Patents

Literature

152results about How to "Play the role of reset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

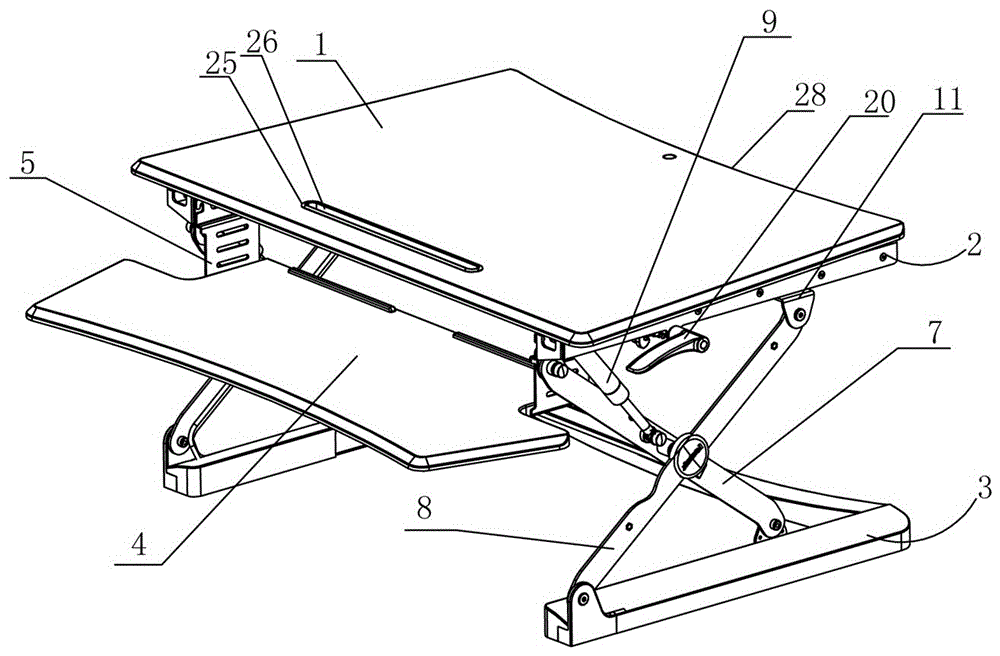

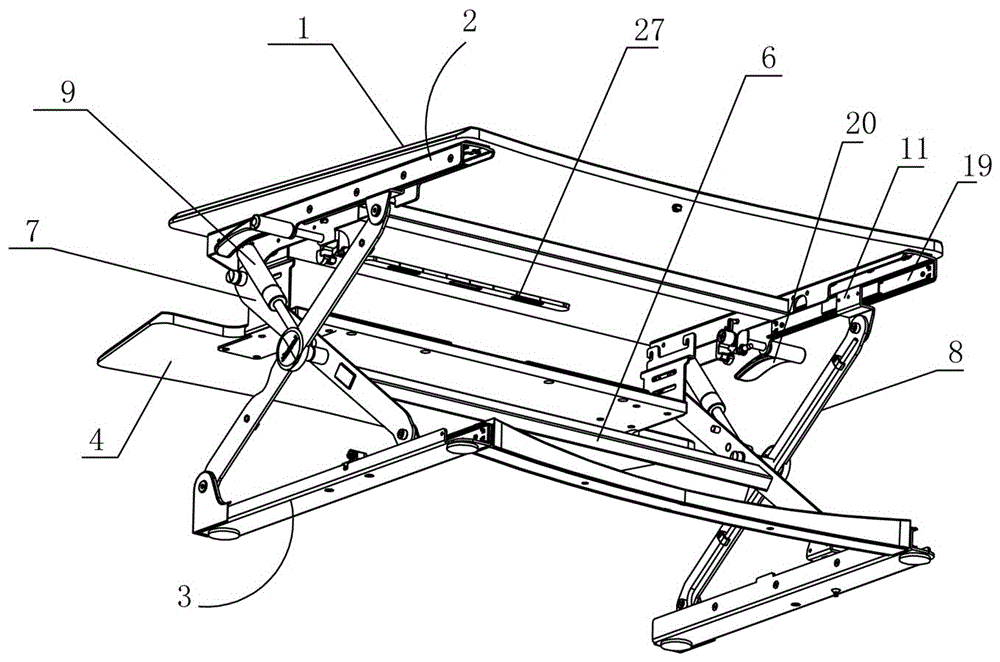

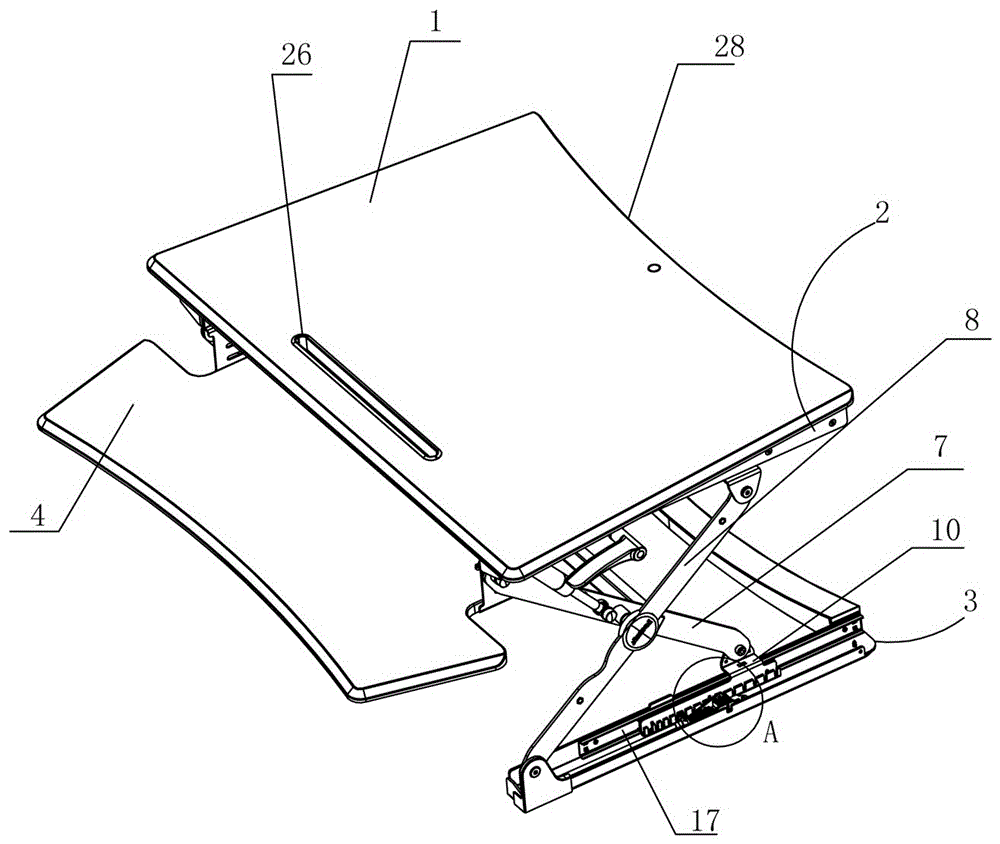

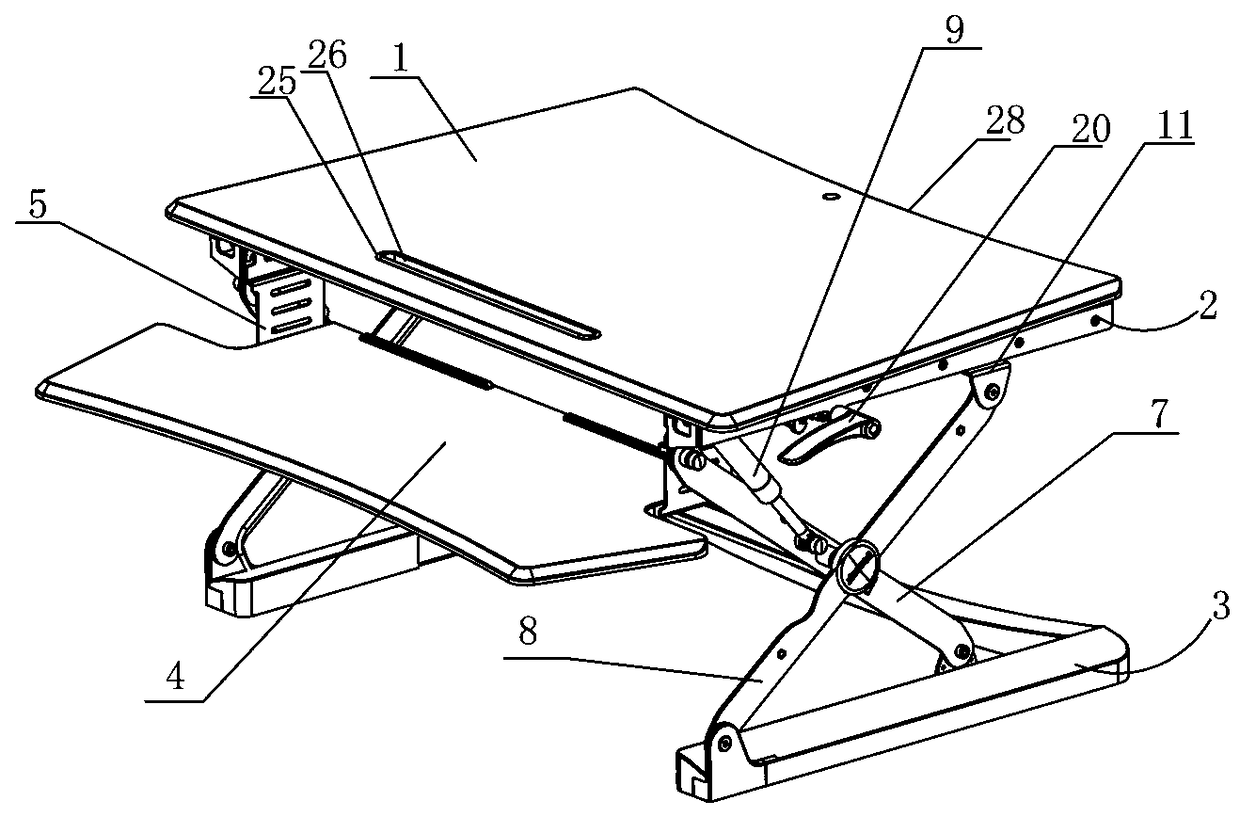

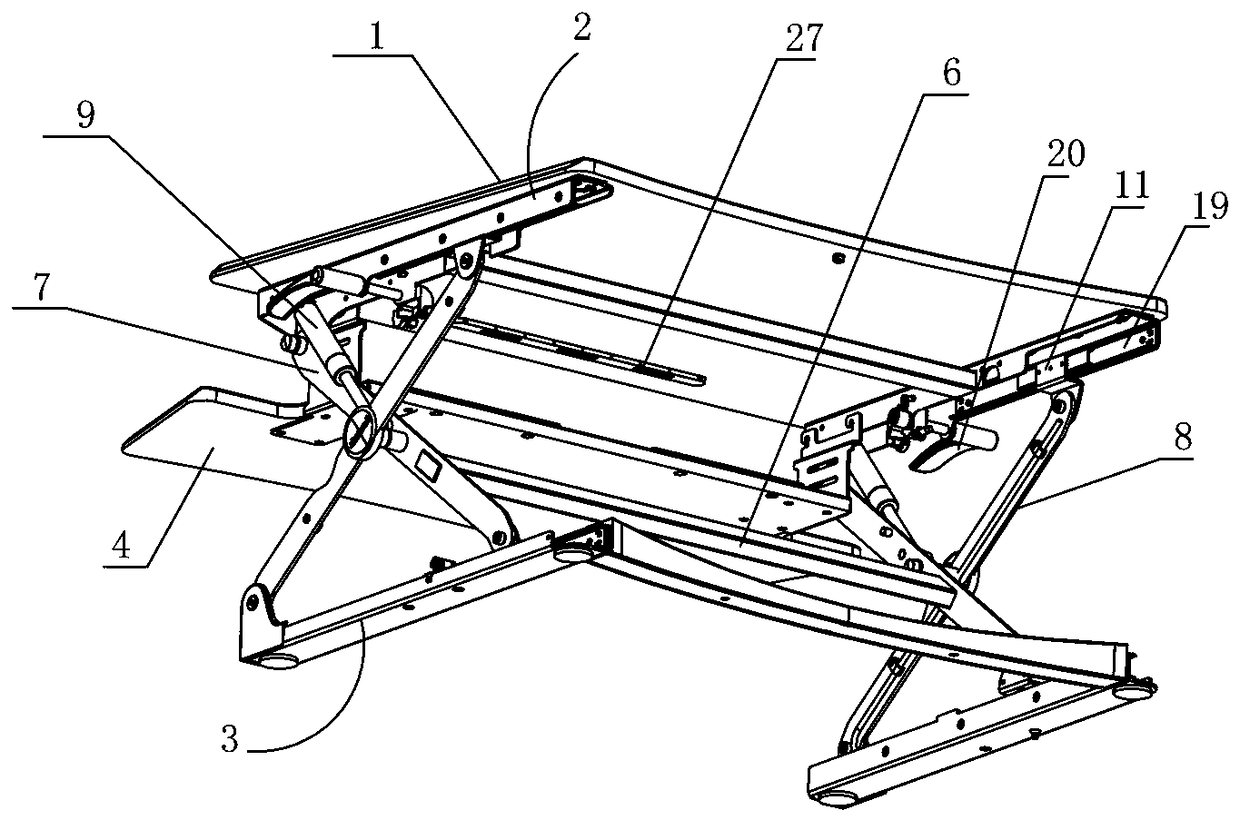

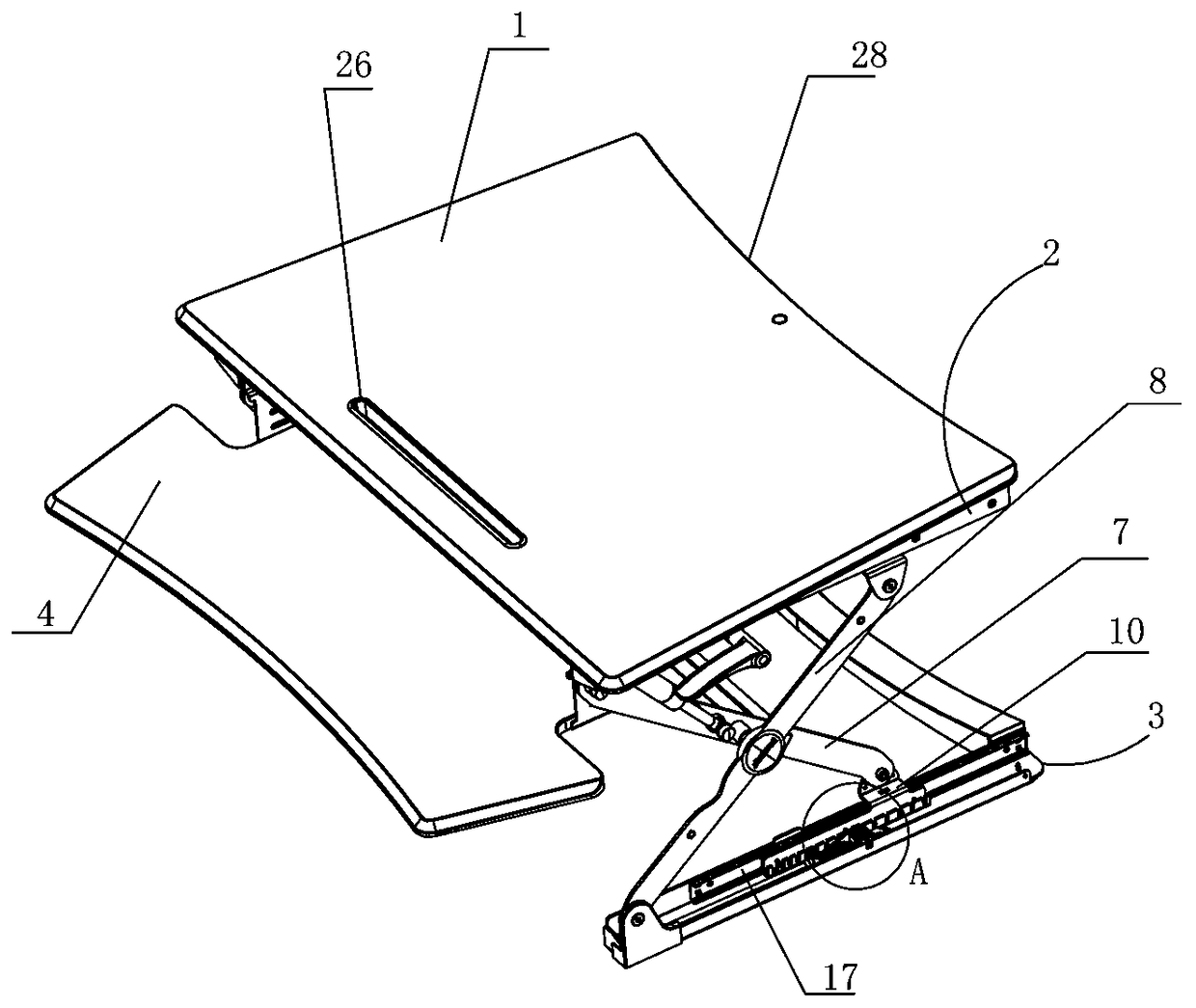

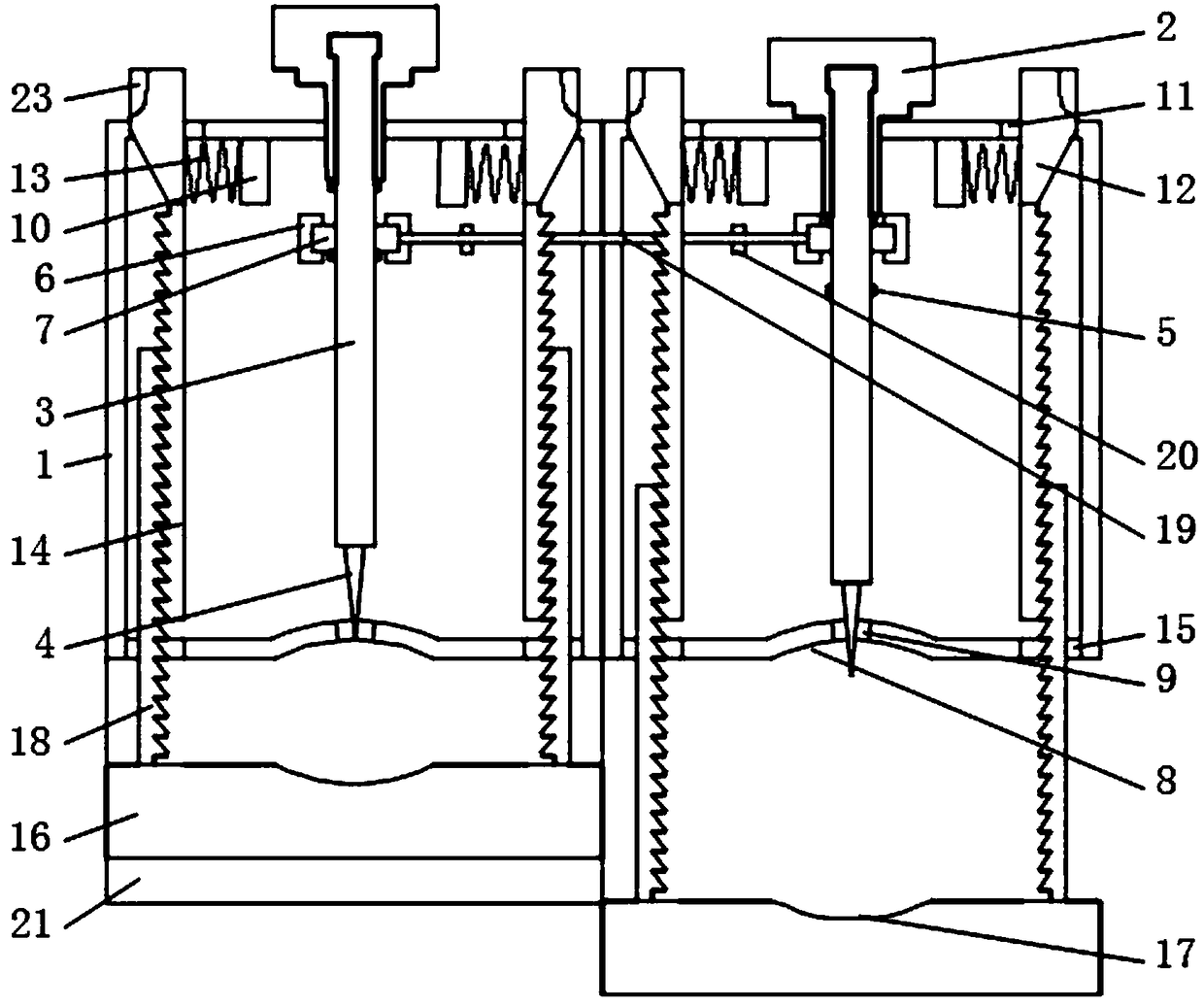

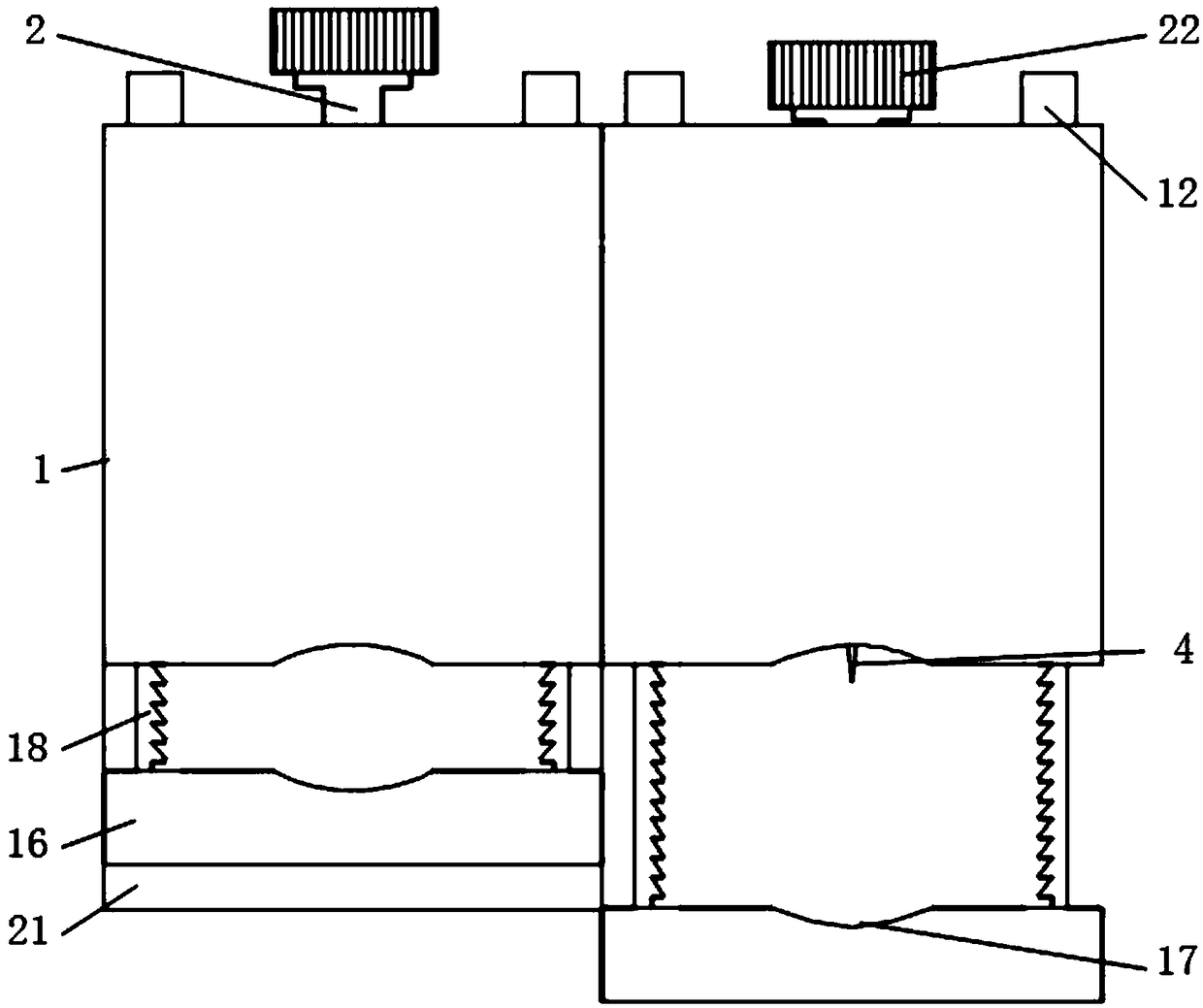

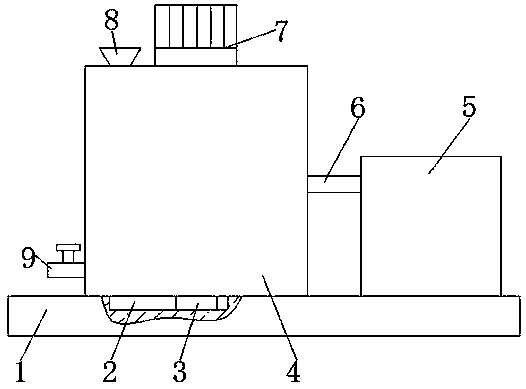

Lifting working platform

ActiveCN105901942ASimple structureIncreased load-bearing capacityOffice tablesVariable height tablesLocking mechanismGas spring

The invention discloses a lifting working platform. The lifting working platform comprises a lifting working platform body, wherein the lifting working platform body comprises a table board, an upper support, a lower support and at least one set of X-shaped lifting mechanism, and the table board is fixedly connected to the top of the upper support. Each set of X-shaped lifting mechanism comprises a first support rod and a second support rod the middle portions of which are hinged to form an X shape, wherein the upper end of the first support rod is hinged to the upper support, the lower end of the first support rod is hinged to a first sliding block, and the first sliding block is in sliding fit with the lower support; the lower end of the second support rod is hinged to the lower support, the upper end of the second support rod is hinged to a second sliding block, and the second sliding block is in sliding fit with the upper support. A locking mechanism is arranged on the lower support. Each set of X-shaped lifting mechanism further comprises a gas spring used for counteracting or partially counteracting the load on the upper support. The lifting working platform is simple in structure, and height adjustment is convenient.

