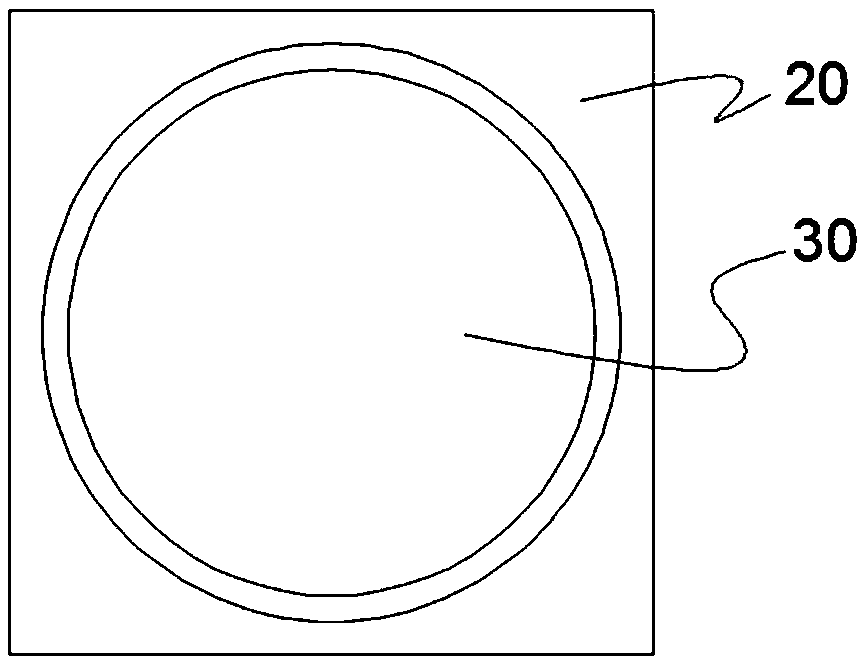

Wafer stage encapsulation LED (light emitting diode)

ActiveCN106784258AMeet the requirements of directional illumination application scenariosAvoid cutting errorsSemiconductor devicesHigh reflectivityDoping

The invention relates to a wafer stage encapsulation LED (light emitting diode), and relates to LED encapsulation. The wafer stage encapsulation LED is provided with an LED chip, a lens and a lens bonding layer, wherein the LED chip is provided with a substrate layer, a doping semiconductor layer, a semiconductor luminous layer, a conducting reflecting layer, an electrode, an insulation layer and a coating medium, wherein the semiconductor luminous layer is arranged between the first doping semiconductor layer and the second doping semiconductor layer; the conducting reflecting layer is arranged under the second doping semiconductor layer; the second electrode realizes the electric conduction with the second doping semiconductor layer through the conducting reflecting layer; the first electrode and the first doping semiconductor layer are directly connected; the insulation among the first electrode, the semiconductor luminous layer, the second doping semiconductor layer and the conducting reflection layer is realized by an insulation layer; the coating medium is arranged on a non-substrate region of the side wall of the LED chip; a through hole is formed inside the substrate layer; the inner wall of the through hole is provided with a high-reflectivity layer; the lens comprises a flat plate part and an optical coupling part; the flat plate part is fixed onto the substrate layer; the optical coupling part is arranged in the through hole of the substrate layer; in addition, the optical receiving surface of the optical coupling part faces the first doping semiconductor layer.

Owner:XIAMEN UNIV

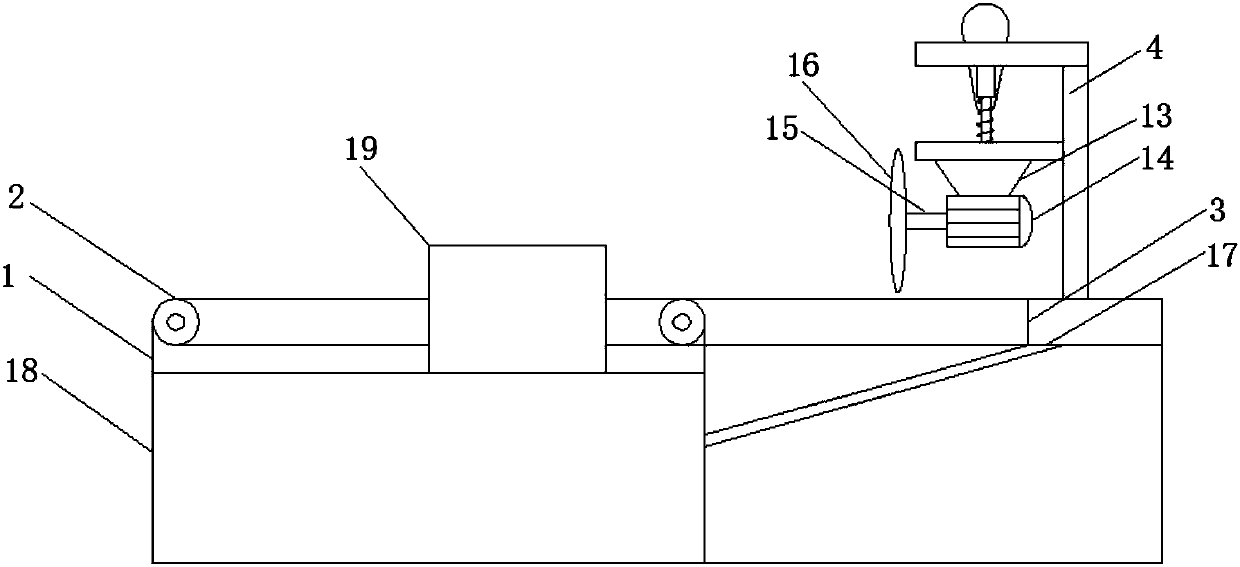

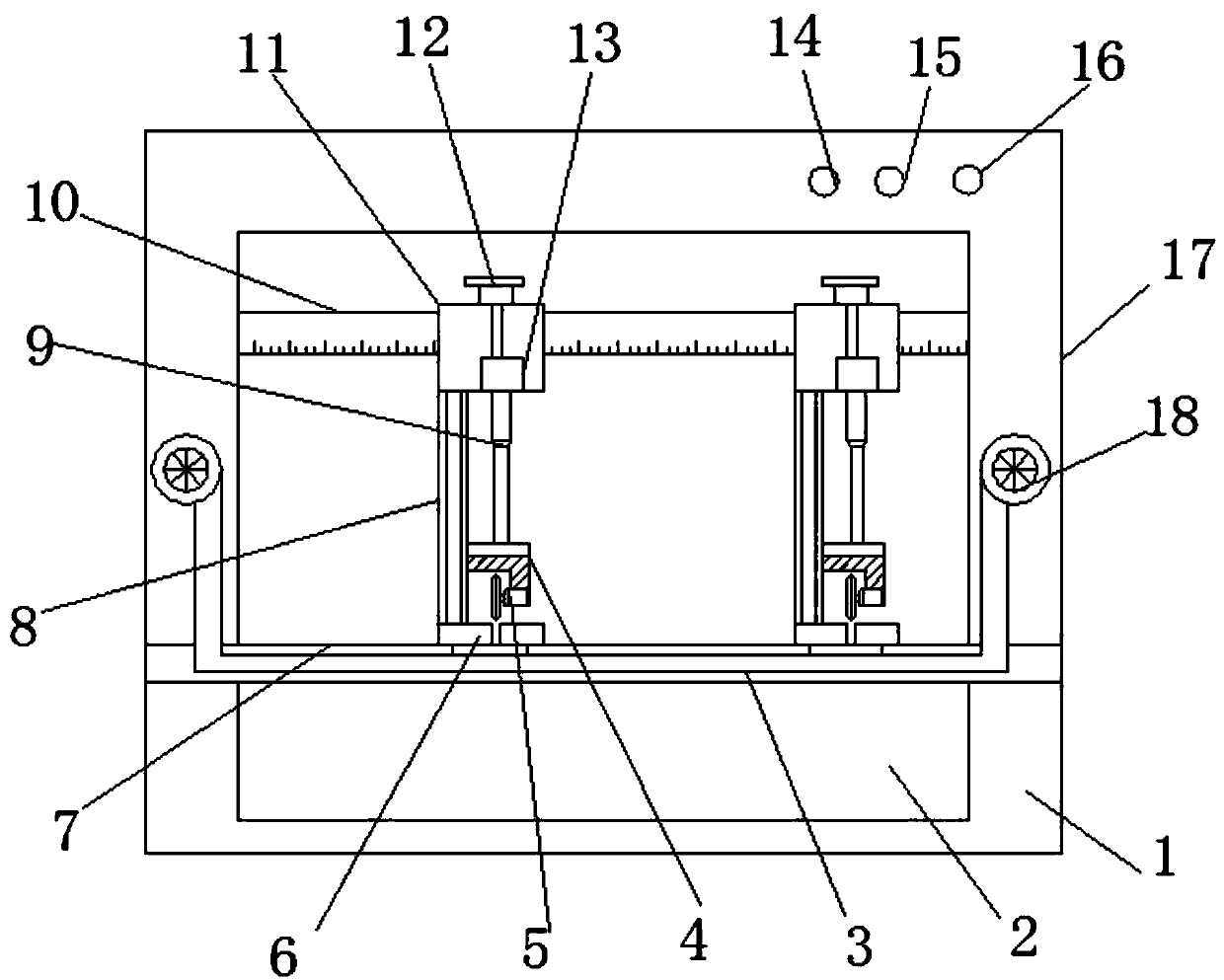

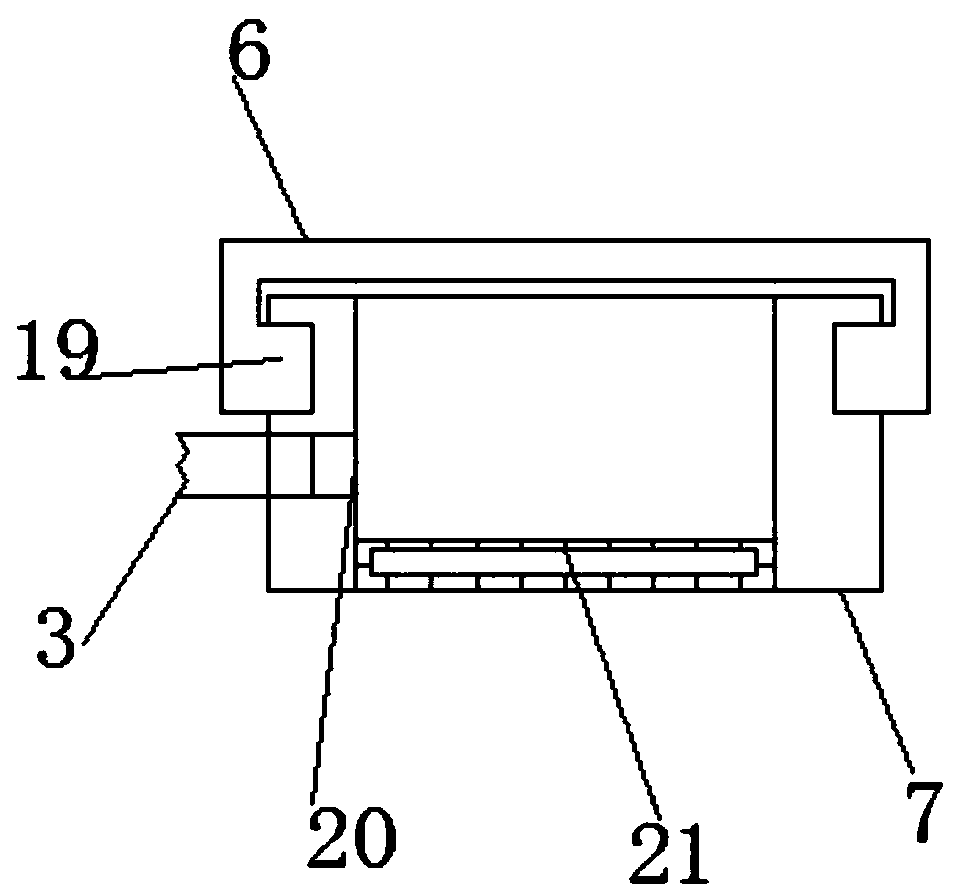

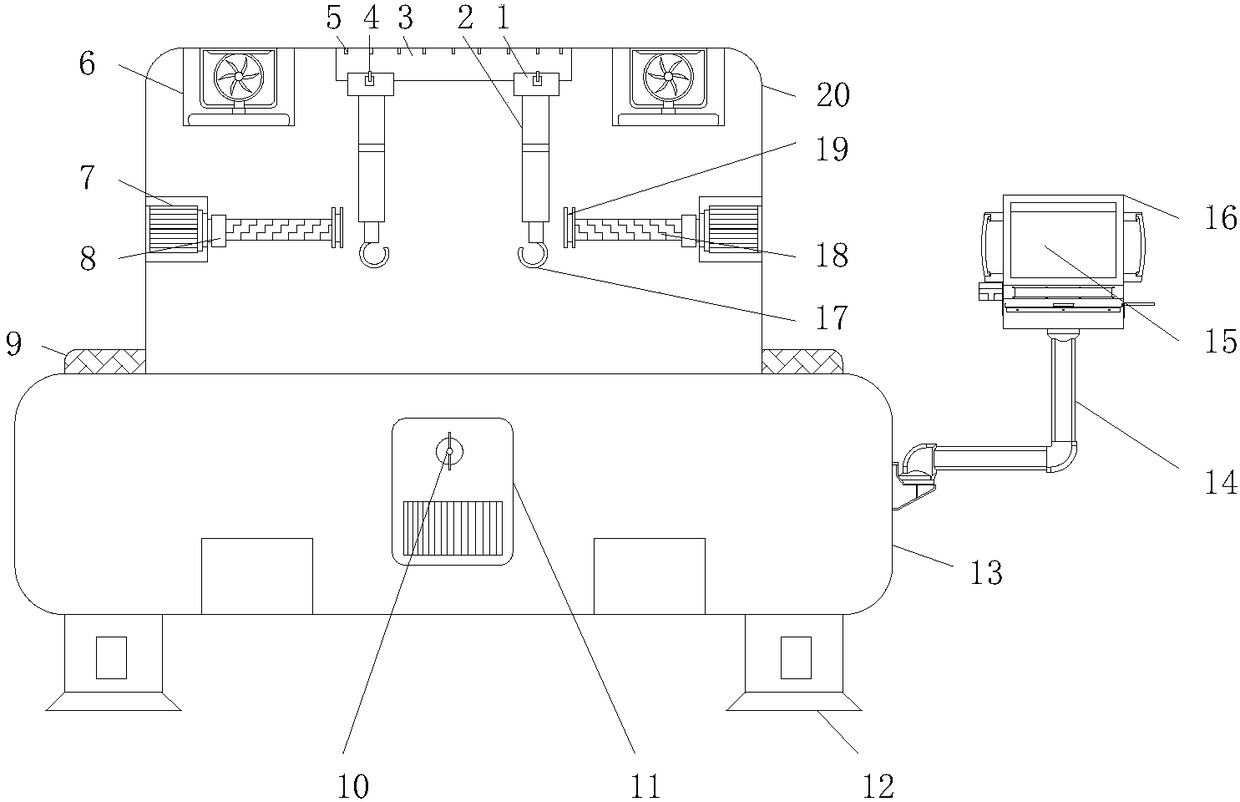

Timber cutting device for preventing timber displacement

The invention discloses a timber cutting device for preventing timber displacement. The timber cutting device comprises a machine seat; a conveying belt is arranged at the front end of the upper planeof the machine seat; a blanking groove is formed in the rear portion of the conveying belt; a limiting frame is arranged on the upper portion of the conveying belt and mounted on the machine seat; athread rod is mounted in the middle of the limiting frame in the left-right direction; sliding blocks are mounted on the thread rod, and fixed rods are connected to the front ends and the rear ends ofthe sliding blocks correspondingly; pulleys are mounted at the outer ends of the fixed rods correspondingly; sliding grooves are formed in the left side and the right side of the limiting frame correspondingly, and the pulleys are mounted in the sliding grooves correspondingly; and limiting blocks are mounted at the bottom ends of the sliding blocks correspondingly. The timber cutting device hasthe beneficial effects that the thread rod is in threaded transmission to drive the sliding blocks on the left and right sides to move towards the middle position so as to drive the limiting blocks onthe left and right sides to move towards the middle position, accordingly deviation of timber during conveying is avoided, and the cutting error is avoided.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

