Washing device for knitwear

A cleaning device and technology for knitwear, applied in textiles and papermaking, equipment configuration for processing textile materials, processing of textile materials, etc., can solve problems such as poor cleaning quality and complicated procedures, and achieve diversified effects, high efficiency, and small contact area small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

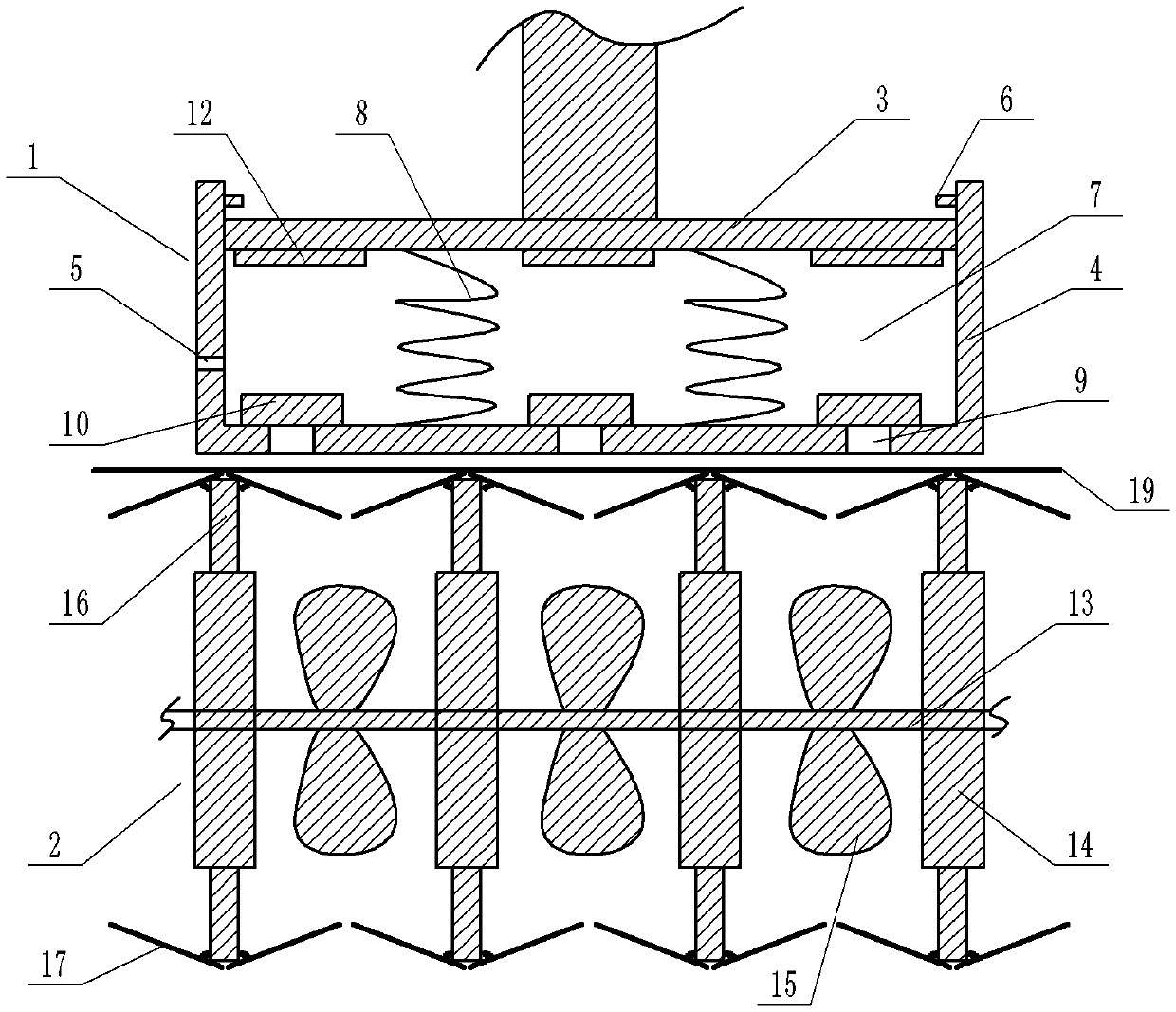

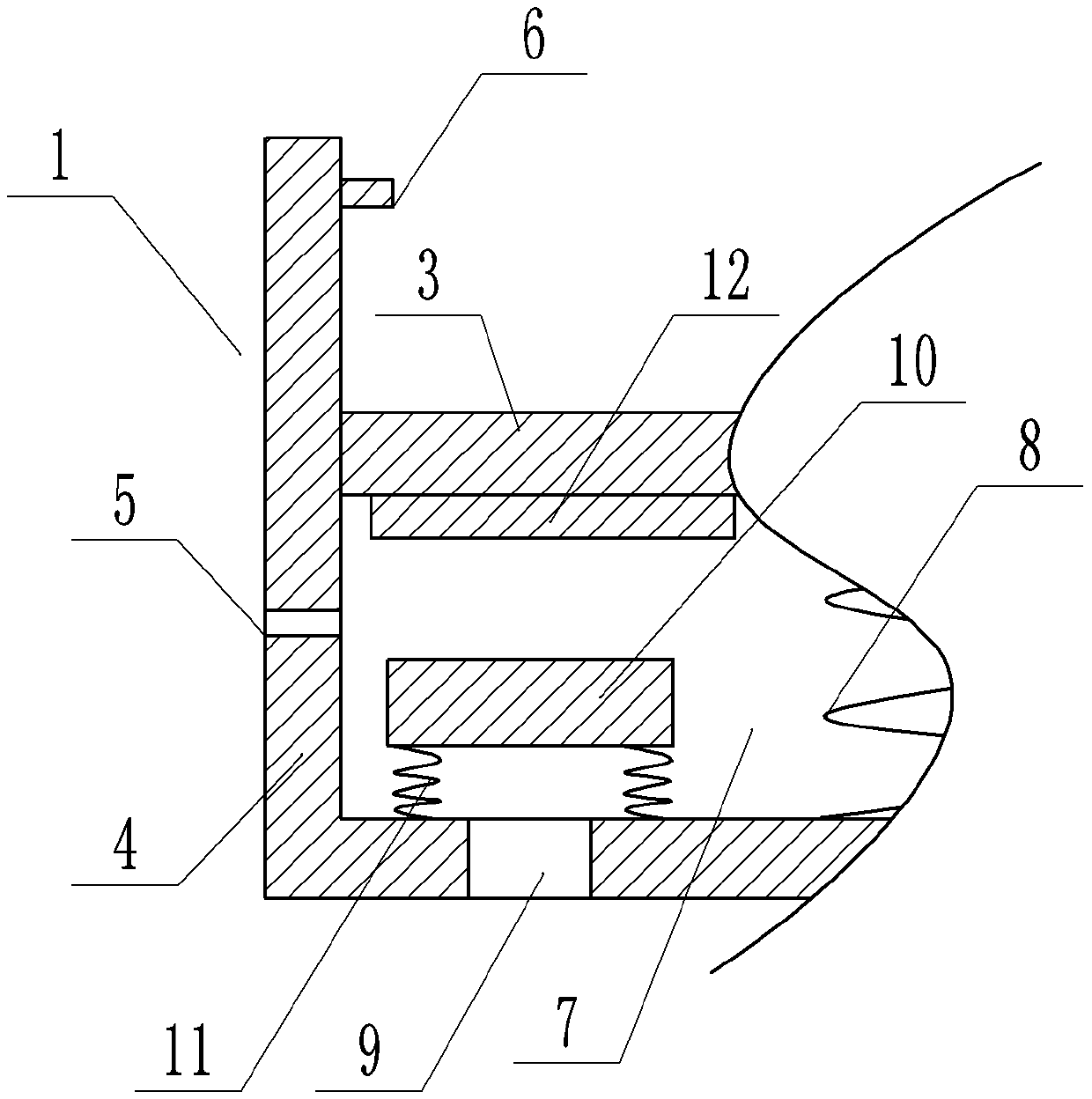

