Operation deviation detection device for mining machinery

A detection device and mechanical technology, applied in transportation and packaging, locomotives, railway car body parts, etc., can solve the problems of complex structure, lost signal, high cost, etc., and achieve the effects of reduced wear, reliable deflection detection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

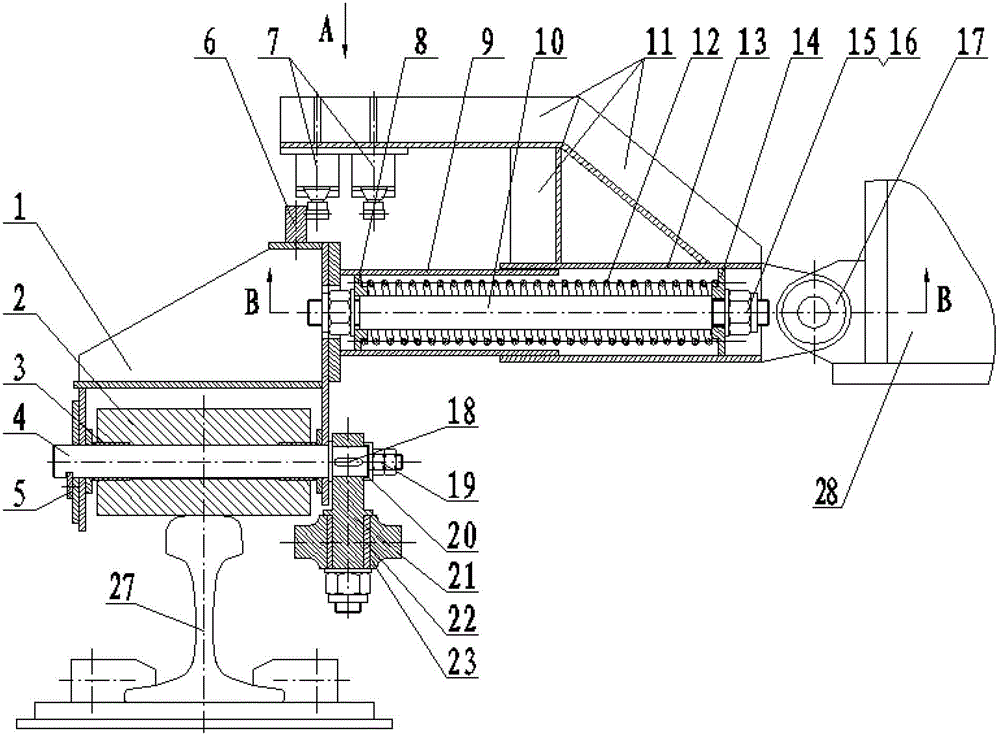

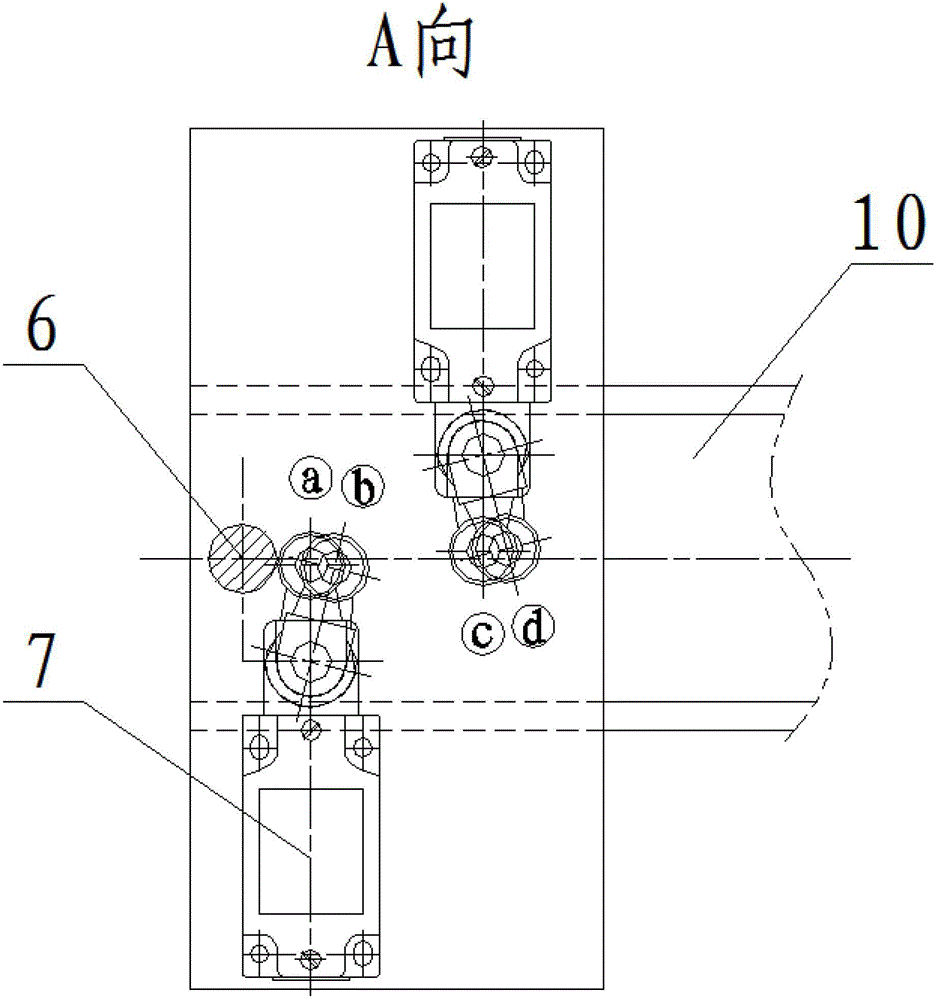

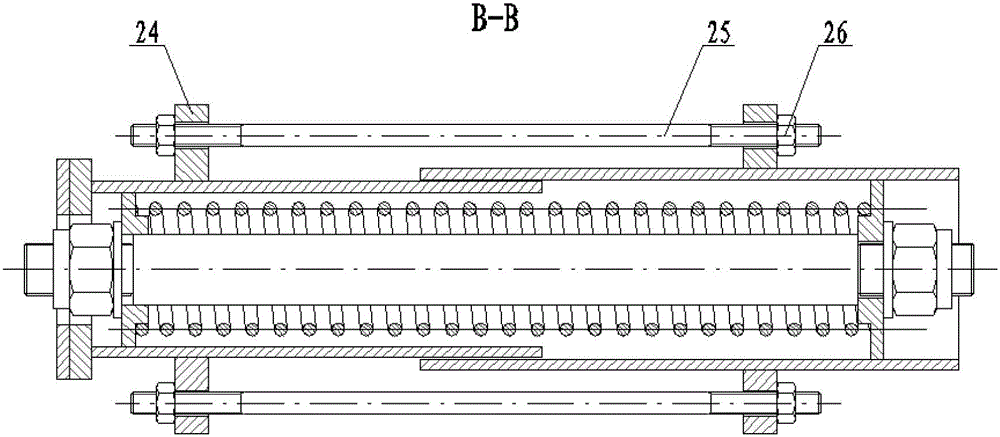

[0023]The deflection detection device includes a parallel movement mechanism 28, a fixed ground mechanism 27 and a deflection detection mechanism. The deflection detection mechanism includes a detection part and a buffer part. , key 18, shaft I fixing bolt 19, shaft III21, bearing 22, roller II23 and transfer switch bracket 11, the buffer mechanism includes square steel pipe I9, shaft II10, spring 12, square steel pipe II13, baffle plate I8, baffle plate II14, shaft II fixing bolts 15, steel plates 24 and double-ended studs 25; the support 1 of the detection part is a grooved frame with the opening downward, and the left and right vertical walls of the grooved frame are provided with shaft holes matched with the shaft I4, and the grooves Both ends of the top surface of the profile frame are provided with vertical plates, the vertical wall on the right side of the channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com