Wafer stage encapsulation LED (light emitting diode)

A technology of wafer-level packaging and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inability to meet the requirements of directional illumination application scenarios, asymmetric light distribution, and easy short circuit of welding, etc., to meet the requirements of directional lighting. The effect of sexual exposure application scene requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

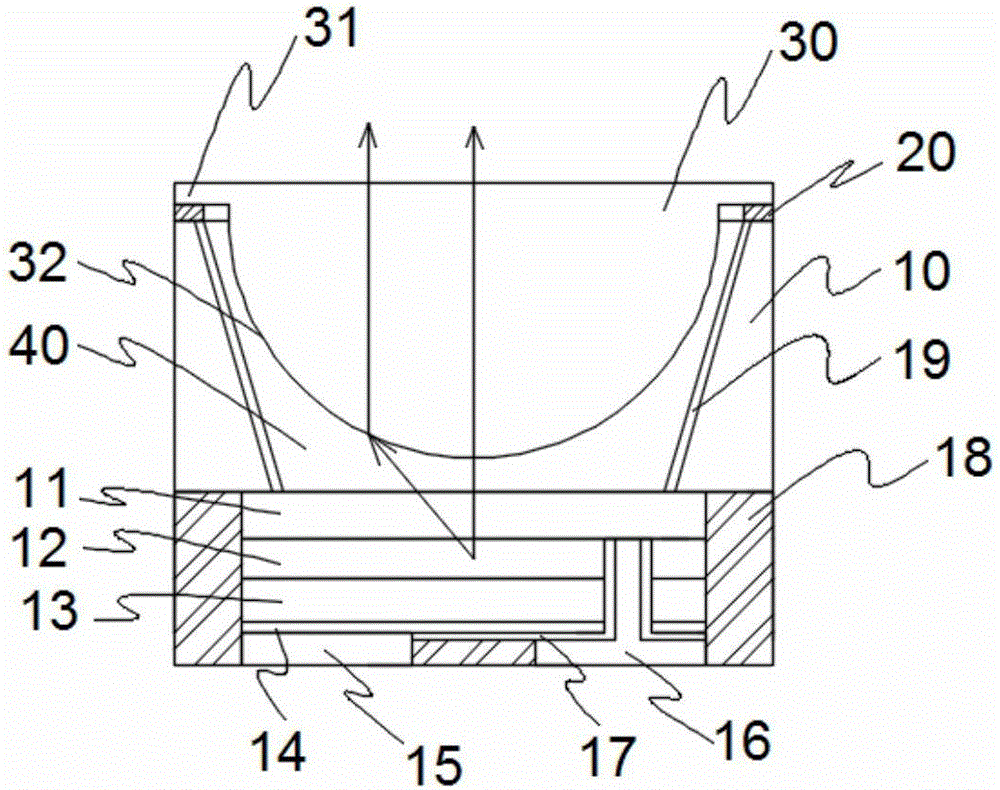

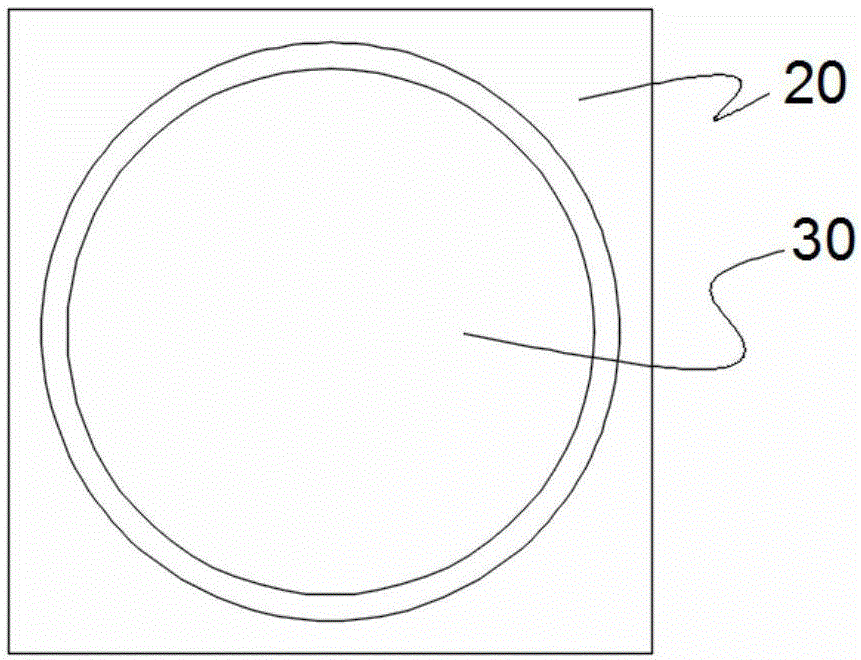

[0022] see figure 1 with 3 The embodiment of the present invention includes an LED chip, a lens 30, and a lens bonding layer 20. The LED chip includes a substrate layer 10 made of GaAs, a first doped semiconductor layer 11 made of AlGaAs, and a semiconductor light-emitting layer made of AlGaAs. 12. The second doped semiconductor layer 13 made of AlGaAs, the conductive light-reflecting layer 14 made of silver, the first electrode 16, the second electrode 15, the insulating layer 17 and the cladding medium 18, and the semiconductor light emitting layer 12 is arranged on Between the first doped semiconductor layer 11 and the second doped semiconductor layer 13, the conductive light-reflecting layer 14 is arranged below the second doped semiconductor layer 13, and the second electrode 15 is connected with the second doped semiconductor layer through the conductive light-reflecting layer 14. 13, the first electrode 16 is directly connected to the first doped semiconductor layer 11...