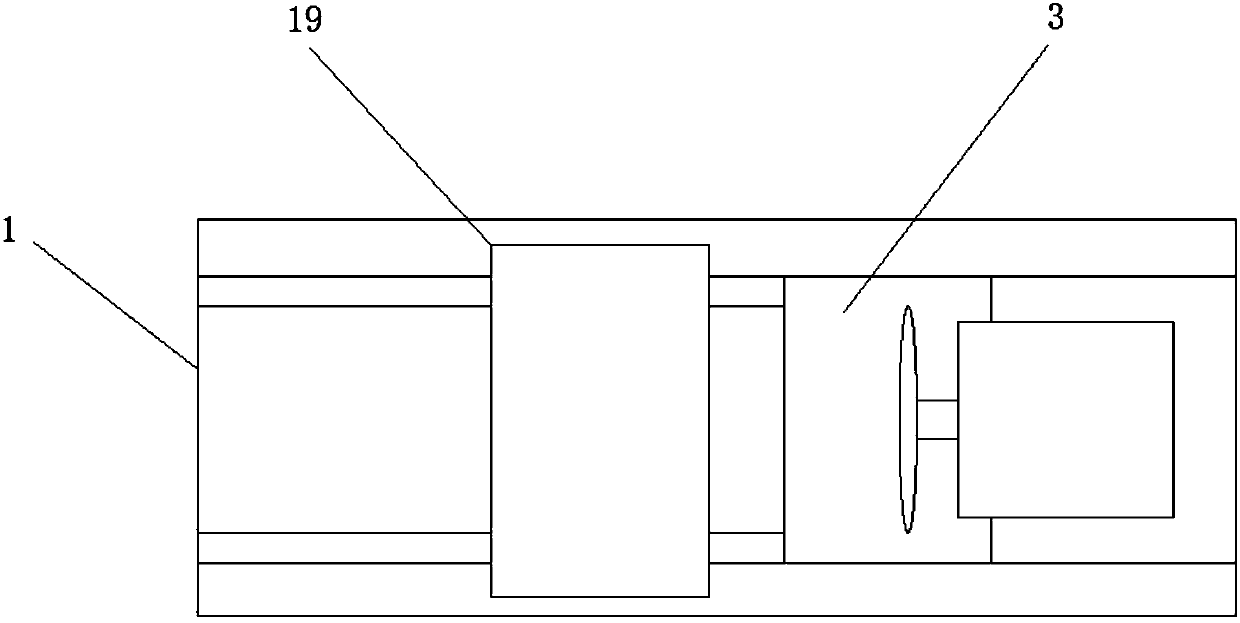

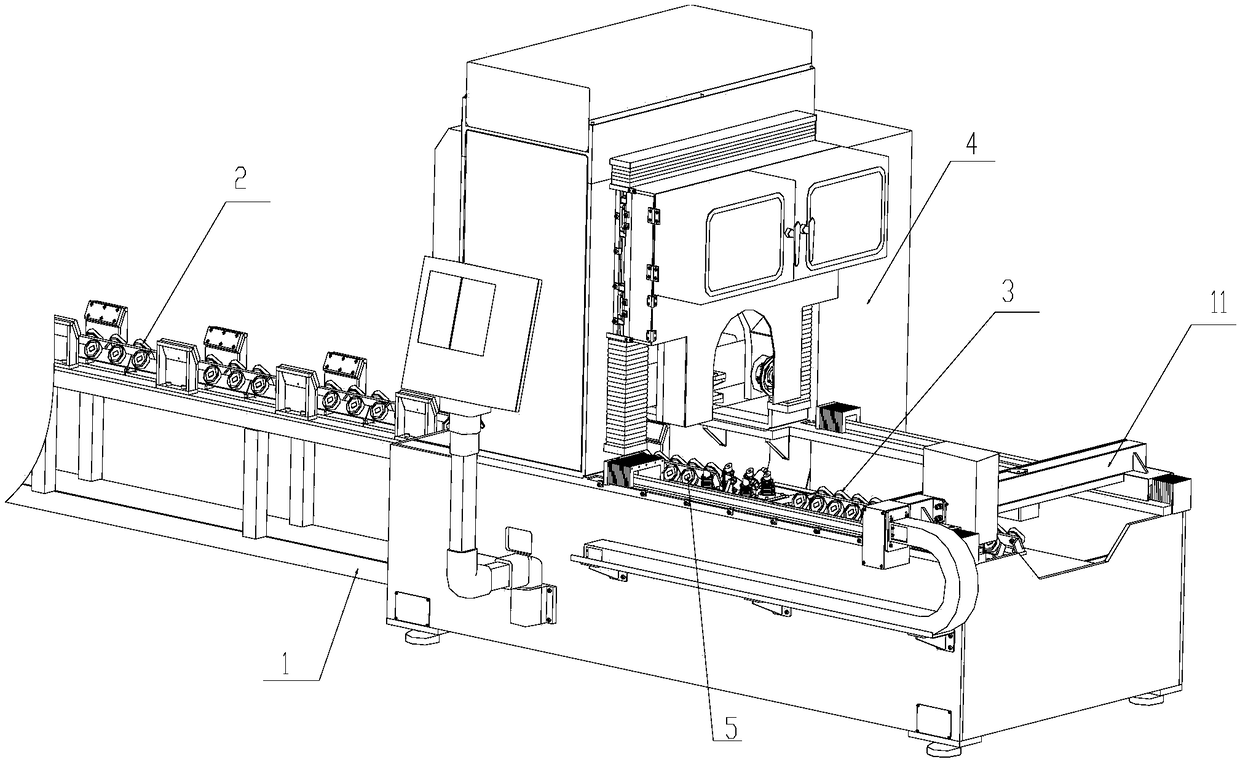

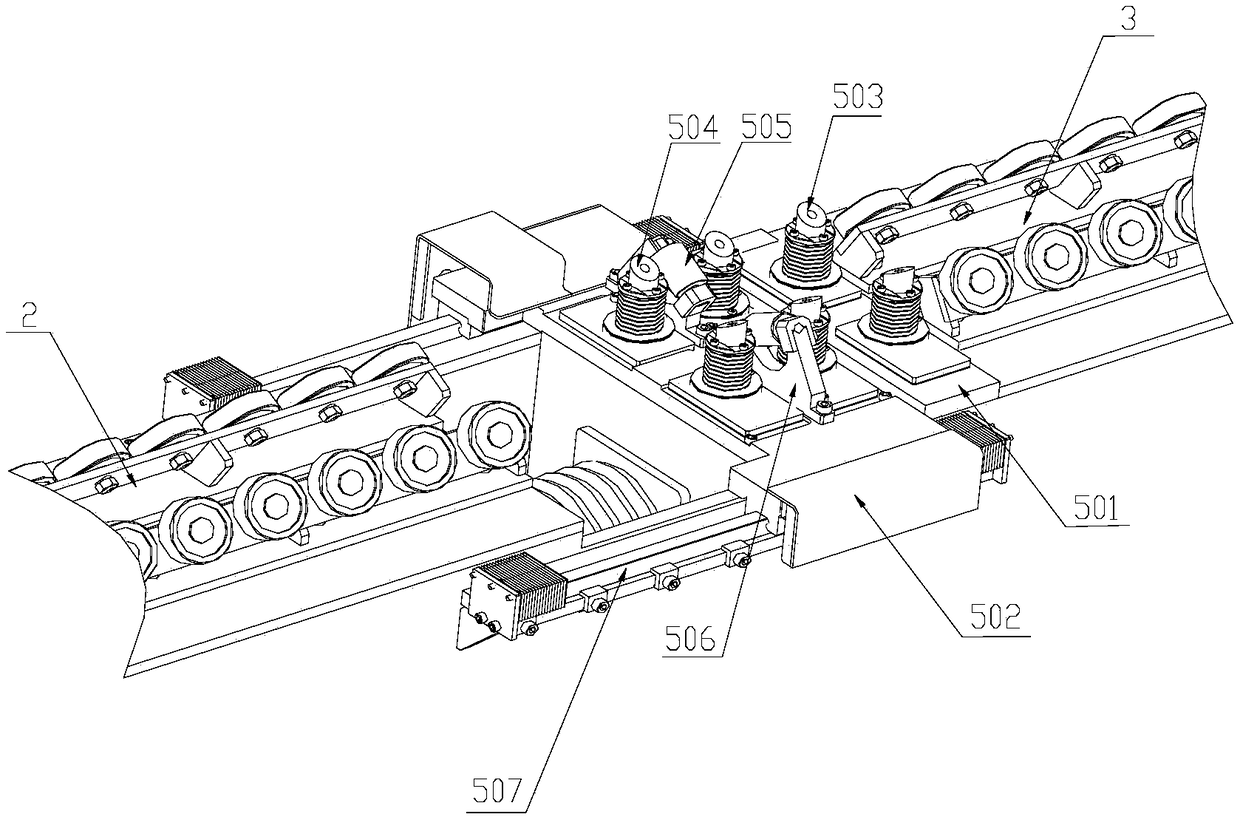

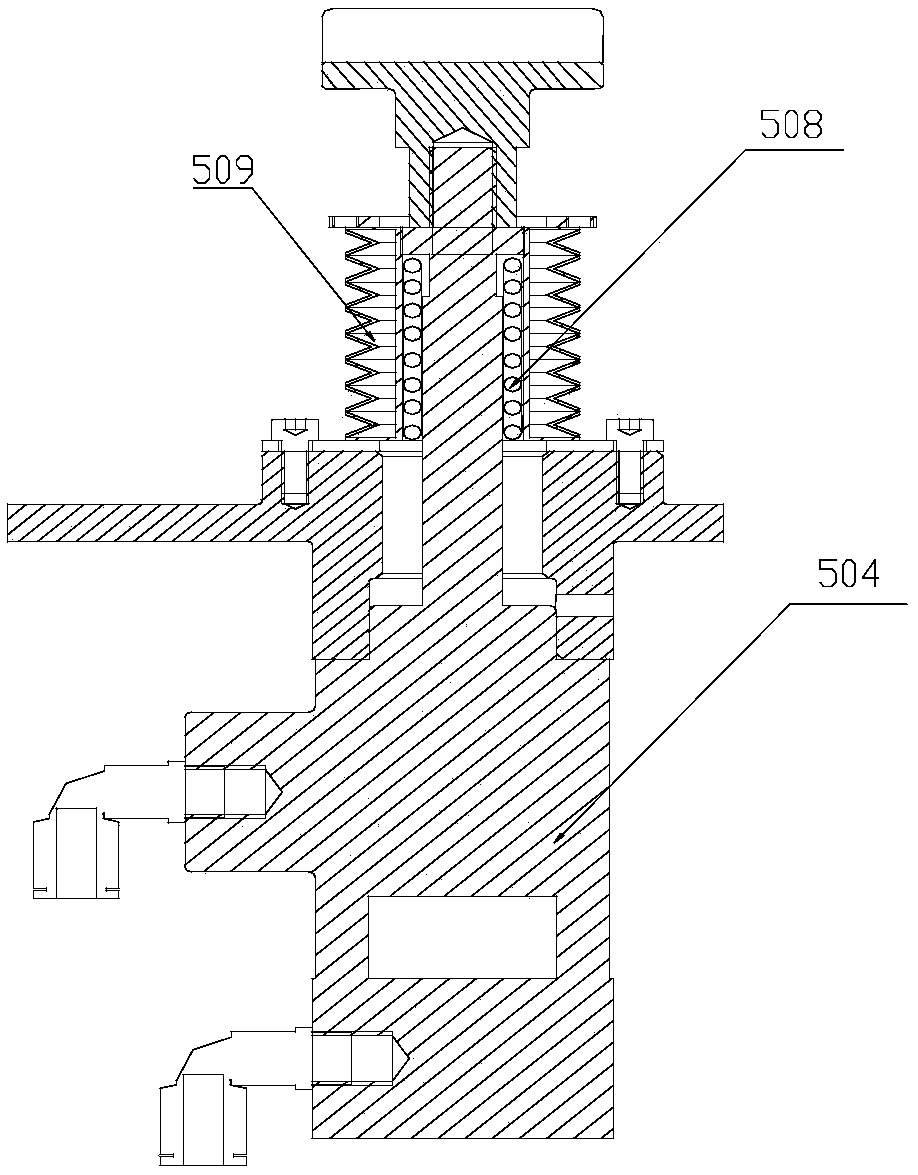

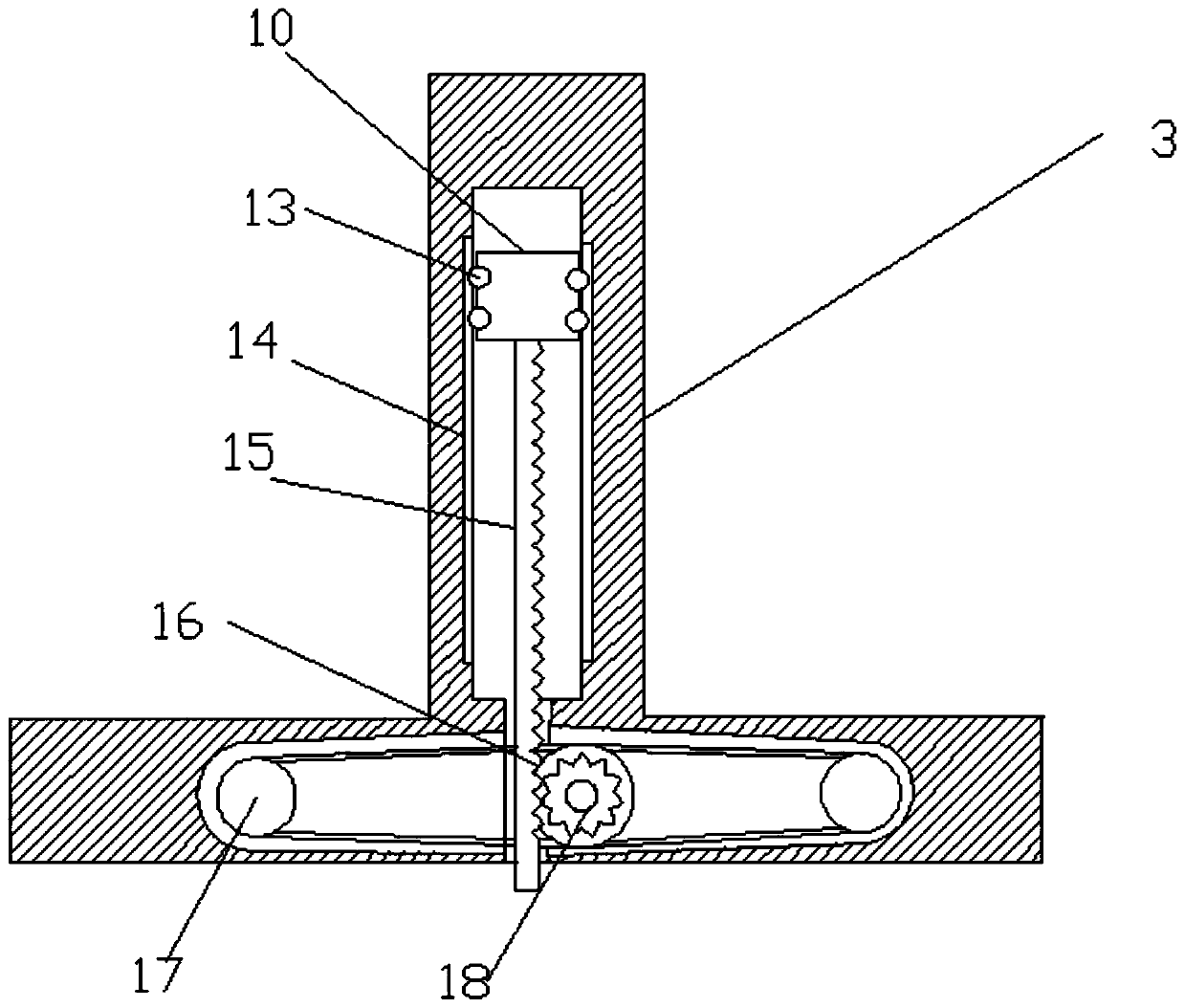

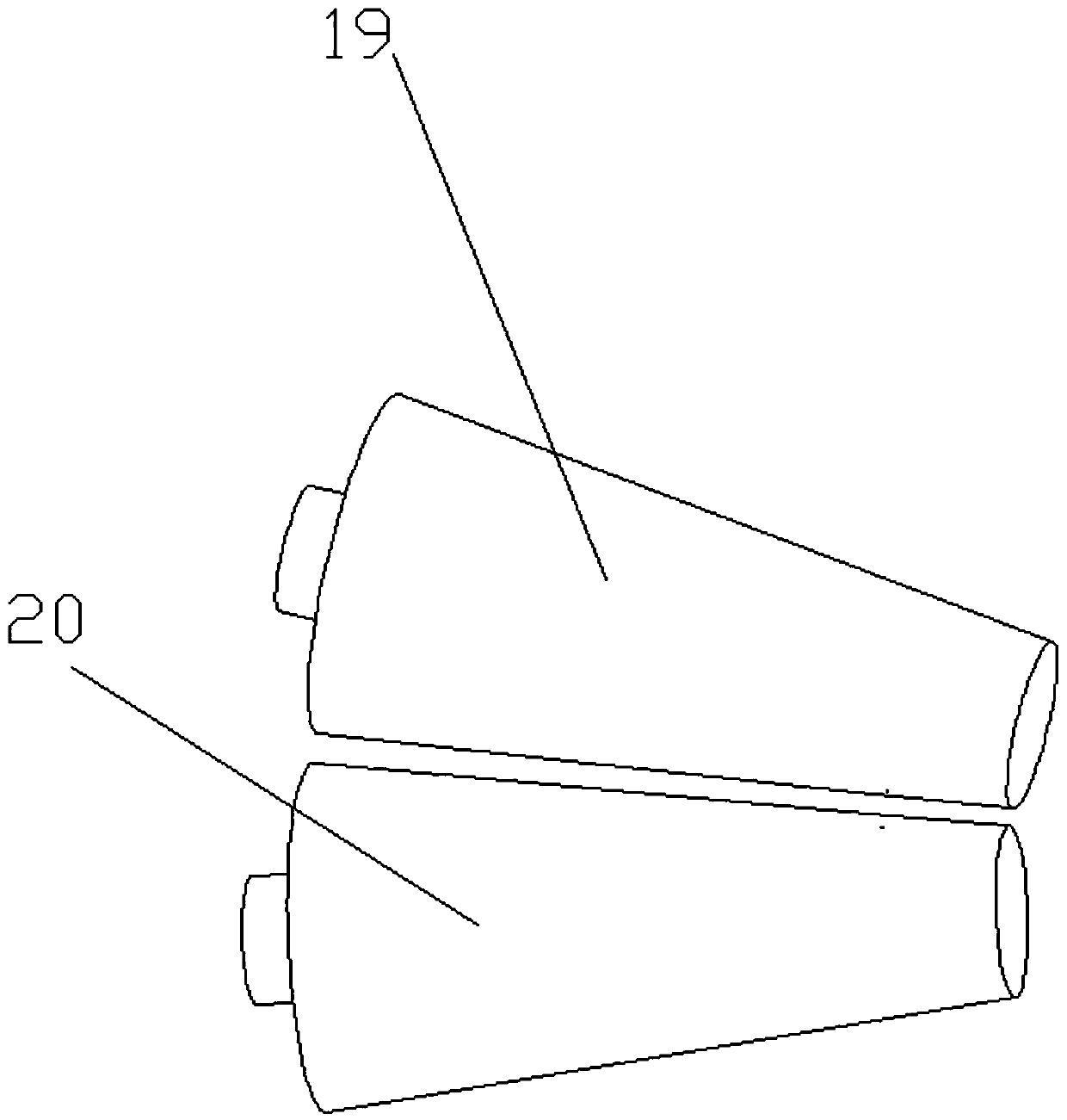

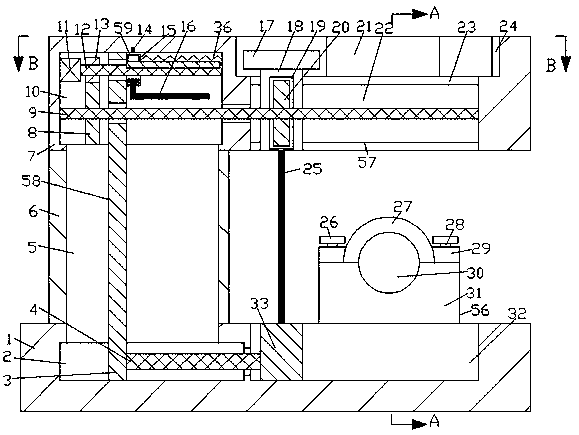

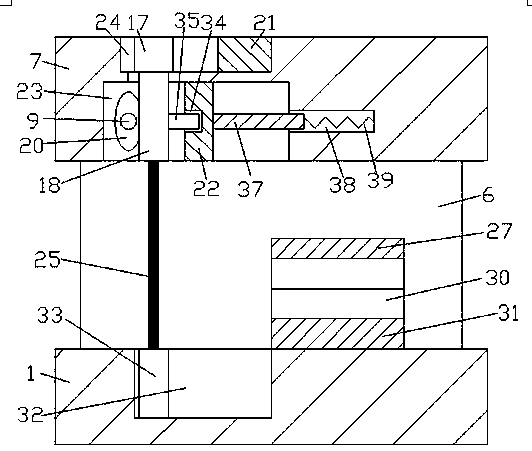

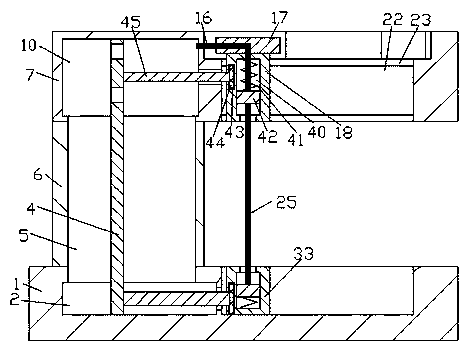

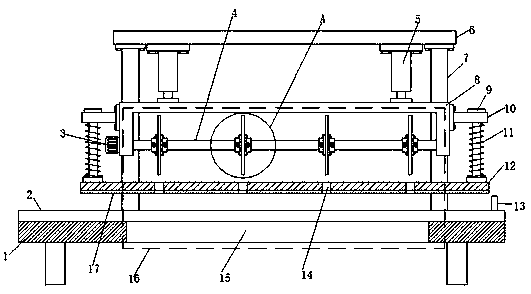

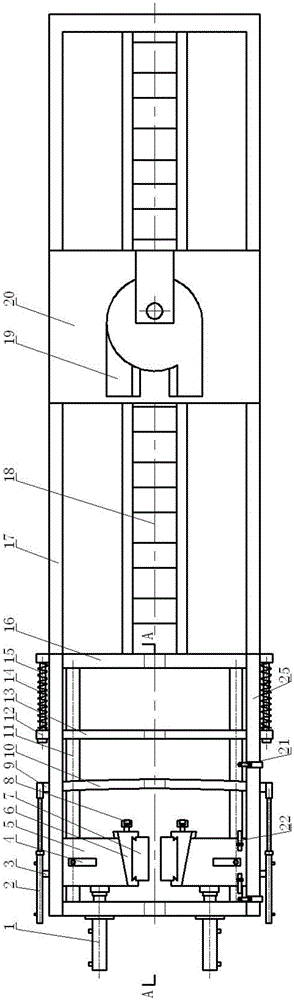

Crystalline silicon single-knife guillotine

PendingCN108748749AAdapt to layout needsIncrease flexibilityWorking accessoriesFine working devicesEngineeringCrystalline silicon

The invention relates to a crystalline silicon single-knife guillotine, and belongs to the technical field of crystalline silicon processing equipment. The crystalline silicon single-knife guillotineincludes a base, a conveying mechanism and a cutting mechanism, wherein the conveying mechanism and the cutting mechanism are located above the base; the conveying mechanism is divided into two levelsin the axial direction of the crystalline silicon, the two levels are the feeding conveying assembly and the discharging conveying assembly respectively, a moving supporting mechanism is arranged between the feeding conveying assembly and the discharging conveying assembly, and the cutting mechanism is arranged above the moving supporting mechanism in a cross mode; and a clamping claw assembly isarranged on the discharging conveying assembly. According to the crystalline silicon single-knife guillotine, the conveying mechanism is combined with the moving supporting mechanism so as to fix thecrystalline silicon with different cutting lengths, and the flexibility is high; and meanwhile, the integration of winding, rewinding and cutting functions is achieved, the structure is compact, theequipment manufacturing cost is reduced, the crystalline silicon single-knife guillotine is also adapt to factory layout needs, the structure is compact, the economy and durability are achieved, and the application prospects are wide.