Owner:LOCTEK ERGONOMIC TECH CORP

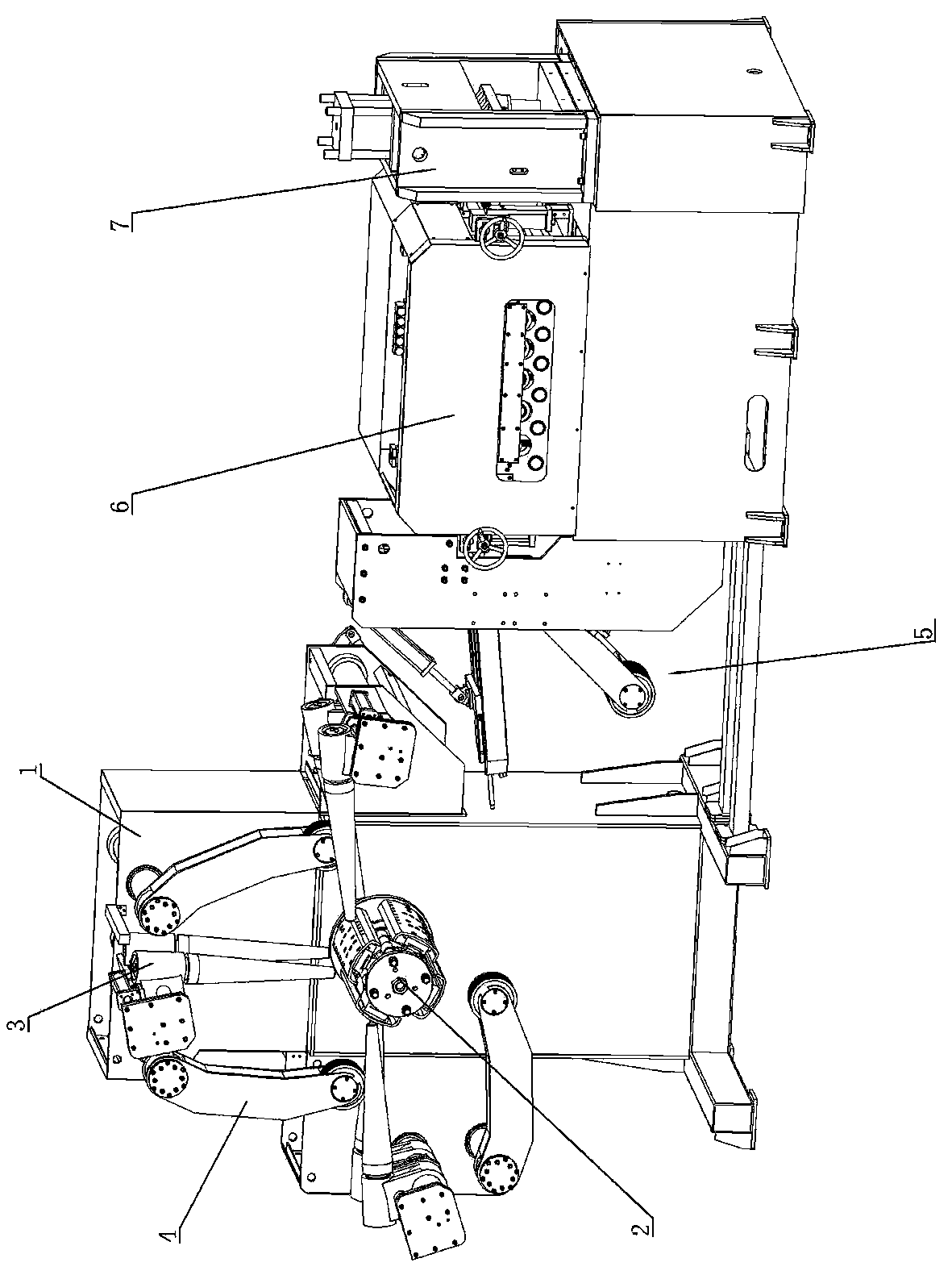

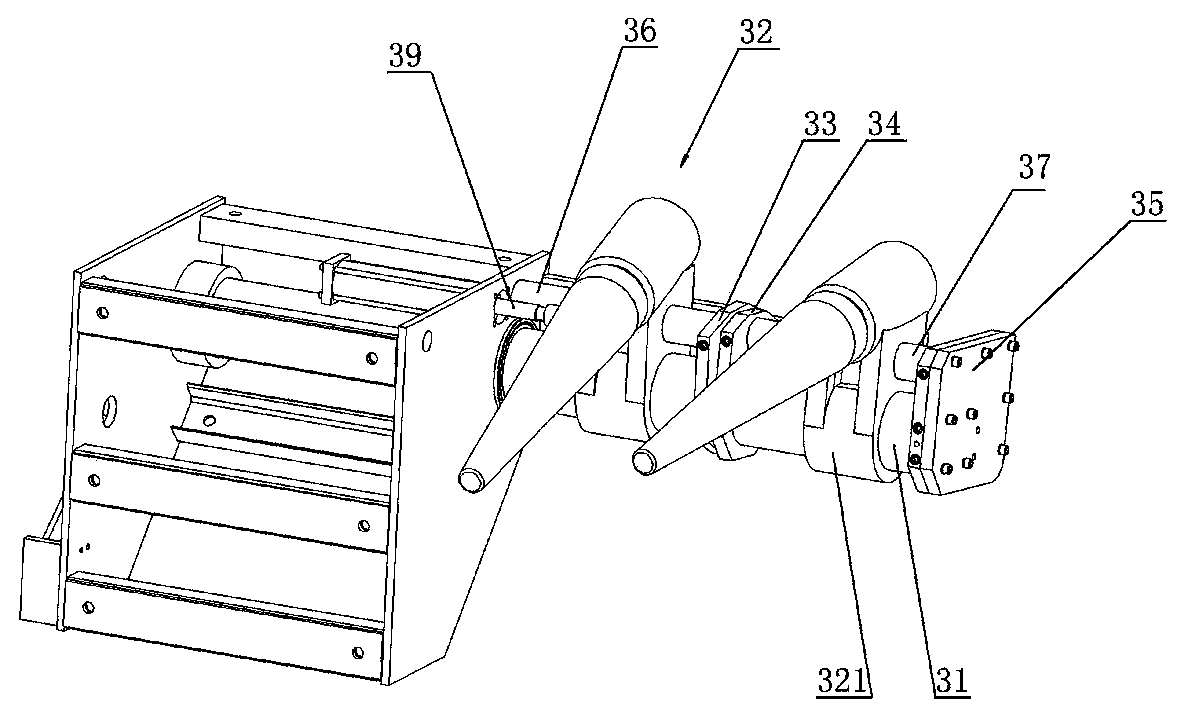

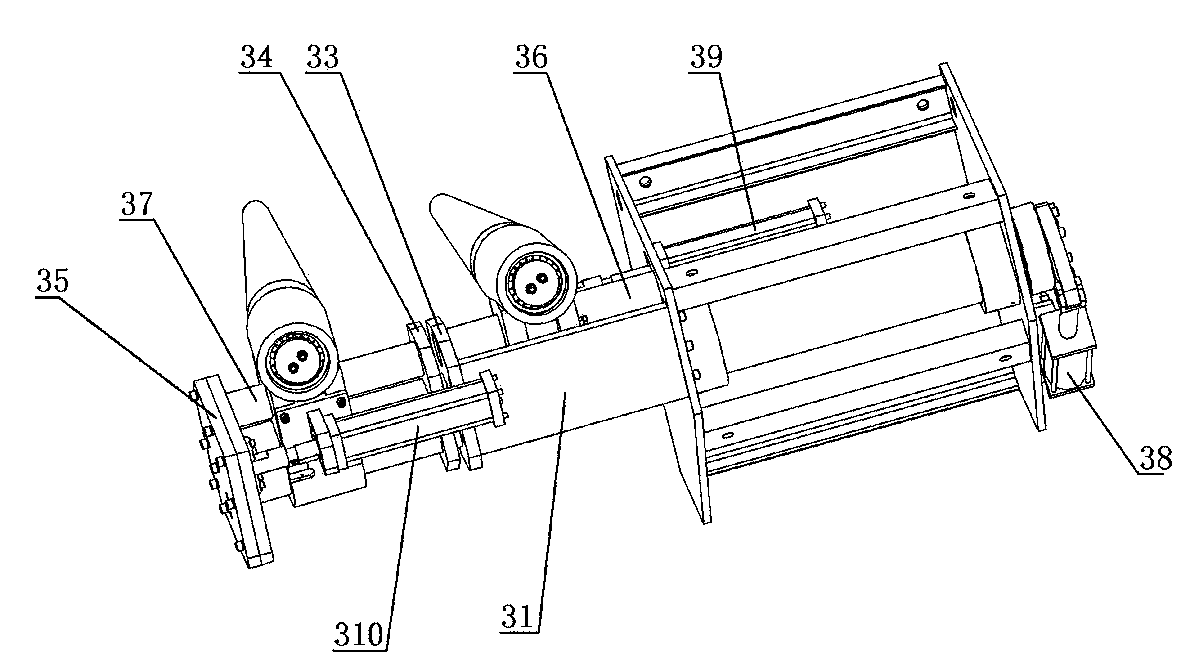

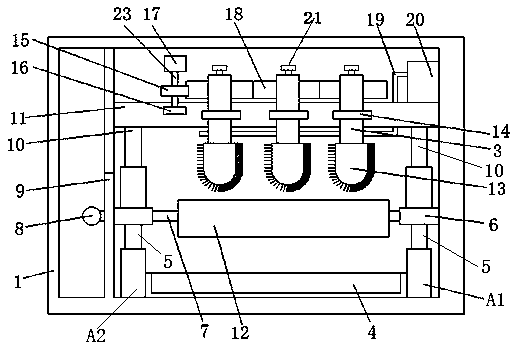

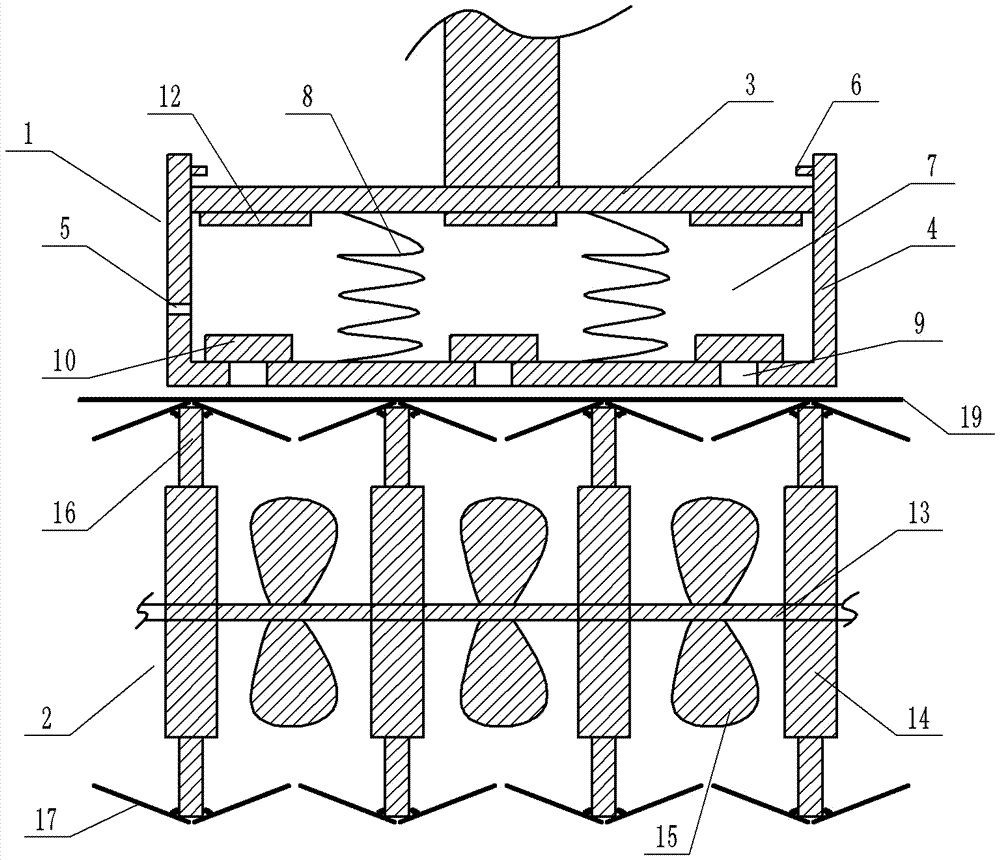

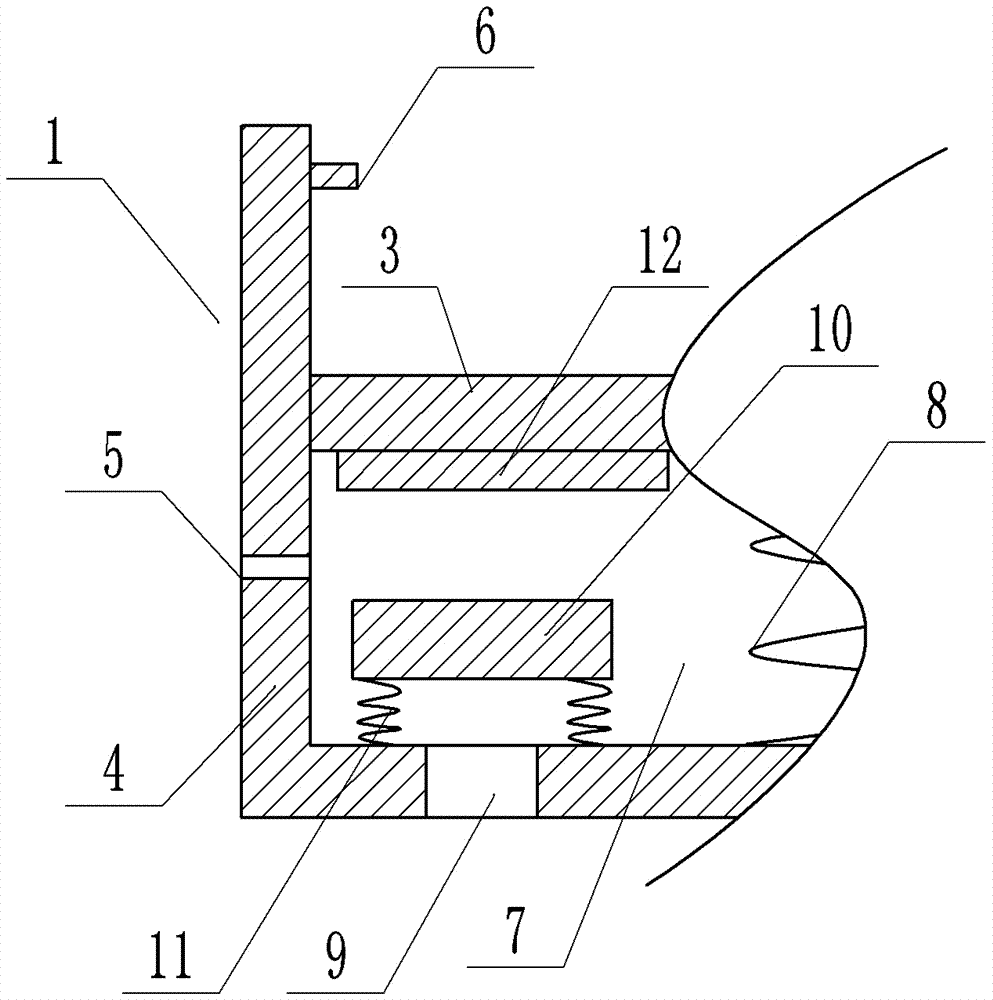

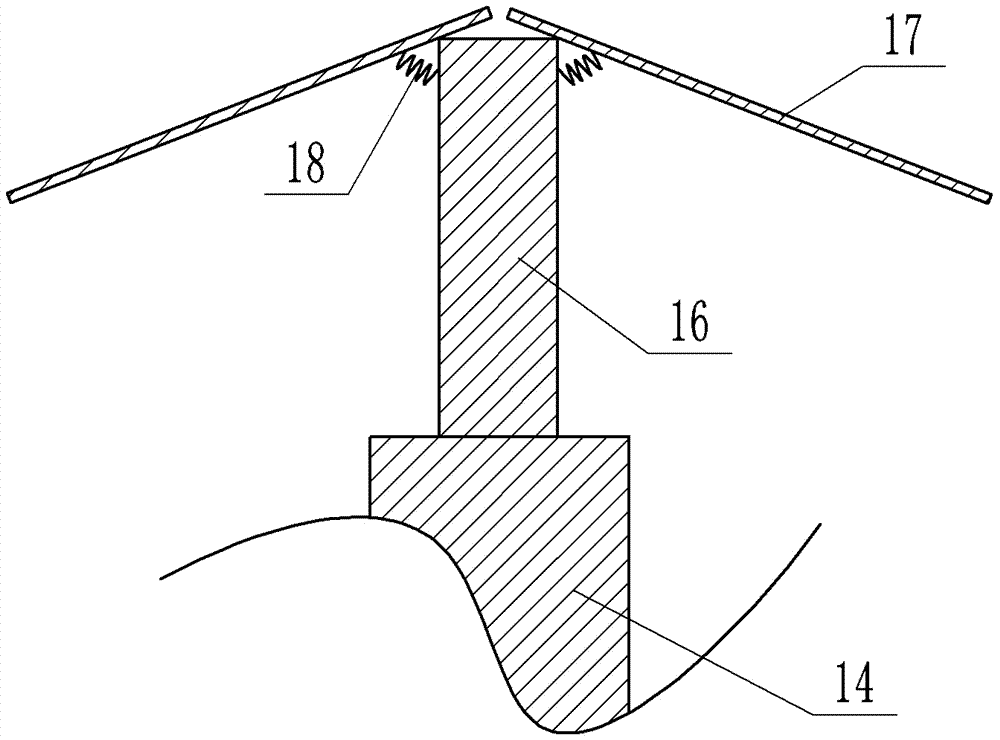

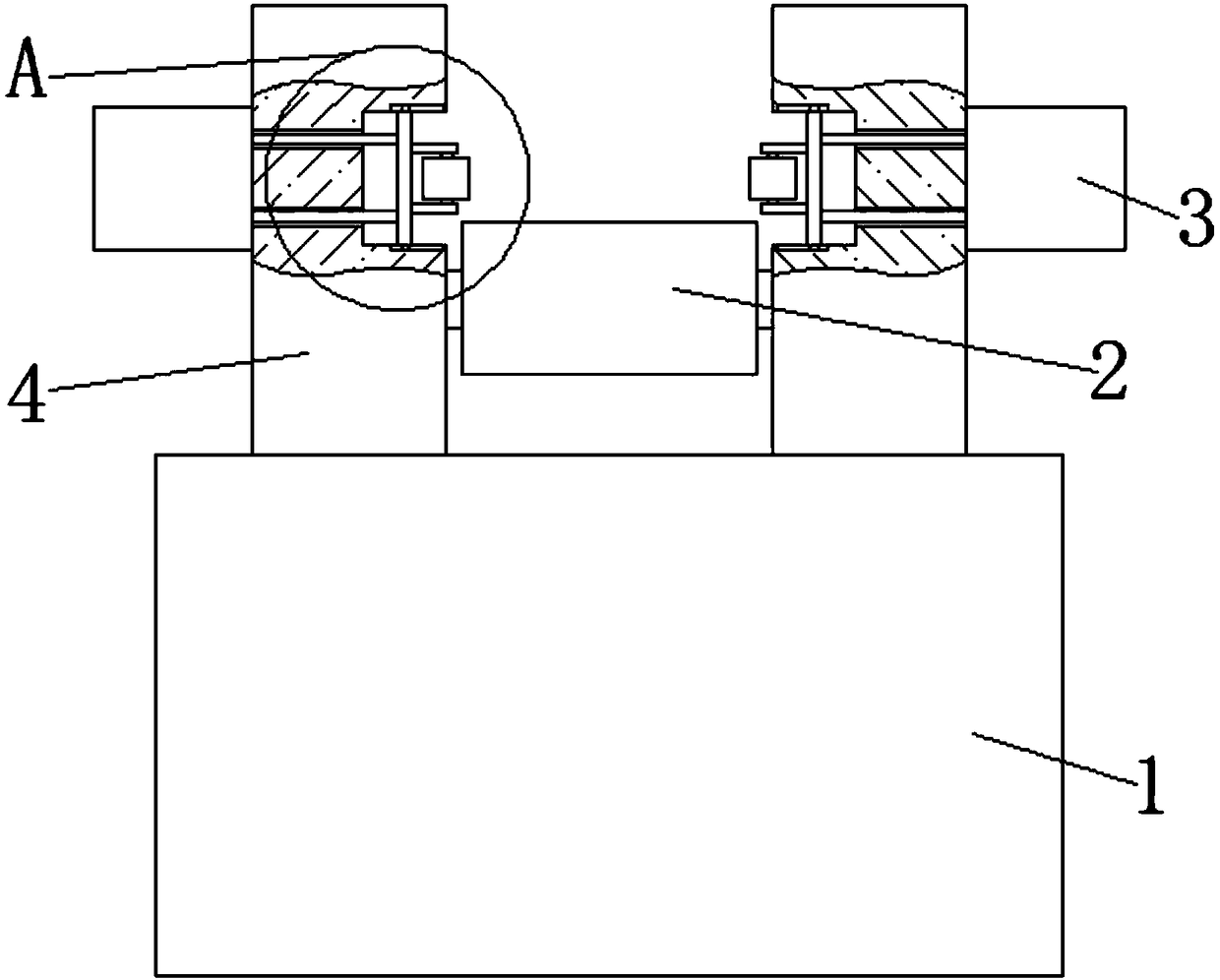

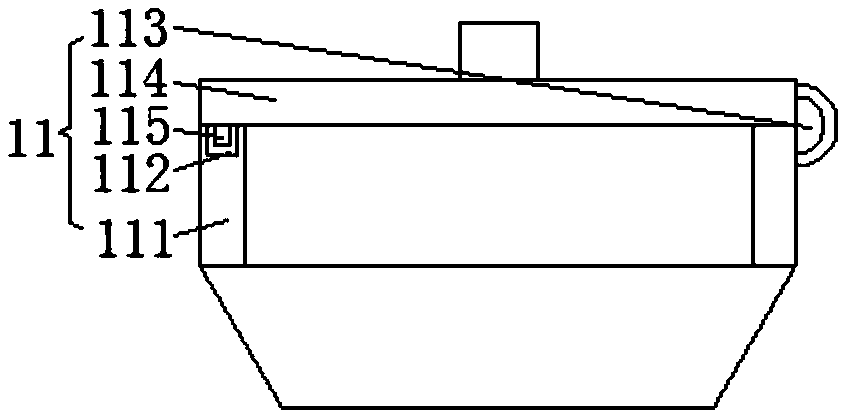

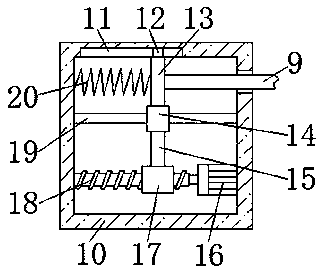

Uncoiling straightening machine special for fine blanking

InactiveCN103894451APlay the role of resetPlay a buffer roleShearing machinesOther manufacturing equipments/toolsMechanical engineeringEngineering

The invention discloses an uncoiling straightening machine special for fine blanking. The uncoiling straightening machine special for fine blanking comprises an uncoiling rack, a material frame, a material blocking mechanism, a material pressing mechanism, a material guiding mechanism, a straightening mechanism and a shearing mechanism. The material blocking mechanism comprises a material blocking arm assembly which comprises an extending arm and a material blocking arm. The front section of the material blocking arm is in the shape of a frustum or a cone. The diameter of the end, close to the material frame, of the material blocking arm is smaller than the diameter of the end, away from the material frame, of the material blocking arm. The straightening mechanism comprises a straightening rack, lower straightening rollers and upper straightening rollers. The lower straightening rollers which are arranged transversely are arranged on the straightening rack. A third sliding groove is formed in the straightening rack, and a third sliding block is arranged in the third sliding groove. The upper straightening rollers are arranged on the third sliding block, an adjusting device is arranged on the straightening rack, the distance between every two adjacent lower straightening rollers is gradually reduced, and the distance between every two adjacent upper straightening rollers is gradually reduced. By means of the structure of the uncoiling straightening machine special for fine blanking, coil stock loaded on the material frame can be reliably and axially limited, the material blocking arm can be prevented from being abraded fast, the straightening quality can be improved, and the uncoiling straightening machine special for fine blanking is suitable for straightening of belt materials with different thicknesses.

Owner:广州卡司顿机电技术有限公司

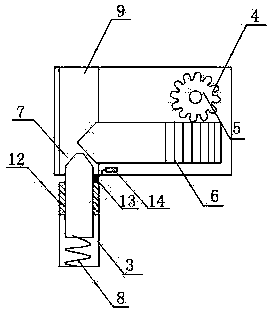

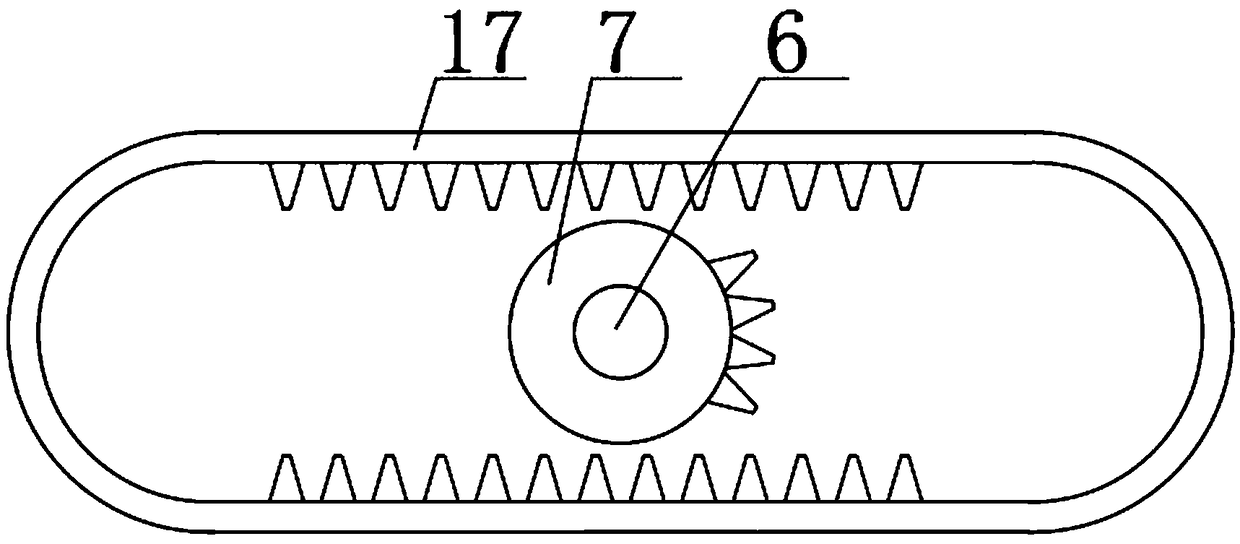

Display device for life and health information propaganda

InactiveCN108648655ASolve the problem of not being able to increase the usable areaIncrease the usable areaBoardsDisplay deviceEngineering

The invention discloses a display device for life and health information propaganda. The display device comprises a display plate; and a first positioning groove and a second positioning groove are formed in the back surface of the first display plate, a rotating shaft is movably connected to an inner cavity of the first display plate, a gear is arranged on the surface of the rotating shaft in a sleeving mode, and a first toothed plate and a second toothed plate are engaged with the top and the bottom of the gear correspondingly. According to the display device, the display plate, a sliding rod, a sliding sleeve, the second toothed plate, a first groove, a first movable plate, the first toothed plate, the gear, the rotating shaft, a second groove, a second movable plate, the first positioning groove, the second positioning groove, a positioning rod, a rotating shell, a tension spring, a connecting plate, a shifting rod, a telescopic rod, a mounting hole and a mounting plate are arranged and cooperatively used, and thus the problem that the using area of an existing display device for life and health information propaganda cannot be increased is solved; and the display device for life and health information propaganda has the advantage that the using area can be increased, and is worth being popularized.

Owner:芜湖天科生物科技有限公司

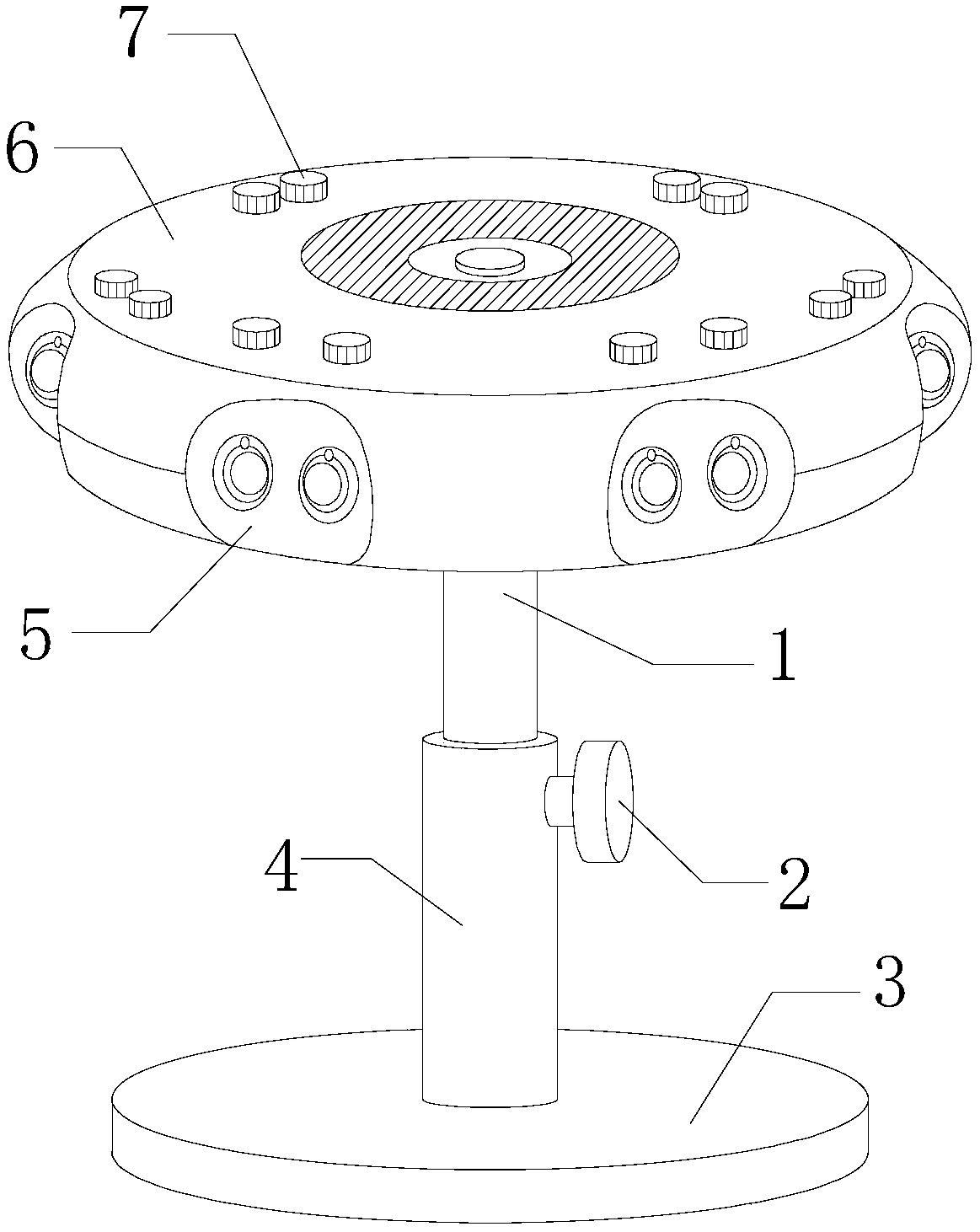

Virtual reality device for achieving panoramic camera

InactiveCN109194885AEasy proofreadingImprove convenienceTelevision system detailsColor television detailsEngineeringVirtual reality

The present invention discloses a virtual reality device for achieving a panoramic camera. The structure of the device comprises a lifting rod, an adjusting knob (2), a fixed bottom plate, a fixed sleeve, a shooting port, a camera host and an adjusting knob (7). The adjusting knob (7) is a circular structure, the middle portion of the surface of the adjusting knob (7) is provided with the fixed sleeve, the bottom portion of the lifting rod is sleeved with the internal portion of the fixed sleeved, and the upper right end of the fixed sleeve is provided with the adjusting knob (2). The internalportion of the shooting port is adjusted by the adjusting knobs, when the angle is controlled, an angle adjustment mechanism drives a camera device and a linkage mechanism to move, the arranged linkage mechanism controls a conductive device and a conductive position to perform turn-up through a transmission mechanism and turn on a timing starter to allow an infrared spotlight on a camera host tobe lightened and irradiate an infrared ray, and therefore, the frame correction between camera devices is convenient according to the infrared rays, workers are convenient to adjust the frames, and virtual reality frames are rapidly and conveniently assembled.