Embodiment 2

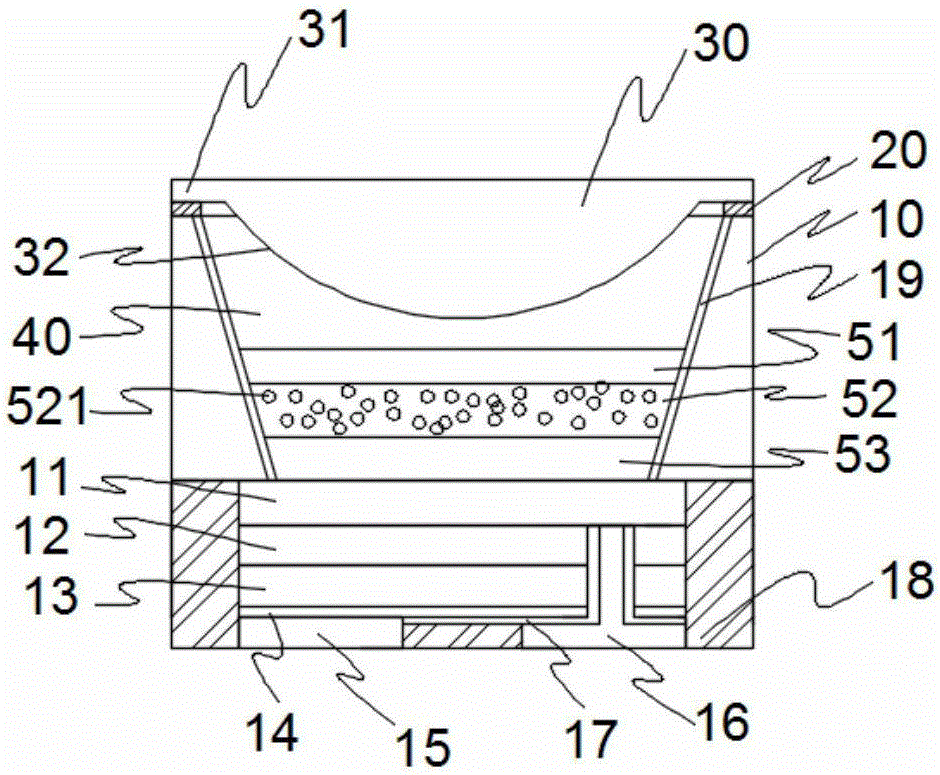

[0030] see figure 2 with 3, a wafer-level package LED, comprising an LED chip, a lens 30, and a lens bonding layer 20, wherein the LED chip comprises a substrate layer 10 made of silicon, a first doped semiconductor layer 11 made of GaN, and made of InGaN The semiconductor light emitting layer 12, the second doped semiconductor layer 13 made of GaN, the conductive reflective layer 14 made of silver, the first electrode 16, the second electrode 15, the insulating layer 17 and the coating medium 18, the semiconductor light emitting The layer 12 is arranged between the first doped semiconductor layer 11 and the second doped semiconductor layer 13, the conductive light-reflecting layer 14 is arranged under the second doped semiconductor layer 13, and the second electrode 15 is realized through the conductive light-reflective layer 14 and the second Electrical conduction between the doped semiconductor layers 13, the first electrode 16 is directly connected to the first doped sem...

Embodiment 3

[0041] see figure 2 with 3 , a wafer-level packaged LED, comprising an LED chip, a lens 30, and a lens bonding layer 20, wherein the LED chip comprises a substrate layer 10 made of GaAs, a first doped semiconductor layer 11 made of AlGaInP, and made of AlGaInP The semiconductor light-emitting layer 12, the second doped semiconductor layer 13 made of AlGaInP, the conductive light-reflecting layer 14 made of Al, the first electrode 16, the second electrode 15, the insulating layer 17 and the coating medium 18, the semiconductor light-emitting The layer 12 is arranged between the first doped semiconductor layer 11 and the second doped semiconductor layer 13, the conductive light-reflecting layer 14 is arranged under the second doped semiconductor layer 13, and the second electrode 15 is realized through the conductive light-reflective layer 14 and the second Electrical conduction between the doped semiconductor layers 13, the first electrode 16 is directly connected to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com