Owner:QINGDAO GAOCE TECH CO LTD

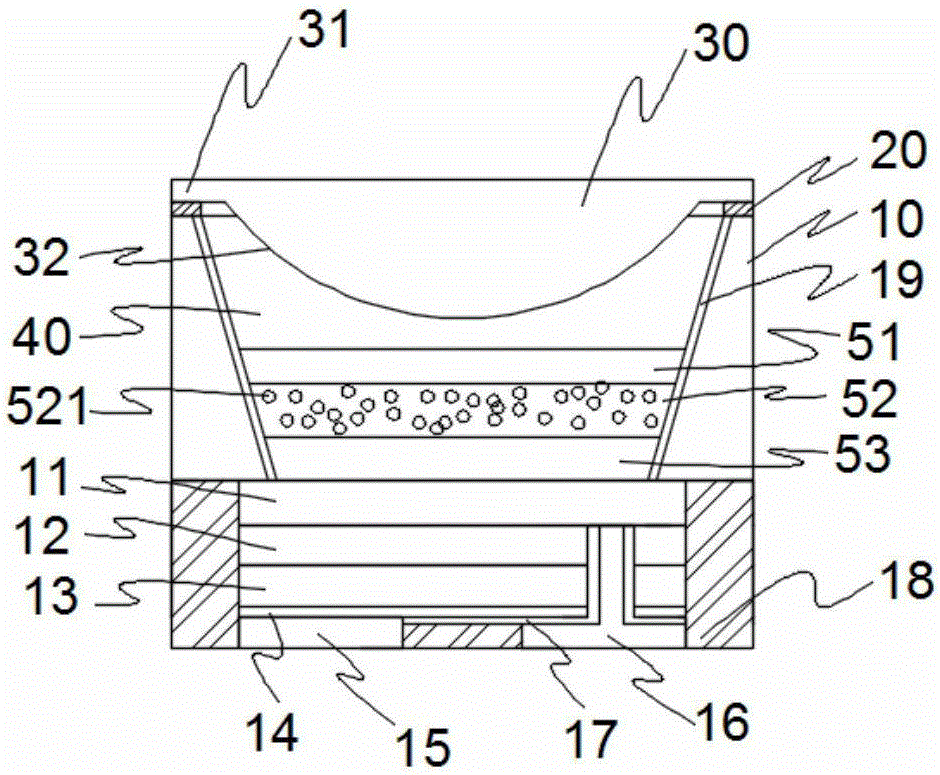

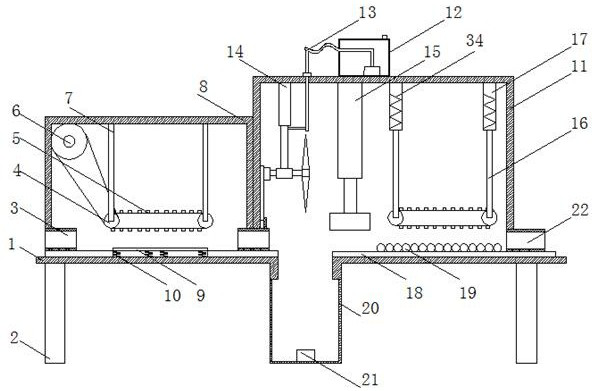

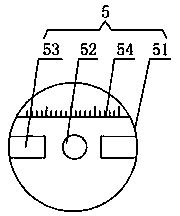

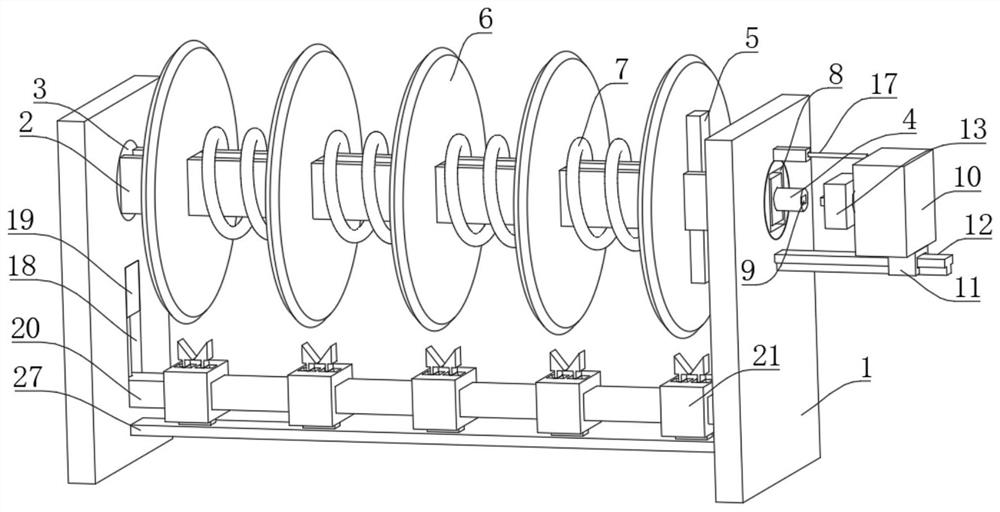

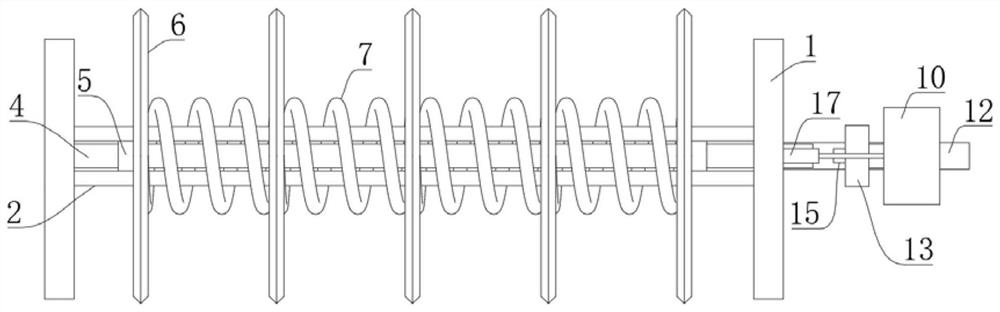

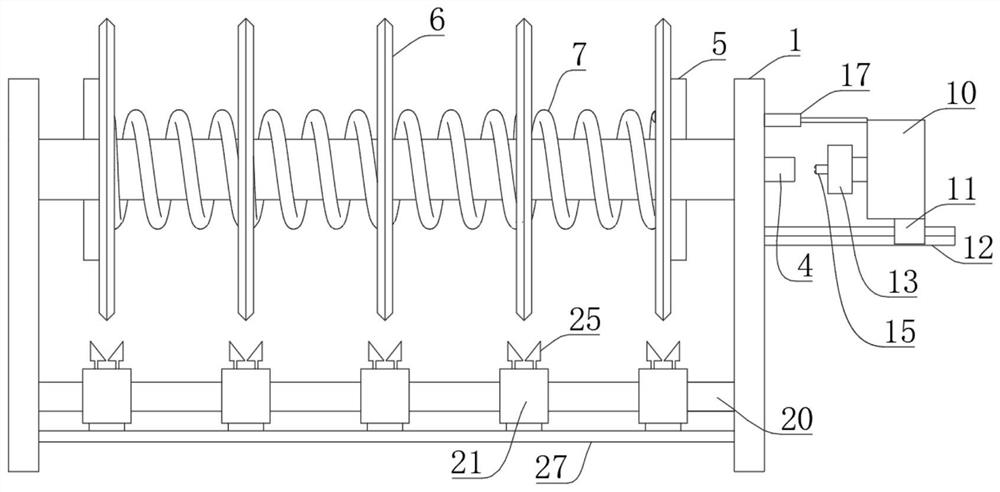

Serpentine spring cutting device

PendingCN107552687AEasy to removeAvoid cutting errorsGas current separationWire springsIron powderEngineering

The invention discloses a serpentine spring cutting device. The serpentine spring cutting device comprises a base and a frame; an iron powder collecting box is arranged in the centre of the base; a spring fixing groove is formed in the upper part of the base; the bottom of the frame is fixedly connected with the left end and the right end of the top of the base; a switch button is arranged at thetop of the front side of the frame; an air blower switch is arranged on the right of the switch button; a control switch is arranged on the right of the air blower switch; and a fixed transverse rod is arranged on the inner side of the frame. According to the serpentine spring cutting device, a filtering net is arranged at the bottom end in the spring fixing groove, and an air blowing opening is formed in the left side of the spring fixing groove, so that the air which is blown out from the air blowing opening cleans chippings produced by cutting through the filtering net after the serpentinespring is cut; a graduated scale is arranged at the bottom of the front side of the fixed transverse rod, and a graduated scale positioning groove is formed in the front side of the moving box, so that the distance, required to be cut, of the serpentine spring is conveniently determined by a user before cutting; and the serpentine spring cutting device is practical, and is suitable to be widely popularized and used.

Owner:NANJING LISHUI LIHUA SPRING FACTORY

Construction steel bar cutting machine

The invention provides a construction steel bar cutting machine, and relates to the field of construction machinery. The machine comprises a workbench, table legs are fixedly arranged at the bottom ofthe workbench, a feeding box is fixedly arranged on the left side of the workbench, a cutting box is fixedly arranged on the right side of the workbench, a collecting box is fixedly arranged in the middle of the bottom of the workbench, a feeding opening is formed in the left side of the feeding box, a base plate is arranged at the bottom of the feeding box, a first spring is arranged at the bottom of the base plate, a cutting device is arranged on the left side of the cutting box, a cooling box is arranged on the top of the cutting box, and a discharging port is formed in the right side of the cutting box. According to the construction steel bar cutting machine, the transportation of steel bars in a machine can be controlled by controlling switches of motors, so that the working efficiency is improved; and a pressing piece is arranged on the right side of the cutting device, and a limiting inserting hole is formed in the bottom of the cutting box, so that cutting errors caused by shaking of the steel bars during cutting are avoided, and cutting is accurate.

Owner:陈洁

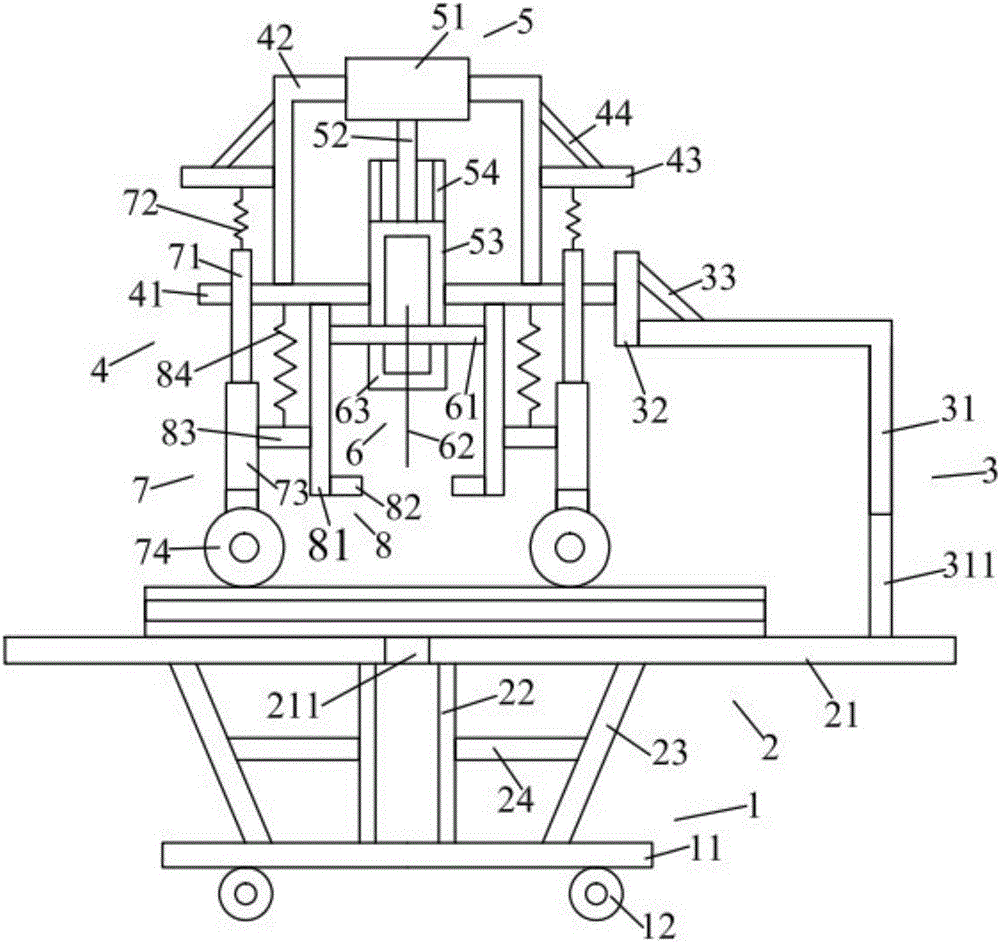

Antiwrinkling cutting device of ponchos

ActiveCN110421626AAvoid cutting errorsAvoid wrinklesMetal working apparatusWebs handlingManufacturing technologyPulp and paper industry

The invention relates to the technical field of poncho manufacturing, and specifically discloses an antiwrinkling cutting device of ponchos. The antiwrinkling cutting device comprises a workbench, a first driving roller and a second driving roller, wherein a door-shaped support frame is fixedly arranged on the upper surface of the workbench, a motor is fixedly installed on the lower surface of thesupport frame, an eccentric wheel is connected to an output shaft of the motor, a vertical chute is formed in the inner side of the support frame, both ends of a cutting knife rack are embedded intothe chute in a sliding mode, a cutting knife is fixedly arranged at the bottom of the cutting knife rack, the lower surfaces of the both ends of the cutting knife rack are elastically connected to theinner bottom of the chute by virtue of first springs, the first driving roller and the second driving roller are arranged on both sides of the support frame on the workbench, both the first driving roller and the second driving roller comprise upper driving rollers and lower driving rollers, and the two groups of upper driving rollers and lower driving rollers are rotatably arranged in the workbench. The antiwrinkling cutting device has the advantages of the simple structure, low production cost, good synchronism, high cutting quality, good stability and convenience in popularization and implementation.