Owner:江莉莉

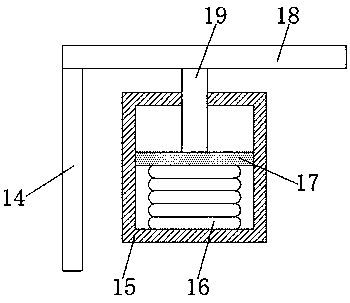

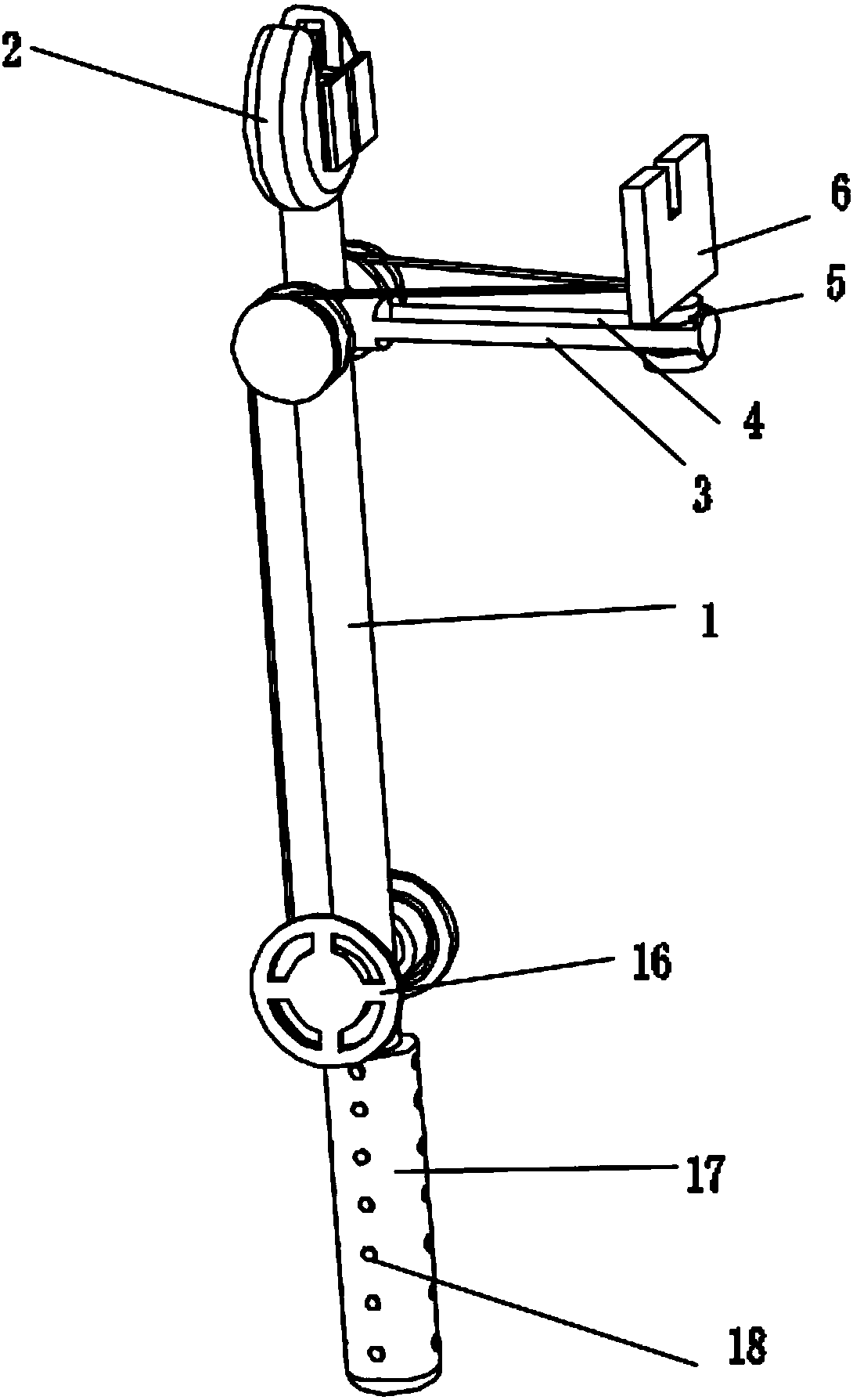

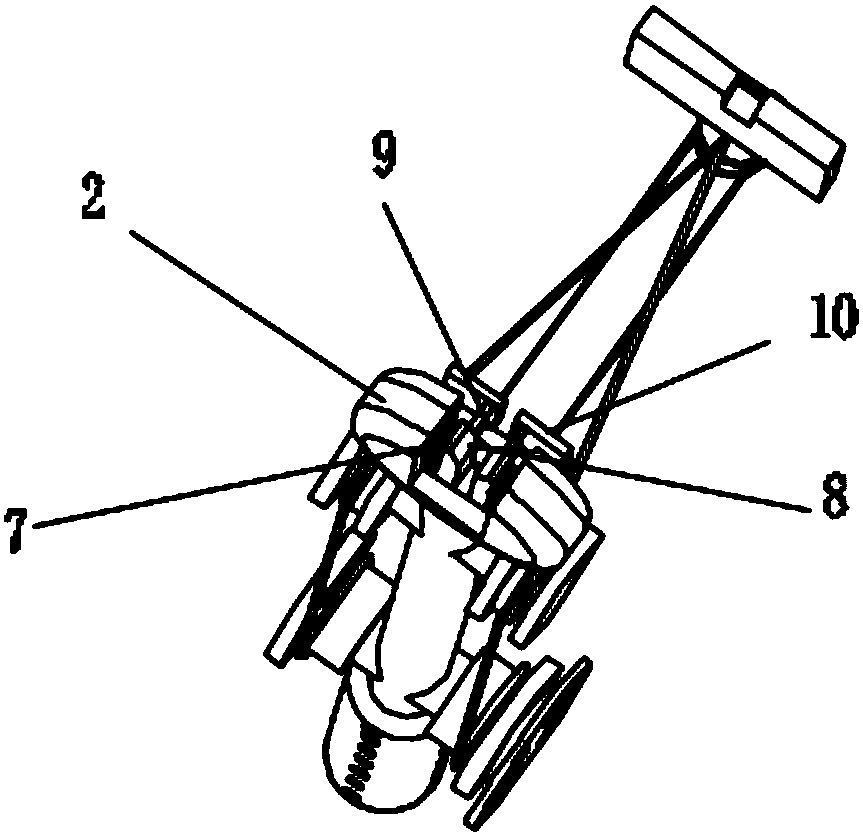

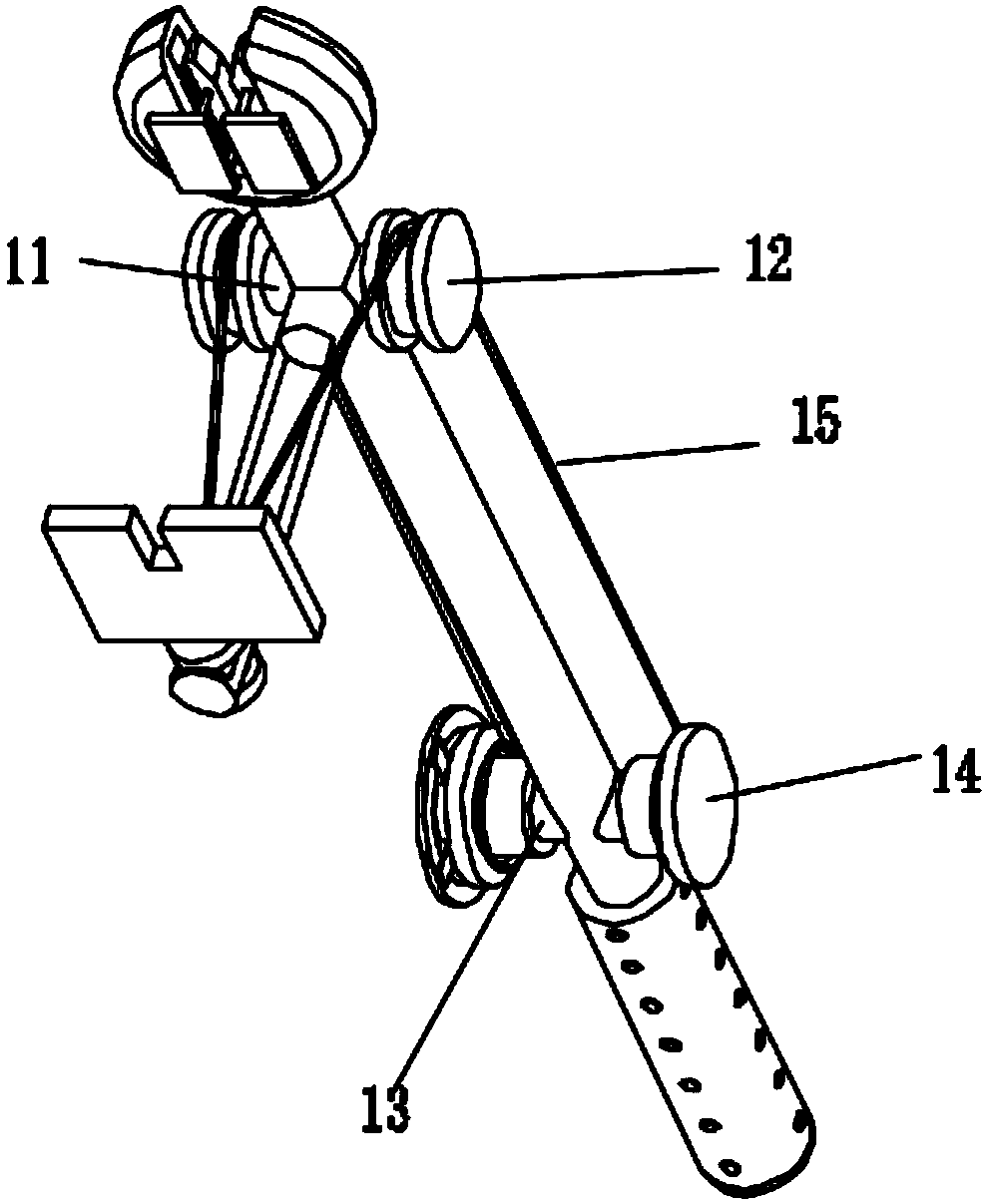

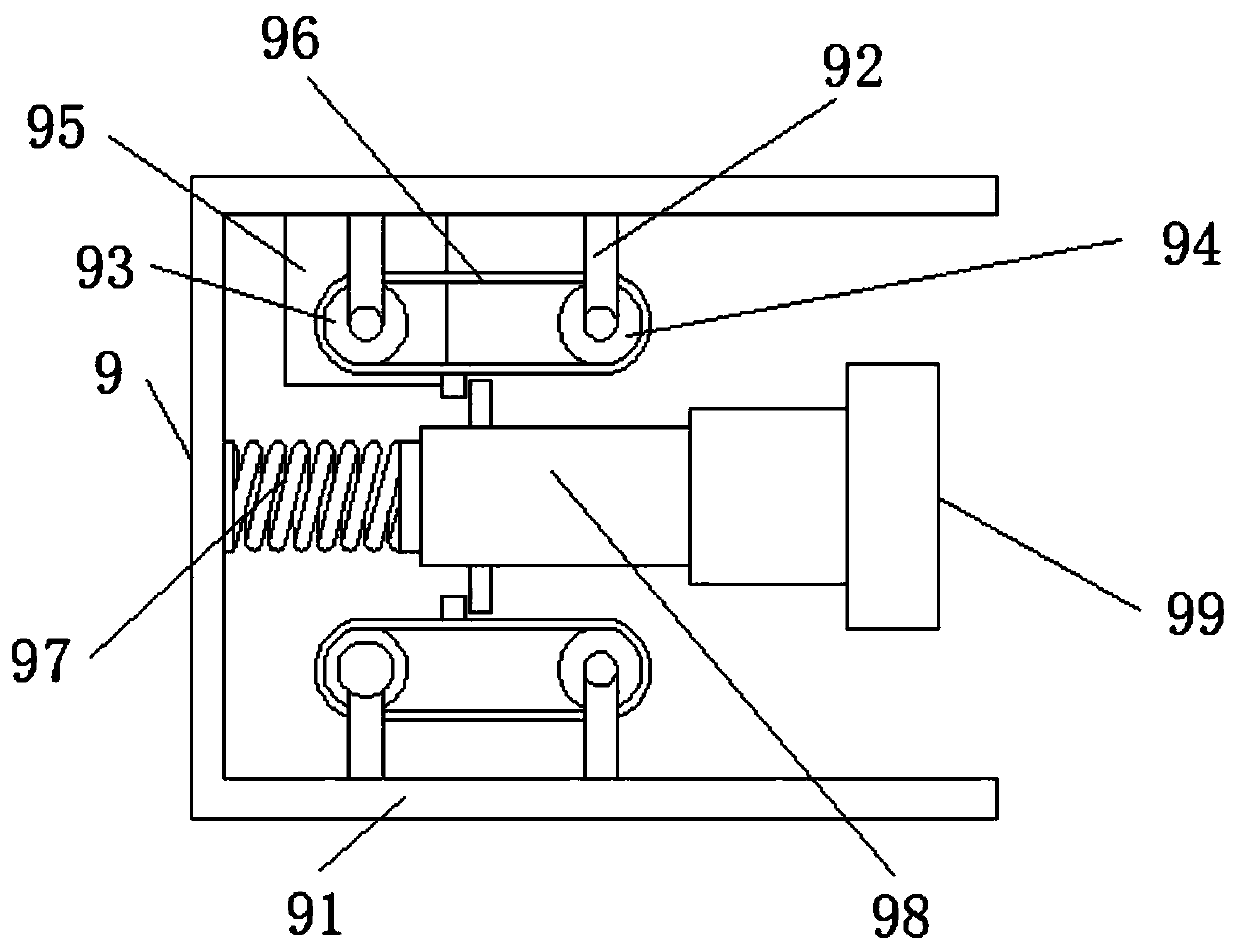

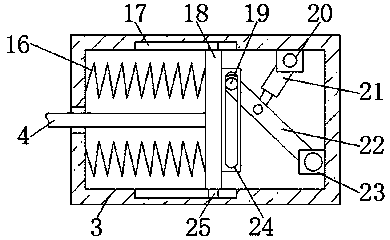

Overhead ground wire shakeproof hammer resetting device

ActiveCN108598998AEasy to pull horizontallySolve the inconvenient maintenanceApparatus for overhead lines/cablesPulley

The invention discloses an overhead ground wire shakeproof hammer resetting device in the technical field of communication. The overhead ground wire shakeproof hammer resetting device comprises a mainrod; a mounting disk is mounted at the top of the main rod; a moving rod is fixedly mounted on the side wall of the main rod; a moving groove is formed at the top of the moving rod; a moving pillar is movably mounted in an inner cavity of the moving groove; a resetting plate is arranged at the top of the moving pillar; and a plurality of groups of springs are arranged in an inner cavity of the mounting disk. According to the invention, by holding a hand-held sleeve with a hand and arranging a moving plate, a wire is inserted between clamping plates; by arrangement of the springs, the wire isclamped; under the action of the resetting plate, a shockproof hammer is blocked; by manually rotating a rotary disc, a No.2 rotating shaft is driven to rotate through the rotary disc; a traction ropeis driven to take up by the No.2 rotating shaft; a direction of the traction rope is changed by a fixed pulley; by matching of the moving groove and the moving pillar, the overhead ground wire shakeproof hammer resetting device is convenient to horizontally pull the resetting plate and move the shakeproof hammer so as to take a resetting effect and solve a problem that due to deflection, certainshakeproof hammers are inconvenient for maintenance personnel to repair.

Owner:安徽省含山县兴建铸造厂

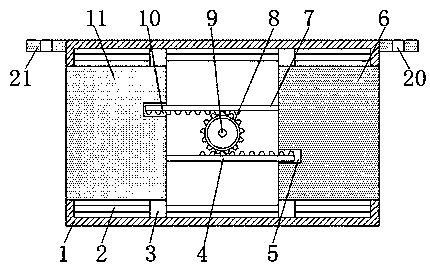

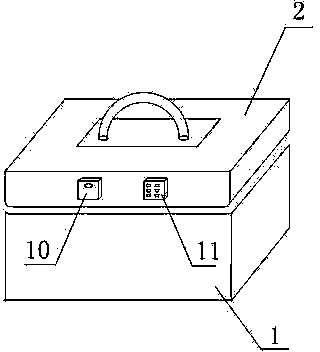

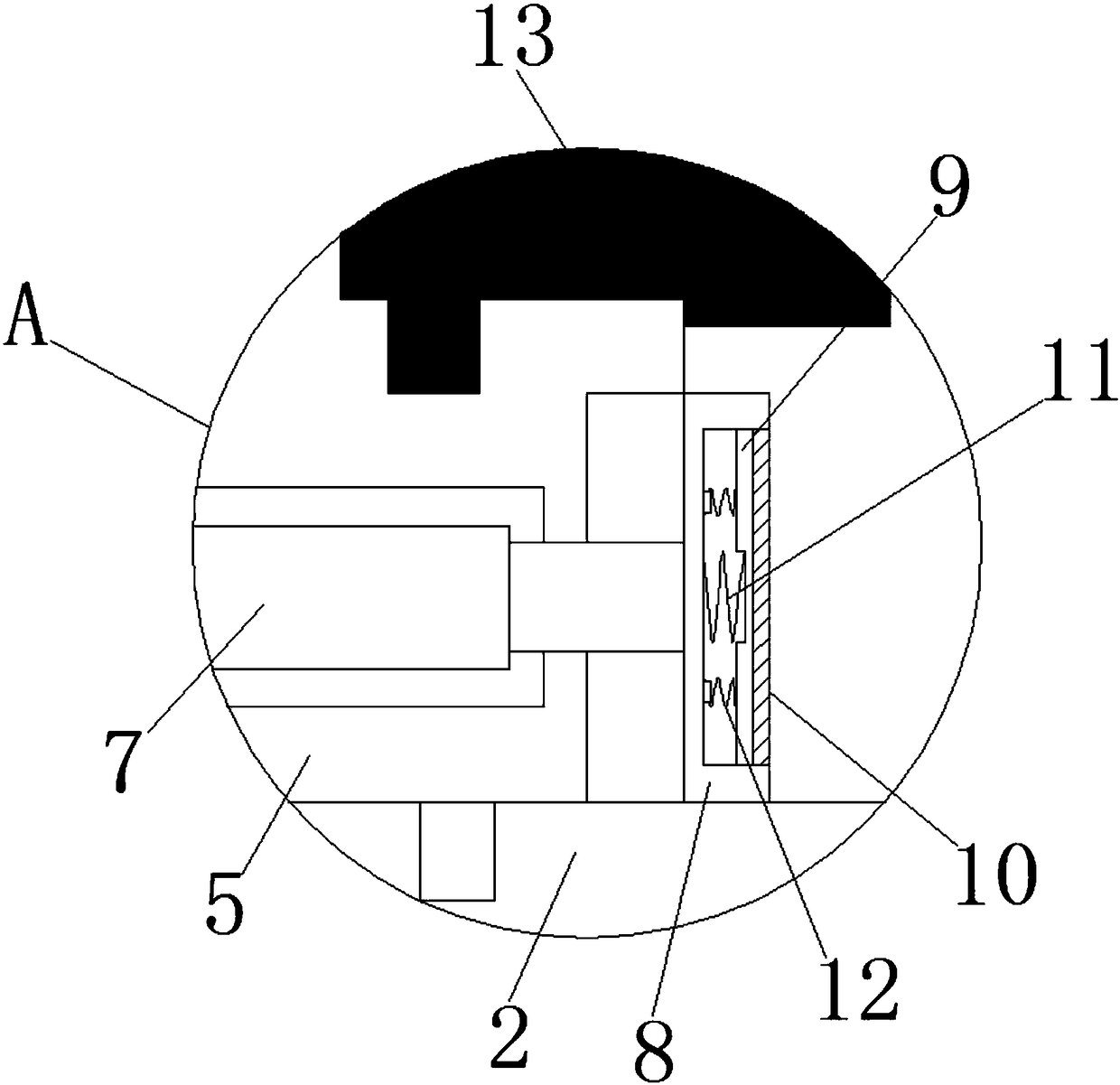

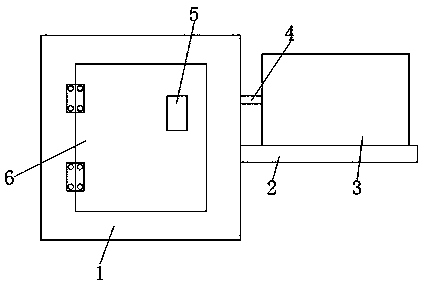

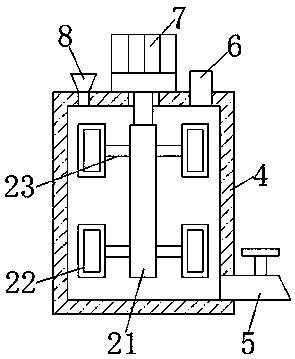

Intelligent fingerprint password lock

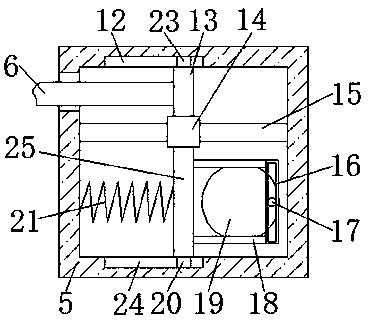

InactiveCN104376622ARealize functionPlay a limiting roleNon-mechanical controlsElectric permutation locksPasswordComputer science

The invention records an intelligent fingerprint password lock. The intelligent fingerprint password lock comprises a box body, and a box cover hinged with the box body, wherein one side wall of the box cover is of a cavity structure; and a cuboid groove is formed in the upper end of one side wall of the box body. The intelligent fingerprint password lock also comprises a lock body arranged in the cavity structure, wherein the lock body comprises a gear and a rack bar meshed with the gear; and the tail end of the rack bar is of a conical structure. The intelligent fingerprint password lock also comprises a sliding rod arranged at the lower side of the rack bar, wherein the upper end of the sliding rod is of a circular truncated cone structure. The intelligent fingerprint password lock also comprises a shell arranged in the cavity structure, wherein the sliding rod is arranged in the shell in a sliding manner; a hole is formed in the shell, and the tail end of the rack bar penetrates through the hole and acts on the upper end of the sliding rod. The intelligent fingerprint password lock also comprises a fingerprint recognition system and a password recognition system which are fixed on the box cover. The intelligent fingerprint password lock has the advantages that due to arrangement of the fingerprint recognition system and the password recognition system, the lock body of a safe box can be unlocked by passwords, and also can be unlocked by fingerprints so as to realize the function of a password and fingerprint integration machine.

Owner:CHENGDU LIBANG TECH

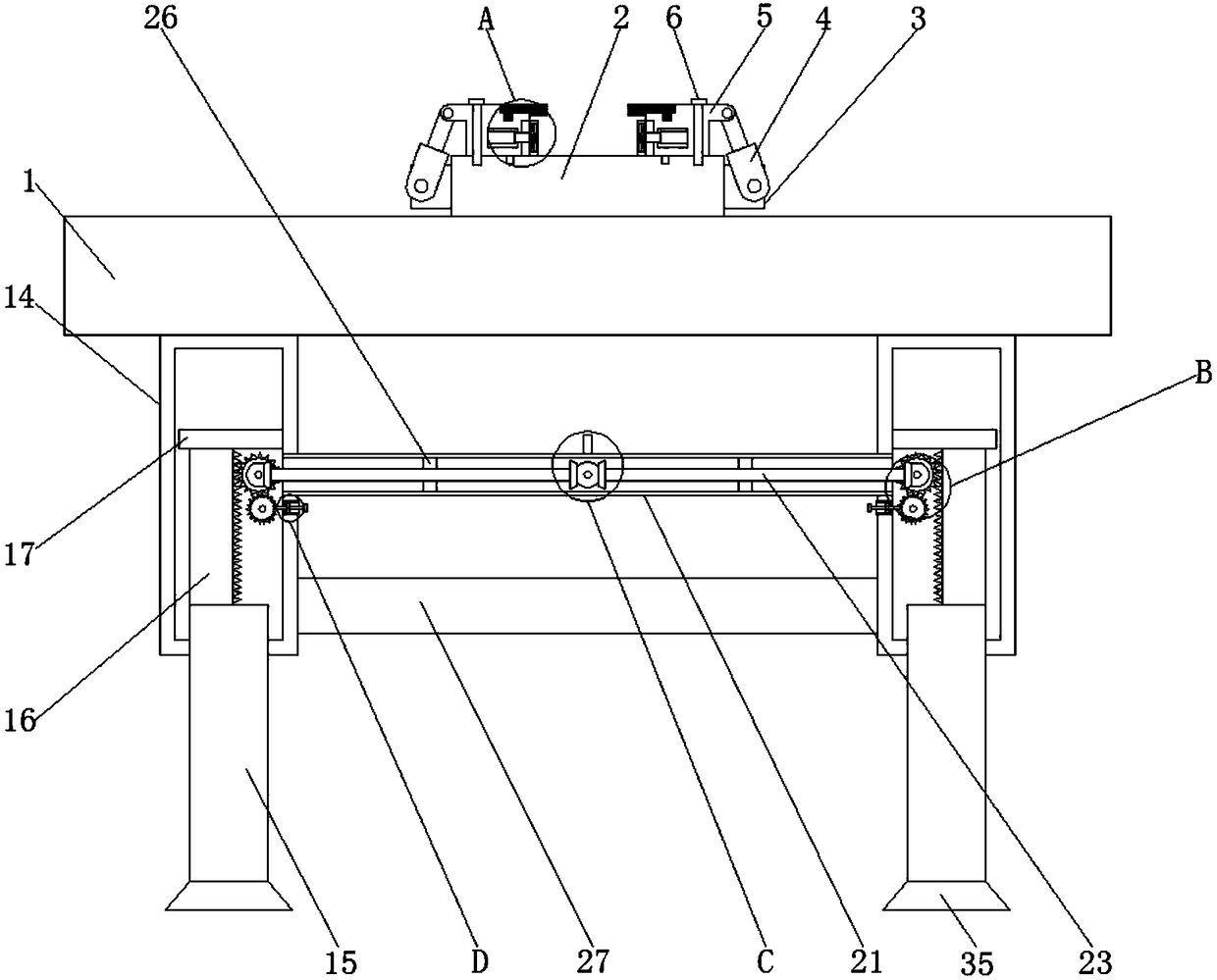

Lifting table

ActiveCN105901942BSimple structureIncreased load-bearing capacityOffice tablesVariable height tablesLocking mechanismGas spring

The invention discloses a lifting working platform. The lifting working platform comprises a lifting working platform body, wherein the lifting working platform body comprises a table board, an upper support, a lower support and at least one set of X-shaped lifting mechanism, and the table board is fixedly connected to the top of the upper support. Each set of X-shaped lifting mechanism comprises a first support rod and a second support rod the middle portions of which are hinged to form an X shape, wherein the upper end of the first support rod is hinged to the upper support, the lower end of the first support rod is hinged to a first sliding block, and the first sliding block is in sliding fit with the lower support; the lower end of the second support rod is hinged to the lower support, the upper end of the second support rod is hinged to a second sliding block, and the second sliding block is in sliding fit with the upper support. A locking mechanism is arranged on the lower support. Each set of X-shaped lifting mechanism further comprises a gas spring used for counteracting or partially counteracting the load on the upper support. The lifting working platform is simple in structure, and height adjustment is convenient.

