Cleaning method of knitted fabric

A technology for knitted cloth and cleaning port, which is applied in the processing of textile materials, textile and paper making, and processing of textile material carriers, etc. It can solve the problems of complicated procedures and poor cleaning quality, and achieve diversified effects, avoid detachment, and have good use effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment A kind of cleaning method of knitted cloth, comprises the following steps:

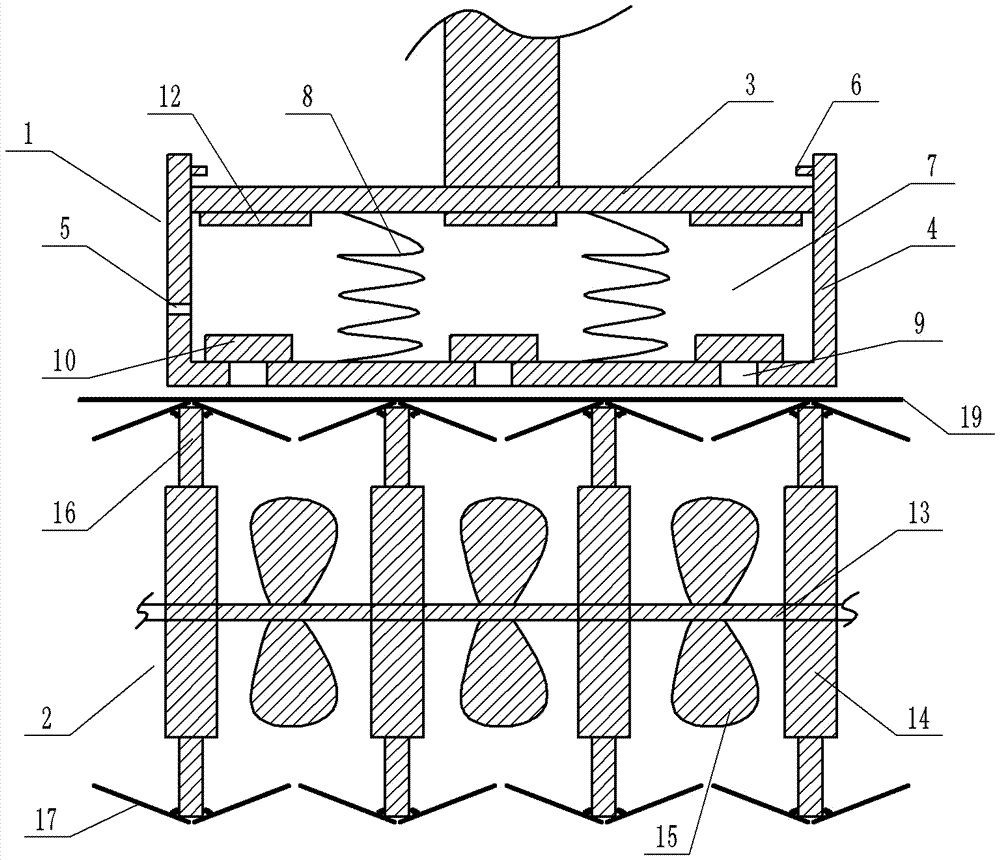

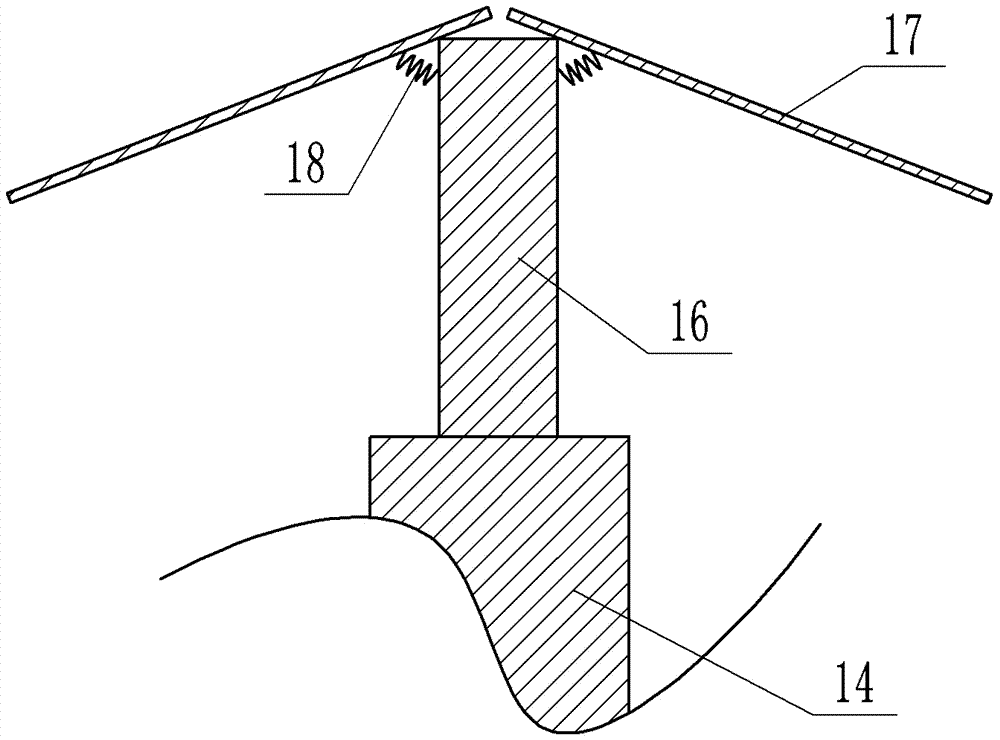

[0030] Step 1: Preparation; need to use the knitwear cleaning device, basically as figure 1 As shown, it includes a frame, and also includes a cleaning extrusion mechanism 1 sequentially arranged