Owner:孙帅

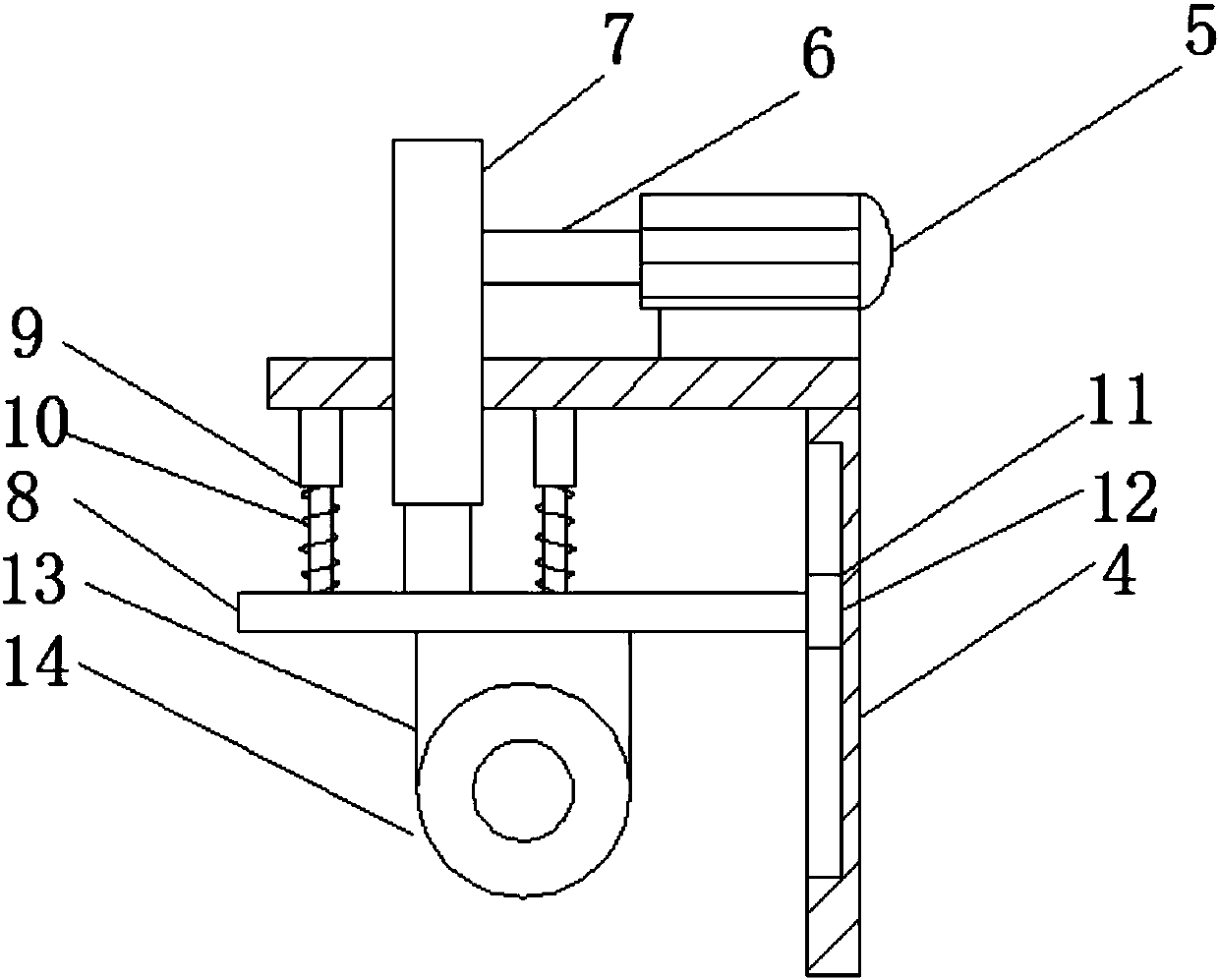

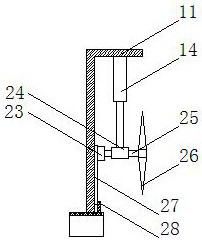

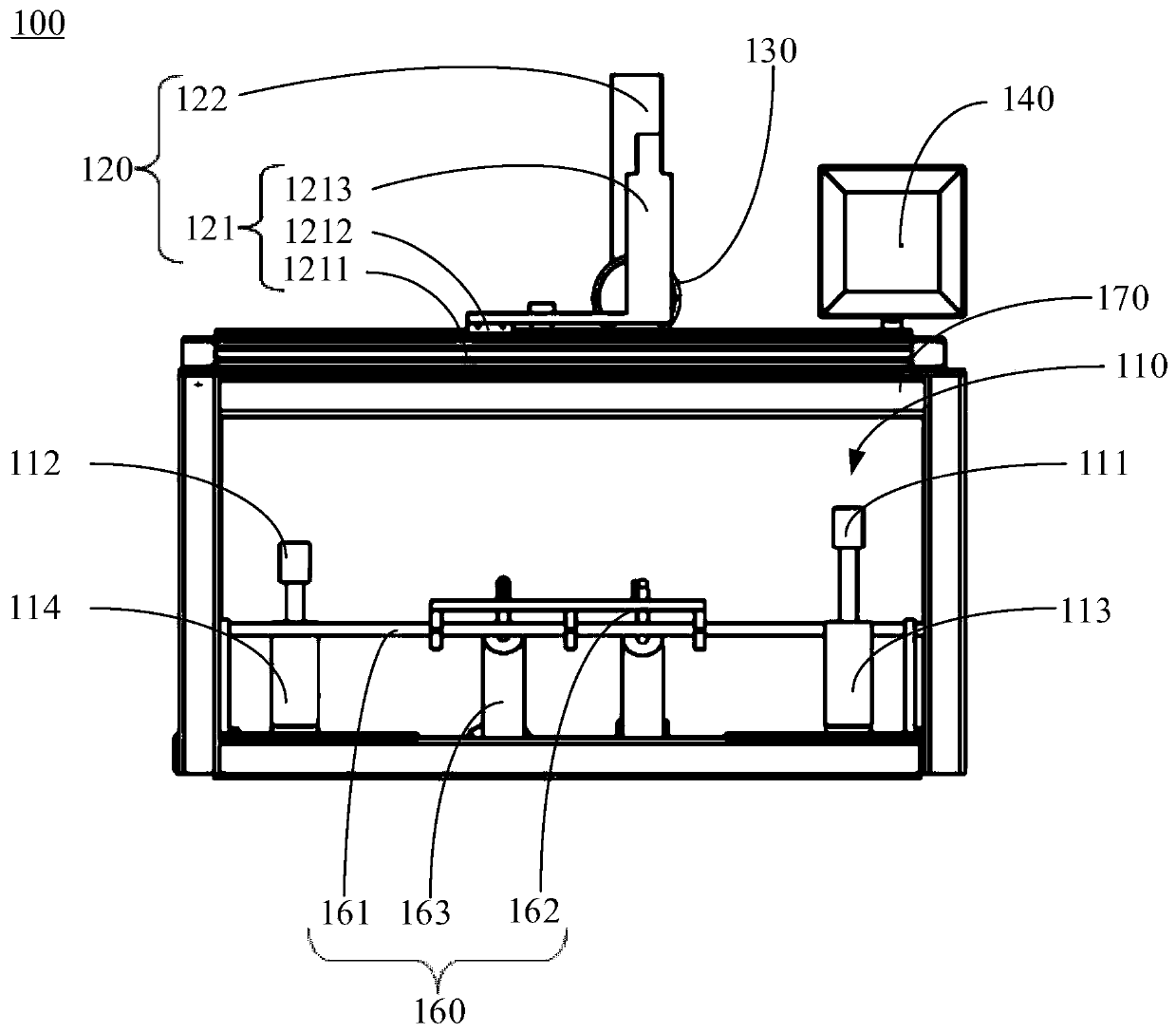

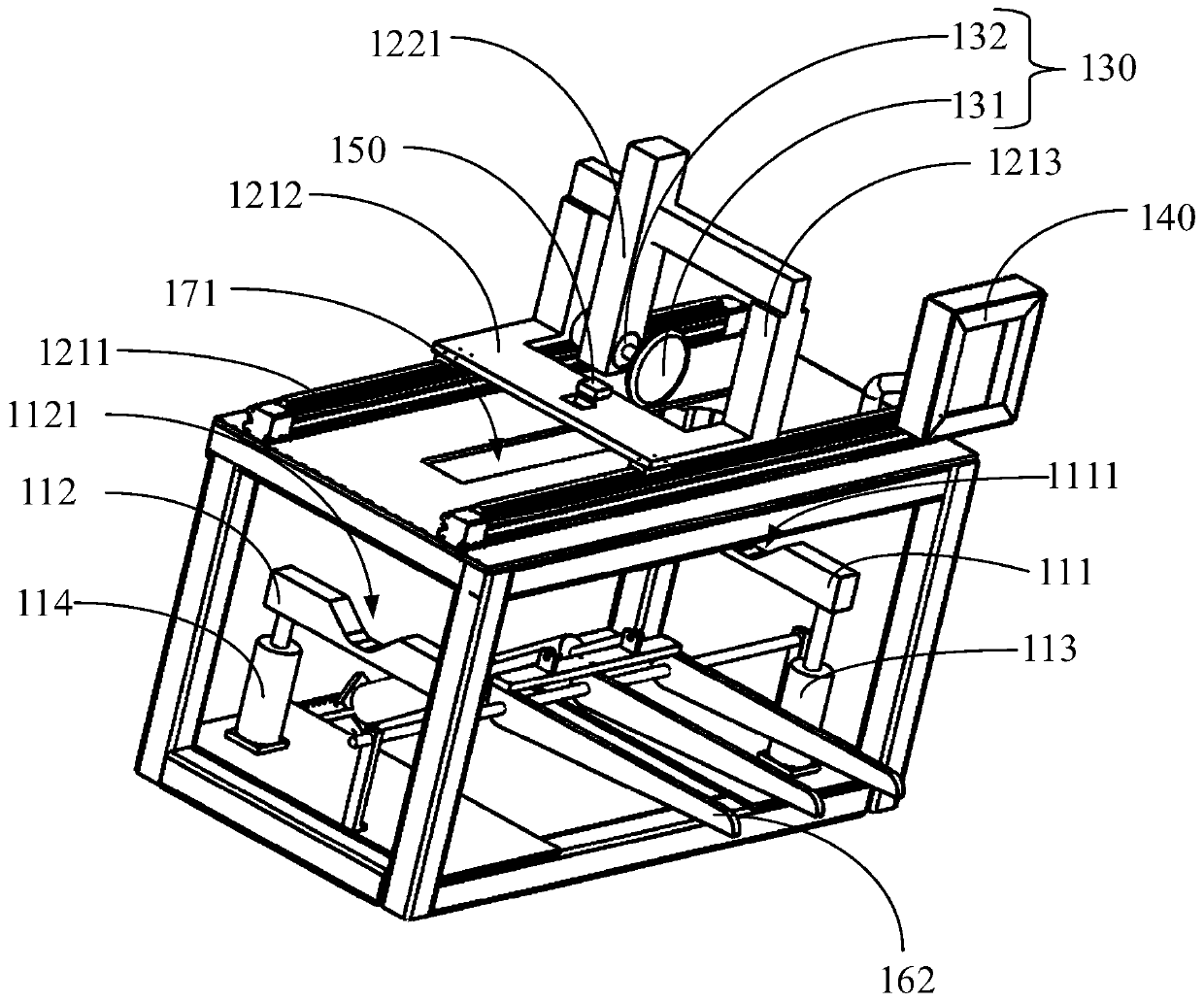

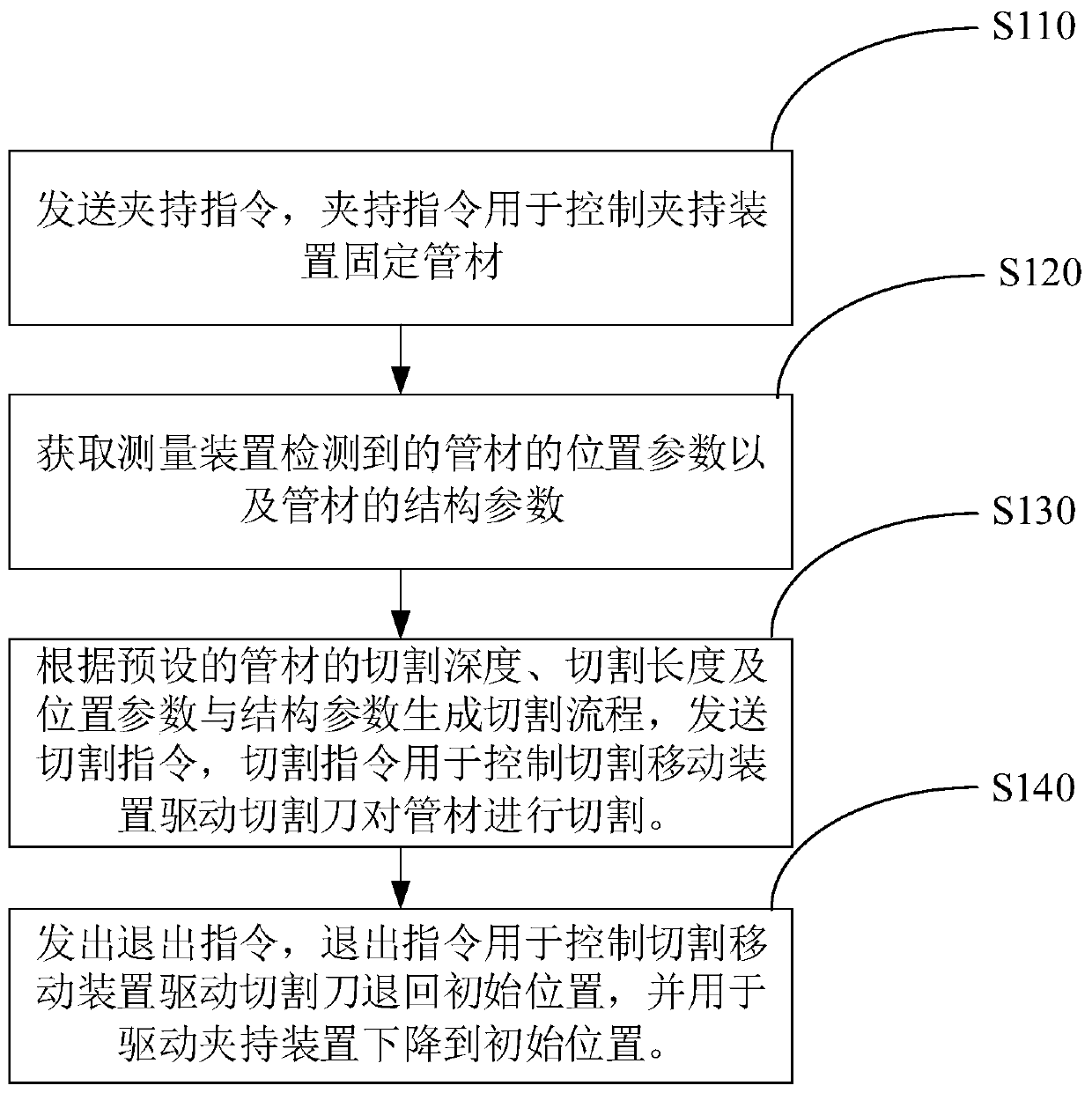

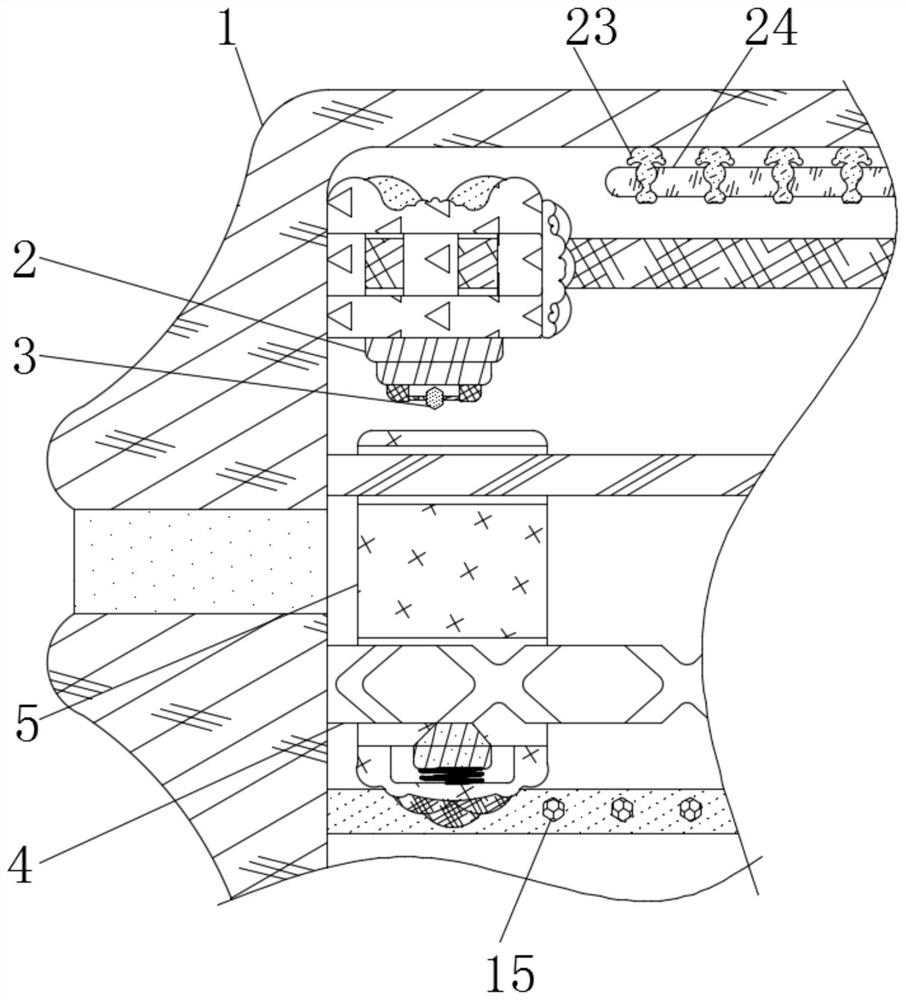

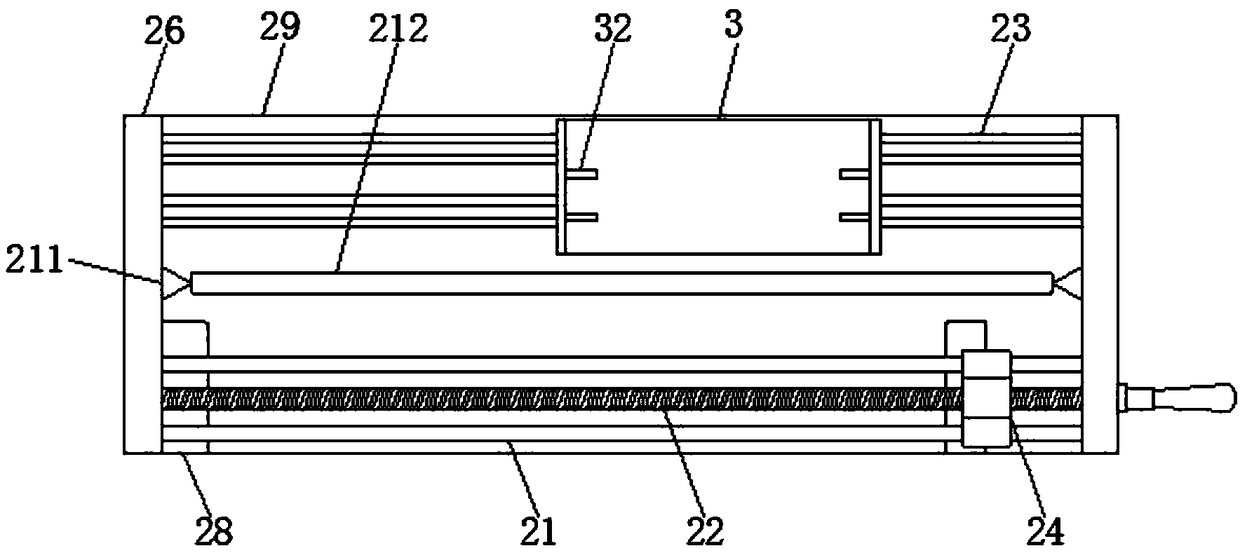

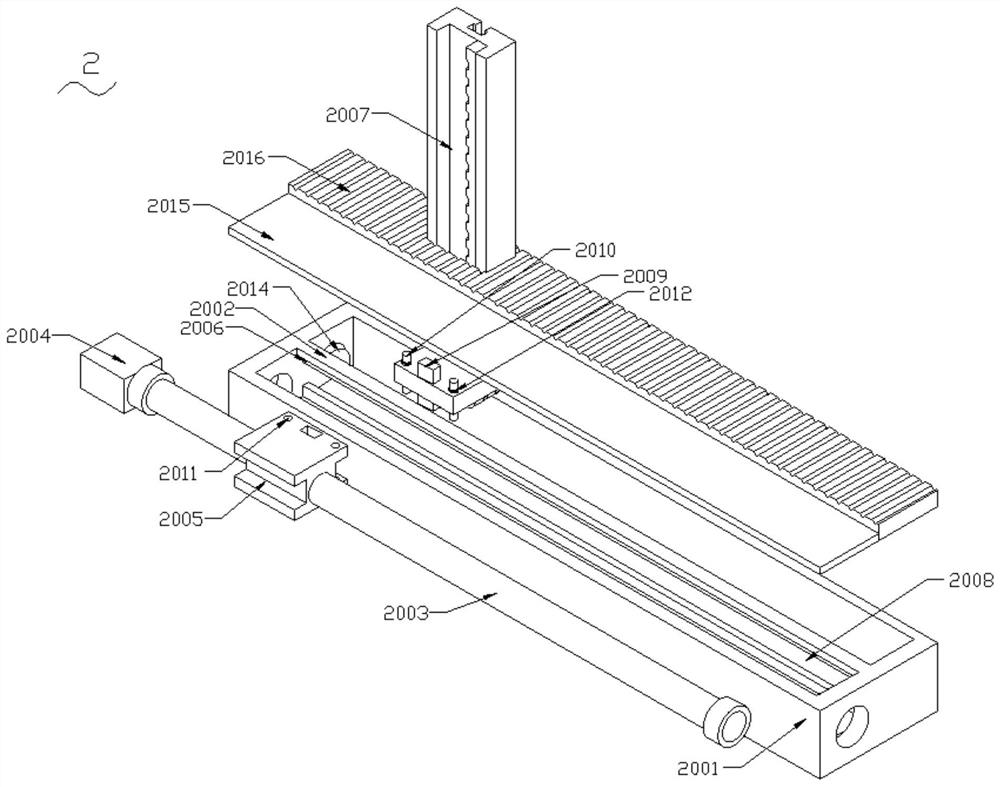

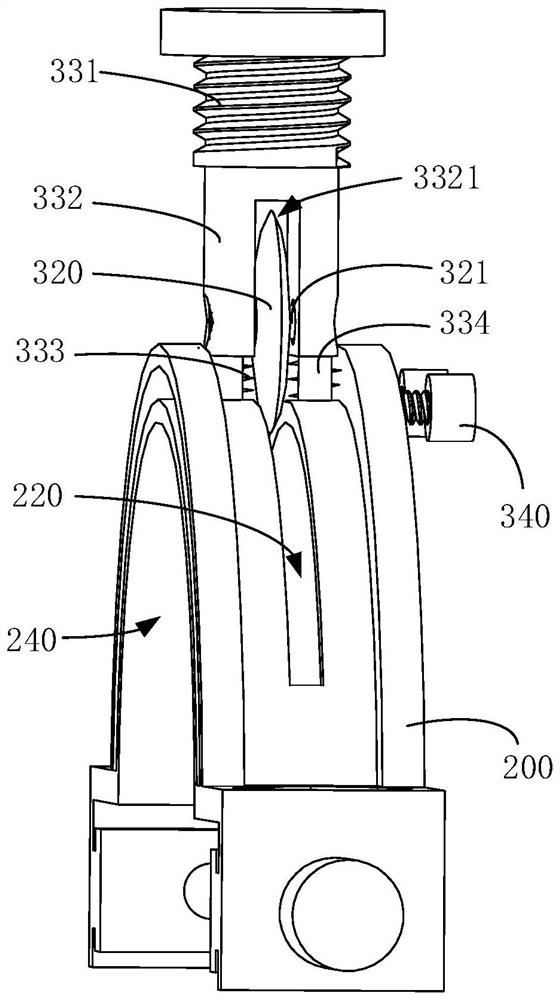

Notch sample preparation equipment and notch sample preparation method

PendingCN109807956AHigh precisionImprove stabilityWithdrawing sample devicesPreparing sample for investigationBiomedical engineeringLocator Parameter

The invention relates to notch sample preparation equipment and a notch sample preparation method. The notch sample preparation equipment comprises a clamping device, a cutting moving device, a cutting knife, a control device and a measuring device. The clamping device is used for clamping and fixing a pipe. The cutting knife is used for cutting the pipe. The cutting moving device is connected with the cutting knife and used for driving the cutting knife to move. The measuring device is mounted on the cutting moving device and used for acquiring position parameters and structure parameters ofthe pipe. The control device is electrically connected with the measuring device and the cutting moving device and used for generating a cutting process according to the preset cutting depth and cutting length and in combination with the position parameters and the structure parameters, and meanwhile controlling the cutting moving device according to the cutting process in order to enable the cutting moving device to drive the cutting knife to cut the pipe. Thus, full-automatic notch sample preparation of the pipe is achieved, cutting errors caused by manual operation are avoided, and the precision and stability of notch sample preparation of the pipe are improved.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

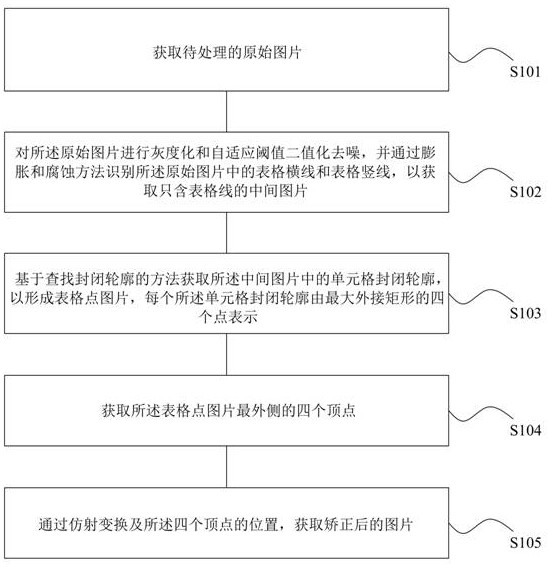

Picture processing method and device, storage medium and computer equipment

ActiveCN111932483AIntegrity guaranteedPromote reductionImage enhancementImage analysisComputer graphics (images)Algorithm

The invention discloses a picture processing method and device, a storage medium and computer equipment. The method comprises the steps of obtaining a to-be-processed original picture; performing graying and adaptive threshold binarization denoising on the original picture, and identifying table horizontal lines and table vertical lines in the original picture through an expansion and corrosion method so as to acquire an intermediate picture only containing table lines; obtaining cell closed contours in the intermediate picture based on a method for searching for the closed contours to form atable point picture, wherein each cell closed contour is represented by four points of a maximum bounding rectangle; obtaining four vertexes of the outermost side of the table point picture; and obtaining a corrected picture through affine transformation and the positions of the four vertexes. The method can solve the problems that in the prior art, table line cutting is prone to making mistakes,and table lines cannot be well restored.

Owner:WIZCARD TECH +1

Preset cutting single crystal silicon rod cutting terminal

ActiveCN110039670ASimple structureEasy to operateFine working devicesEngineeringMechanical engineering

The invention discloses a preset cutting single crystal silicon rod cutting terminal. A base and a supporting block are included. The upper end surface of the base is fixedly provided with a fixing mechanism capable of clamping a single crystal silicon rod, the upper end surface of the supporting block is fixedly provided with a fixing block, the fixing block is internally provided with a cuttingmechanism with a preset movement trajectory, the cutting mechanism includes a moving chamber with a downward opening, the left end wall of the moving chamber is provided with a driving mechanism capable of driving a moving rod to synchronously move along with a sliding rod, the driving mechanism includes a driving cavity, and the driving cavity is internally provided with a rotating mechanism capable of controlling a rope to do rapid movement. By means of the device, the single crystal silicon can be cut through the preset cutting path, a cutting face different from transverse cutting or vertical cutting is obtained, automatic operation ensures stable cutting, the cutting surface is relatively flat, no manual manipulation of the path is needed, cutting errors caused by manual subjective factors are avoided, and the cutting efficiency is improved.