Owner:LOCTEK ERGONOMIC TECH CORP

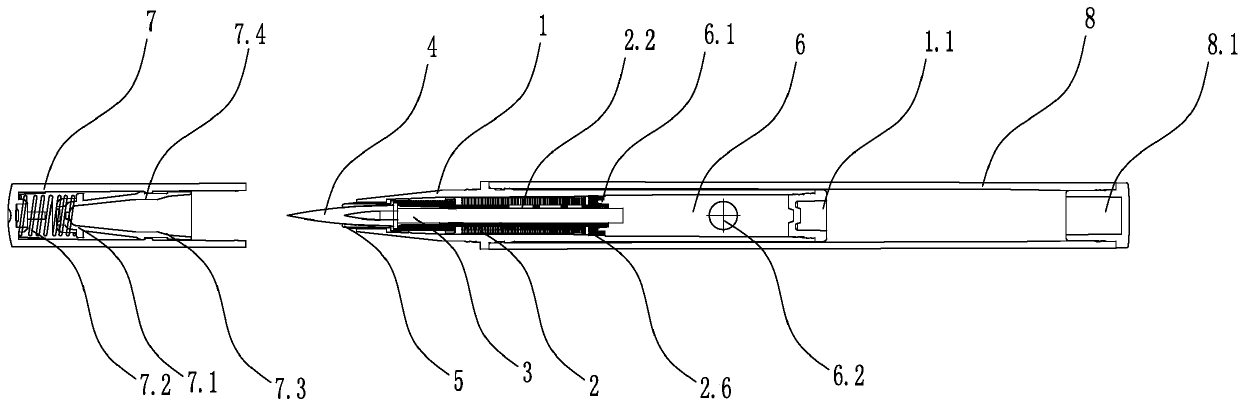

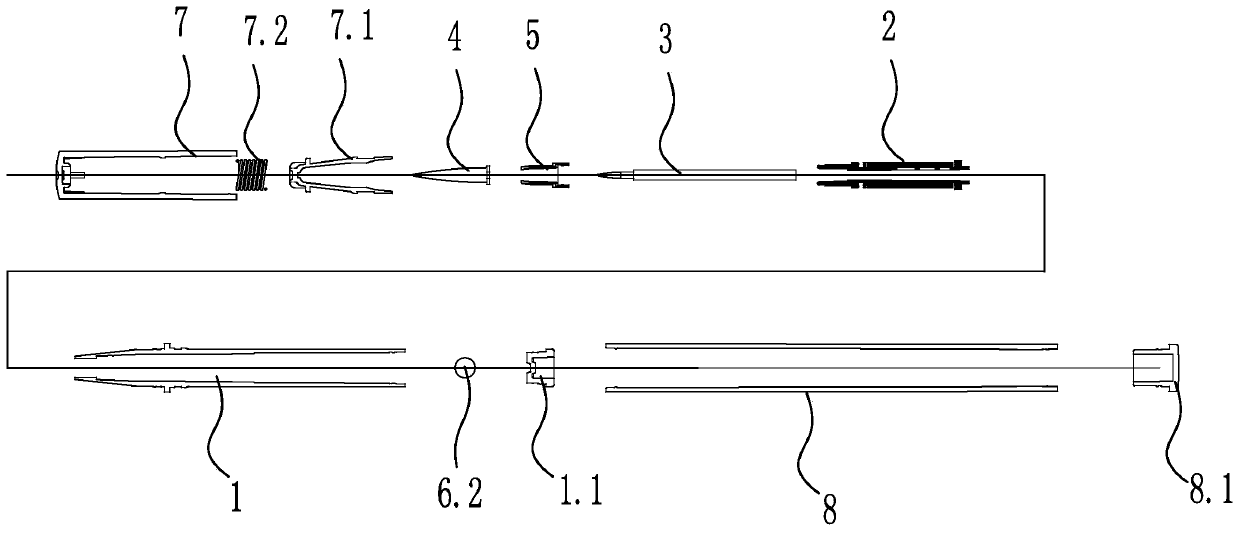

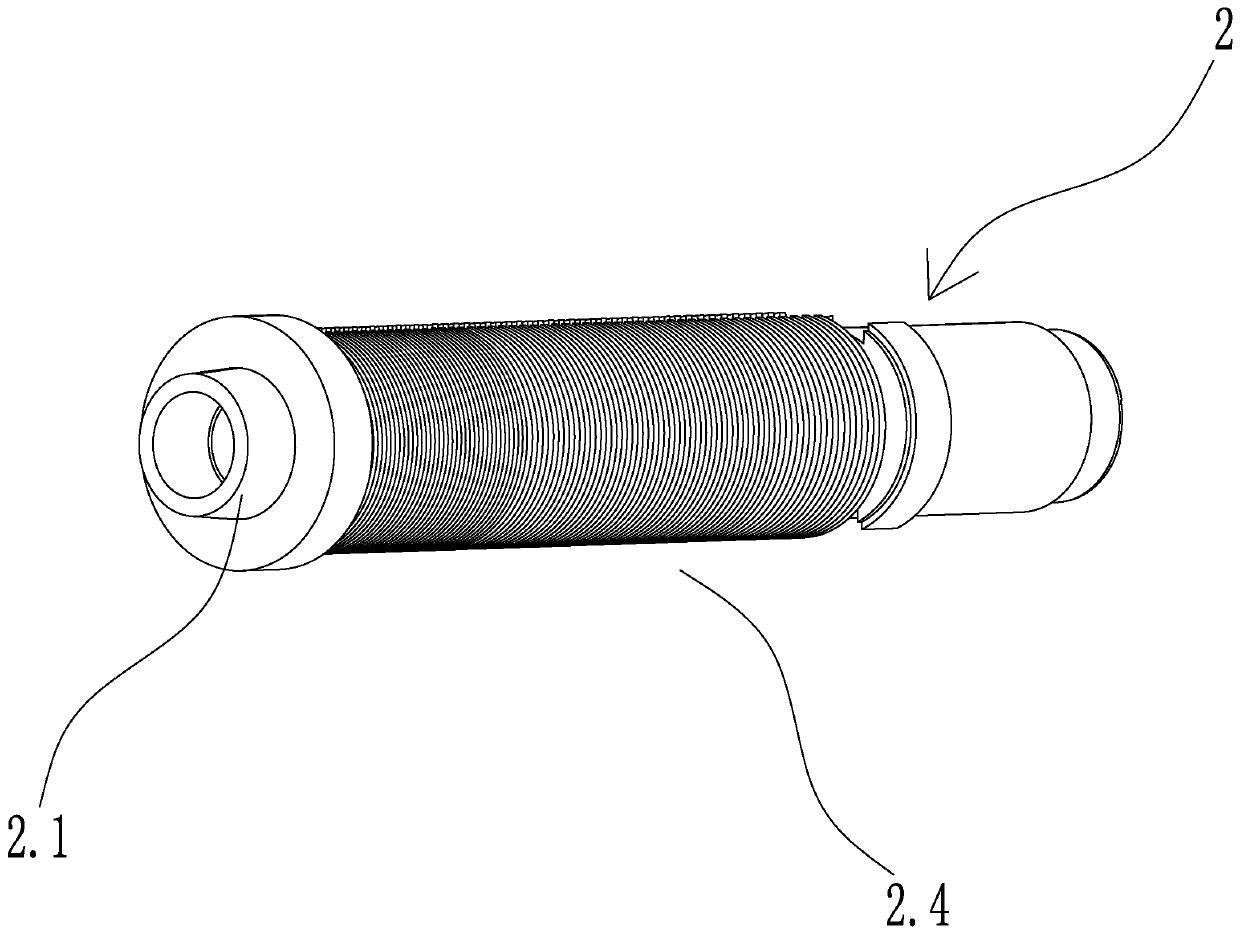

Regulator eyeliner

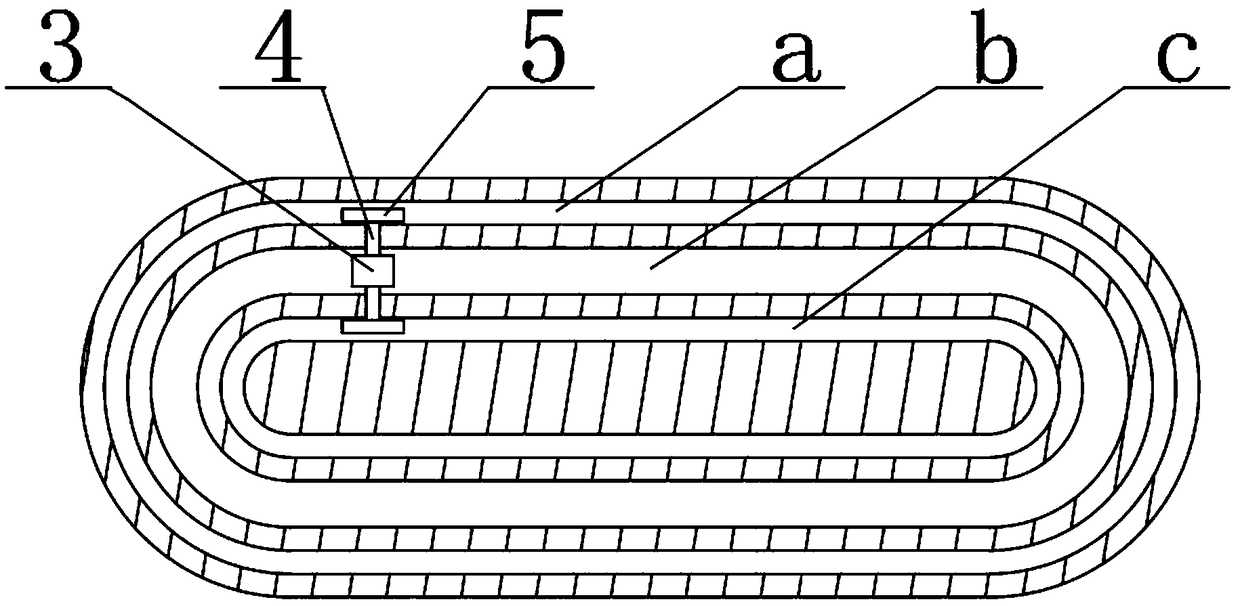

ActiveCN110367680AUniform dischargeEasy to controlBrushesPackaging toiletriesEngineeringCapillary action

The invention discloses a regulator eyeliner. The eyeliner comprises a pen tube, a brush arranged at the front end of the pen tube and used for smearing, a liquid storage cavity used for storing eyeliner liquid, a liquid guide core used for conveying the eyeliner liquid from a liquid guide cavity to the brush, and a regulator used for adjusting the liquid outlet amount of the brush through the capillary action. The regulator comprises a drainage tube. The liquid guide core is arranged in the drainage tube. The regulator eyeliner is characterized in that the side wall of the drainage tube is provided with a regulating channel for communicating the inner and outer side surfaces of the drainage tube, and a regulation area composed of a plurality of spacers arranged on the outer surface of thedrainage tube. The regulation area comprises a plurality of regulation sections with different capillary gravitation at the regulating channel. The capillary gravitation of the regulation sections close to the liquid storage cavity is larger than those of the regulation sections close to the brush. The liquid outlet amount of the eyeliner can be adjusted, so that the liquid outlet amount is uniform. The eyeliner is easy to control by a user.

Owner:NINGBO JIELI COSMETIC PACKAGING

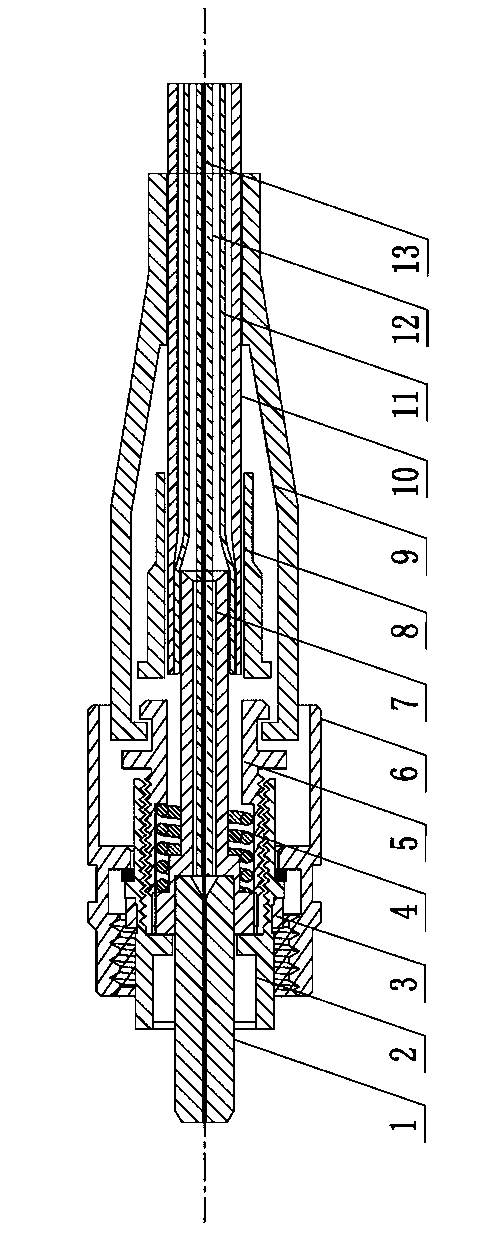

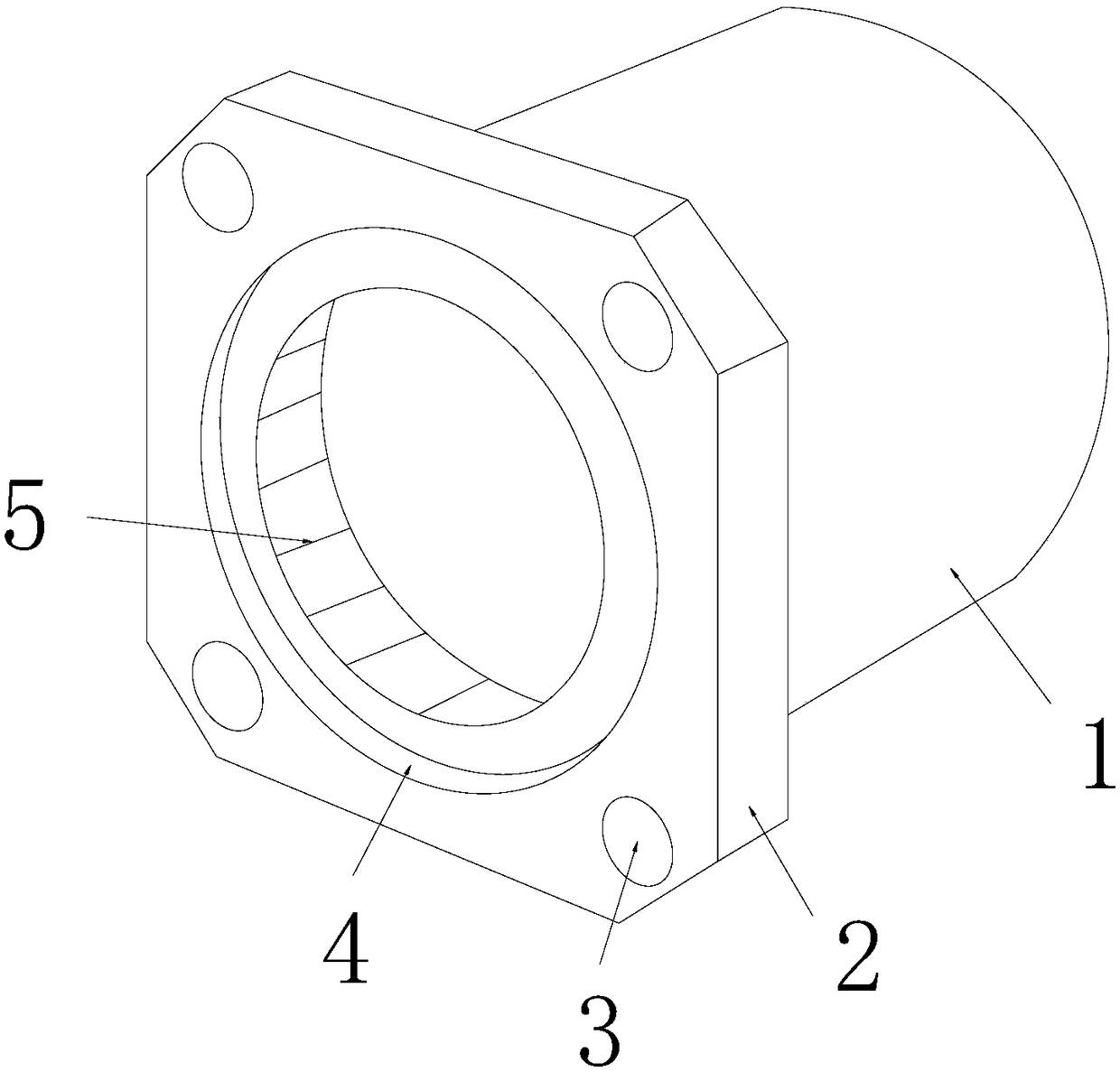

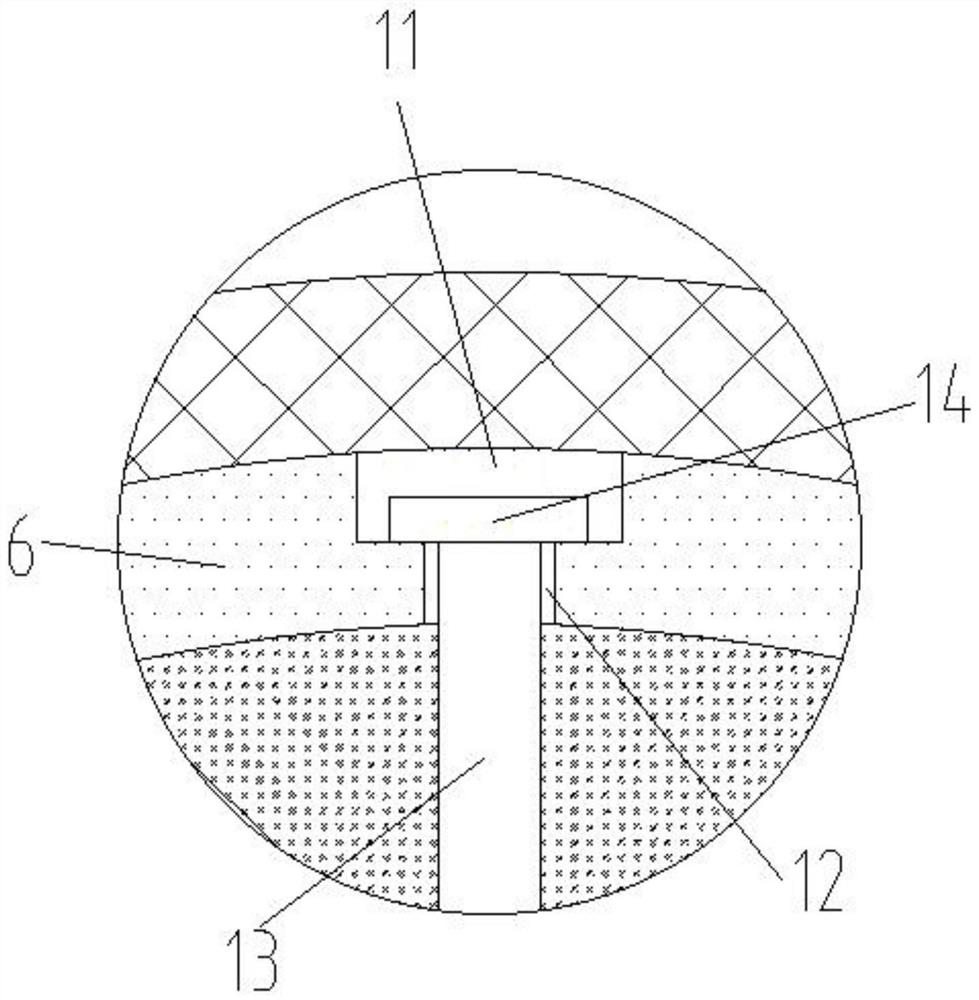

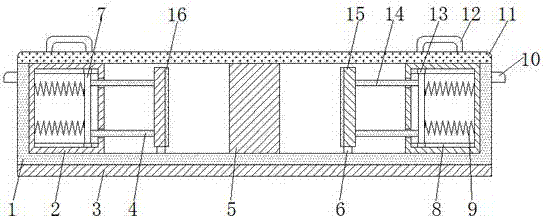

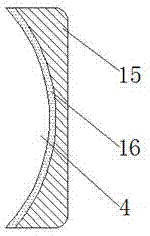

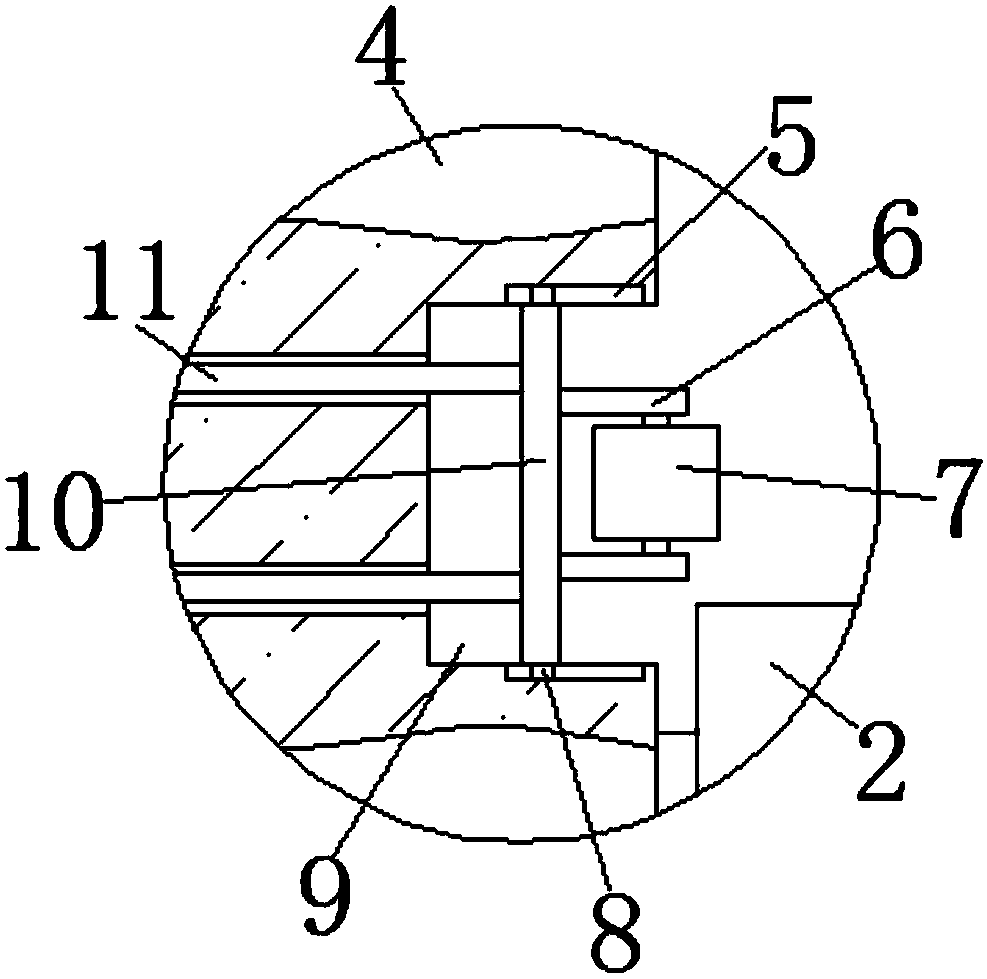

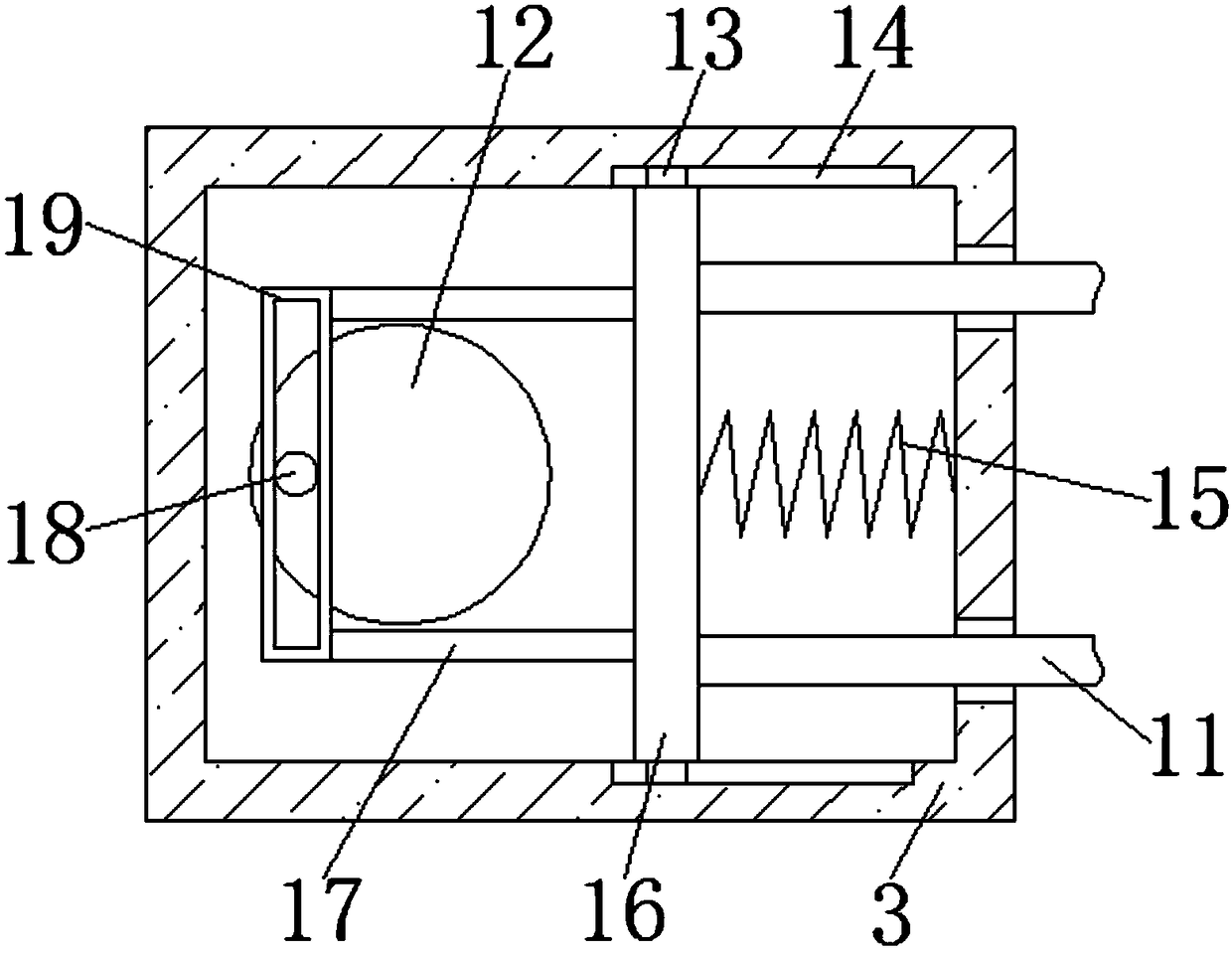

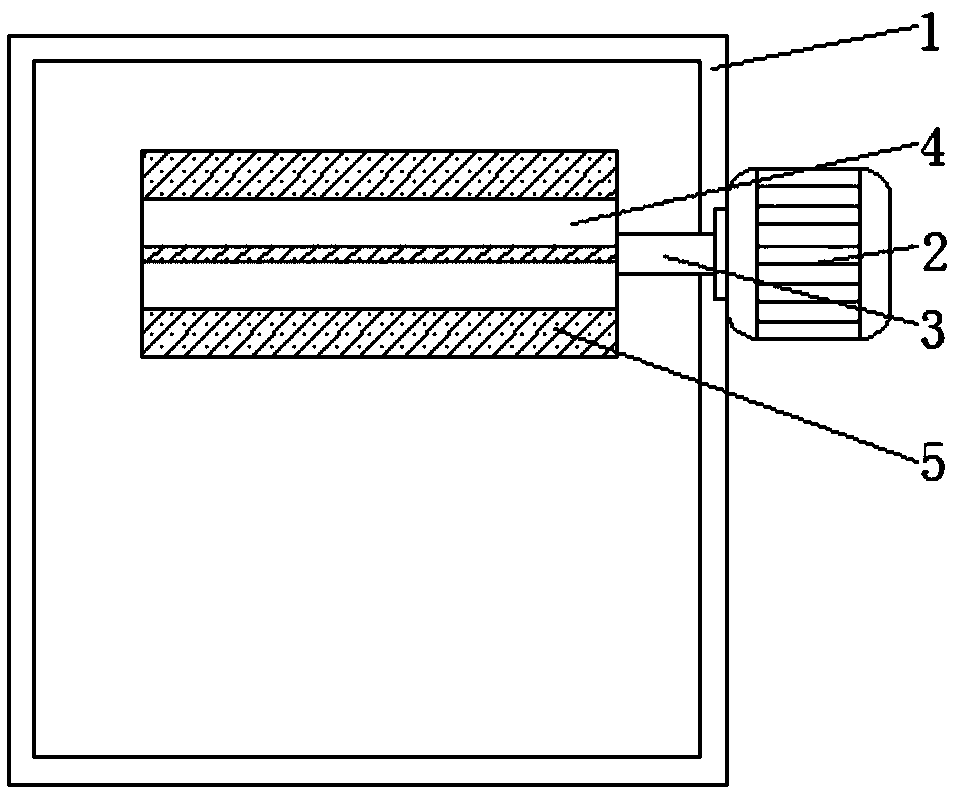

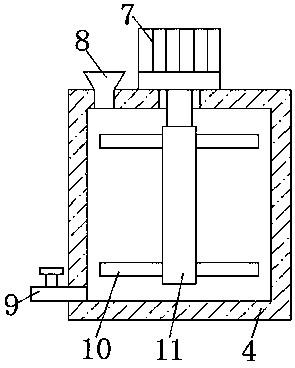

Optical fiber connector capable of moving bodily

ActiveCN103105648AAvoid defects caused by bendingPlay the role of resetCoupling light guidesOptical fiber connectorOptical fiber cable

The invention relates to an optical fiber connector capable of moving bodily. The optical fiber connector capable of moving bodily comprises a ceramic inserting core, a spring, a rear shell, a metal tail handle, a jacket and an optical fiber, wherein the metal tail handle is arranged inside the rear shell in a sleeved mode, the metal tail handle and the rear shell form a sliding pair, the spring is arranged between the metal tail handle and the rear shell in a lamping mode, one end of the metal tail handle is connected with the ceramic inserting core, the other end of the metal tail handle is connected with the jacket, and the metal tail handle is bodily and movably connected with the optical fiber through the jacket. The optical fiber connector capable of moving bodily has the advantages that when the optical fiber connector is in a butting joint mode, the ceramic inserting core connected with one end of the metal tail handle can receive pushing force to cause the metal tail handle to move backward, the spring is compressed, butted optical fibers can move bodily backward under the action of the pushing force of the metal tail handle, the defect generated by bending of the optical fibers caused by the retroposition of the ceramic inserting core under stress is avoided, and when the butting joint is finished, the spring can perform the function of resetting, and the metal tail handle is fixed on a working position through the elasticity of the spring.