on the frame from top to bottom and a cloth 19 conveying and paving mechanism 2 that can drive the cloth 19 to walk;

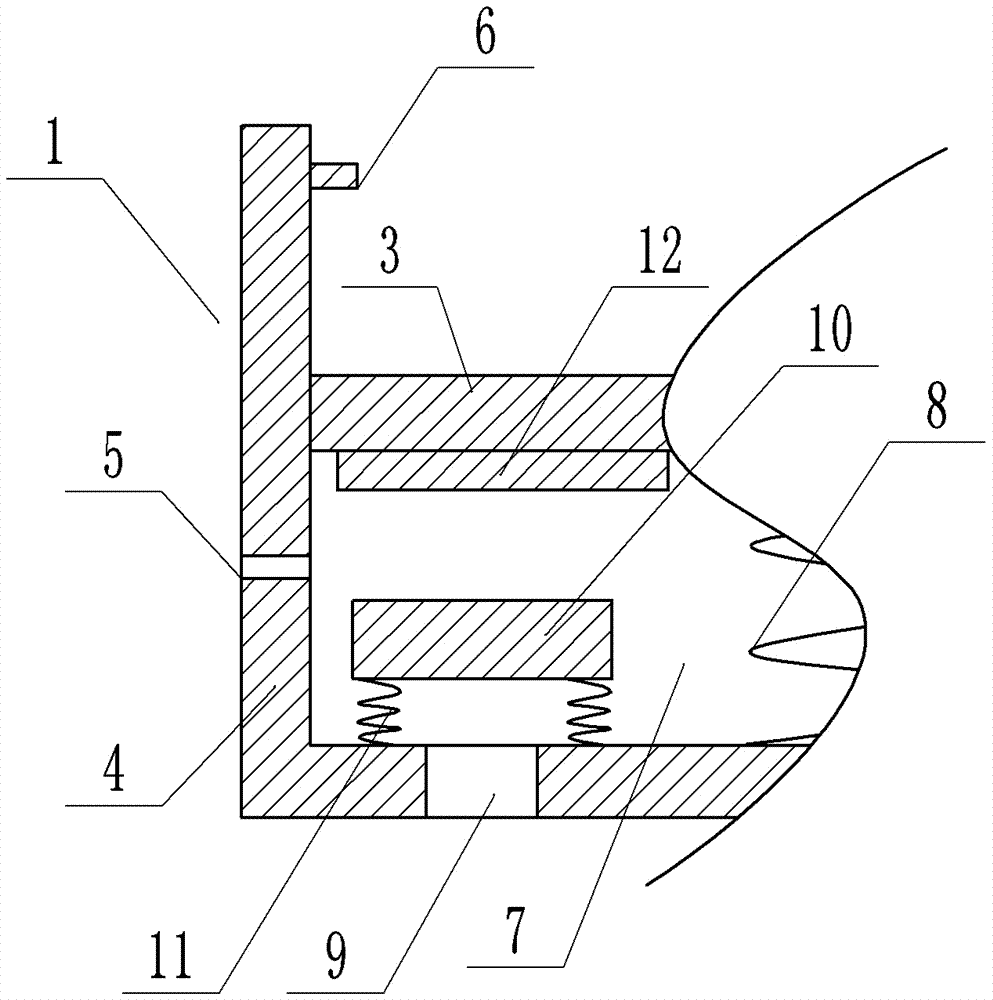

[0031] The cleaning extrusion mechanism 1 includes a fixed plate 3 fixedly connected to the frame and a water storage tank 4 slidingly connected to the fixed plate 3 in the circumferential direction. The lower end side wall of the water storage tank 4 is provided with a water inlet 5, and the upper end of the water storage tank 4 is provided with a limit plate 6. , the fixed plate 3 and the water storage tank 4 cooperate to form a water storage cavity 7, a number of tension springs 8 are arranged between the fixed plate 3 and the water storage tank 4, and the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com