Owner:泰安市东方印制板有限公司

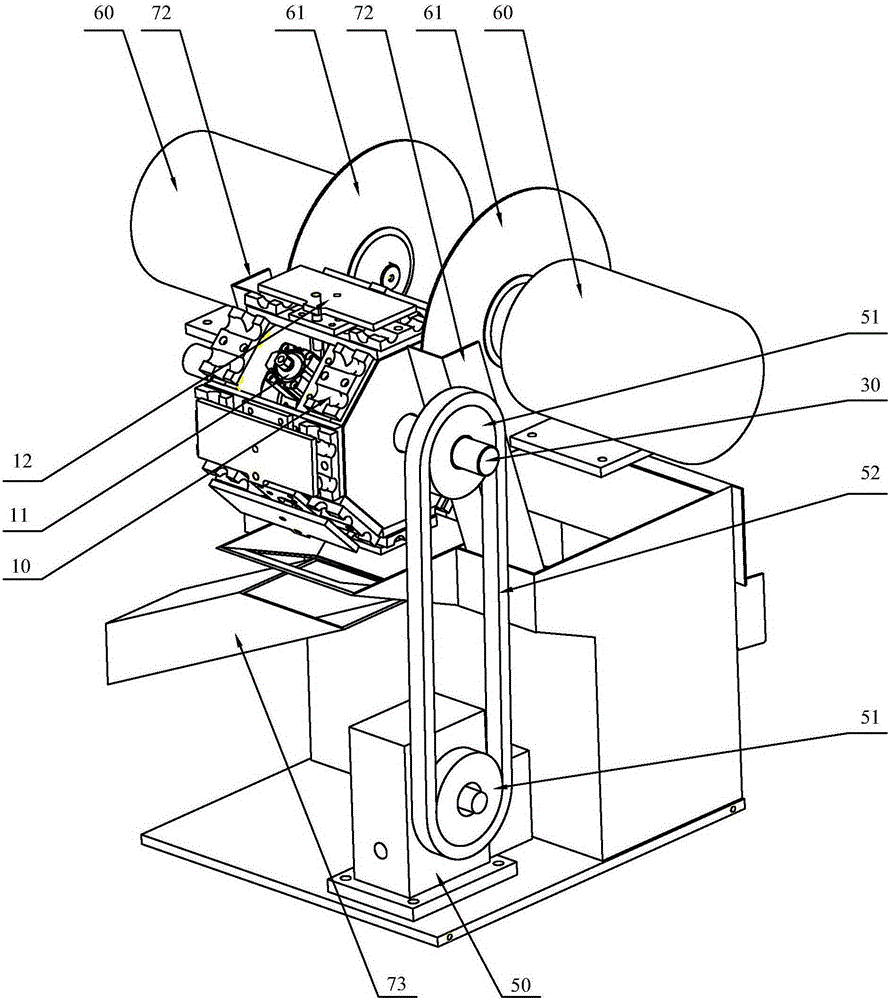

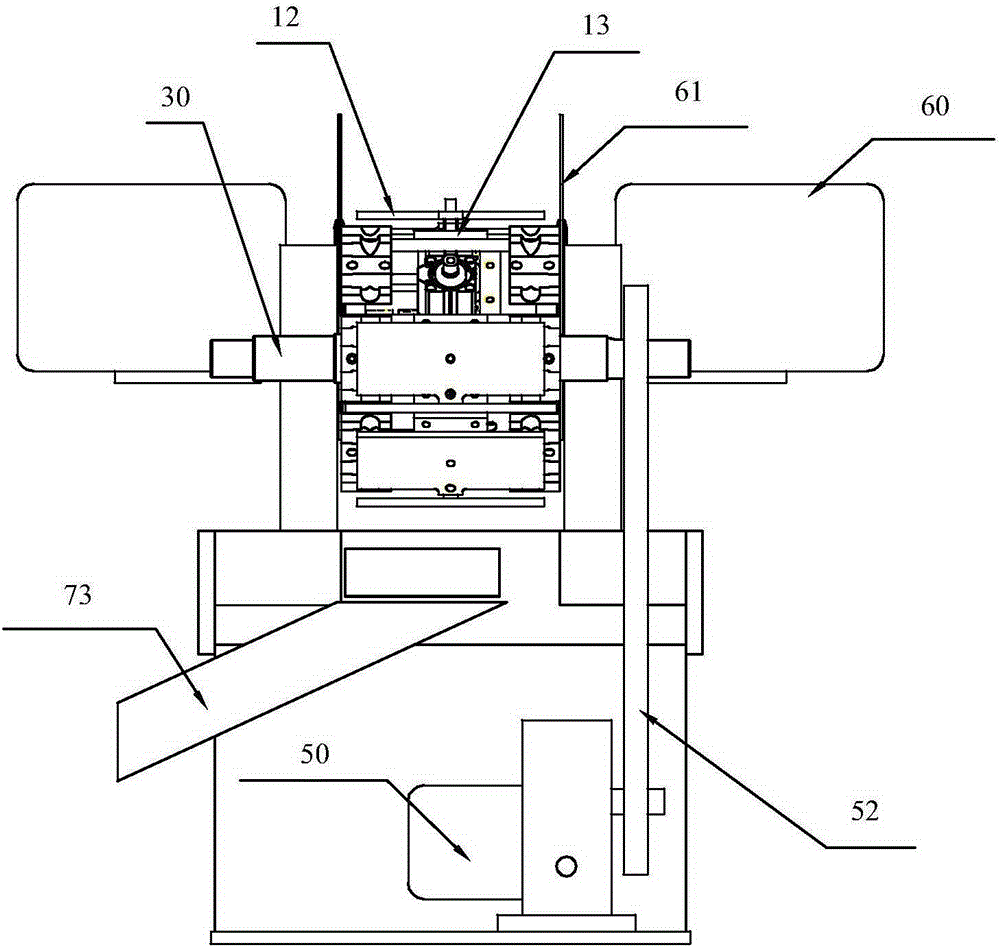

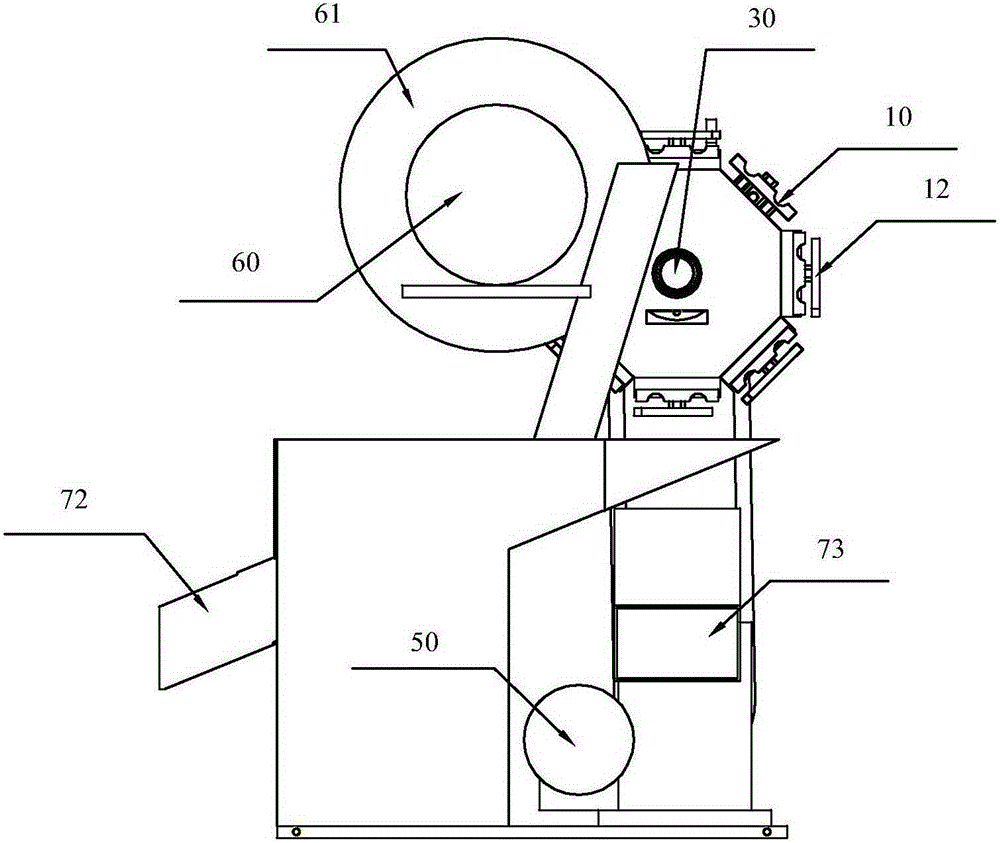

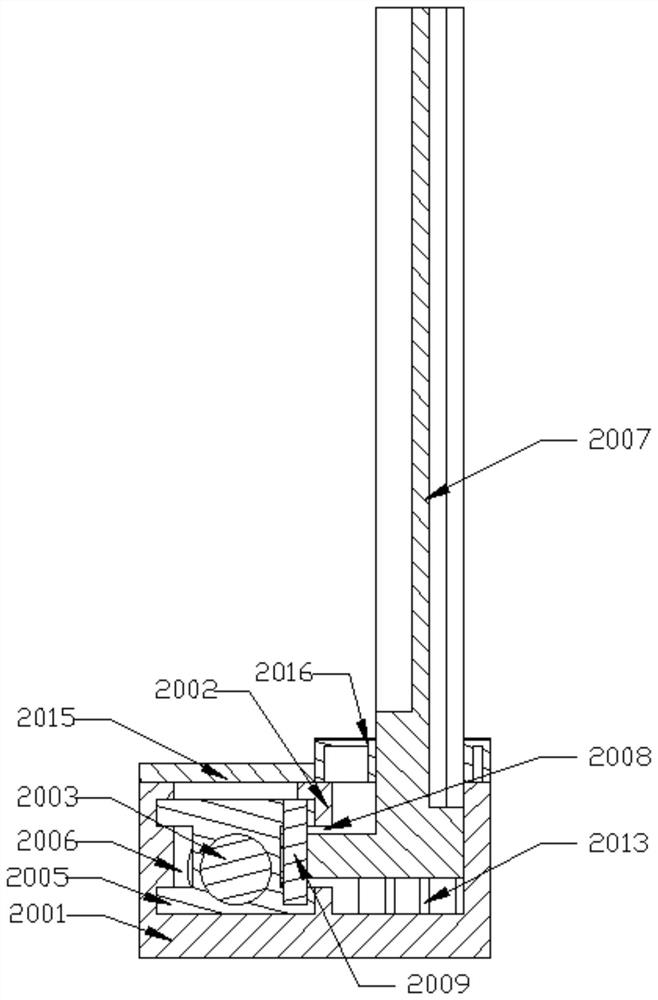

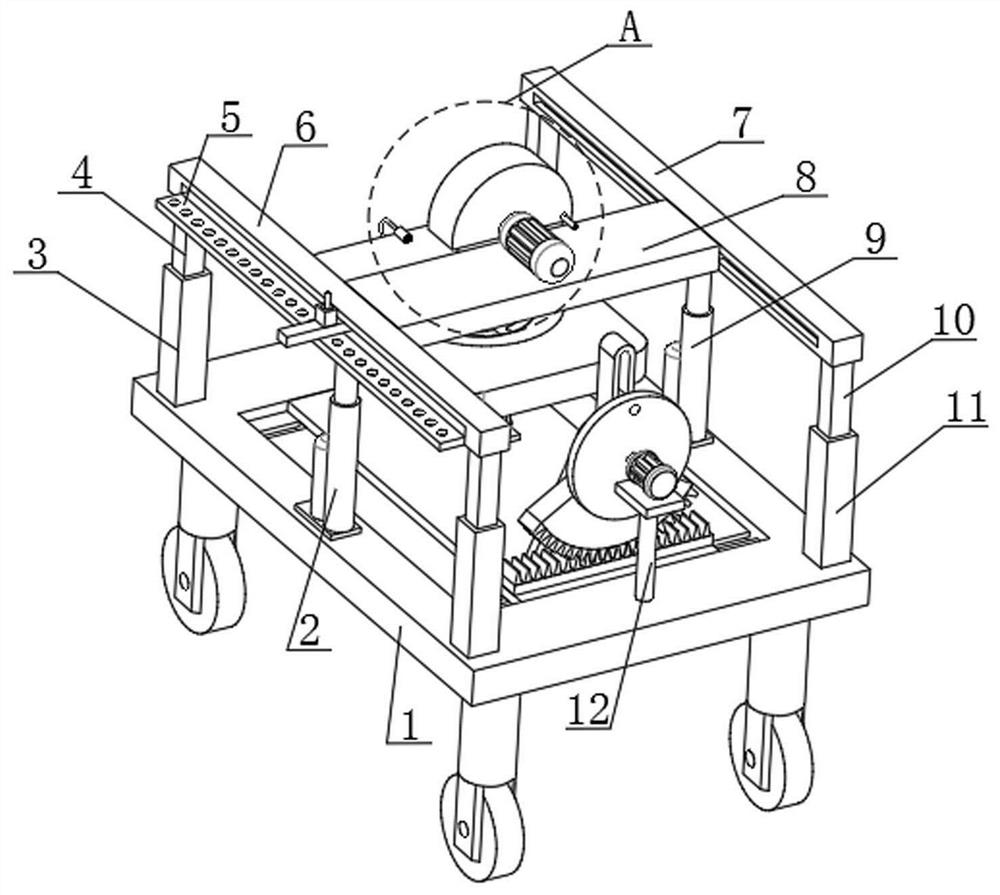

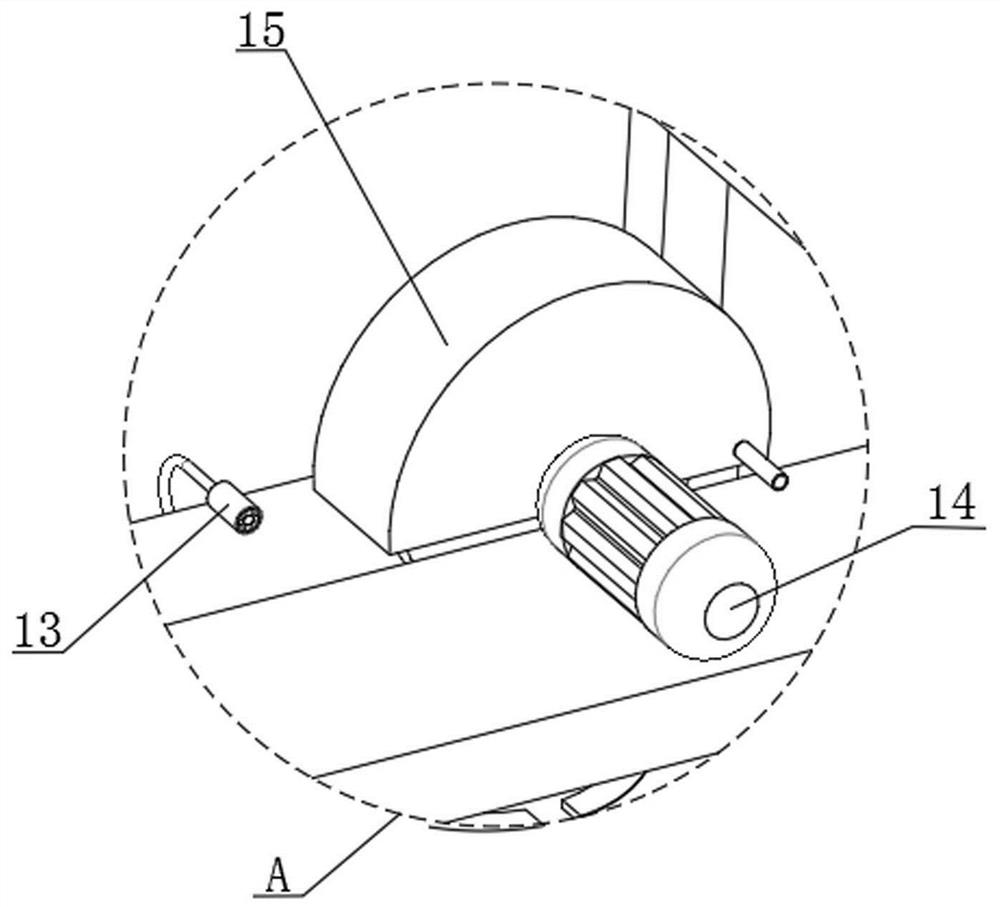

Continuous cutting and automatic discharging cutting machine special for angle valve quick opening

ActiveCN105397171AAvoid cutting errorsGuaranteed uninterrupted cuttingStock shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to a continuous cutting and automatic discharging cutting machine special for angle valve quick opening. The continuous cutting and automatic discharging cutting machine comprises a rolling feeding mechanism and a cutting mechanism; a workblank sample is fixed to a jig of the rolling feeding mechanism, and a cutting sheet of the cutting mechanism is arranged to be aligned with a cutting point of the workblank sample; the rolling feeding mechanism conducts rolling feeding around a horizontally-arranged rotating shaft; when being located at the feeding position, the jig is used for fixing the workblank sample, the rolling feeding mechanism drives the workblank sample to roll to the cutting sheet, and the cutting mechanism conducts cutting on the workblank sample; and the rolling feeding mechanism continuously rolls, the cutting mechanism completes cutting of the workblank sample, the workblank sample is released through the jig, and discharging is completed. The continuous cutting and automatic discharging cutting machine is specially used for angle valve quick opening cutting, automatic circulation cutting is achieved through rolling of the rolling feeding mechanism, continuous cutting is guaranteed, and the cutting efficiency is greatly improved. The workblank sample is positioned in an air cylinder clamping manner; and compared with a manual compression manner, the cutting error caused by swinging of the workblank sample is avoided.

Owner:JOMOO KITCHEN & BATHROOM

Cutting device based on adhesive product adhesive tape and cutting method

InactiveCN108858369AAchieve clampingPrecise Width ControlNon-rotating vibration suppressionMetal working apparatusElastic compressionAdhesive

The invention discloses the technical field of adhesive products, and relates to a cutting device based on an adhesive product adhesive tape. The cutting device comprises a working table, an adhesivetape body is arranged in the middle of the top of a rotary disc, clamping plates are arranged at the left and right ends of the adhesive tape body, a hydraulic device is arranged in the center of thetop of a top plate, the two ends of a movable transverse plate are connected with guide supports on the left and right sides, the other end of a folding auxiliary rod is provided with an elastic compression block, and the output end of a cutting motor is connected with a cutter through a coupler. The cutting device is simple in operation; an adjusting handle is rotated to enable the clamping plates to move on the outer wall of a screw, the adhesive tape body is clamped, scale marks are arranged on the top of the rotary disc, and the cutting width needed by the adhesive tape body is conveniently and accurately controlled; guide sliding rods are inserted into the two ends of the movable transverse plate, and cutting errors, caused by inclining falling of the movable transverse plate, of theadhesive tape body are avoided; and rubber anti-sliding gaskets are installed at the bottoms of four supporting feet, and therefore vibration of the device during cutting work is effectively reduced.

Owner:苏州盛迪通电子科技有限公司

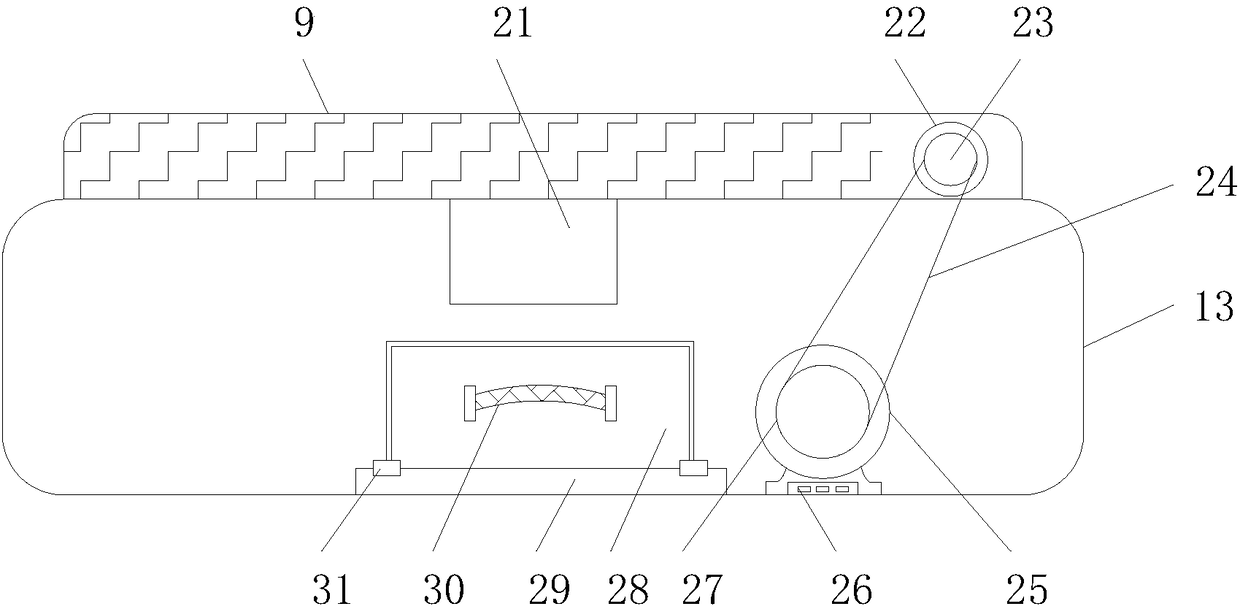

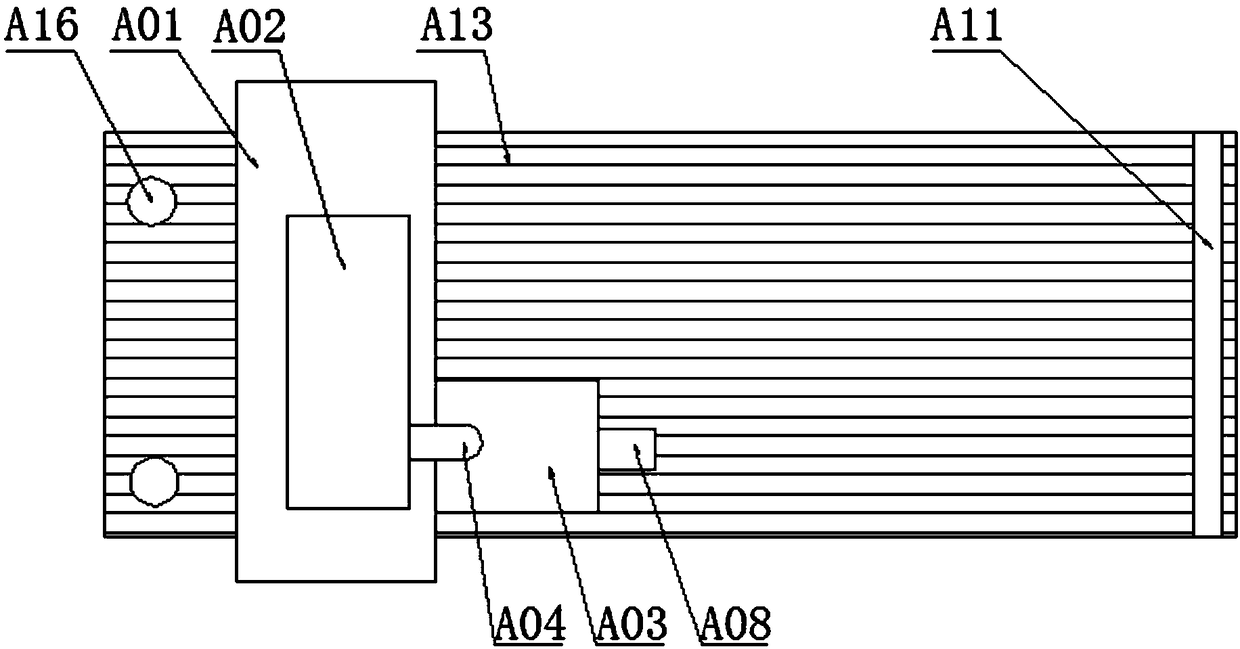

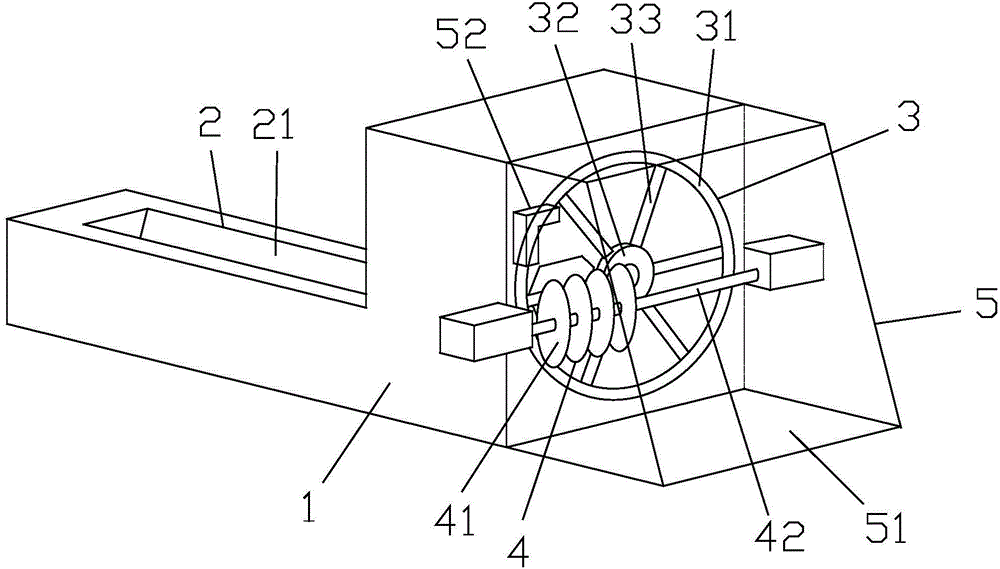

Aluminum rod fixed-length cutting-off mechanism for hollow glass

InactiveCN108188483AAvoid cutting errorsAvoid quality impactMeasurement/indication equipmentsMaintainance and safety accessoriesAluminiumEngineering