Owner:SHENZHEN SDGI OPTICAL NETWORK TECH +1

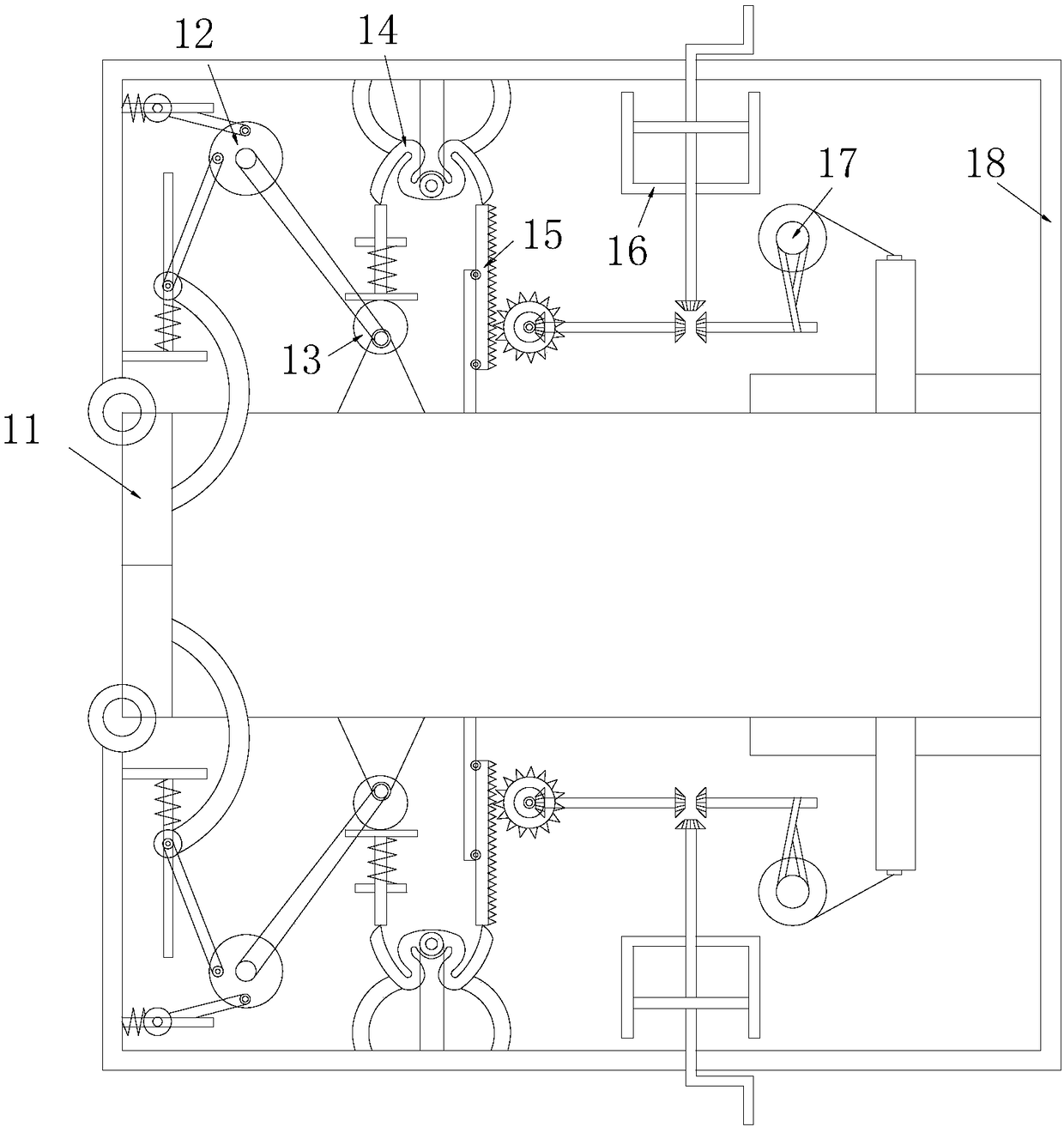

Fiber cotton material distribution process

InactiveCN111893742AAchieve separationQuality improvementMechanical cleaningPressure cleaningFiberAgricultural engineering

The invention relates to the technical field of fiber cotton processing, in particular to a fiber cotton material distribution process. The fiber cotton material distribution process comprises the following steps: S1, placing fiber cotton on material distribution equipment; S2, moving an operation table, so that the to-be-cut position of the fiber cotton is located under a slitting mechanism; S3,operating a lifting mechanism, so that pressing plates are pressed on the two sides of the top of the fiber cotton; S4, operating the slitting mechanism, cutting off the fiber cotton, then enabling the pressing plates to move towards the outer side, and separating the cut fiber cotton through the pressing plates; and S5, operating the lifting mechanism, enabling the pressing plates to rise and a wool collecting roller to make contact with the surface of the fiber cotton, moving the operation table, and enabling the wool collecting roller to make uniform contact with the surface of the fiber cotton so as to remove cotton fiber on the surface of the fiber cotton. Through ingenious arrangement of the pressing plates and the wool collecting roller, the fiber cotton is firstly pressed and slit,then an adjustable top seat is used in cooperation to separate a measuring pressing plate, separation of the fiber cotton is achieved at the same time, finally the wool collecting roller is ingeniously put down to remove impurities and dust from the fiber cotton, and high-quality fiber cotton can be obtained.

Owner:淮南德元化工科技有限公司

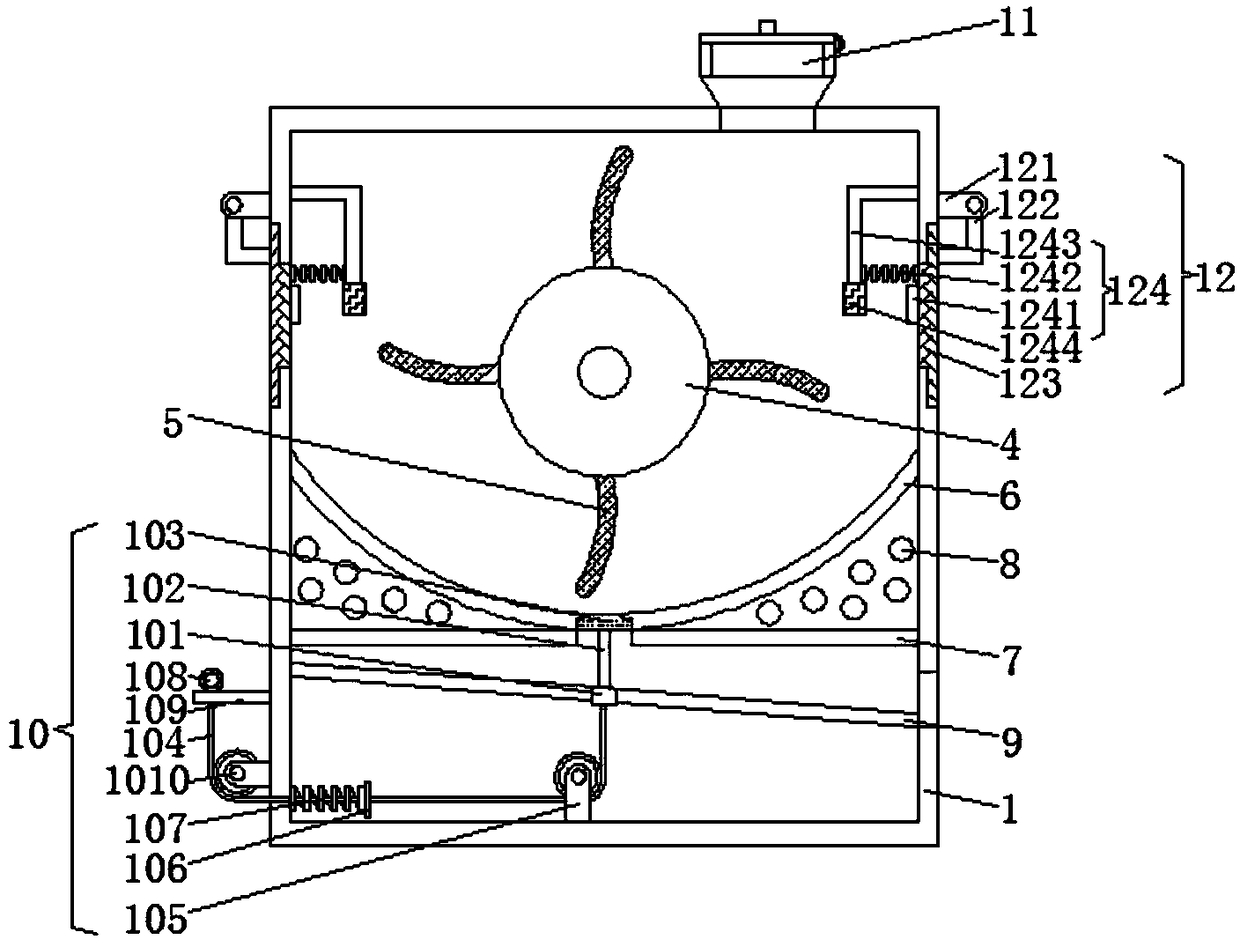

Intelligent feed grinding device

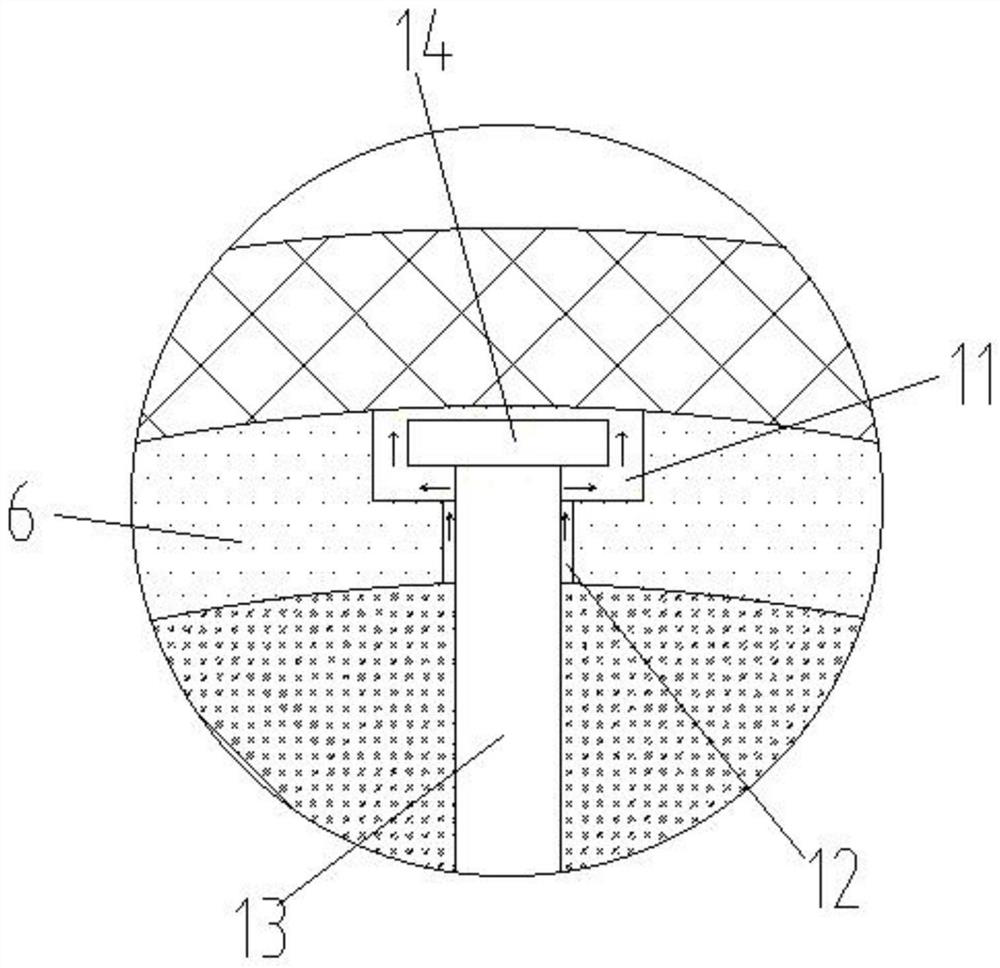

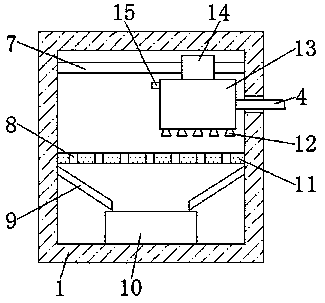

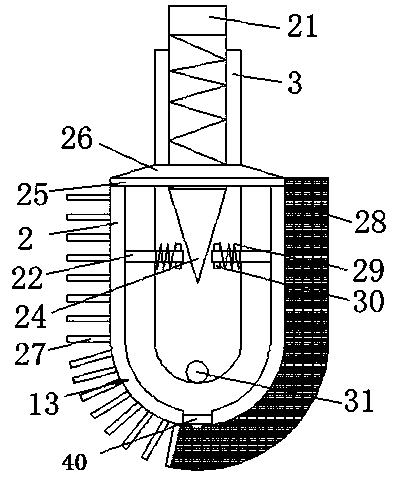

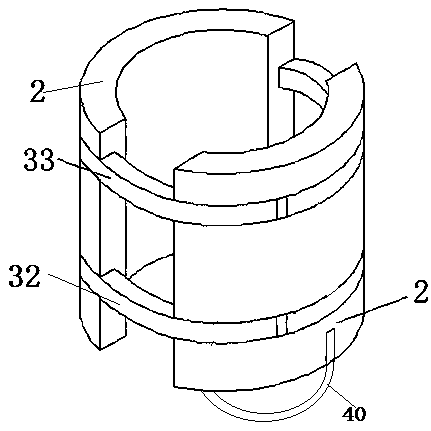

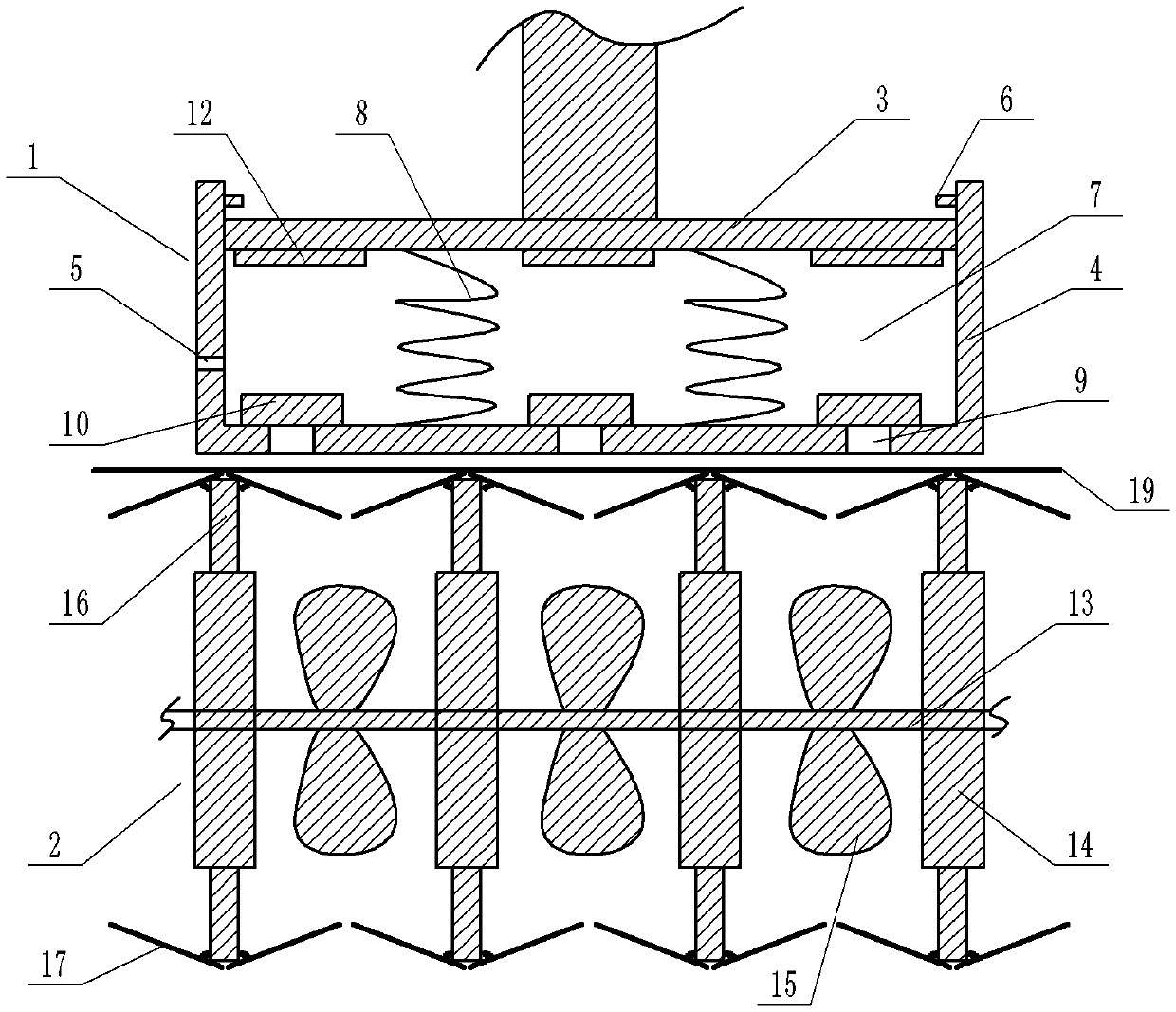

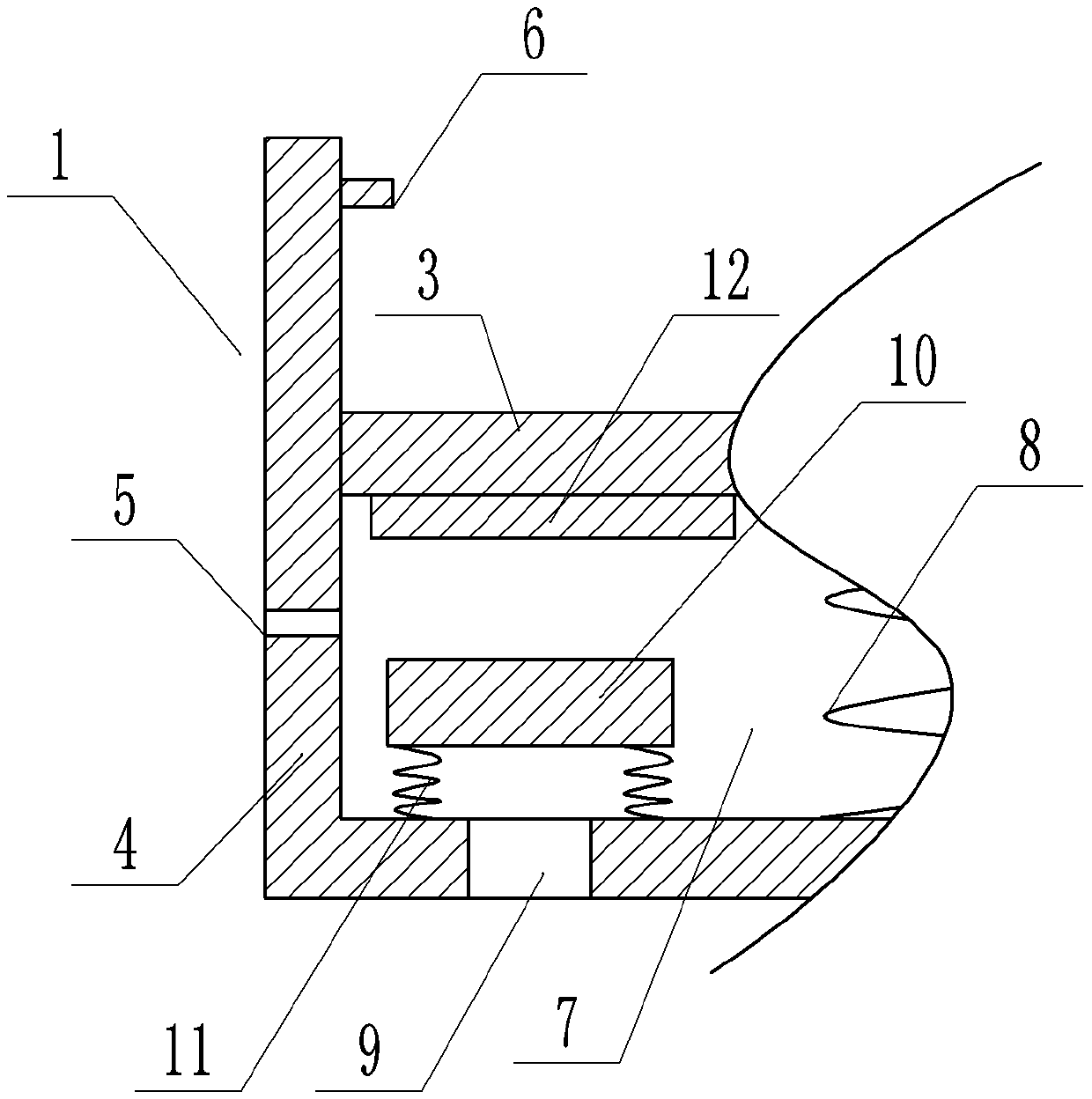

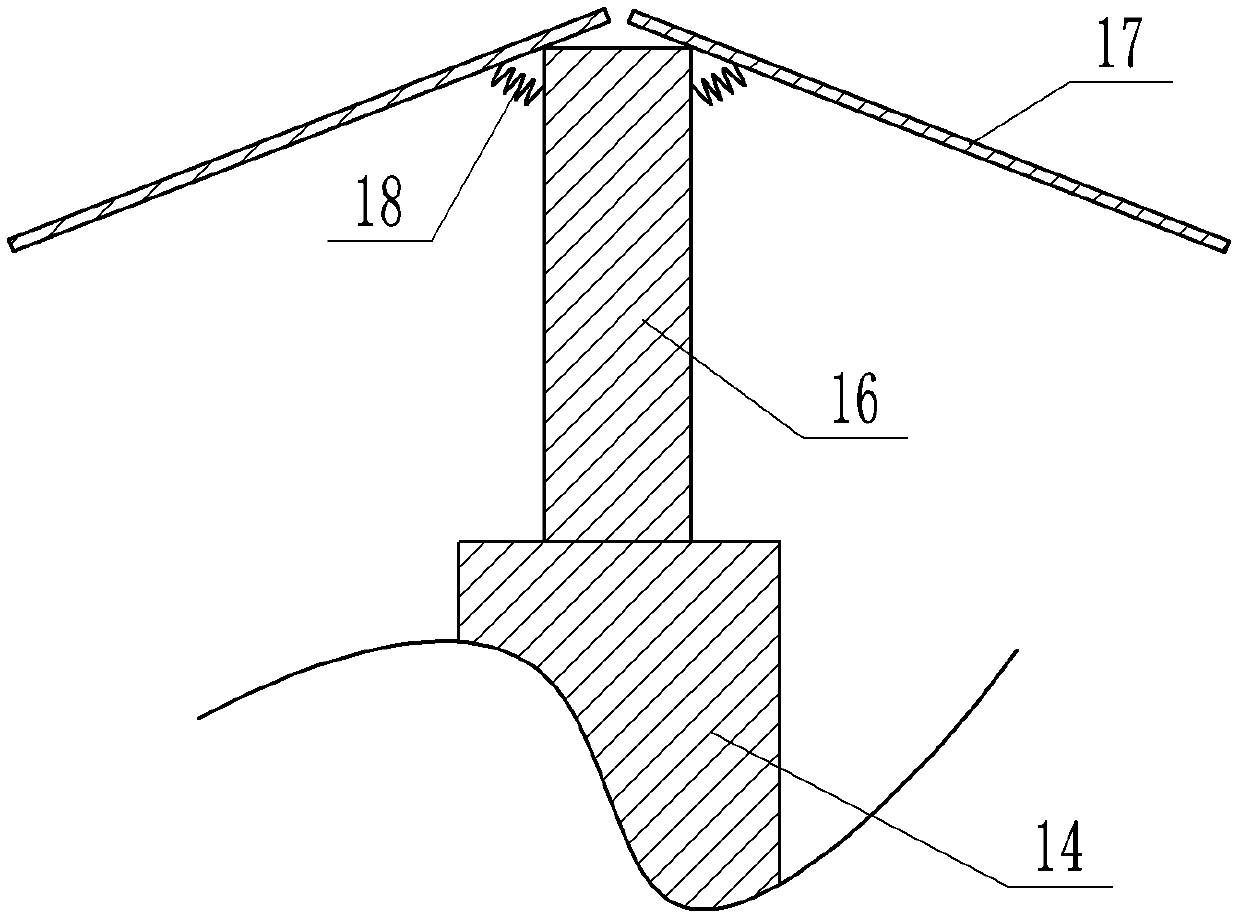

InactiveCN110449203AThere will be no jammingPlay the role of resetFeeding-stuffGrain treatmentsEngineeringSlide plate

The invention discloses an intelligent feed grinding device which comprises a first box body. A second box body is arranged below the first box body, the top of the second box body is fixedly connected with the first box body through a supporting rod, a conveying device is arranged between the first box body and the second box body, a feeding port is formed in the top of the first box body, a distributing box is arranged inside the first box body, a stirring wheel is arranged inside the distributing box, a stirring blade is arranged on the stirring wheel, a transverse plate is arranged insidethe first box body, the transverse plate is located below the distributing box, a pushing member is arranged on the upper surface of the transverse plate, one side of the transverse plate is fixedly provided with a sliding plate, the bottom of the first box body is provided with a discharge opening, and the bottom end of the sliding plate is located above the discharge opening. The intelligent feed grinding device can screen feed after the feed is ground, the feed which does not reach the standard is sorted, and blockage of the feed in the grinding process is avoided.