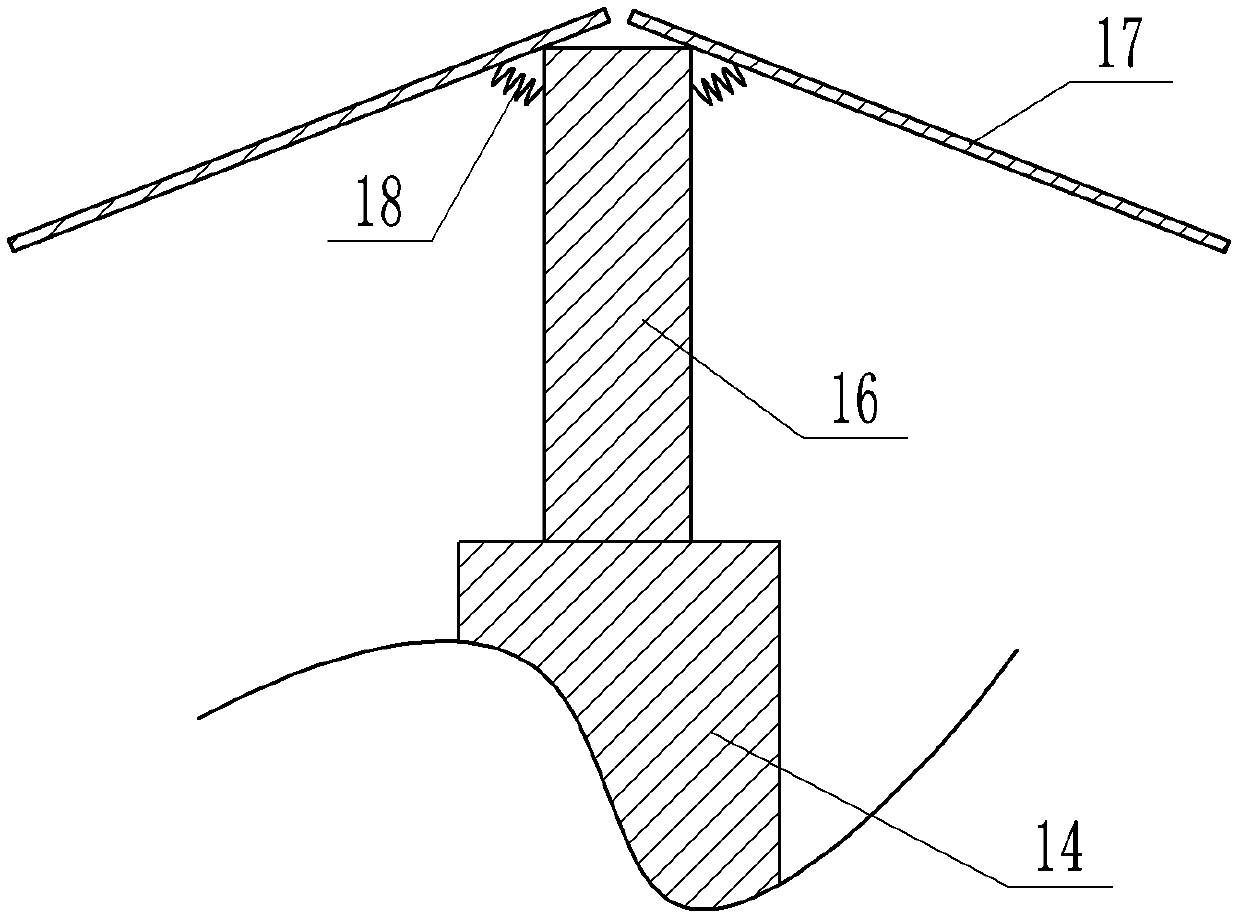

[0022] The reference signs in the accompanying drawings of the specification include: cleaning extrusion mechanism 1, cloth conveying and paving mechanism 2, fixed plate 3, water storage tank 4, water inlet 5, limit plate 6, water storage chamber 7, extension spring 8, cleaning Mouth 9, sealing cover 10, spring 11, electromagnet 12, rotating shaft 13, driving wheel 14, blade 15, bearing bar 16, paving plate 17, stage clip 18, cloth 19.

[0023] The embodiment is basically as figure 1 The cleaning device for knitwear shown includes a frame, and also includes a cleaning extrusion mechanism 1 sequentially arranged on the frame from top to bottom, a cloth 19 conveying and paving mechanism 2 that can drive the cloth 19 to travel, and a cleaning extrusion mechanism 1 It includes a fixed plate 3 fixedly connected to the frame and a water storage tank 4 slidingly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com