The invention discloses an aluminum rod fixed-length cutting-off mechanism for hollow glass. The mechanism comprises a base. A power box is fixedly connected to the center position of the front surface of the base, a control box is fixed to one side of the base through a supporting frame, a conveying belt is arranged on the surface of the bottom end of the base, the conveying belt penetrates in amain box body installed on the surface of the base, the positions on the two sides of the top end inside the main box body are each fixedly connected with a set of installation boxes, the center position of the top end inside the main box body is fixedly connected with a telescopic rod through a first sliding block installed on a first sliding rail, the center position of the side wall inside themain box body is fixedly connected with a main shaft through a coupler installed at the front end of a first motor, a dust outlet is formed in the bottom end position inside the main box body, and a dust collection box is fixedly connected to the position under the dust outlet through a second sliding block. By arranging the structure comprising an air blower, a scale bar, a detector and the dustcollection box, the mechanism has the advantages that fixed-length cutting operation is carried out, and the interior of the device is clean and tidy.

Owner:宁波星瑞克中空铝条有限公司

wafer level package led

ActiveCN106784258BAvoid cutting errorsMeet the requirements of directional illumination application scenariosSemiconductor devicesInsulation layerSemiconductor package

The invention relates to a wafer stage encapsulation LED (light emitting diode), and relates to LED encapsulation. The wafer stage encapsulation LED is provided with an LED chip, a lens and a lens bonding layer, wherein the LED chip is provided with a substrate layer, a doping semiconductor layer, a semiconductor luminous layer, a conducting reflecting layer, an electrode, an insulation layer and a coating medium, wherein the semiconductor luminous layer is arranged between the first doping semiconductor layer and the second doping semiconductor layer; the conducting reflecting layer is arranged under the second doping semiconductor layer; the second electrode realizes the electric conduction with the second doping semiconductor layer through the conducting reflecting layer; the first electrode and the first doping semiconductor layer are directly connected; the insulation among the first electrode, the semiconductor luminous layer, the second doping semiconductor layer and the conducting reflection layer is realized by an insulation layer; the coating medium is arranged on a non-substrate region of the side wall of the LED chip; a through hole is formed inside the substrate layer; the inner wall of the through hole is provided with a high-reflectivity layer; the lens comprises a flat plate part and an optical coupling part; the flat plate part is fixed onto the substrate layer; the optical coupling part is arranged in the through hole of the substrate layer; in addition, the optical receiving surface of the optical coupling part faces the first doping semiconductor layer.

Owner:XIAMEN UNIV

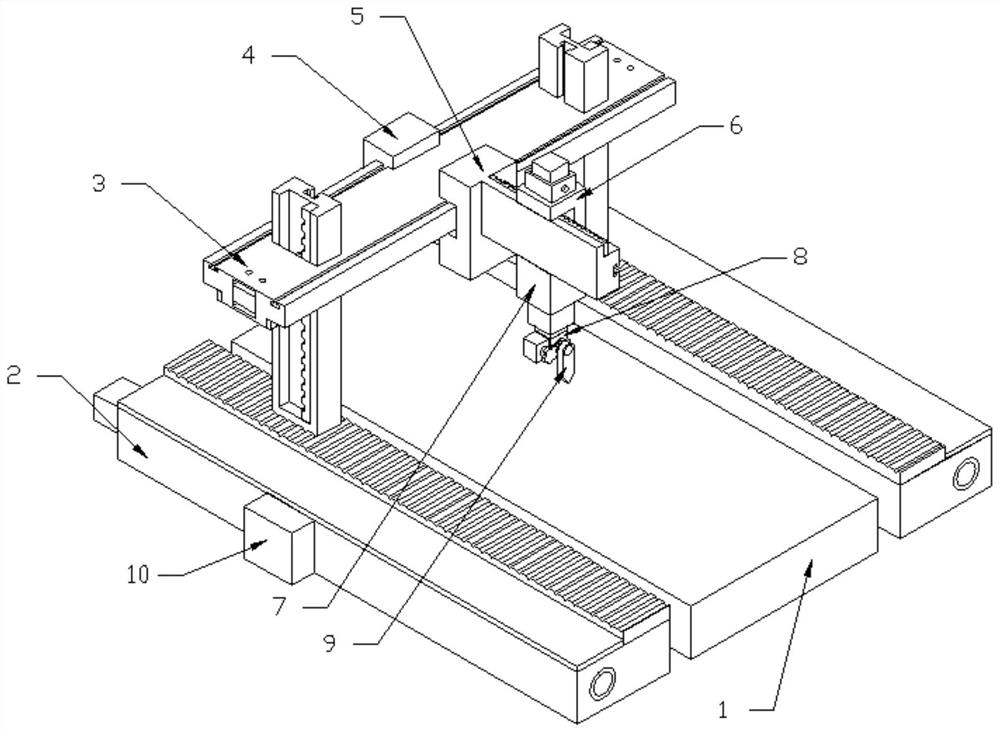

Full-automatic numerical control cutting method

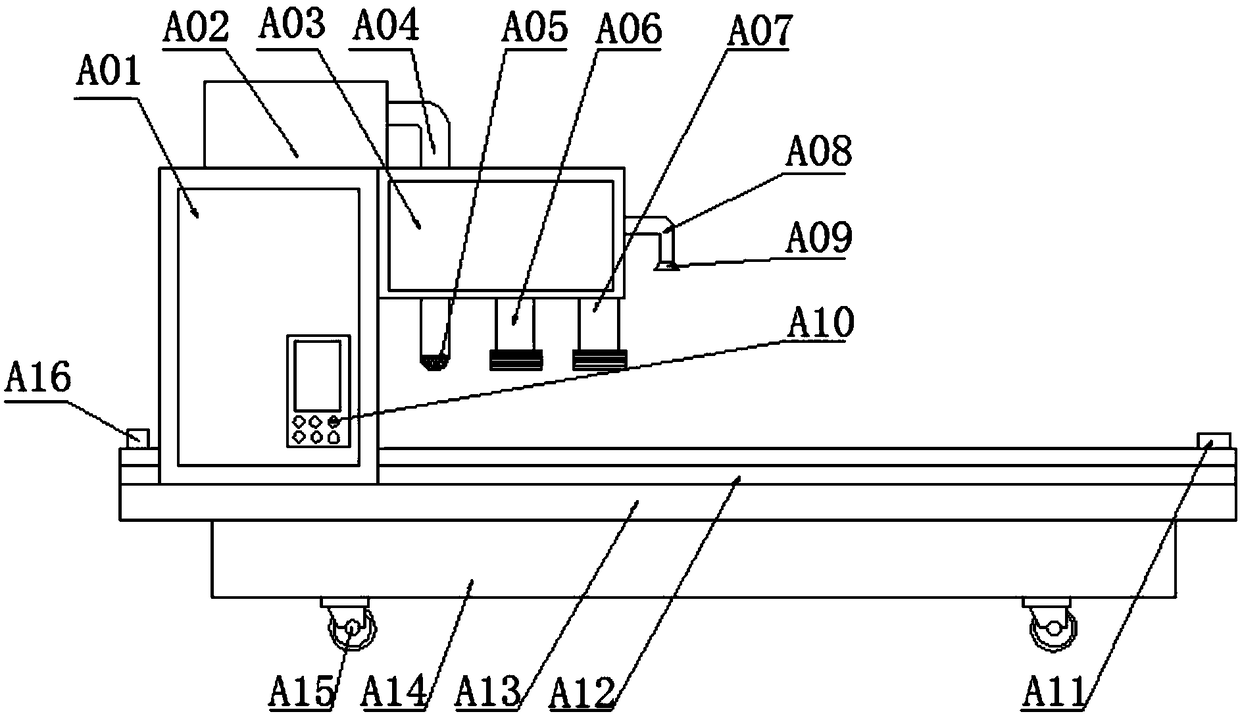

InactiveCN108214696AEasy to movePrecise positioningProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlMilling cutter

The invention discloses a full-automatic numerical control cutting method and an application method thereof. According to the full-automatic numerical control cutting method, a cutting machine is conducted with a power supply and a material pushing device is used for pushing a plate material needing to be cut onto a worktable of a lathe bed; a positioning air cylinder is responsible for accuratelypositioning the plate material needing to be cut; a numerical control controller is used for controlling a portal frame to slide on a portal frame sliding rod; a first milling cutter and a second milling cutter under a movement device can be used for cutting the plate material; a dust suction head is used for sucking saw dust and dust into a saw dust collection box through a dust suction pipe; alamp head is used for providing illumination and universal self-locking wheels below a base can be used for helping the cutting machine to move freely.

Owner:湖州酷趣电子商务有限公司

Fixed-length cutting and dust removing device for LED lamp manufacturing

InactiveCN112936409AAvoid wastingReduce manufacturing costMetal working apparatusDust controlLED lamp

The invention relates to the technical field of LED lamps and discloses a fixed-length cutting and dust removing device for LED lamp manufacturing. The device comprises a first shell, an electric telescopic rod is fixedly connected into the first shell, a cutting head is fixedly connected to the outside of the electric telescopic rod, a screw rod is movably connected into the first shell, and a sliding block is movably connected to the outside of the screw rod. Under the interaction of a second shell, sliding rods, iron blocks, retaining springs, electromagnets, a control gear, a water outlet pipe and a water inlet pipe, when a cutting machine cuts an LED lamp, the device can automatically remove dust, in this way, chippings generated after cutting can be prevented from flying into the air, accordingly, the flying chippings can be prevented from being sucked into the body of people, thus, the physical health of the people can be protected, in addition, the chippings are removed in the cutting process, the situation that the chippings generated after cutting jam parts in the cutting machine can be avoided, and therefore, the service life of the cutting machine can be prolonged.

Owner:盛艳根

Excess material removal technology for alloy die casting piece

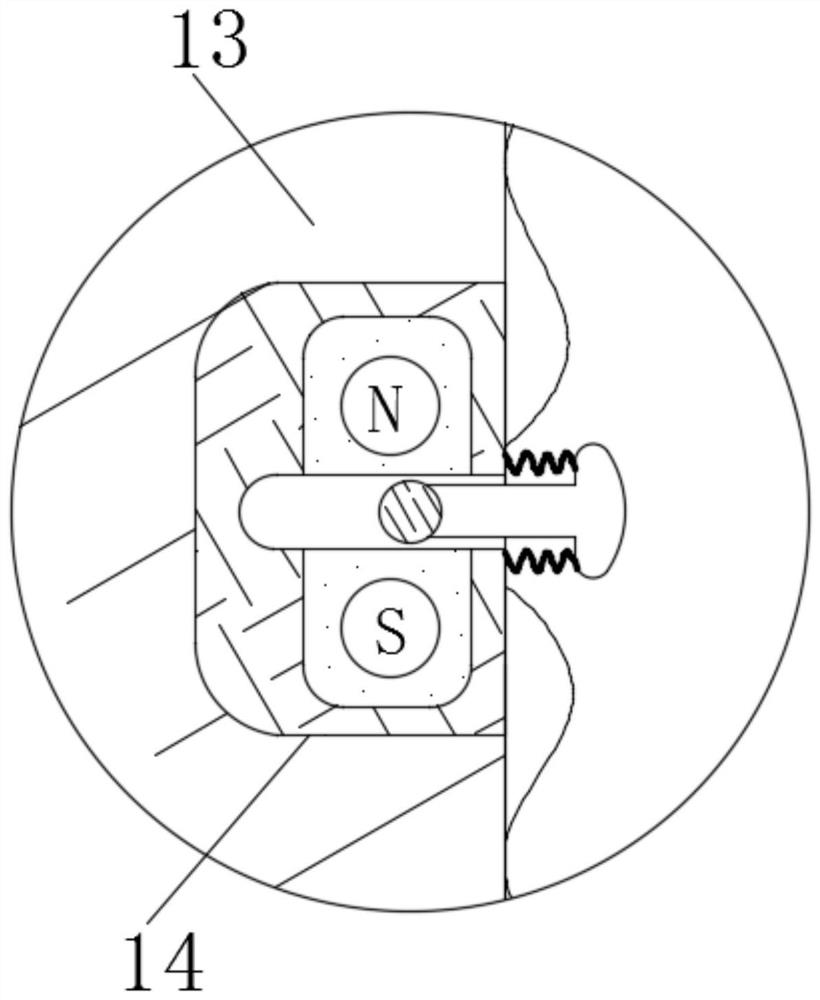

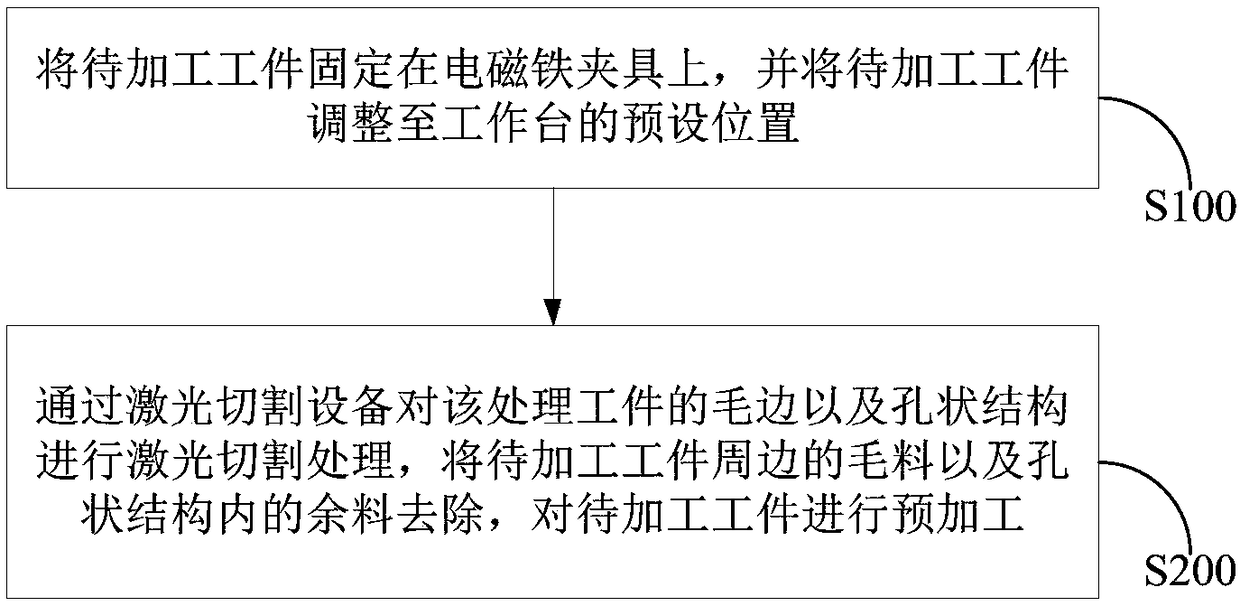

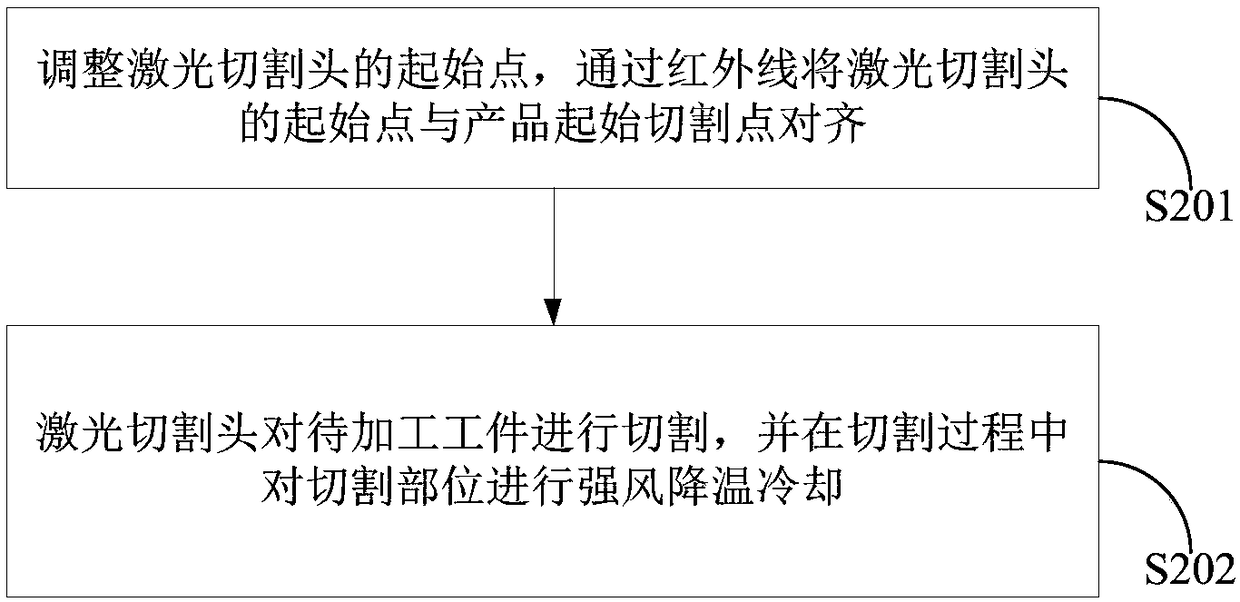

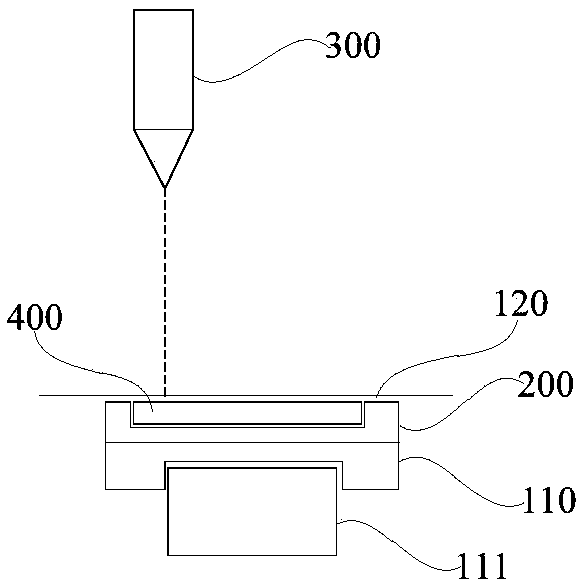

InactiveCN109352188AQuick fixEffectively fixedWelding/cutting auxillary devicesAuxillary welding devicesMaterial removalDie casting

The invention discloses an excess material removal technology for an alloy die casting piece. The excess material removal technology comprises the following steps that a to-be-machined workpiece is fixed to an electromagnet clamp, and the to-be-machined workpiece is adjusted to the preset position of a workbench; and laser cutting equipment is used for conducting laser cutting treatment on rough edges and a hole-shaped structure of the treated workpiece, rough materials on the periphery of the to-be-machined workpiece and excess materials in the hole-shaped structure are removed, and pre-machining is conducted on the to-be-machined workpiece. The to-be-machined workpiece is fixed through the electromagnet clamp, then the laser cutting equipment is used for conducting laser cutting treatment on the rough edges and the hole-shaped structure of the treated workpiece, the rough materials on the periphery of the to-be-machined workpiece and the excess materials in the hole-shaped structureare removed, then rapid cutting of the excess materials of the alloy die casting piece can be achieved, and accordingly the alloy die casting piece excess material removal efficiency is improved; andmeanwhile, the electromagnet clamp can rapidly and effectively fix the workpiece, product fixing through a complex die structure is not needed, and the workpiece installing efficiency is improved.