Owner:邳州市小河科技发展有限公司

Pipeline flange joint device for petroleum refining

InactiveCN108561646AReduce lossesPlay a role in boostingFlanged jointsJoints with fluid cut-off meansPetroleumFlange

The invention discloses a pipeline flange joint device for petroleum refining, which comprises a sealing adjusting device, a connecting disc, a positioning hole, a rubber sealing ring and a flange plate, wherein the sealing adjusting device is electrically welded on the right side of the connecting disc and is vertical to each other, the four positioning holes are embedded in the four corners of the surface of the connecting disc and are connected to each other, the rubber sealing ring is arranged at the inner side of the positioning hole and is adhesively connected with the surface of the connecting disc, the flange plate is arranged behind the rubber sealing ring and is welded with the connecting disc. The pipeline flange joint device for petroleum refining adopts a closed adjusting device provided, seals the two ends of the pipeline together when there is no petroleum transmission is carried out, temporarily closes the two ends of the pipeline when petroleum is transferred by petroleum transmission device while staffs operating the device, so that the two ends of the pipeline are closed and separated, thereby the refined petroleum cannot be transferred temporarily, and the lossof petroleum leakage and other accidents could be reduced.

Owner:柯永华

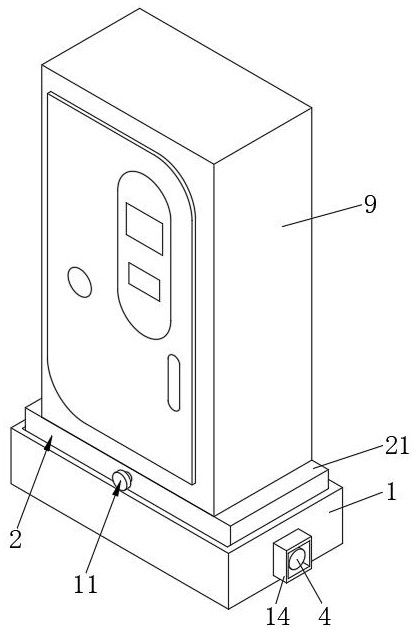

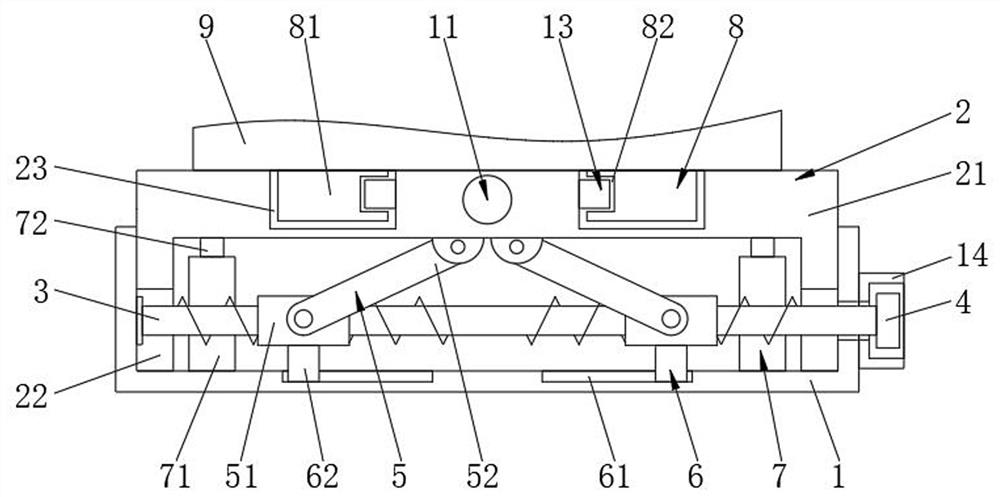

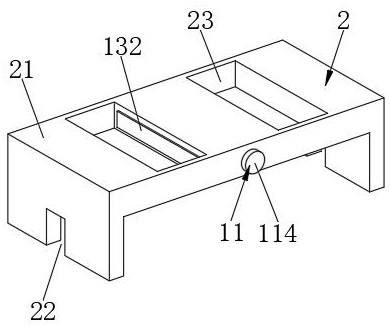

New energy automobile charging pile mounting structure

InactiveCN112319285AEasy to installEasy to prevent standing waterCharging stationsElectric vehicle charging technologyElectrical and Electronics engineeringNew energy

The invention discloses a new energy automobile charging pile mounting structure, and the structure comprises a mounting base and a charging pile body; a placement mechanism is arranged in an inner cavity of the mounting base, a bidirectional threaded rod is movably connected to the left side of the inner cavity of the mounting base through a bearing, and opposite threads are arranged on the surface of the bidirectional threaded rod. The two mounting blocks are placed in the inner cavities of the two mounting grooves correspondingly, the second knob is rotated, the second knob finally drives the second wedge block to enter the inner cavity of the strip-shaped groove to lock the two mounting blocks, and the first knob and the first knob are rotated to finally drive the mounting frame and the charging pile body to ascend, so that the purposes of convenient mounting and water accumulation prevention are achieved; the new energy automobile charging pile installation structure has the advantages of being convenient to install and capable of preventing water accumulation, cement does not need to be adopted for pouring, the function of rapid disassembly and assembly is achieved, the lifting height of the charging pile can be conveniently controlled according to the installation position, and the charging pile is not prone to being soaked by accumulated water.

Owner:郭连坤

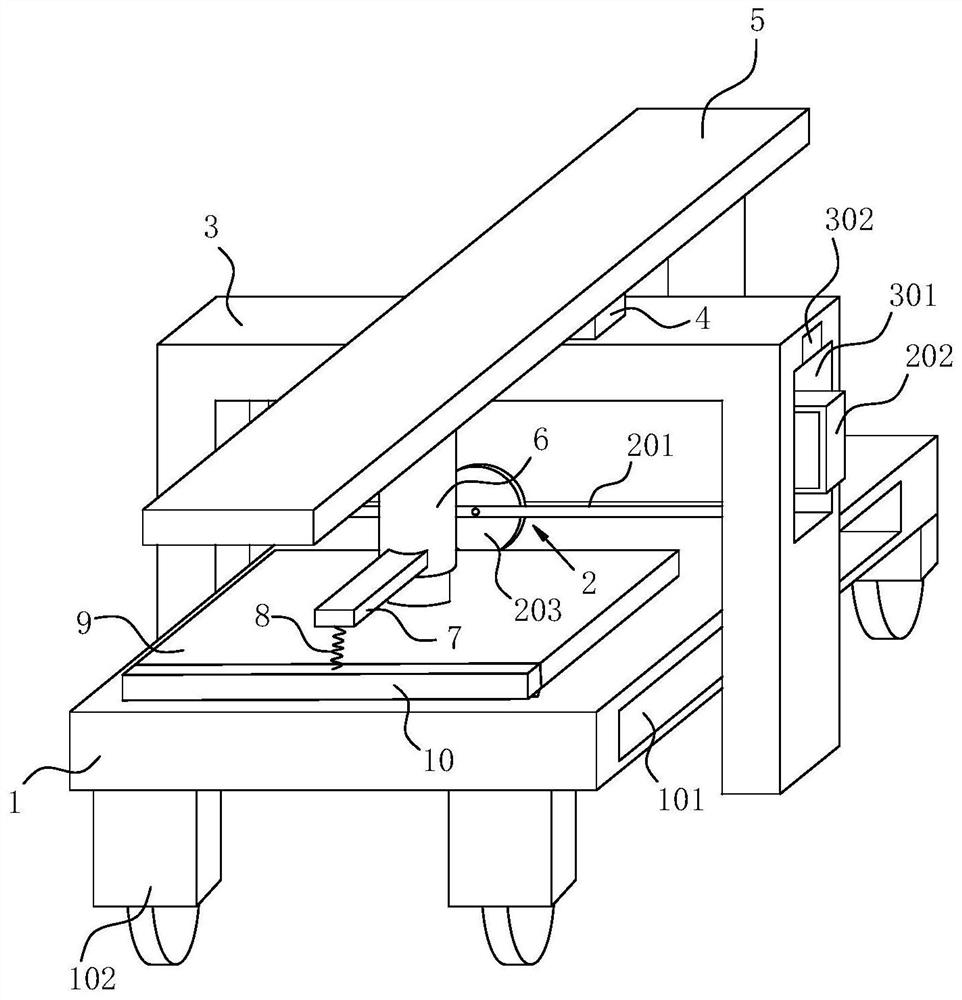

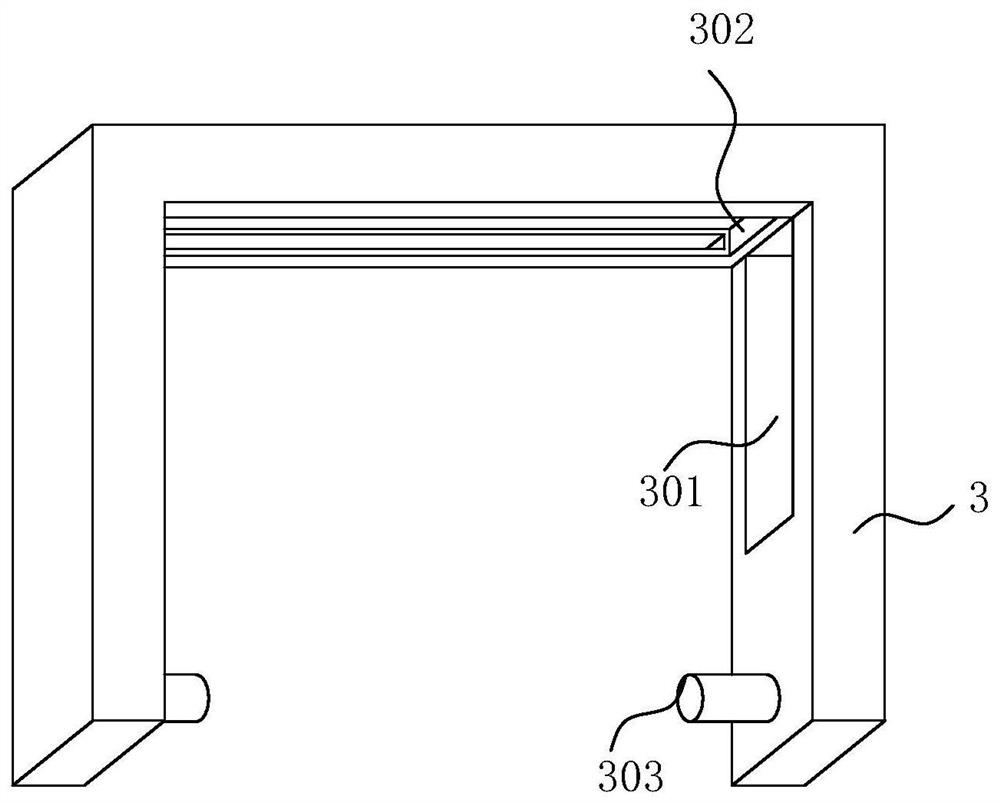

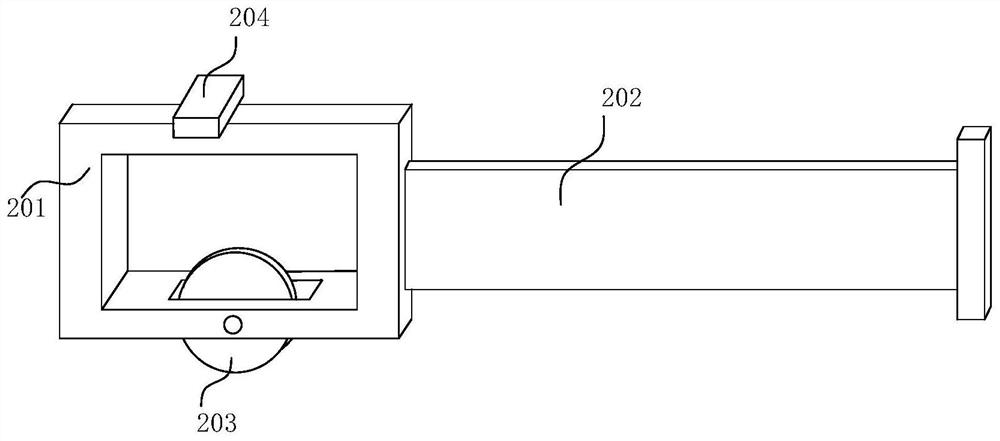

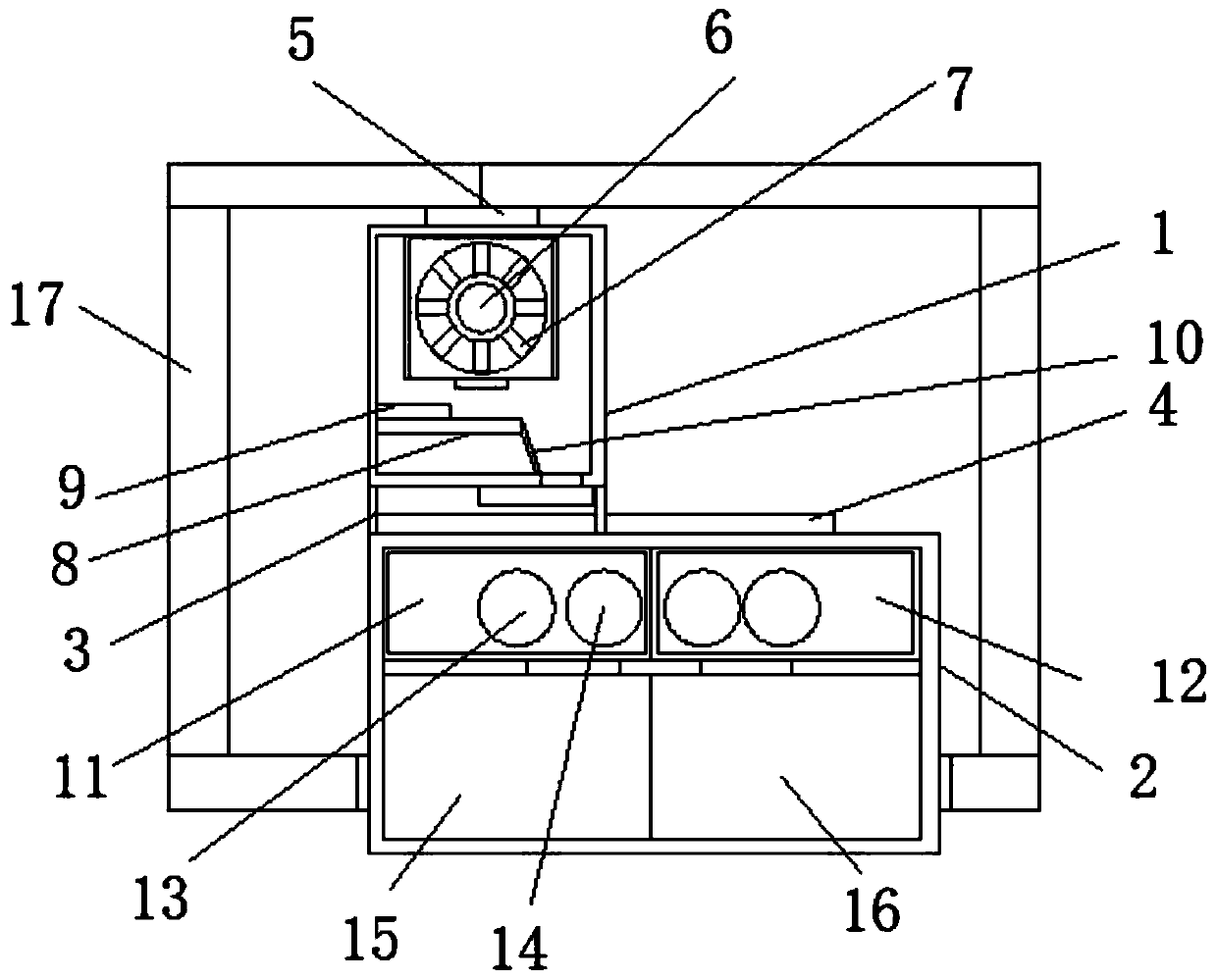

Machining table for hardware fitting

The invention provides a machining table for hardware fitting, relating to the field of hardware fitting manufacture equipment. The machining table for hardware fitting comprises a workbench, whereina placement plate is fixedly arranged at the top of the workbench, two fixed blocks are fixedly arranged at two sides of the placement plate respectively, a connecting rod is movably arranged betweenthe two fixed block by a middle shaft; a fixture block is movably arranged at one end, far away from the fixed block, of the connecting rod by the middle shaft; a fixed rod is arranged at the top of the fixture block, and the bottom end of the fixed rod runs through the top of the fixture block and extends into the placement plate. According to the machining table for hardware fitting, the hardware fitting is clamped by the matched application of the fixture block and a splint, and is extruded into the splint by a push plate, so that a spring is extruded to generate an outward thrust to push the push plate to tightly cling to a part, and therefore, the clamping effect is improved, and part loosening or sliding is avoided; the machining table can be applicable to parts of different sizes bythe stretching of a push rod, so that the practicability of the machining table is improved.

Owner:新昌县盛南建材有限公司

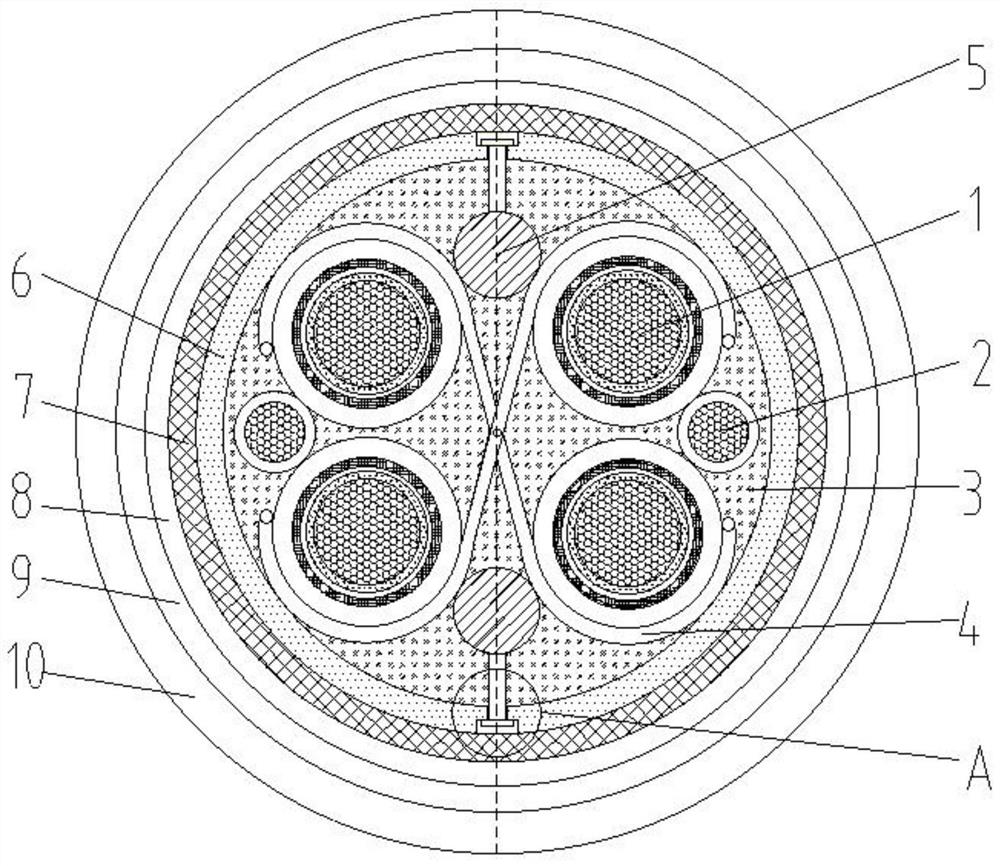

High-temperature-resistant photovoltaic cable suitable for salt spray environment

ActiveCN111799023AImprove protectionImprove impact resistanceFloating cablesPower cables including optical transmission elementsElectric cablesMetal mesh

The invention discloses a high-temperature-resistant photovoltaic cable suitable for a salt spray environment. The cable comprising a cable body, and the cable body comprises a cable core and a cablesheath. The special-shaped support is composed of two staggered fixed supports of an S-shaped structure. Wires are embedded in the arc-shaped parts of the two end parts of each fixing support; opticalfiber units attached to the tops of the two adjacent wires are arranged between the arc-shaped parts of the tops of the two fixed supports. Two lifting bodies are respectively arranged at the intersection of the two fixed support; the cable sheath sequentially comprises a wear-resistant layer, a heat conduction layer, a hydrophobic layer and an outer protective layer from inside to outside. A metal net-shaped body is arranged between the wear-resistant layer and the heat conduction layer; and a heat dissipation mechanism is arranged in the wear-resisting layer and comprises a heat dissipationgroove formed in the wear-resisting layer, a lifting rod fixed to the top end of the lifting body and a sealing gasket matched with the heat dissipation groove, the cable has high pressure-resistanceperformance, and the heat dissipation effect can be improved through the heat dissipation mechanism under the action of external impact force.

Owner:ANHUI LINGYU CABLE TECH +1

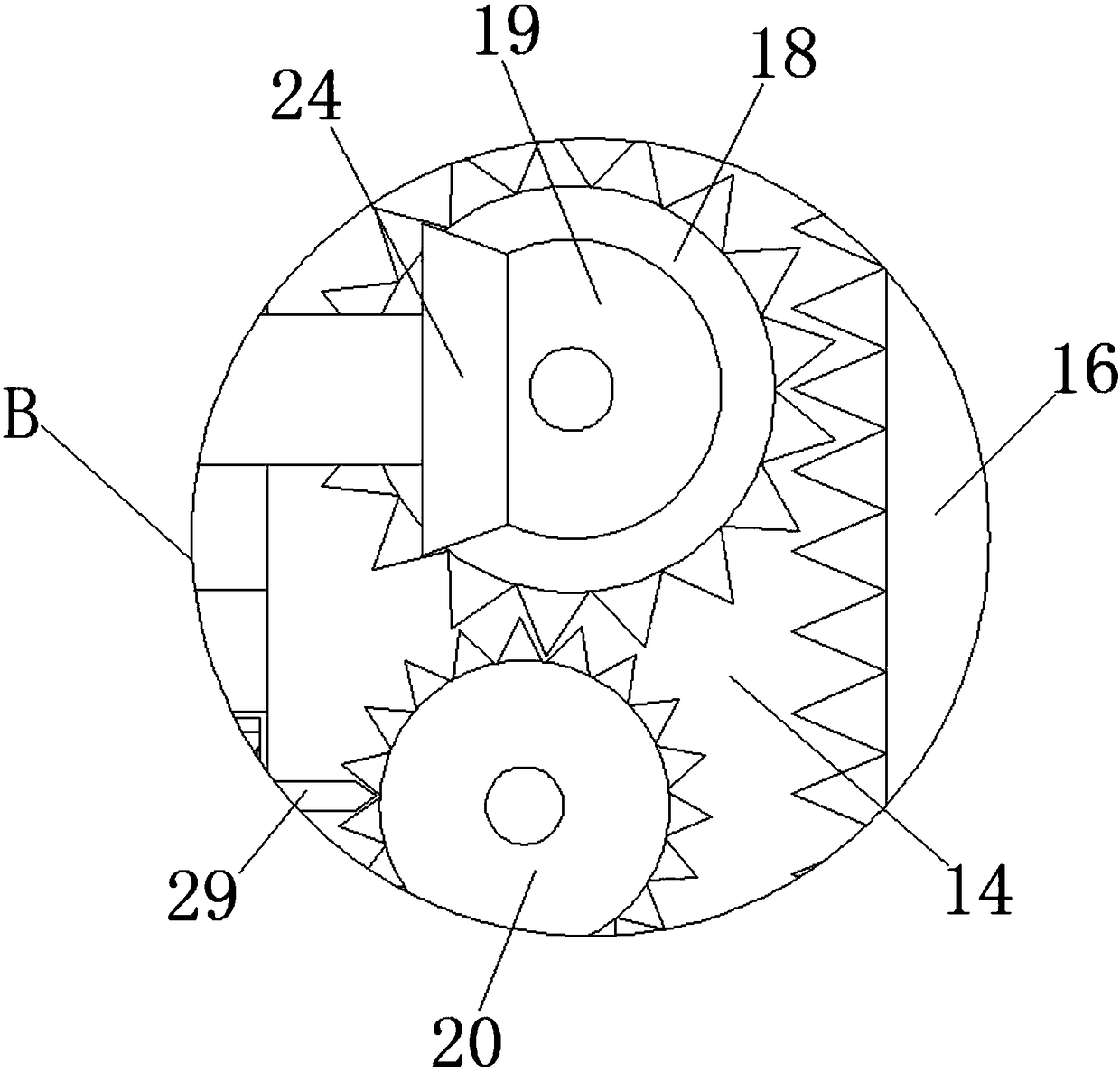

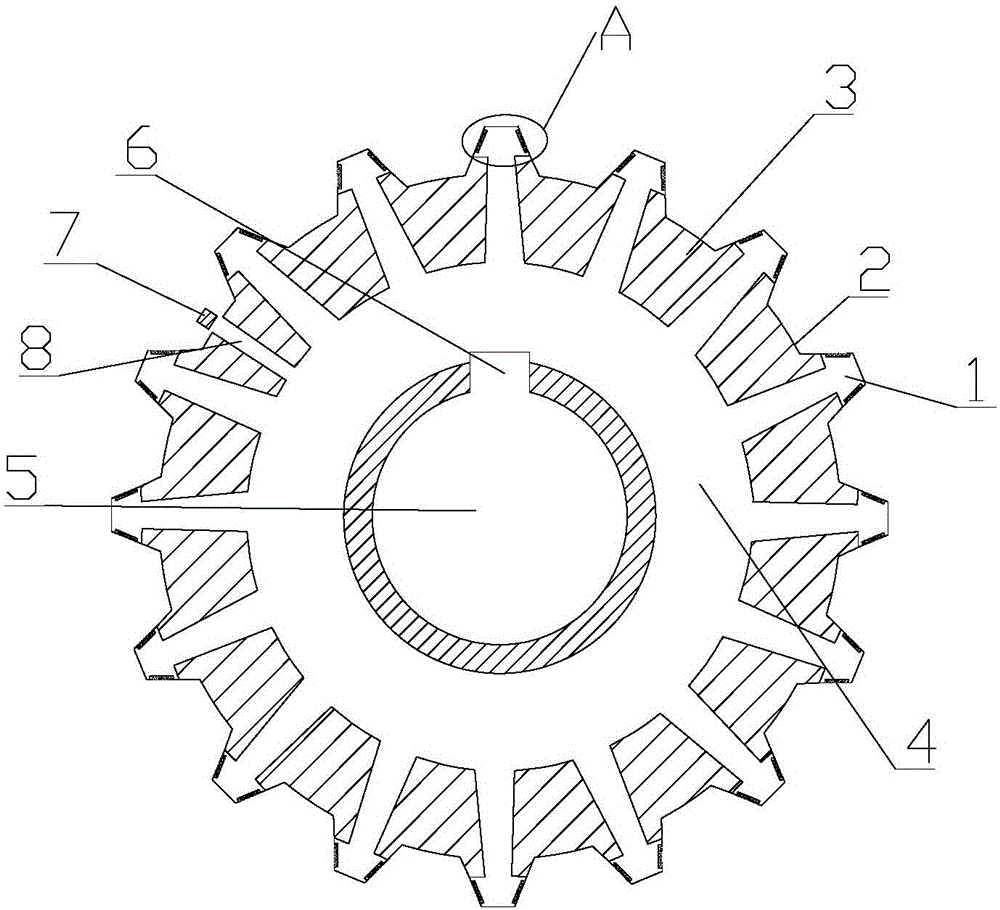

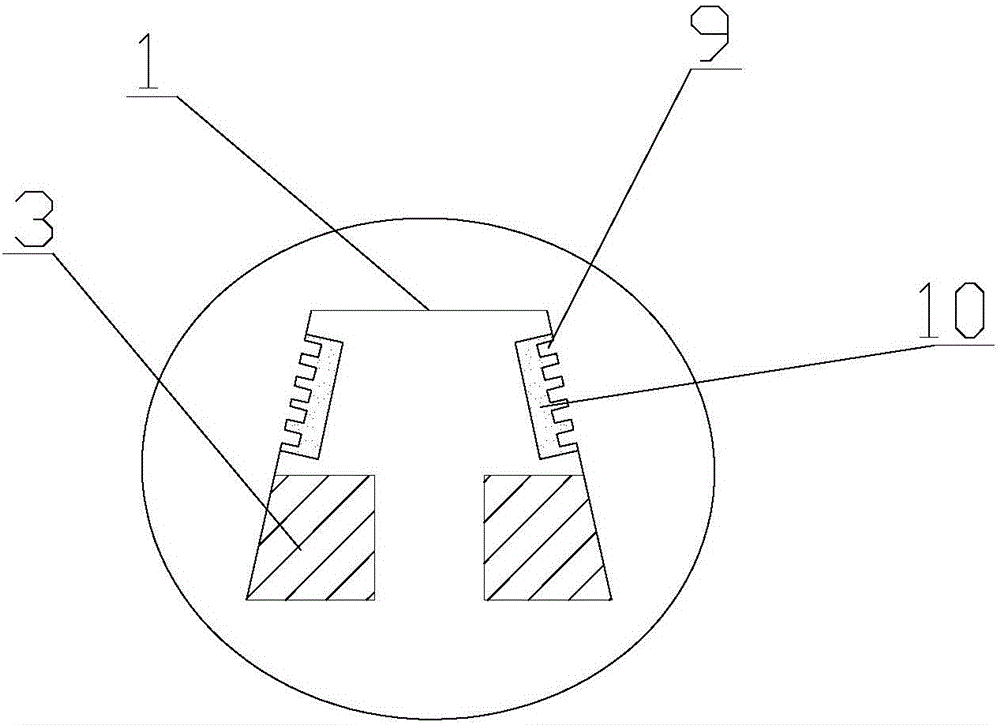

Noise elimination gear

InactiveCN105782398APlay the role of resetReduce noiseGear lubrication/coolingPortable liftingDamping functionNoise reduction

The invention discloses a noise elimination gear which comprises a gear body, and further comprises elastic gaskets, wherein gear teeth are arranged on the outer profile of the gear body; tooth grooves are formed between the adjacent gear teeth; a shaft hole is formed in the center of the gear body; a keyway is formed in the inner wall of the shaft hole in the radial direction of the gear body; straight holes with the same size as the elastic gaskets are formed in the outer surfaces of the two sides of the gear teeth; the elastic gaskets are embedded in the straight holes in the two sides of the gear teeth; and the outer surfaces of the elastic gaskets are flush with the outer surfaces of the gear teeth. According to the noise elimination gear, the structure is novel, the design is reasonable, and the elastic gaskets are arranged on the gear teeth, so that when two gears are mutually meshed for operation, and when the gear teeth are in contact with each other, the elastic gaskets can exert a reset function, the nose generated during gear transmission can be reduced, the vibration damping function is achieved, and the noise reduction effect is achieved.

