Machining tool for artificial floors

An artificial floor and tooling technology, applied in the field of artificial floor processing tooling, can solve the problems of inability to adjust the width of cutting boards, inconvenience, and non-adjustable spacing, etc., achieve the best cache and release effect, enhance applicability, and avoid blade breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

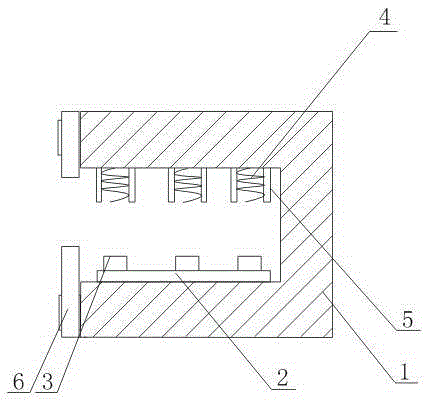

[0024] Such as figure 1 , figure 2 , image 3 As shown, a processing tool for artificial flooring includes a working body 1 whose side surface opening is a cavity structure, a punch platform 2 arranged on the bottom of the inner cavity of the working body 1, and several cutting knives arranged on the punch platform 2 3; a spring 4 is installed at the upper part of the inner cavity of the working body 1 corresponding to the position of the cutter 3; it also includes guide columns 5 arranged on both sides of the spring 4 and a feeding sleeve 6 sleeved at the opening of the side surface of the working body 1, the The guide post 5 is fixed on the upper part of the inner cavity of the working body 1 .

[0025] In this embodiment, when the floor is to be cut, the floor is placed in the cavity of the working body 1, and the feeding sleeve 6 plays a role in fixing the floor, so as to avoid cutting errors caused by shaking of the floor during the cutting process. . After the floor...

Embodiment 2

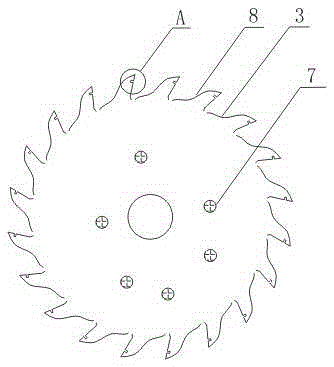

[0027] In this embodiment, on the basis of Embodiment 1, one or more through holes 7 are opened on the cutting surface of the cutting knife 3 . The through hole 7 is filled with polymer sound-absorbing material.

[0028] The sound-absorbing material arranged in the through hole 7 is used to absorb noise during the cutting process of the cutter, reduce the sound pressure value, and avoid damage to the worker's body due to excessive noise during operation.

Embodiment 3

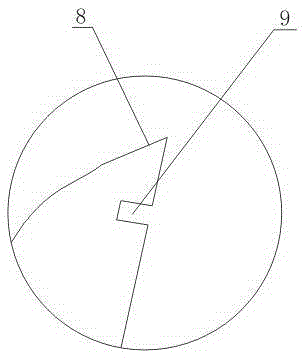

[0030] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, several serrated blades 8 are arranged on the edge of the cutting knife 3 , and grooves 9 are opened on the side walls of the blades 8 along the direction from the edge to the back of the blade.

[0031] In this embodiment, the groove 9 provided on the blade 8 along the direction from the blade edge to the back of the blade enables buffering and release of the impact stress suffered by the cutting knife 3 during the cutting process, preventing the blade 8 from breaking due to excessive stress concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com