Owner:JINYAHAO PRECISION METAL SCI & TECH SHENZHEN CO LTD

Novel rubber processing equipment

PendingCN114227784ARealize equidistant adjustmentNo lossMetal working apparatusScrew threadKnife blades

The invention discloses novel rubber processing equipment which comprises two vertical plates, a long square frame is arranged between the two vertical plates, rotating discs are integrally formed at the two ends of the long square frame, the two rotating discs are rotationally connected with the vertical plates close to the rotating discs through bearings correspondingly, and two-way threaded rods are rotationally connected to the inner walls of the two sides of the long square frame. The right end of the two-way threaded rod penetrates through the long square frame, the vertical plate and the rotating disc located on the right side and the two-way threaded rod are connected with a driving switching device, two pushing plates are symmetrically connected to the two-way threaded rod in a threaded mode, and the long square frame is slidably sleeved with a plurality of cutting blades at equal intervals. The cutting blades located on the two sides abut against and make contact with the two pushing plates correspondingly, and an elastic device is connected between every two adjacent cutting blades. The cutting width can be equidistantly adjusted or unequidistantly adjusted according to requirements, meanwhile, the grinding efficiency is high, and the structure is more compact.

Owner:吴年贵

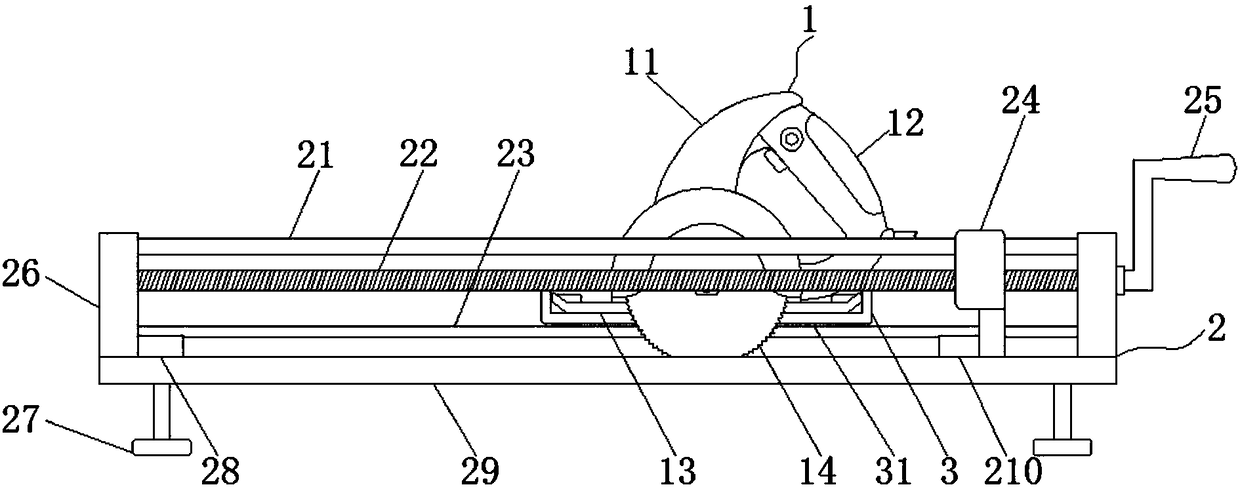

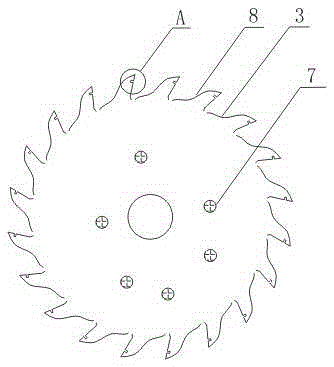

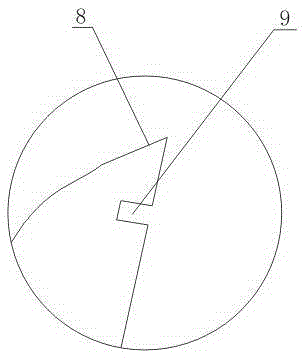

Wood floor cutting-off device for building decoration

InactiveCN108381673AKeep straightWeight increaseSawing componentsCircular sawsPulp and paper industryWood plank

The invention discloses a wood floor cutting-off device for building decoration. The wood floor cutting-off device comprises a cutting machine, a cutting frame and a moving frame. The cutting machineis arranged on the upper portion of the moving frame, and the cutting frame is arranged on the lower portion of the moving frame; a clamping block is arranged on the lower bottom face of the moving frame, and clamping plates are arranged at the two ends of the upper surface of the moving frame correspondingly; and the cutting machine comprises a cutting machine body, a handle, a flat plate and a saw blade, and the handle is arranged on one side of the upper portion of the cutting machine body. The wood floor cutting-off device for building decoration has the beneficial effects that by designing the cutting frame and the moving frame, when a wood plate is cut off, the wood plate is clamped on the cutting frame firstly, and the cutting machine is mounted on the moving frame; the cutting lineof the cutting machine cuts the wood plate in the direction of a clamping groove frame, and it is ensured that the cutting line is perfectly straight, so that the situation that the cutting line shakes due to human factors, and consequently the cutting error is caused is avoided; and the weight of the cutting machine supported by the cutting frame and the moving frame simultaneously is increased,operation of workers is convenient, and the labor intensity is reduced.

Owner:ANHUI CAREMIC CONSULTING CO LTD

Cutting device for metal furniture processing

InactiveCN109591114AIncrease productivityEasy to cutProfiling/shaping machinesEngineeringMechanical engineering

The invention discloses a cutting device for metal furniture processing. The cutting device for metal furniture processing comprises a supporting plate. Two supporting columns are fixedly mounted in positions, close to front and back sides, of the top end of the supporting plate, a mounting plate is fixedly mounted at the top ends of the supporting columns jointly, a reversed U-shaped mounting rack is arranged at the bottom end of the mounting plate, a rotating rod is rotatably mounted between two vertical wall bodies of the mounting rack, a plurality of cutting blades are fixedly mounted on the rod body of the rotating rod, and guide blocks are fixedly mounted on the sides, far away from each other, of the two vertical wall bodies of the mounting rack. The cutting device for metal furniture processing disclosed by the invention is novel in design, reasonable in structure and convenient to operate, can improve the production efficiency, and is convenient to use, so that the cutting device can cut materials to different lengths and is perfect in function.

Owner:安徽喜聚美家居有限公司

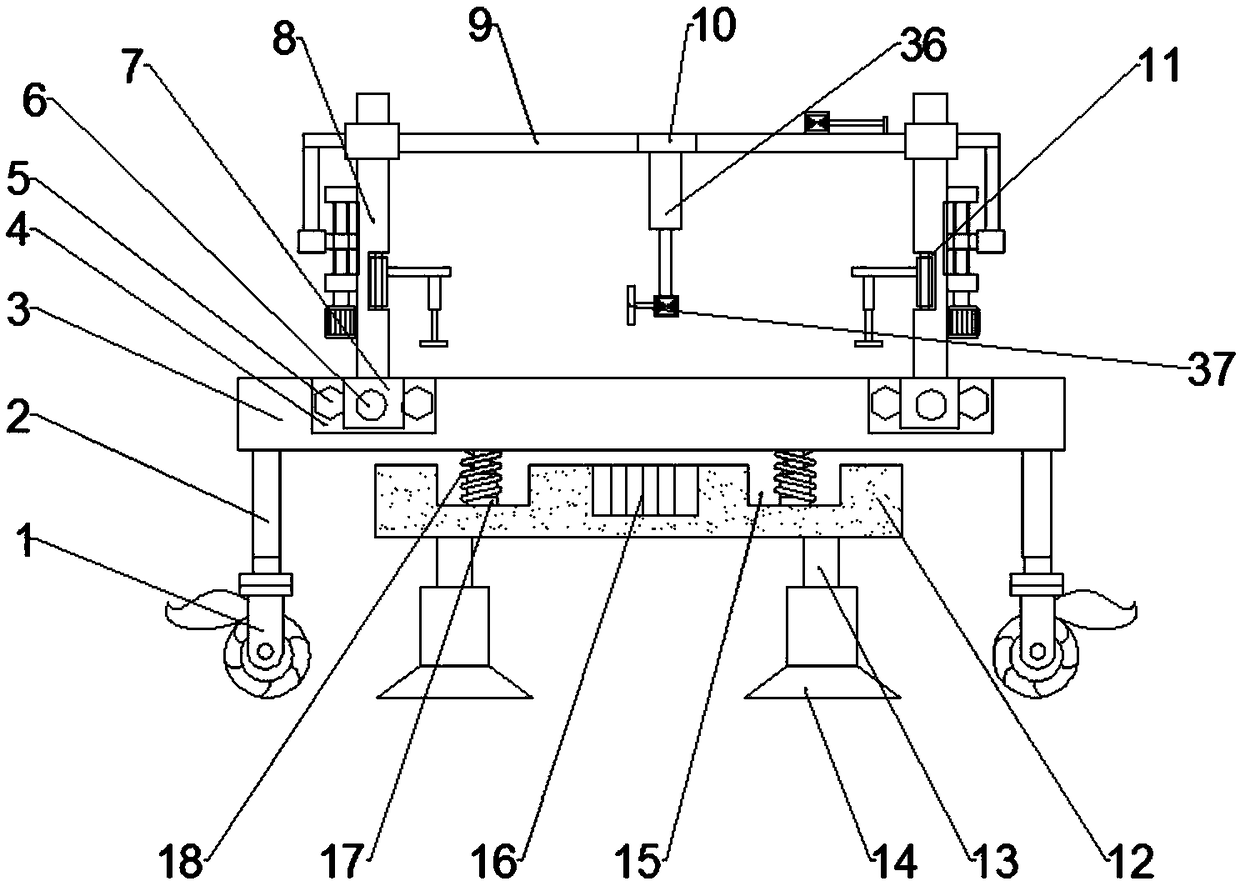

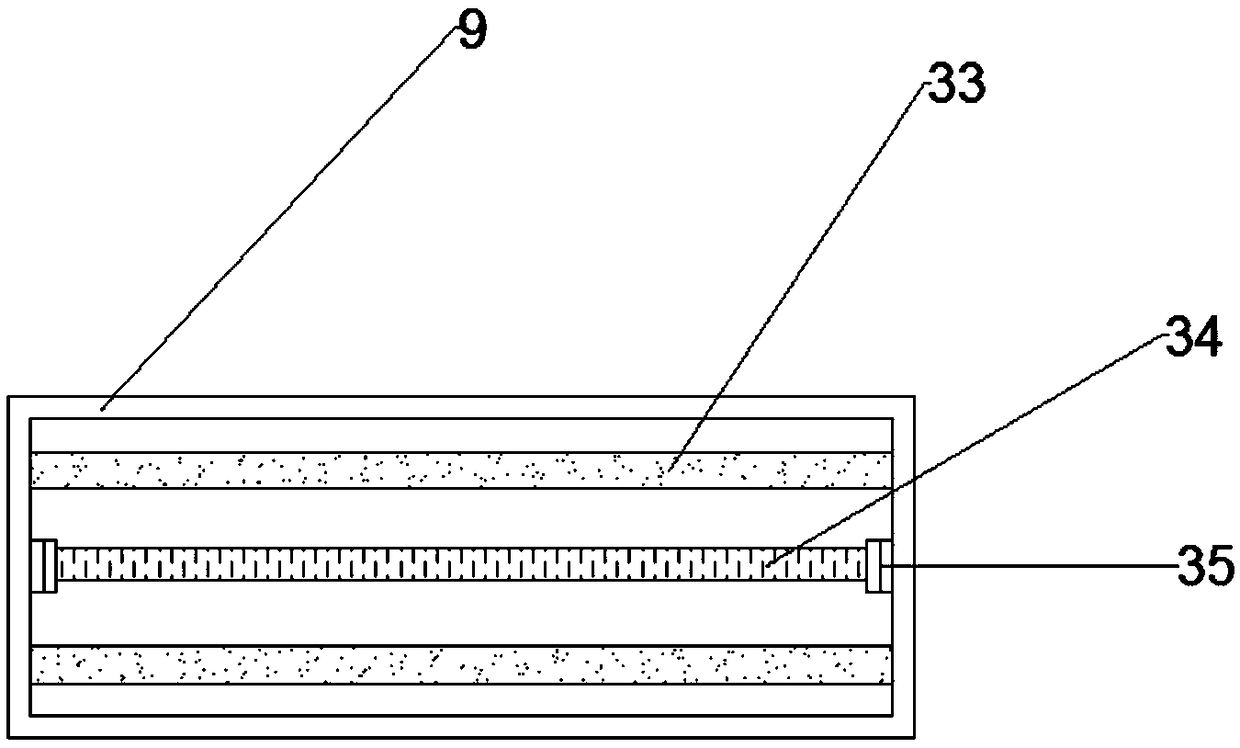

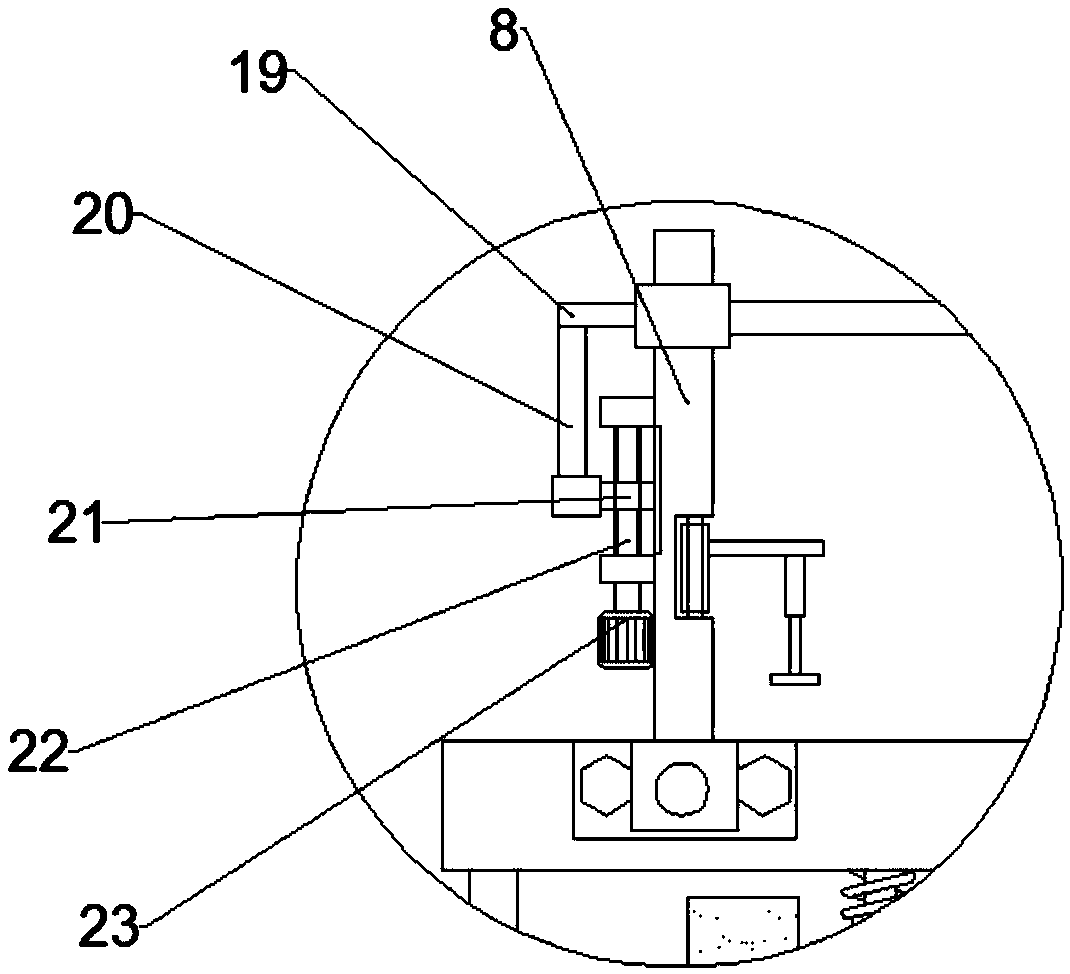

Adjustable cutting device for smart home production

InactiveCN108818772AReduce vibrationAvoid cutting errorsGuide fencesProfiling/shaping machinesEngineering

The invention belongs to the technical field of smart homes, and particularly relates to an adjustable cutting device for smart home production. Aiming at the problems that a plate material cutting device cannot fix plate materials, has low adjustable capability and poor movability, the adjustable cutting device for smart home production comprises a fixing plate, wherein four telescopic rods are fixed to the outer wall of the bottom of the fixing plate through bolts and are respectively located at positions, close to the middle, of the outer wall of the bottom of the fixing plate; a connectingplate is fixed to the outer walls of the bottoms of the telescopic rods through the bolts; four first power-driven telescopic rods are fixed to the outer wall of the bottom of the connecting plate through the bolts; and a base is fixed to the outer walls of the bottoms of the four first power-driven telescopic rods through the bolts. The vibration of the device in a using process can be effectively reduced; cutting errors caused by the vibration of the device in use are avoided; the adjustable cutting device can buffer external acting force very well; the buffering effect of the device is improved; the device can be moved very well; and the device is relatively convenient to move and use.

Owner:朱雪英

Improved silicon slice laser cutting reduction process

InactiveCN101733557AAvoid cutting errorsGuaranteed precise cuttingLapping machinesLaser beam welding apparatusLaser cuttingSilicon

The invention relates to an improved silicon slice laser cutting reduction process, which can ensure the cutting quality of a silicon slice, improve energy output and lower production cost. The reduction process comprises backside grinding and laser cutting working procedures, and is characterized in that the laser cutting working procedure is carried out on the silicon slice firstly, and then the backside grinding is carried out on the silicon slice.

Owner:WUXI CREATIVE SENSOR TECH

Five-axis spherical laser cutting device

The invention discloses a five-axis spherical laser cutting device. The five-axis spherical laser cutting device comprises a cutting platform, first longitudinal moving devices are arranged on the two sides of the cutting platform, a lifting cross beam is arranged between the two first longitudinal moving devices, a balance weight device is arranged on one side face of the lifting cross beam, and a transverse moving device is arranged on the other side face of the lifting cross beam; and a second longitudinal moving device is arranged on one side face of the transverse moving device, a telescopic arm is arranged on the lower end face of the second longitudinal moving device, a rotating device is arranged on the lower end face of the telescopic arm, a laser cutter is arranged on one side face of the rotating device, and a control module is arranged on one side face of the first longitudinal moving device. According to the device, five-axis freedom degrees can be formed, slope cutting is facilitated, the cutting precision can be improved, cutting errors are avoided, and the device production cost is reduced.

Owner:杭州圣通智能科技有限公司

Efficient mechanical type automation cutting equipment

InactiveCN106583827AEfficient cuttingEffectively fixedTube shearing machinesShearing machine accessoriesEngineeringAutomation

The invention discloses efficient mechanical type automation cutting equipment which comprises a bottom plate device, a supporting plate device, a bracket device, a transverse plate device, an electric cylinder device, a cutting knife device, a pushing device and a locating device; a bottom plate and universal wheels are arranged on the bottom plate device; the supporting plate device comprises a supporting plate, first supporting rods, second supporting rods and first fixing rods; the bracket device comprises a first bracket, a connecting plate and a second fixing rod; the transverse plate device comprises a first transverse plate, second brackets, first transverse rods and third fixing rods; the electric cylinder device comprises an electric cylinder, a pushing rod, a movable frame and a locating frame; the cutting knife device comprises a fixing plate, a cutting knife and a fixing bracket; the pushing device comprises a first vertical rod, a first spring, a second vertical rod and a pushing wheel; and the locating device comprises a third vertical rod, a limiting block, a locating rod and a second spring located on the locating rod. The efficient mechanical type automation cutting equipment can cut a pipeline effectively, and is high in cutting efficiency and low in manual labor intensity.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

High-speed vegetable cutter

ActiveCN104802212ASimple structureHigh degree of automationMetal working apparatusEngineeringAutomation

The invention discloses a high-speed vegetable cutter, which comprises a rack, wherein a feeding device, a longitudinal cutting device and a transverse cutting device are arranged on the rack. The high-speed vegetable cutter is simple in structure, high in automation degree, cutting accuracy and speed, free of manual intervention and low in manpower consumption and labor cost; vegetables can be cut into small sections with required lengths only by being placed on a conveying belt and fed into the longitudinal cutting device and the transverse cutting device, and the fed vegetables can be cut into sections without placement or arrangement, so that the working efficiency is further improved, and the working adaptability is also enhanced.

Owner:青岛顺昌食品有限公司

Tube drawing bench with feeding device

The invention relates to a tube drawing bench with a feeding device. The tube drawing bench comprises a bench body, a bench head, the feeding device, a trolley and a chain. The chain is installed at the top of the bench body. The trolley is installed between two side plates, at the two sides of the chain, of the bench body in a sliding mode. A clamp is installed on the trolley. The bench head is installed on one side of the bench body. The feeding device is installed in the bench head, and comprises an installation frame, a pushing mechanism, a pushing plate and a straightening plate. The installation frame is a rectangular frame. Two plain shafts are fixedly arranged between a left side plate and a right side plate of the installation frame in a vertically-symmetric mode. The pushing mechanism, the pushing plate and the straightening plate are sequentially installed between the two plain shafts at intervals in a sliding mode. Feeding holes are coaxially formed in the centers of the pushing plate, the straightening plate and the left side plate and the right side plate of the installation frame. An annular tool is coaxially installed in the feeding hole of the right side plate of the installation frame. The tube drawing bench is used for ejecting the heads of bars out of the annular tool through the pushing mechanism, so that the heads of the bars are clamped by the clamp of the trolley; the drawing-down procedure of the heads of the bars is omitted, labor is saved, and the working efficiency is improved.