Owner:李志聪

Color spray device used for textile fabric

InactiveCN107904810ASolve the problem of uneven spray colorImprove dyeing efficiencyTextile treatment containersTextile treatment machine arrangementsInsertion stentAgricultural engineering

The invention discloses a color spraying device for textile fabrics, which comprises a box body, the inner cavity of the box body is fixedly connected with a sliding bar and a placing plate in a horizontal direction from top to bottom, and the surface of the sliding bar is covered with a sliding sleeve , the bottom of the sliding sleeve is fixedly connected with a material box, the bottom of the material box is connected with an atomizing nozzle, and the center of the right side of the material box is fixedly connected with a push rod. The present invention adopts box body, supporting plate, shell, push rod, sliding rod, placing plate, atomizing nozzle, material box, sliding sleeve, baffle plate, movable rod, first bracket, electric telescopic rod, connecting rod, second The cooperative use of the bracket and the transmission frame solves the problem of uneven color spraying of the existing color spraying device for textile cloth. The color spraying device for textile cloth has the advantage of uniform color spraying, which speeds up the development The dyeing efficiency brings great convenience to users, improves the practicability of the color spraying device for textile fabrics, and is worth popularizing.

Owner:苏州旺谦纺织科技有限公司

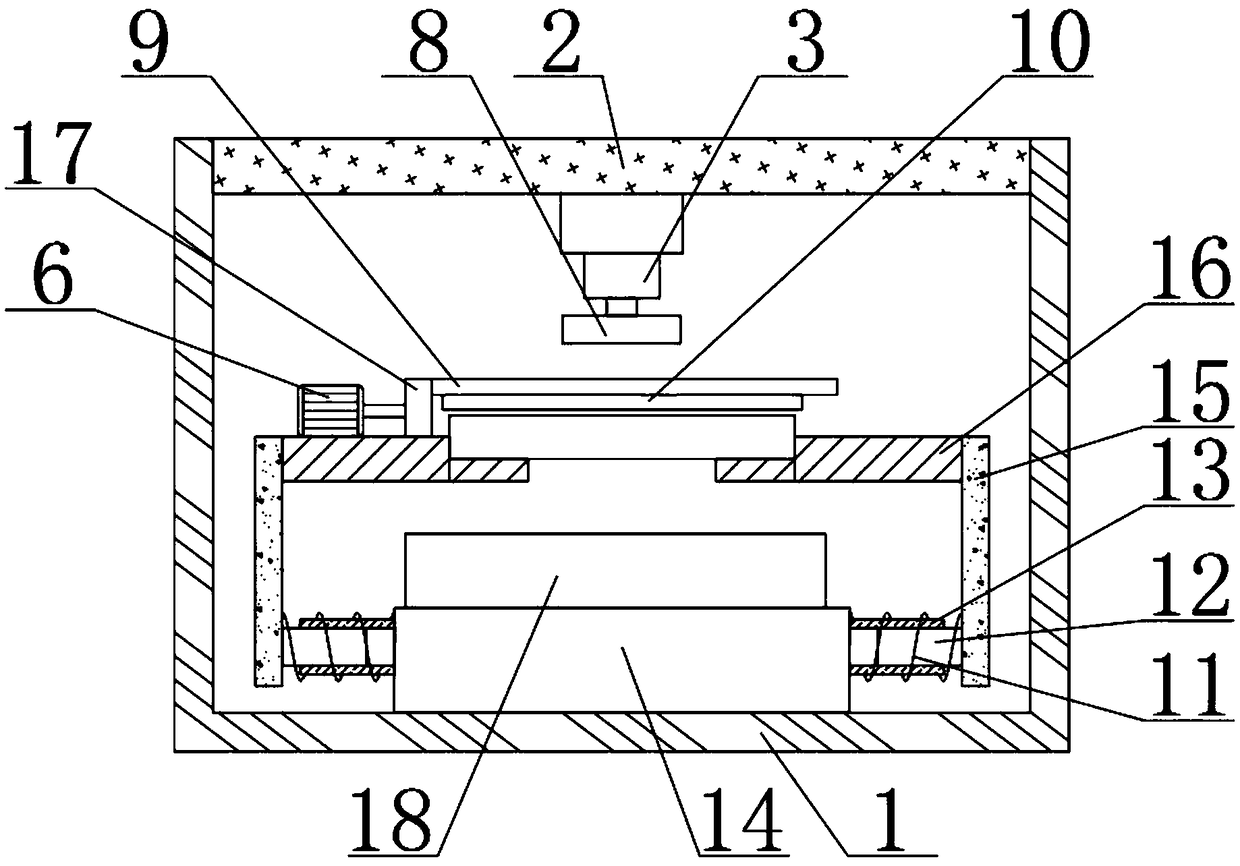

Plate polishing device for manufacturing of electric fire box

InactiveCN109227336AClampPlay the role of resetPolishing machinesGrinding drivesEngineeringWood panel

The invention relates to the technical field of polishing, in particular to a plate polishing device for manufacturing of an electric fire box. A rail plate is fixedly connected to the inner side of aworking frame, a second sliding groove, a placing groove and a first sliding groove are formed in the inner side of the rail plate from inside to outside in sequence, electric wheels are slidably connected to the inner side walls of the first sliding groove and second sliding groove respectively, and connecting rods are rotatably connected to the inner sides of the two electric wheels through rotating shafts respectively; an electric retractable rod is fixedly connected to the inner sides of the two connecting rods, the bottom of the electric retractable rod is fixedly connected with a polishing machine, a base is fixedly connected to the inner side of the bottom of the working frame, casing pipes are fixedly connected to the left and right ends of the base respectively, and sleeve rods are slidably connected to the inner sides of the casing pipes. Through arrangement of the electric wheels, the connecting rods and the sliding grooves, polishing of a whole wooden plate is completed automatically, the process is simple, the operation is stable, the working efficiency of the device is greatly improved, and meanwhile the labor cost is reduced.

Owner:苏州家望宝科技有限公司

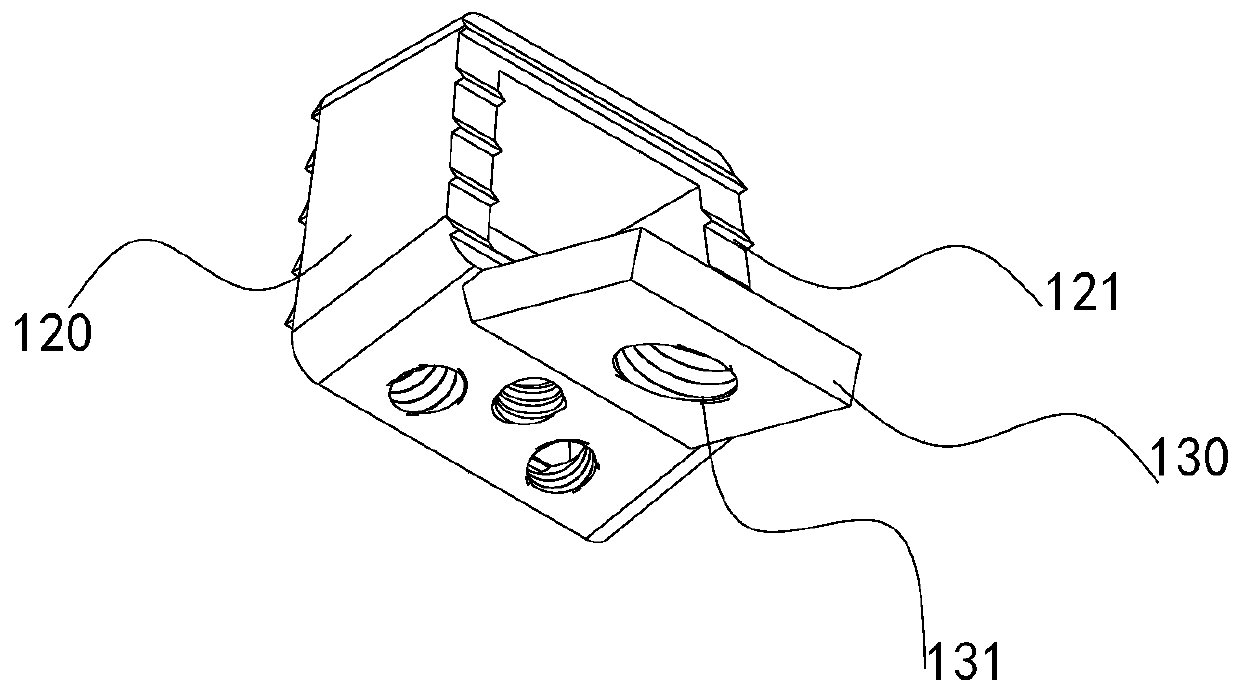

Packaging box for bearing

Owner:HUNAN MEIBEIDA TECH CO LTD

Test tube washing device adjustable in washing diameter and for middle school chemistry experiment teaching

PendingCN109304341APrevent test tube from slippingDiameter size adjustmentHollow article cleaningTest tubeEngineering

The invention particularly relates to a test tube washing device adjustable in washing diameter and for middle school chemistry experiment teaching. The device comprises a tank water groove, a test tube base, a square mounting board, a lifting mechanism for lifting or descending a test tube groove and a mounting frame, and a washing device body. The washing device body comprises a motor, a drive wheel, a driven wheel and a brush head device; the brush head device comprises a first rotary shaft, a first bearing and an elastic cleaning sleeve; the motor drives the first rotary shaft to rotate; the bottom of the first rotary shaft is sleeved with an elastic cleaning sleeve; and the degree of thickness of the interior of the elastic cleaning sleeve is changed through vertical movement of a cone so that the device can adapt to washing of test tubes of different inner diameters. Placement of the test tubes is achieved through lifting of the lifting mechanism. The test tube washing device adjustable in washing diameter and for middle school chemistry experiment teaching meets the requirement of washing of the test tubes of different diameters, has no dead corner during washing, is convenient to operate and can be widely applied and popularized.

Owner:宝应县安宜高级中学

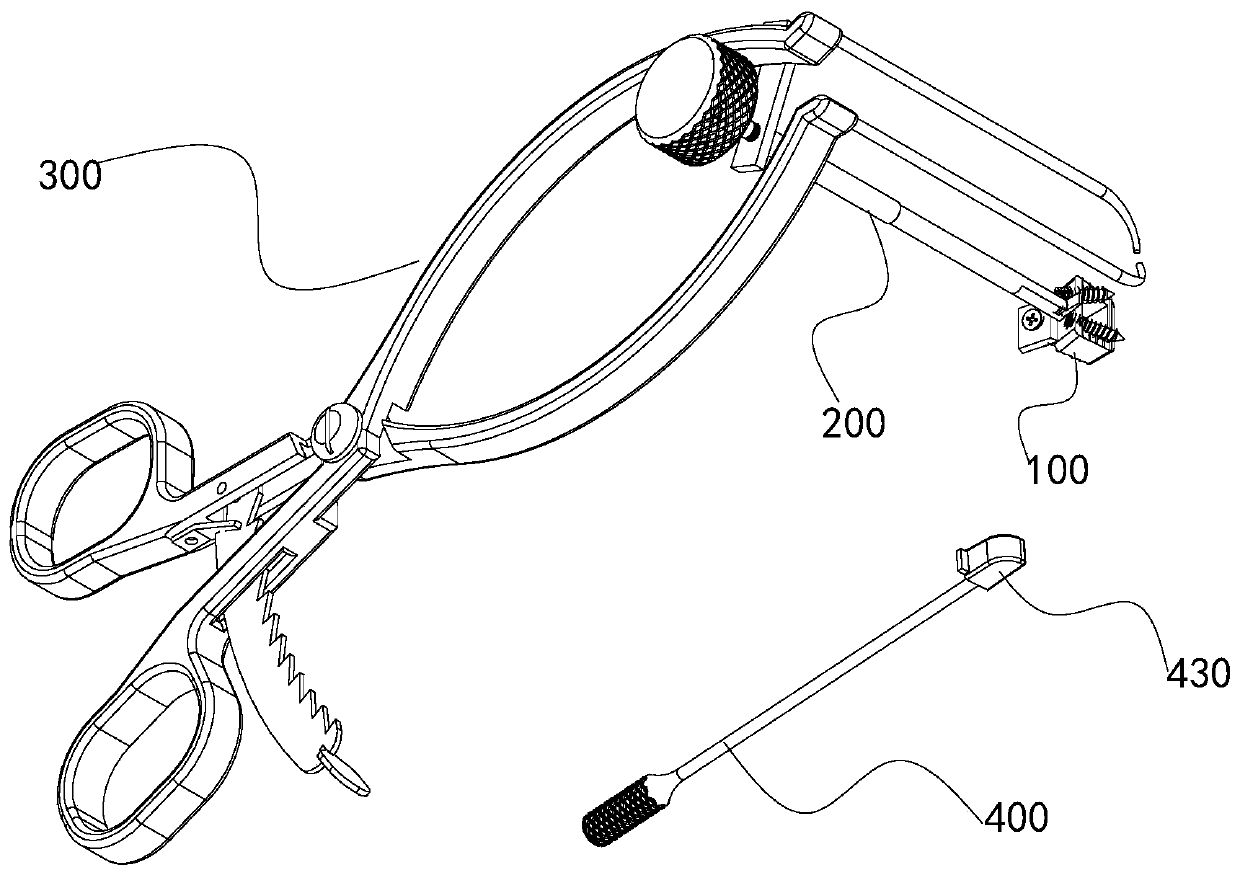

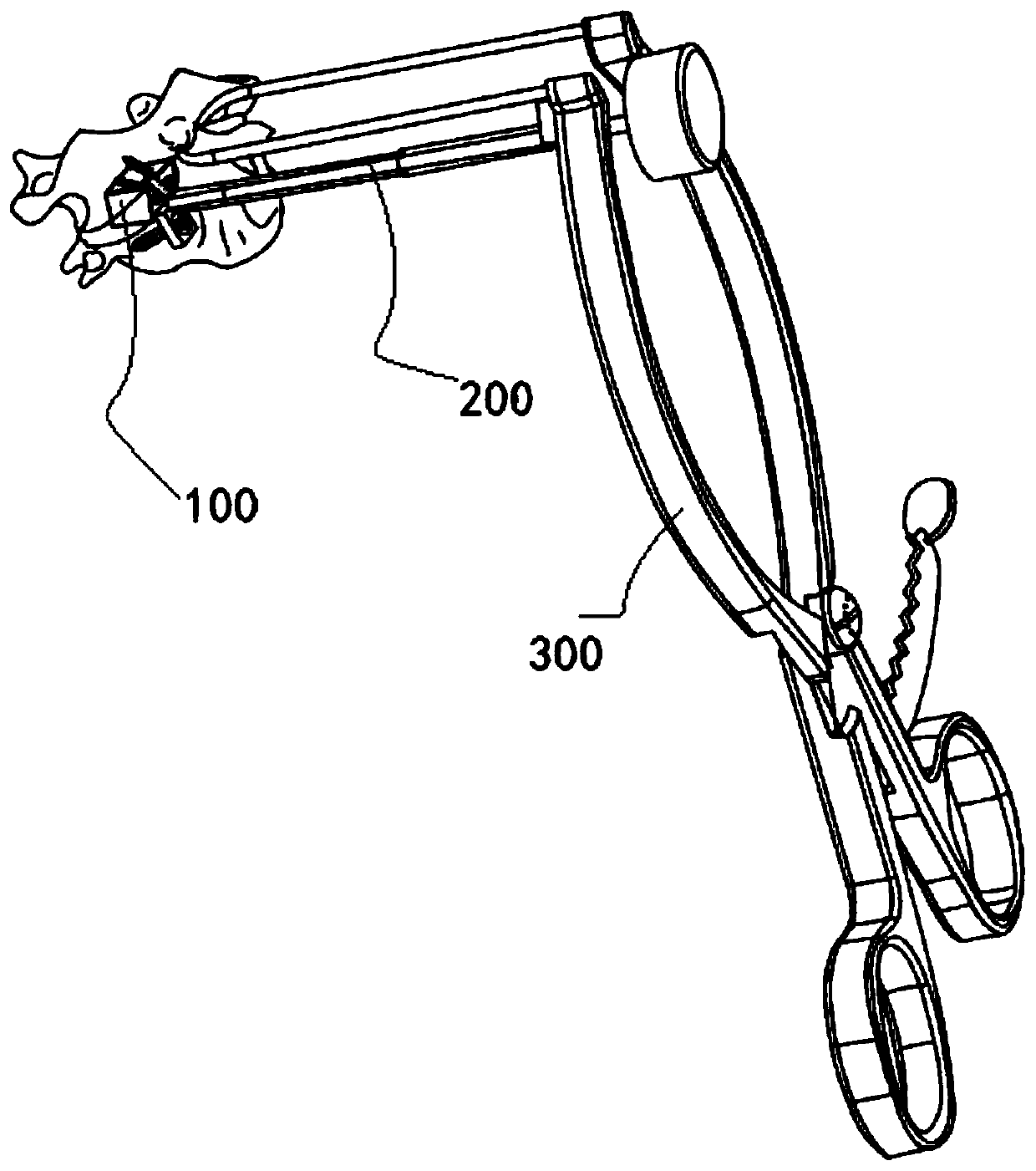

Transoral anterior atlantoaxial lateral mass embolia fusion cage system and using method thereof

ActiveCN109771106AImprove stabilityAvoid displacementSpinal implantsOsteosynthesis devicesAtlantoaxial dislocationEngineering

The invention discloses a transoral anterior atlantoaxial lateral mass embolia fusion cage system and a using method thereof. The system comprises a fusion fixing device, a holding restorer and lifting-pulling restoring pincers; a first connecting part is arranged on the fusion fixing device, a second connecting part is arranged on the holding restorer, the fusion fixing device is connected with the holding restorer through the first connecting part and the second connecting part, the lifting-pulling restoring pincers at least comprise a first conduction part and a second conduction part, andthe holding restorer is located between the first conduction part and the second conduction part. The system is used for an atlantoaxial dislocation and basilar invagination operation; meanwhile, whenthe system is in use, the atlantoaxial anterior release restoring and fusion interior fixation operation can be ideally completed simply through one operation incision.

Owner:杨进城

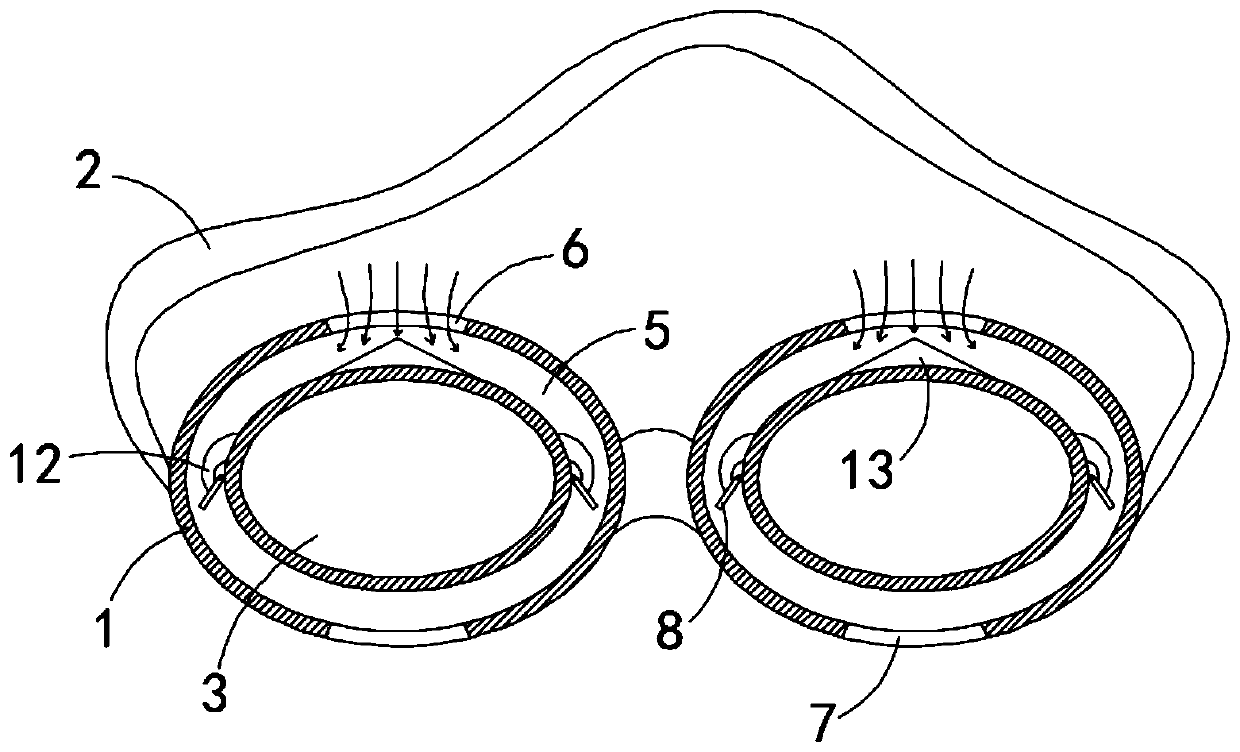

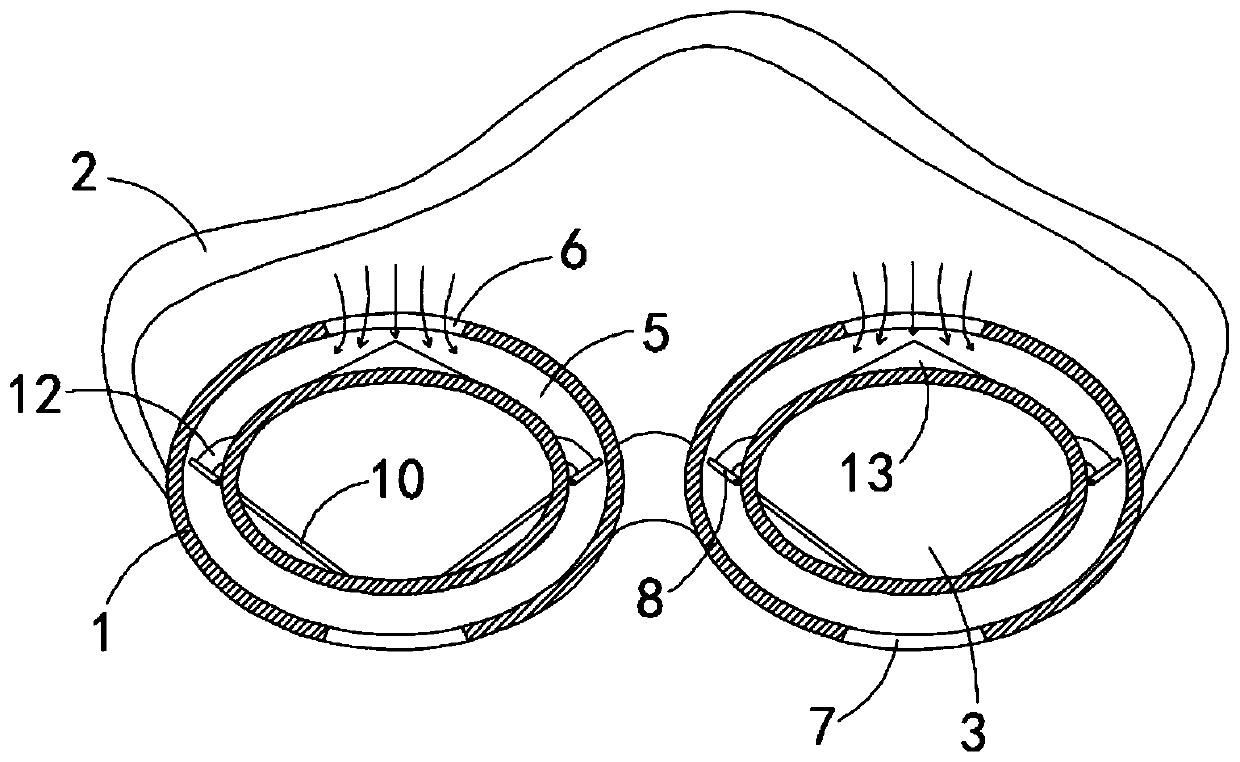

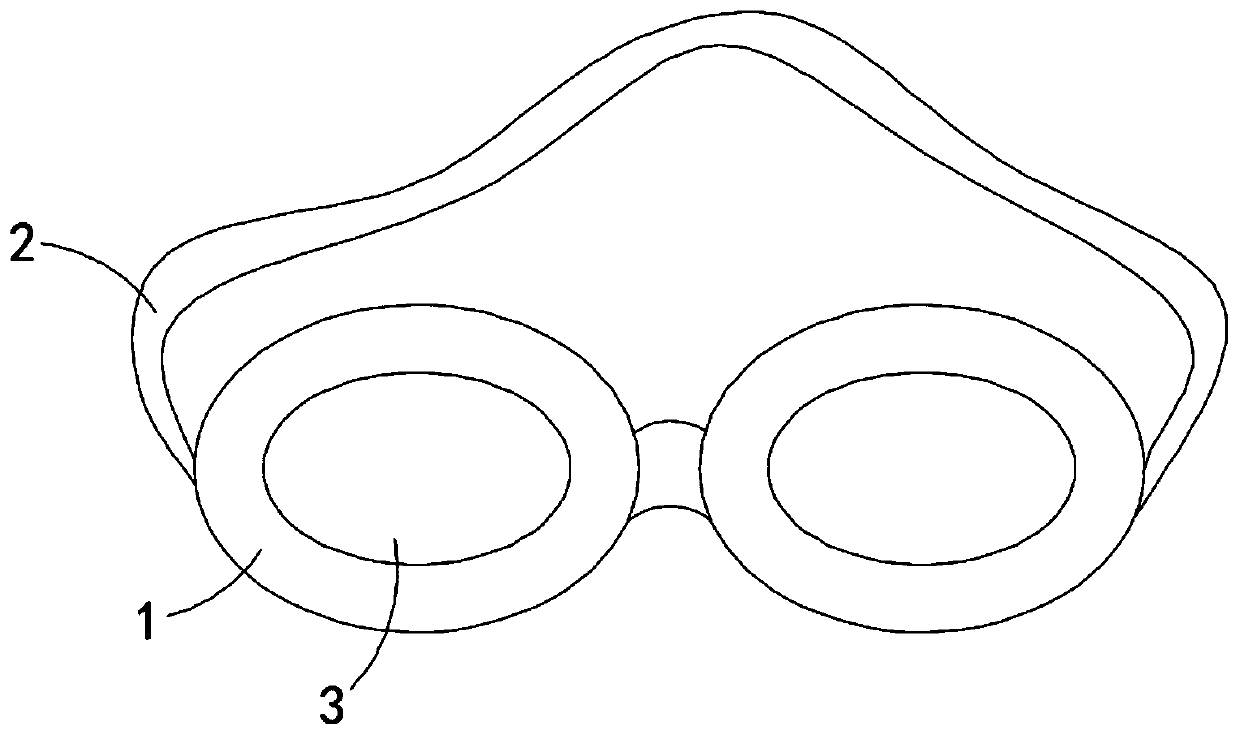

Anti-fog swimming goggles

The invention belongs to the field of swimming equipment, and particularly relates to an anti-fog swimming goggles, which comprise a mirror frame, wherein a binding band is fixedly connected to the mirror frame, a lens is arranged in the mirror frame, a sealing cover is fixedly connected to the rear side wall of the mirror frame, an annular cavity parallel to the lens is arranged in the mirror frame, a water inlet is arranged at the upper end of the annular cavity, a water outlet is arranged at the lower end of the annular cavity, two sides of the annular cavity are respectively provided witha water blocking plate, the water blocking plate is rotationally connected with the rear side wall of the annular cavity through a rotating shaft, the other end of the rotating shaft penetrates through the mirror frame and is rotatably in sealing connection with the mirror frame, a scraping strip used for scraping off the water mist on the lenses, is fixedly connected with one end the rotating shaft which is position outside the annular cavity. A receiving groove for receiving the scraping strip is arranged on the inner top surface of the mirror frame; the upper side wall of the water blockingplate is fixedly connected with an elastic bellow; a through hole connected with the outside is arranged on the rear side wall of the annular cavity. According to the anti-fog swimming goggles, the water flow is utilized to drive the scraping strip to scrape off the water mist on the lenses, and the temperature difference inside and outside the lenses can be controlled through the annular heat conducting sheet, so that the fogging condition is reduced.

