Uncoiling straightening machine special for fine blanking

A straightening machine and fine blanking technology, applied to other manufacturing equipment/tools, accessories of shearing machines, shearing devices, etc., can solve the axial limit of steel coils, inconvenient adjustment of the gap between the upper and lower rolls, poor straightening quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

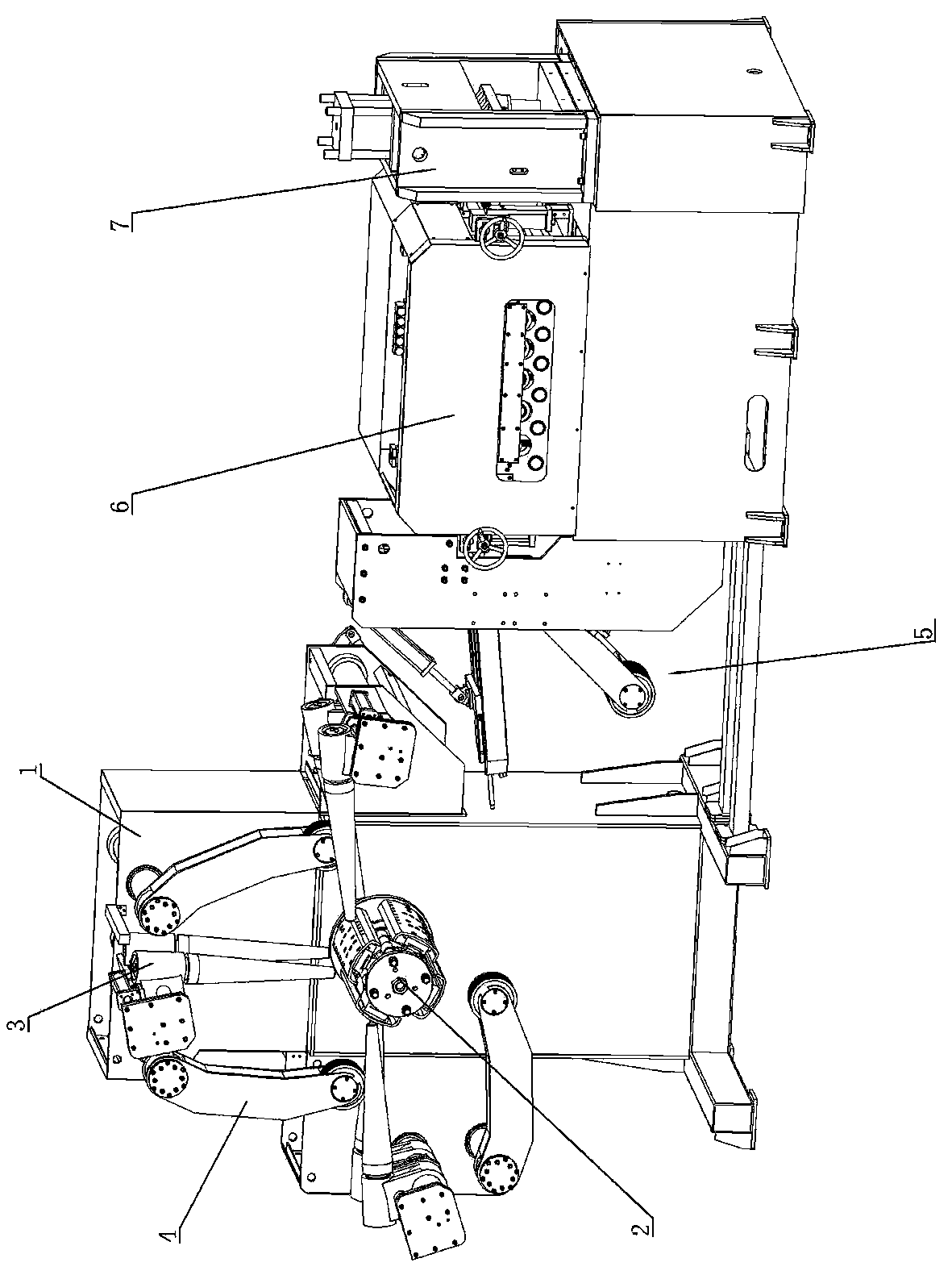

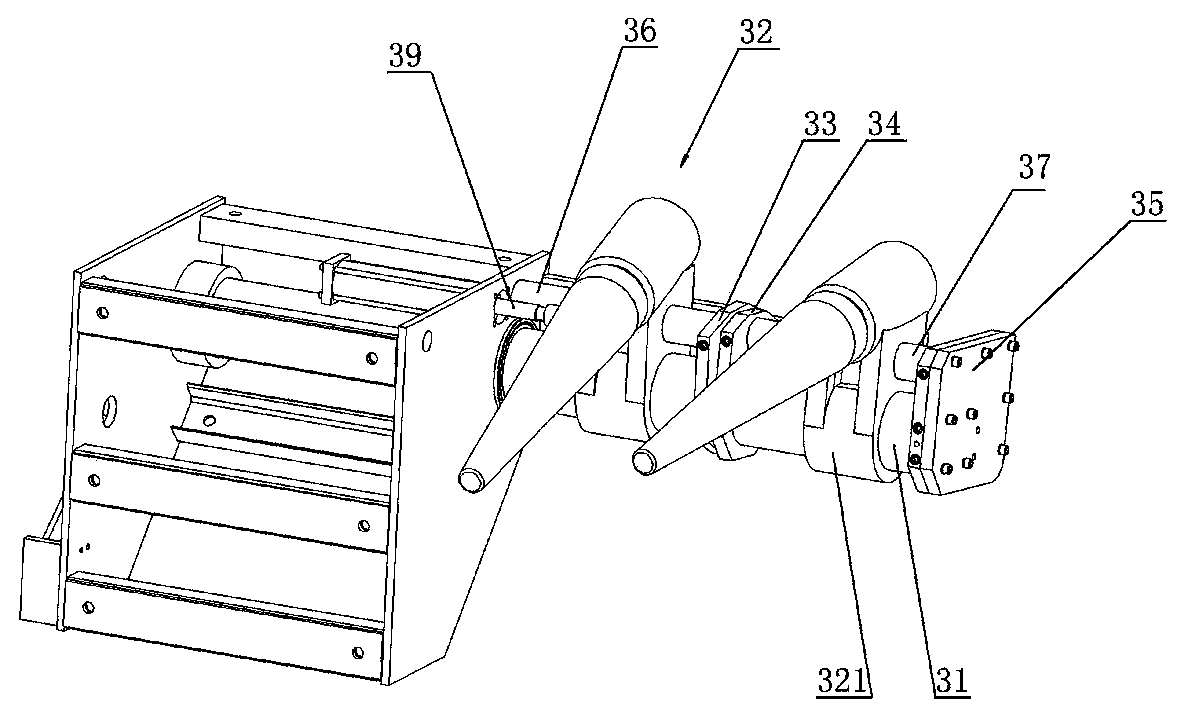

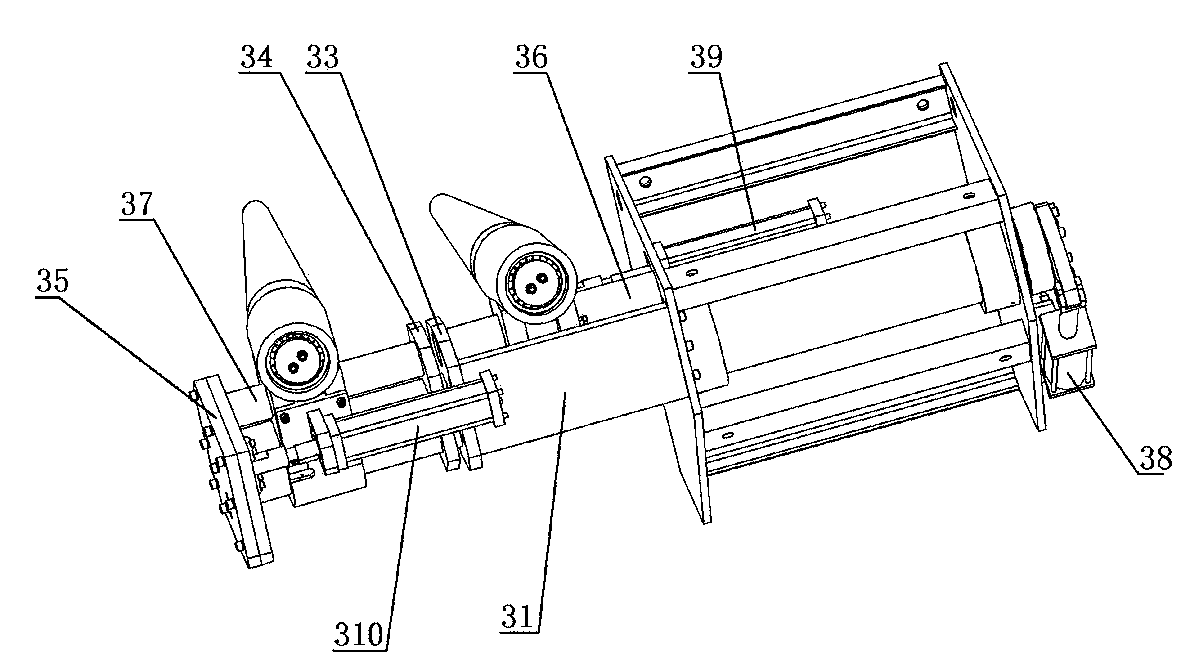

[0039] like Figure 1 to Figure 4 As shown, the special uncoiler straightening machine for fine blanking includes an uncoiler frame 1 , a material frame 2 , a material blocking mechanism 3 , a material pressing mechanism 4 , a material guiding mechanism 5 , a rectifying mechanism 6 , and a shearing mechanism 7 .

[0040] like Figure 5 and Image 6 As shown, the uncoiling frame 1 includes a bottom plate 11 , a base frame 12 and a column 13 . The bottom plate 11 is welded to the bottom of the base frame 12, and a first reinforcing rib plate 14 is welded between the bottom plate 11 and the base frame 12 to improve the connection strength between the bottom plate 11 and the base frame 12, thereby improving the uncoiling frame. The base frame 12 includes a transverse beam 121 and a longitudinal beam 122, and the longitudinal beam 122 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com