Owner:TIANJIN DONGQI VALVE MFG CO LTD

Processing device for semiconductor graphite wafer and processing method thereof

InactiveCN111976041AEasy to move back and forthSmooth rotationSemiconductor/solid-state device manufacturingWorking accessoriesWaferEngineering

The invention discloses a processing device for a semiconductor graphite wafer and a processing method of the processing device for the semiconductor graphite wafer. The processing device for the semiconductor graphite wafer comprises a base. The top surface of each first T-shaped sliding block is fixedly connected to the bottom surface of a moving plate. An adjusting assembly is arranged on the edge of one side of the top surface of the moving plate, a rotating assembly is arranged in the middle of the top surface of the moving plate, and a workbench is fixedly connected with the top of a fixing shaft in the rotating assembly. A clamping groove is formed in the middle of the top surface of the workbench, and a negative pressure groove is axially formed in the middle of the top surface ofthe clamping groove. A cutting assembly is fixedly connected to the middle of the top of a supporting plate, a water guide pipe penetrates through one side of a cutter cover in the cutting assembly, one end of a water outlet pipe is arranged in the middle of the water guide pipe, and the other end of the water outlet pipe is located on one side face of a cutter. According to the processing devicefor the semiconductor graphite wafer, the workbench can be moved forwards and backwards through an adjusting device, the workbench can be rotated through a rotating device, and therefore the wafer canbe cut in different directions, the working efficiency is improved, and the cutting error is avoided. Meanwhile, the cutter can ascend and descend, and therefore the wafer is conveniently cut.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

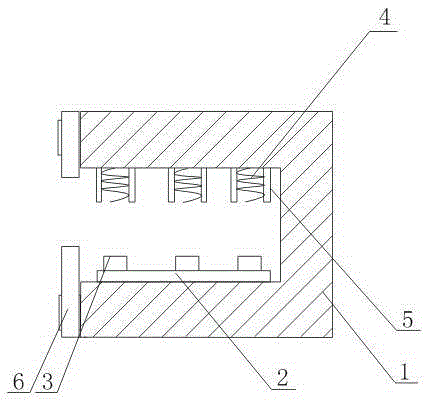

Machining tool for artificial floors

InactiveCN105269626AImprove applicabilityAdjustable cutting widthGripping devicesClamping devicesPunch pressEngineering

The invention discloses a machining tool for artificial floors. The machining tool comprises a tool body, a punch press platform and a plurality of cutters, wherein the side surface of the tool body is open, the tool body is of a cavity structure, the punch press platform is arranged at the bottom of the inner cavity of the tool body, and the cutters are arranged on the punch press platform. Springs are mounted at the positions, corresponding to the cutters, of the upper portion of the inner cavity of the tool body. The machining tool further comprises guiding columns and a feeding sleeve, wherein the two sides of each spring are each provided with the corresponding guiding column, and the feeding sleeve is arranged at the opening of the side surface of the tool body in a sleeving mode. The guiding columns are fixed on the upper portion of the inner cavity of the tool body. According to the machining tool, the cutting width is adjustable through the arrangement of the punch press platform and the cutters, so that the adaptability of machining equipment is enhanced. The feeding sleeve plays a role of floor fixing, and cutting errors caused by shaking of the floors in the cutting process are avoided. The springs mounted at the positions, corresponding to the cutters, of the upper portion of the inner cavity of the tool body play a role of resetting on the cutters.

Owner:万世蓉

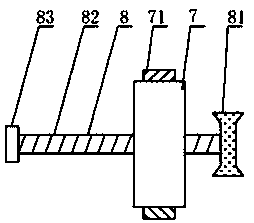

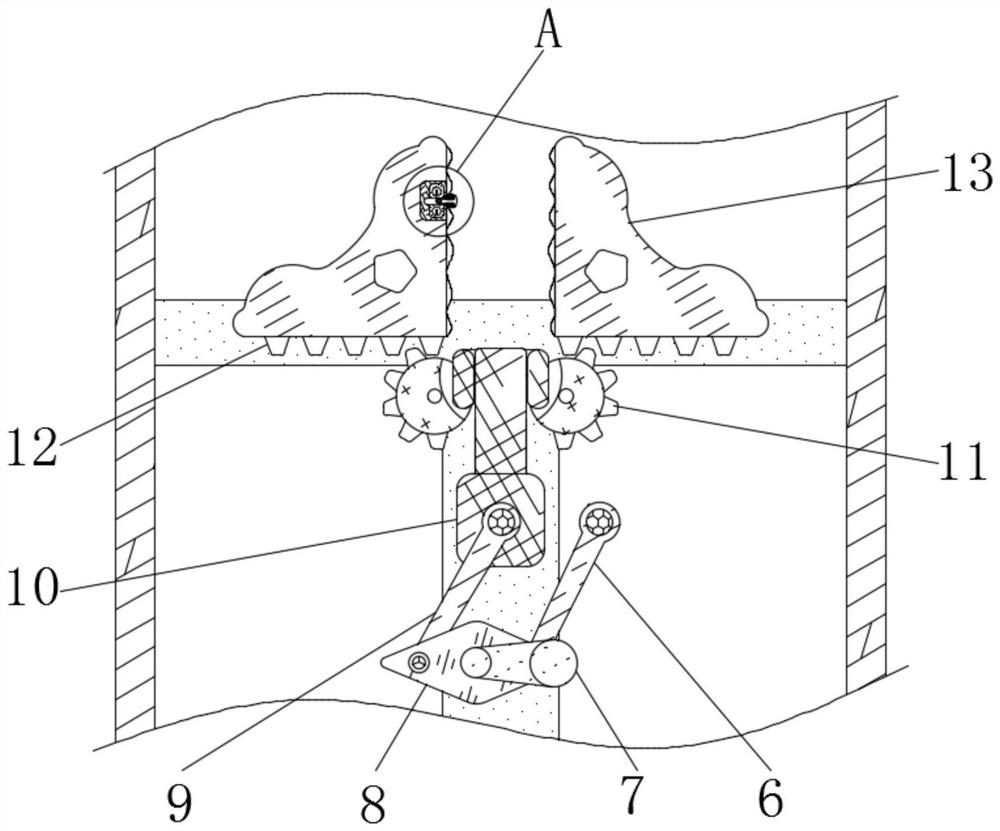

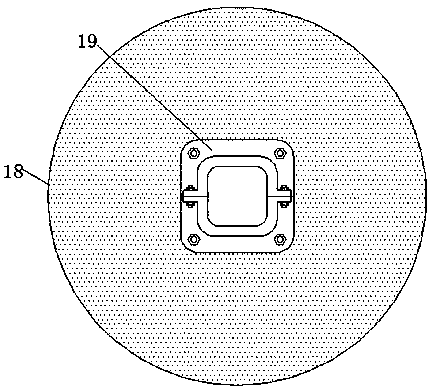

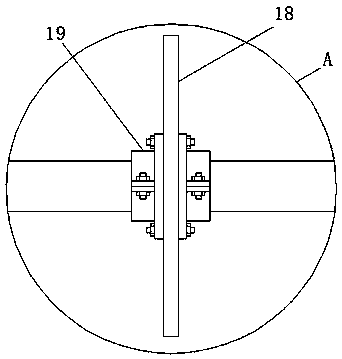

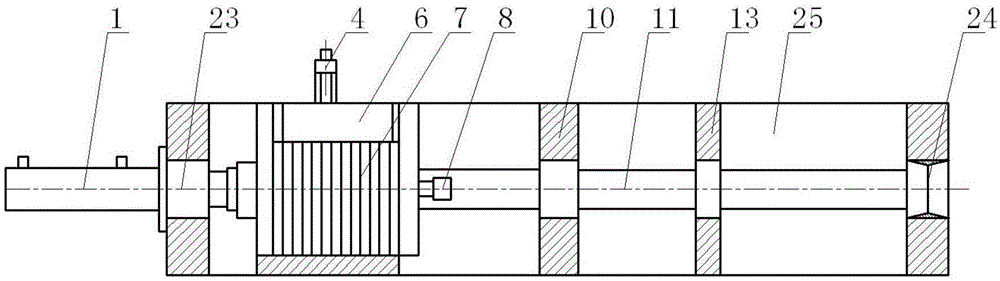

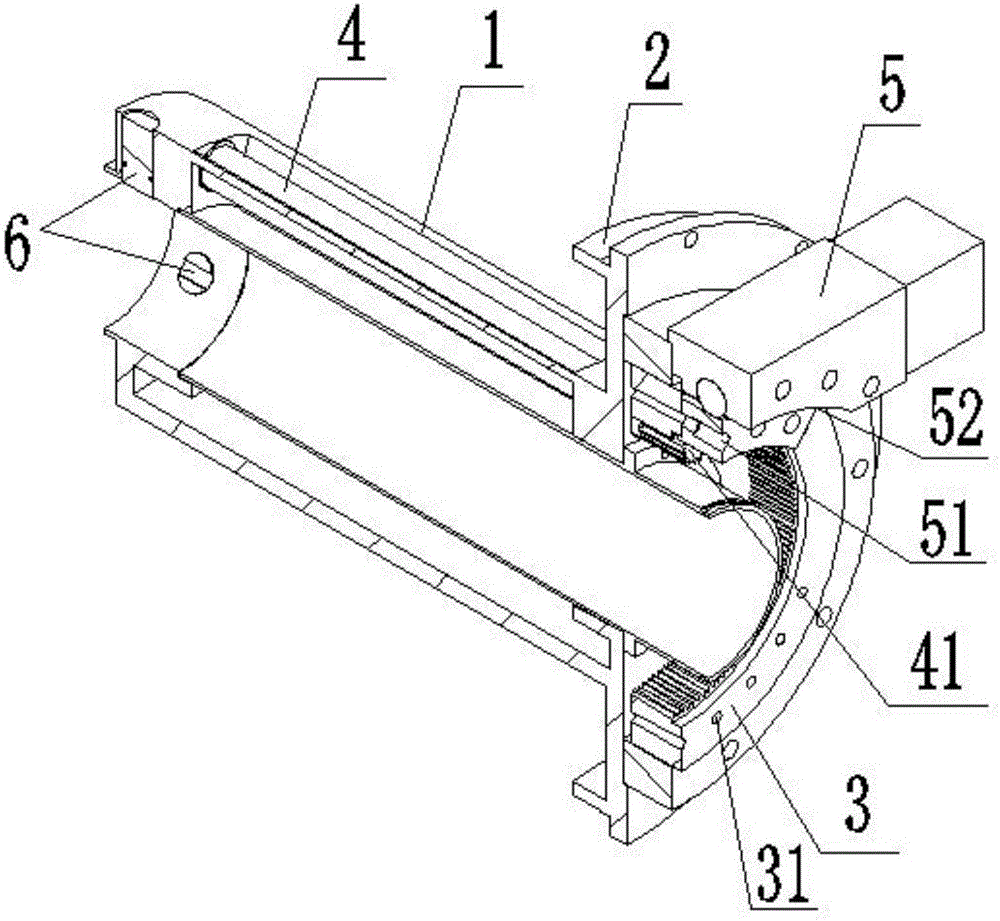

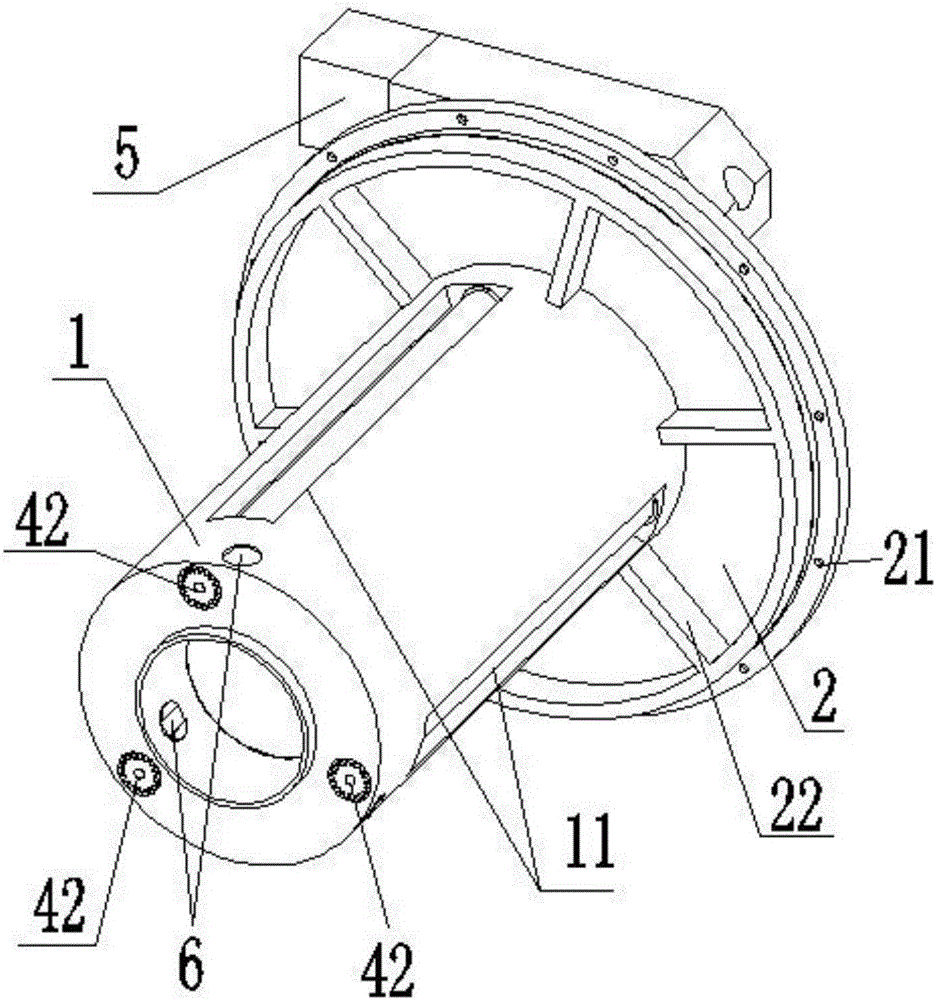

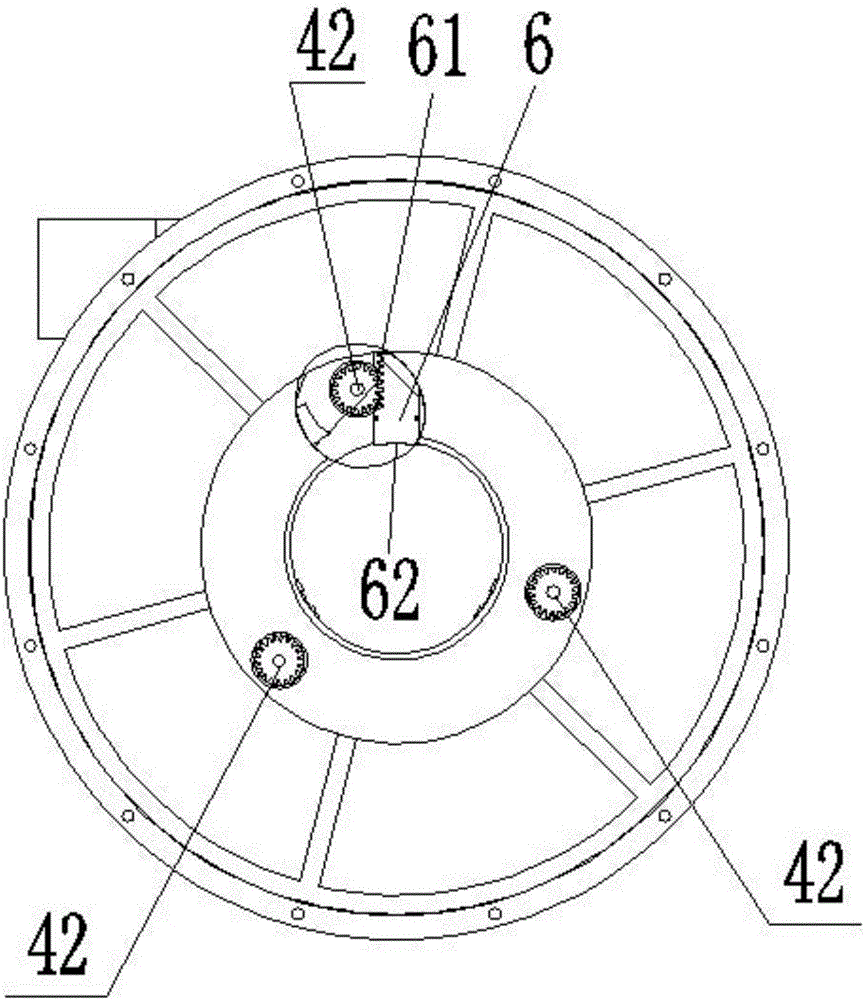

Clamping device for tube cutting machine

InactiveCN106002350AGuarantee the quality of productionGuarantee product qualityWork clamping meansPositioning apparatusGear transmissionDrive shaft

The invention discloses a clamping device for a tube cutting machine. The clamping device comprises a device shell, a connecting disc, an inner tooth rotating wheel, gear transmission shafts, a fixing mechanism and fixing blocks. The connecting disc is fixedly and integrally connected with the device shell. The inner tooth rotating wheel is cooperatively connected to the inner side of the connecting disc. The gear transmission shafts are fixedly installed in the device shell. The fixing mechanism is cooperatively connected to the connecting disc. The fixing blocks are arranged at the tail portion of the device shell. The two ends of the gear transmission shafts are engaged and connected with the inner tooth rotating wheel and the fixing blocks. By means of the clamping device for the tube cutting machine, the fixing mechanism and the fixing blocks are used for fixing a long pipe, cutting errors caused by vibration generated by rotation of the long pipe are prevented, and the production quality of the long pipe is ensured.

Owner:金华畅能机械有限公司

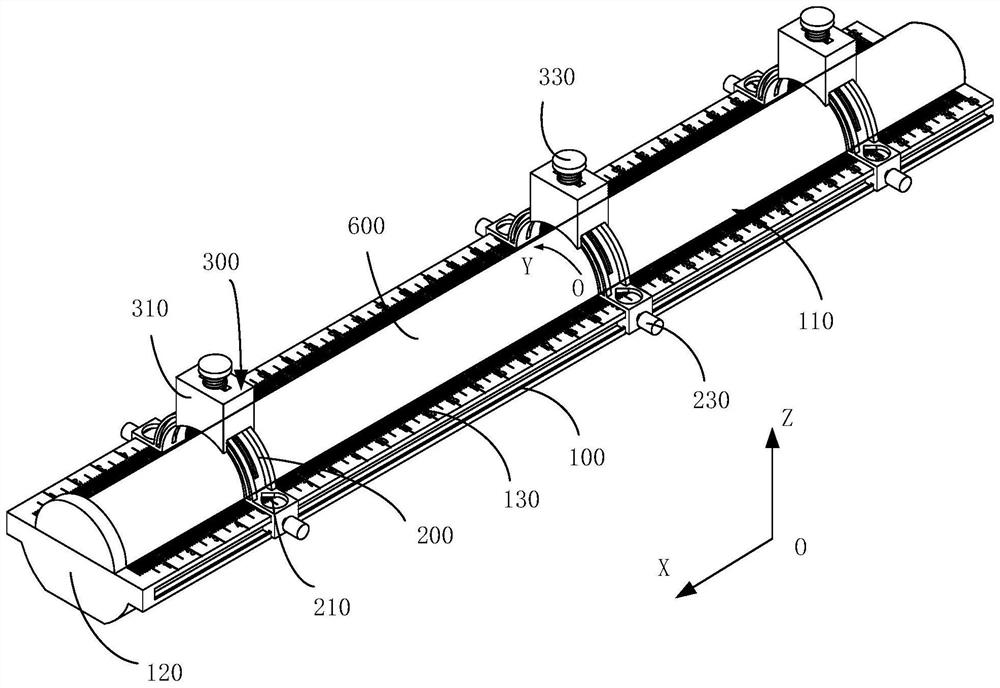

Cable head manufacturing tool

ActiveCN114361911AImprove production accuracyImprove production efficiencyLine/current collector detailsElectronic waste recyclingEngineeringMechanical engineering

The invention relates to a cable head manufacturing tool which comprises a measuring seat, a sliding mechanism and a cutting mechanism, scales are arranged on the measuring seat, and the length direction of the scales is the axial direction of a cable head; the sliding mechanism is slidably connected with the measuring seat along a first direction, and the sliding mechanism is provided with a first cavity with an opening facing the measuring seat; the cutting mechanism and the sliding mechanism are in sliding connection in the second direction, a cutting knife of the cutting mechanism extends into the first cavity, and the second direction is matched with the circumferential direction of the cable head. When the cable head is manufactured, the sliding mechanism is moved, so that the sliding mechanism drives the cutting mechanism to move to the required scale position, then the cutting mechanism is moved in the second direction OY, and the outer sheath of the cable head is cut through the cutting mechanism. Namely, after the measurement is completed, cutting can be directly carried out at the measurement position, so that the accuracy of the cable head is improved by reducing the cutting error. Secondly, after measurement is completed, cutting can be directly carried out at the measurement position, line drawing is not needed, operation is easy, and efficiency is high.

Owner:SHENZHEN POWER SUPPLY BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com