Owner:金鹏飞

Cleaning method of knitted fabric

ActiveCN107574608AImprove processing efficiencyComprehensive effectTextile treatment containersTextile treatment machine arrangementsCleaning methodsMechanical engineering

The invention discloses a cleaning method of knitted fabric. The method includes the steps of preparation, wherein a kitted article cleaning device needs to be used; winding and conveying, wherein processed fabric is wound into a fabric roll and conveyed to the kitted article cleaning device; fabric cleaning and wringing, wherein fabric cleaning and drying are conducted through the kitted articlecleaning device. According to the method, fabric conveying and dewatering can be completed on the basis of fabric cleaning, so that diverse effects are achieved, and the fabric treatment efficiency ishigh.

Owner:宁波隆锐机械制造有限公司

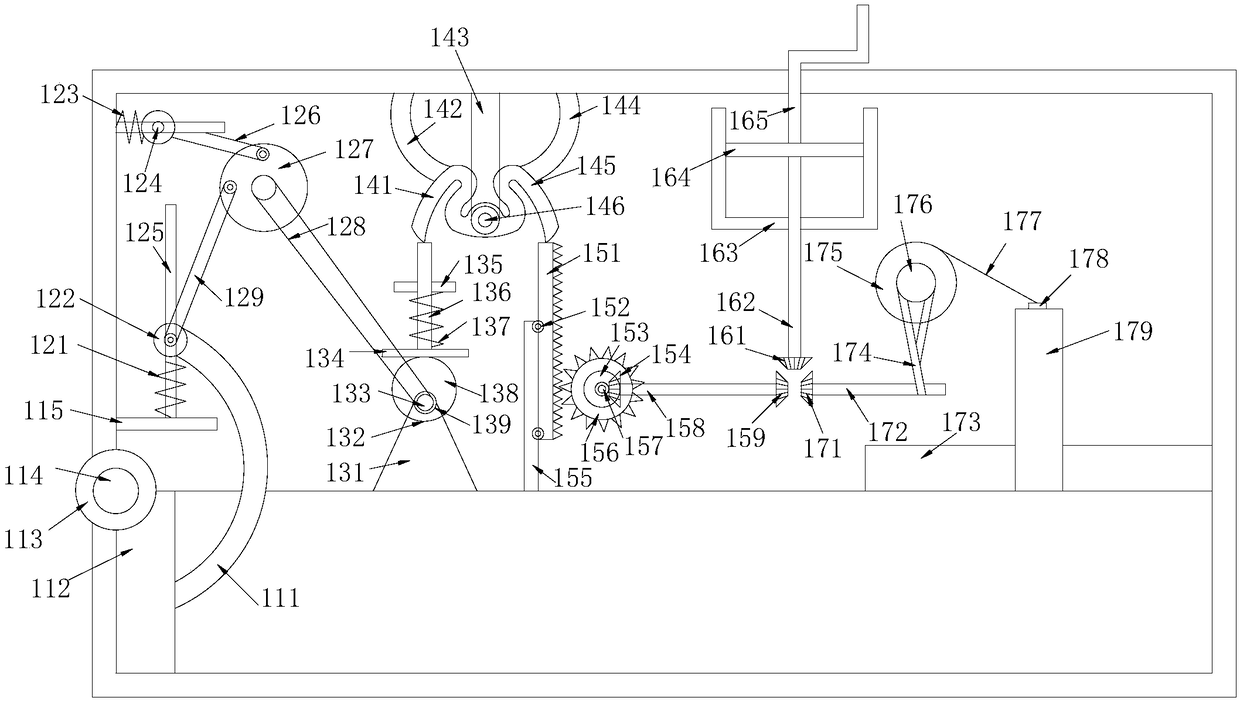

Automatic feeding device for grinding machine

PendingCN108161726ASolve the problem of poor delivery performanceReduced usabilityGrinding feedersElectric machineryElectric machine

The invention discloses an automatic feeding device for a grinding machine. The device comprises a feeding device body, baffles are fixedly connected to the two sides of the top of the feeding devicebody, a driving belt is movably connected to the opposite sides of the two baffles, grooves are formed in the opposite sides of the two baffles, support plates are in longitudinal sliding connection with the interiors of the grooves, and fixed rods are fixedly connected to the tops and the bottoms of the sides, close to the driving belt, of the support plates. Accordingly, by means of cooperationof the feeding device body, a shell, the baffles, the fixed rods, a guide wheel, the grooves, the support plates, a push rod, a rotary table, a connecting plate, a connecting rod, a movable rod, a transmission box and a motor, the problem that an existing grinding machine automatic feeding device is poor in pipe transporting effect is solved, the automatic feeding device for the grinding machine has the advantage of being good in pipe transporting effect, great convenience is brought to use of a user, the practicability of the automatic feeding device for the grinding machine is lowered, and the device is worthy of popularization.

Owner:南通久高智能装备科技有限公司

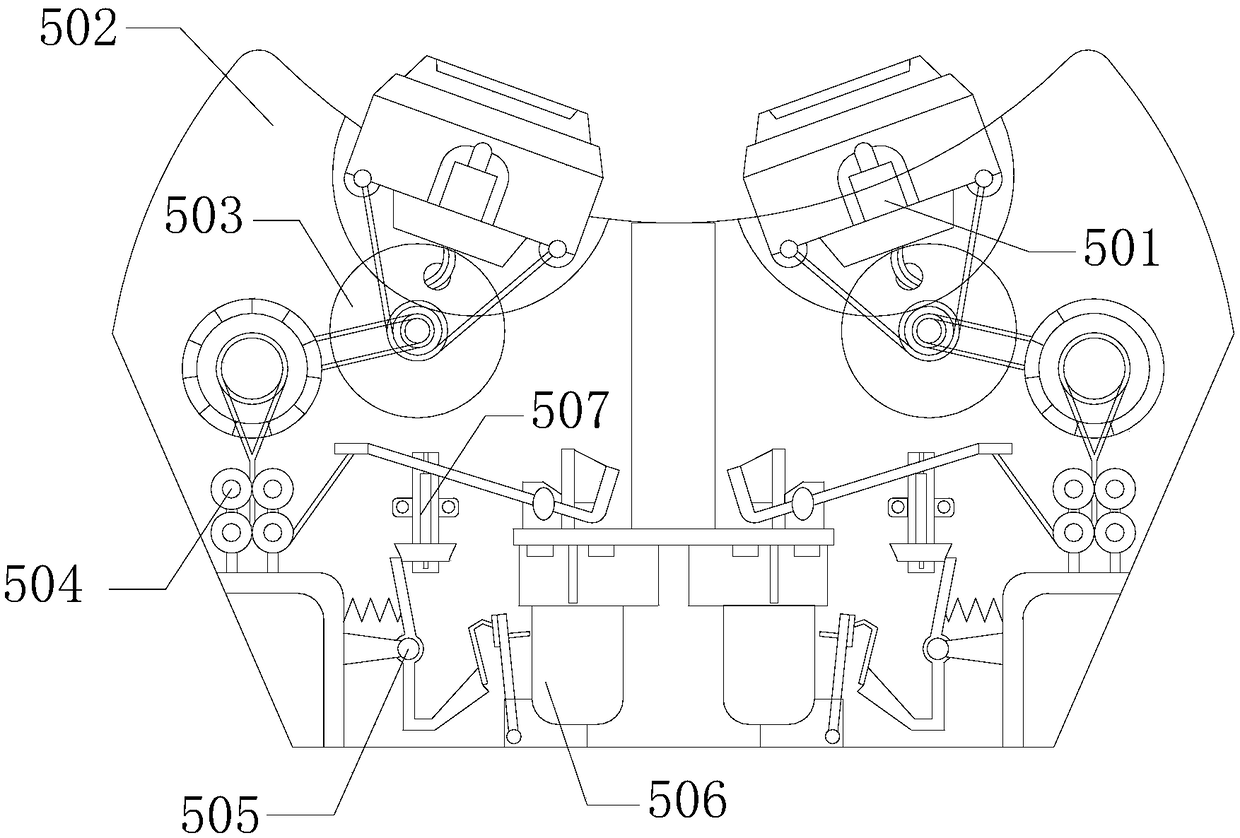

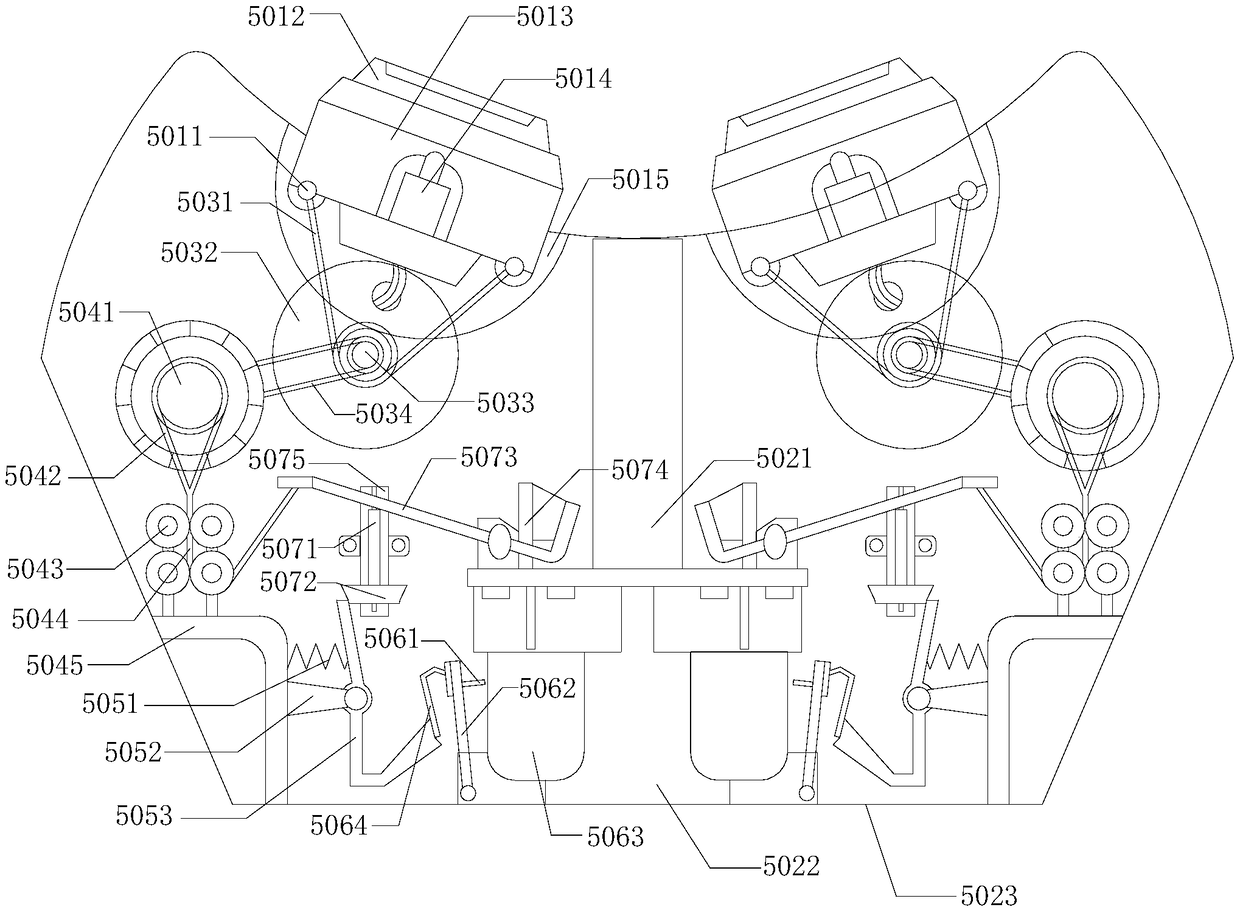

Puncture-type electric power fitting

ActiveCN108418003AGuaranteed clamping degreeAvoid displacementElectric connection structural associationsClamped/spring connectionsElectric powerInternal cavity

The invention discloses a puncture-type electric power fitting, and the electric power fitting comprises puncture systems which are adjacent in a lateral direction. Each puncture system comprises a housing, and the central part of the upper side wall of each housing is provided with an adjustment head, wherein the adjustment head vertically passes through the central part of the upper side wall ofthe housing. The interior of each adjustment head is provided with an adjustment rod, and the lower end of each adjustment rod is provided with a puncture needle. The upper and lower sides of the outer side wall of each adjustment rod are provided with limiting rings. The interior of each housing is provided with a fixed seat between the upper and lower limiting rings. The interior of each fixedseat is provided with an adjustment nut, and each adjustment nut is in threaded connection with the corresponding adjustment rod. The central part of the lower side wall of the hosing is provided witha first clamping groove, and the lower side wall of the housing and the upper side of the first clamping groove are provided with puncture holes in a passing-through manner. The upper surface of an inner cavity of each housing is provided with resetting seats in a manner of lateral symmetry. The left and right ends of the upper side wall of each housing are provided with resetting through holes in a passing-through manner. The electric power fitting can clamp wires with different diameters, can firmly clamp the wires, and facilitates the removing of the wires.

Owner:江苏大举钢结构有限公司

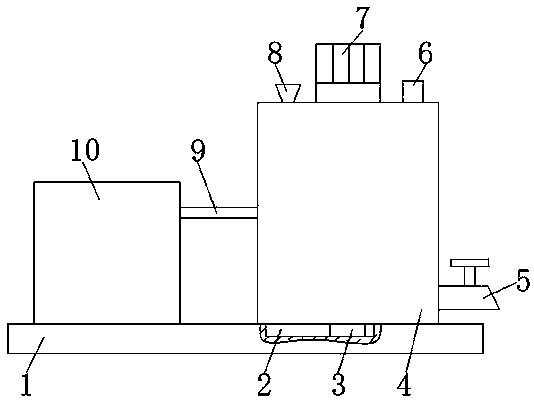

Automatic stir-frying device for Chinese chestnuts

The invention discloses an automatic stir-frying device for Chinese chestnuts. The device comprises a shell, a motor is fixedly installed at the rear side of the shell, a main shaft is in transmissionconnection with one end of a rotating shaft of the motor through a coupler, one end of the main shaft extends into the shell and is fixedly connected with a round roller, evenly-distributed turnoverplates are evenly welded to the outer surface of the round roller, a frying pan is fixedly installed inside the shell, baffles are welded to the two sides of an inner cavity of the shell, evenly-distributed heating pipes are fixedly installed at the other two sides of the inner cavity of the shell, a discharge plate is fixedly installed inside the shell, a discharge mechanism is arranged at one side of the discharge plate, and sealing mechanisms are arranged at the two sides of the outer surface of the shell. According to the automatic stir-frying device for Chinese chestnuts, by arranging thesealing mechanisms, the sealing effect is achieved; when no shell needs to be used, a ventilation position is automatically clamped and fixed, the phenomenon that dust and impurities are attached tothe surfaces of Chinese chestnuts during stir-frying of Chinese chestnuts is avoided, and then the appearance of the Chinese chestnuts is improved.

Owner:林长辉

Pesticide dilution device for agriculture

InactiveCN108031373ASolve the problem of low dilution efficiencyImprove dilution efficiencyShaking/oscillating/vibrating mixersMixing methodsEngineeringThreaded rod

The invention discloses a pesticide dilution device for agriculture. The pesticide dilution device comprises a base; a shell and a box body are sequentially arranged on the top of the base from left to right; a second motor is fixedly connected with the bottom at the right side of an inner cavity of the shell; an output end of the second motor is fixedly connected with a threaded rod, and the leftend of the threaded rod is movably connected with the inner wall of the shell. The pesticide dilution device is provided with the base, the box body, a first motor, a pull rod, the shell, a connecting rod, a sliding sleeve, a vertical rod, the second motor, a threaded bush, the threaded rod, a sliding rod, a rotating shaft, a mixing frame and a stirring rod which are used cooperatively, so that the problem that the existing pesticide dilution device for agriculture is low in dilution efficiency is solved. The pesticide dilution device for agriculture has the advantage of being high in dilution efficiency, reduces the work load of a user, increases the working efficiency of the user, brings great convenience to the user, and improves the practicality of the pesticide dilution device, thusbeing worth popularizing.

Owner:衡阳博思科技有限公司

Mixing device for applying fertilizer to grape

InactiveCN107803148AImprove the mixing effectPromote growthShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMixing effect

The invention discloses a mixing device for applying a fertilizer to grape. The mixing device comprises a base, a tank body and a shell are sequentially arranged at the top of the base from left to right, a first motor is fixedly connected to the center of the top of the tank body, an output end of the first motor extends to the inner part of the tank body and is fixedly connected with a rotatingshaft, the top and the bottom on the two sides of the rotating shaft are fixedly connected with a stirring rod, and the left side of the top of the tank body is communicated with a feed hopper. The base, the tank body, the shell, a push rod, the first motor, the stirring rods, the rotating shaft, a fixing rod, a slide sleeve, a slide bar, a transmission frame, a movable rod, a connecting rod, a rotating disc, a second motor and a vertical rod are matched in use, so that the problem of relatively poor mixing effect of the conventional mixing device for applying the fertilizer to the grape is solved. The mixing device for applying the fertilizer to the grape has the advantage of good mixing effect and accelerates the growth of the grape, and the practicality of the mixing device for applyingthe fertilizer to the grape is improved.

Owner:衡阳博思科技有限公司

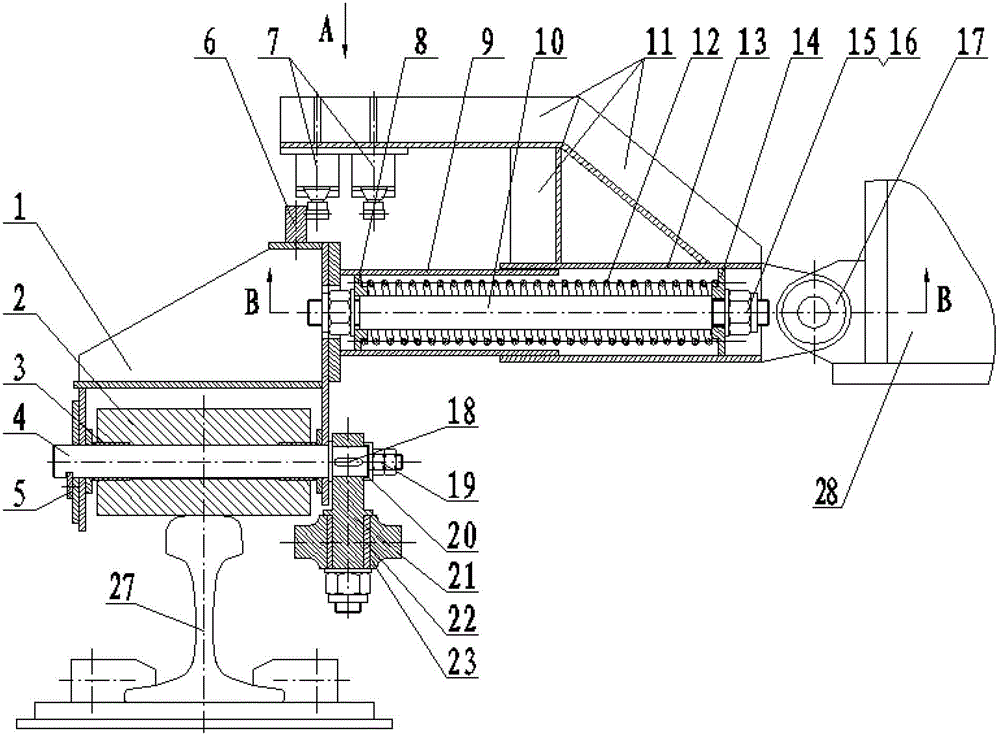

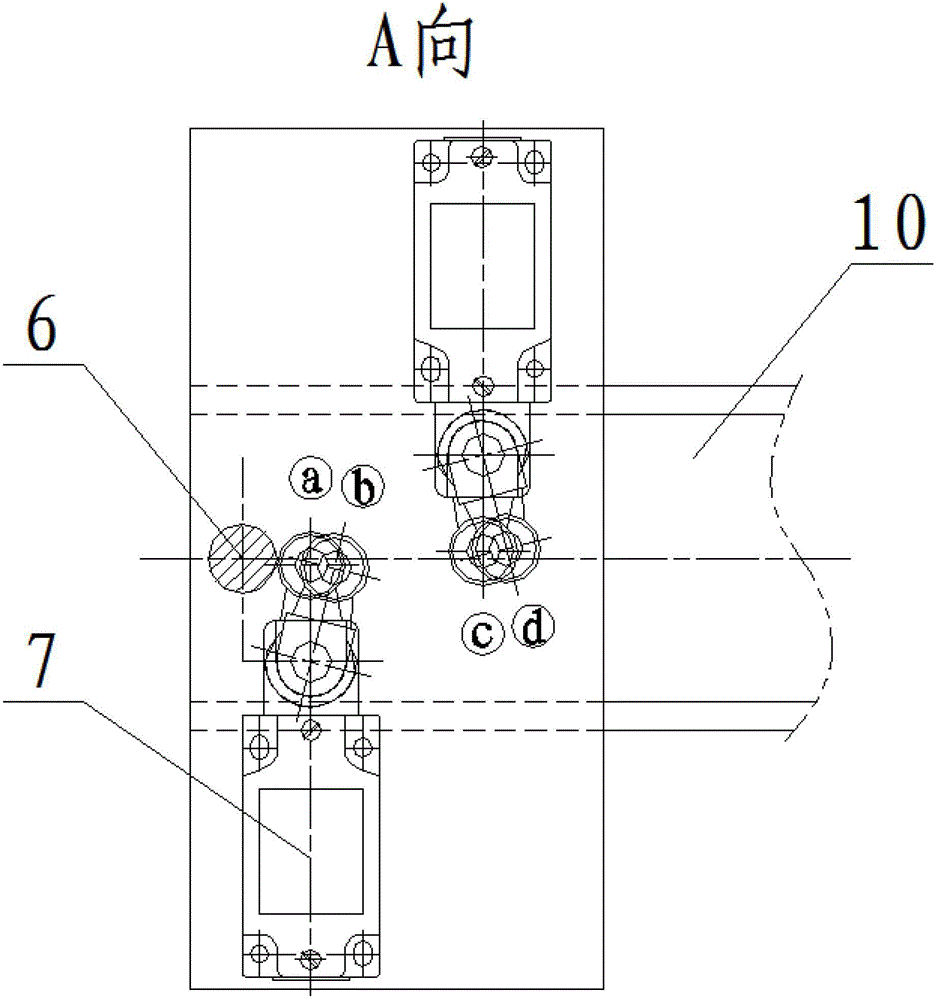

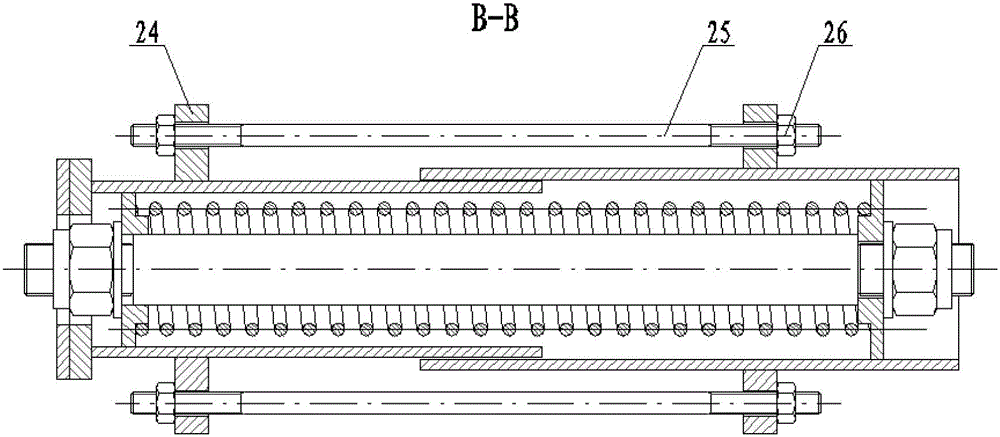

Operation deviation detection device for mining machinery

ActiveCN102862584ASimple structureLow costRail derailment preventionLocomotivesDual actionCantilever

The invention provides an operation deviation detection device for mining machinery, comprising a parallel movement mechanism, a stationary ground mechanism and a deviation detection mechanism, wherein the deviation detection mechanism comprises a detection part and a buffer part; a shaft I of the detection part is fixed on a support; a rolling wheel I is installed on the shaft I; the surface of the rolling wheel I is connected onto the stationary ground mechanism in an overlapping way; a shaft III is installed in a manner perpendicular to the shaft I; a rolling wheel II is installed on the shaft III; a change-over switch is installed on the front end of a front cantilever of a change-over switch bracket; the rear part of the change-over switch bracket is fixed on a square steel pipe II; the left end of a square steel pipe I of a buffer mechanism is fixed on the support, and the right end is connected into the left end of the square steel pipe II in a sheathing way; the shaft II is fixedly connected between a baffle plate I and a baffle plate II; and a spring is sheathed on the shaft II. The operation deviation detection device for the mining machinery has the advantages of simple structure, low cost, convenience in maintenance and repair, and reliable deviation detection; a spring mechanism of the buffer part has double functions of buffering and resetting; and a detection touch-leaning mechanism has small friction and a little abrasion.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Washing device for knitwear

ActiveCN107723966AImprove processing efficiencyComprehensive effectTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsWater storageDrive wheel

The invention discloses a washing device for knitwear. The washing device comprises a rack and further comprises a washing squeezing mechanism and a cloth conveying and spreading mechanism capable ofdriving cloth to travel which are arranged sequentially on the rack from top to bottom, the cleaning squeezing mechanism comprises a fixed plate fixedly connected on the rack and a water storage tankslidably connected in the circumferential direction of the fixed plate, a water inlet is formed in the side wall of the lower end of the water storage tank, a limiting plate is arranged at the upper end of the water storage tank, the fixed plate and the water storage tank are matched to form a water storage cavity, and a plurality of tension springs are arranged between the fixed plate and the water storage tank; a plurality of washing ports communicated with the water storage cavity and facing the cloth conveying and spreading mechanism are formed in the undersurface of the water storage tank, a pressing and spreading mechanism comprises a pressure bearing rod perpendicularly connected in the circumferential direction of a driving wheel and two spreading plates hinged on two sides of thetop of the pressure bearing rod, and pressure springs are connected between the bottoms of the spreading plates and the pressure bearing rod. The washing device can wash cloth and can also complete conveying and dewatering of the cloth, thereby being diverse in effect and high in cloth treatment efficiency.

Owner:宁波隆锐机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com