Fiber cotton material distribution process

A fiber cotton and process technology, applied in the field of fiber cotton processing, can solve the problems of affecting the quality of fiber cotton, redundant cotton wadding or dust, and easy entanglement of cotton wadding, so as to save the time of removing entanglements and improve the efficiency of material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

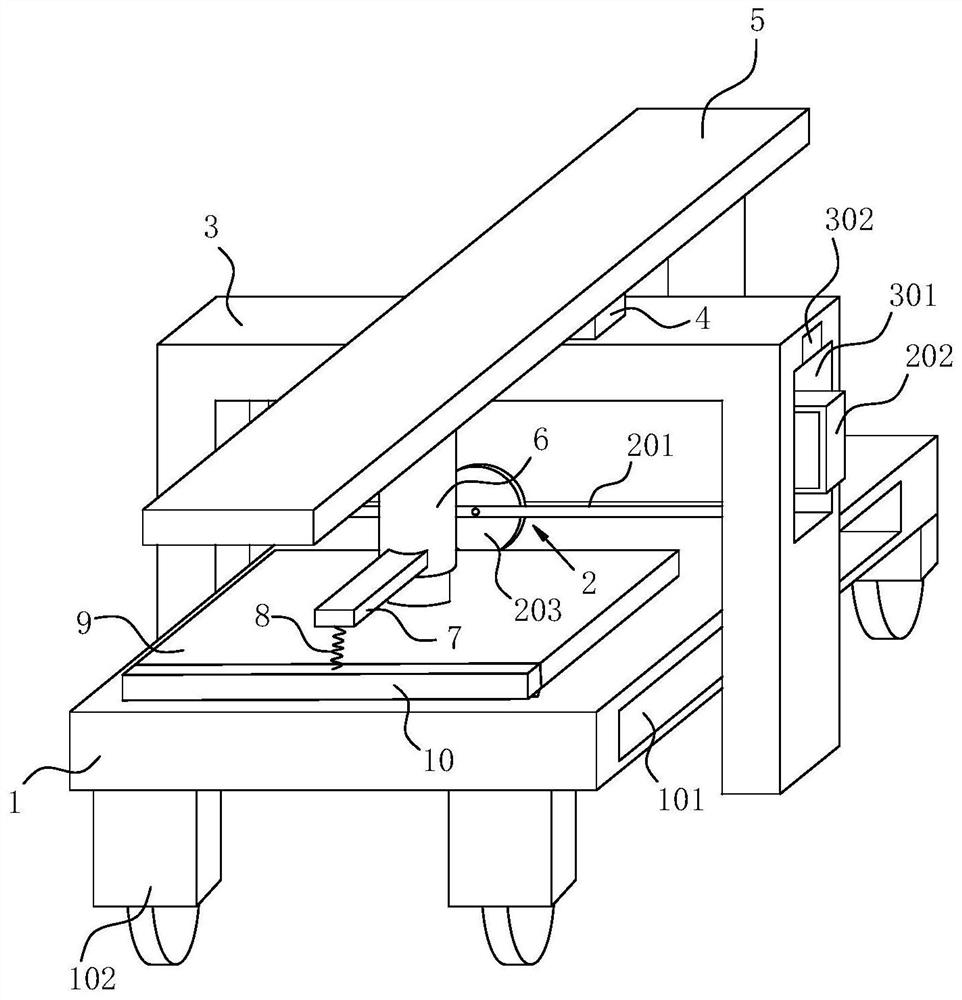

[0043] Such as Figure 1-Figure 5 Shown, a kind of material distribution process of fiber cotton, comprises following fiber cotton material distribution steps:

[0044] S1: Put the fiber cotton on the distribution equipment;

[0045] S2: Move the operating table so that the fiber cotton to be cut is directly below the cutting mechanism;

[0046] S3: Operate the lifting mechanism to press the pressing plate on both sides of the top of the fiber cotton;

[0047] S4: Run the slitting mechanism to cut the fiber cotton, and then move the pressing plate to the outside, and the pressing plate separates the cut fiber cotton;

[0048] S5: Operate the lifting mechanism to raise the pressure plate, the sticking roller is in contact with the surface of the fiber cotton, and the operating table is moved to make the sticking roller and the surface of the fiber cotton evenly contact and remove the wadding on the surface of the fiber cotton;

[0049] The powder equipment in the step S1 com...

Embodiment 2

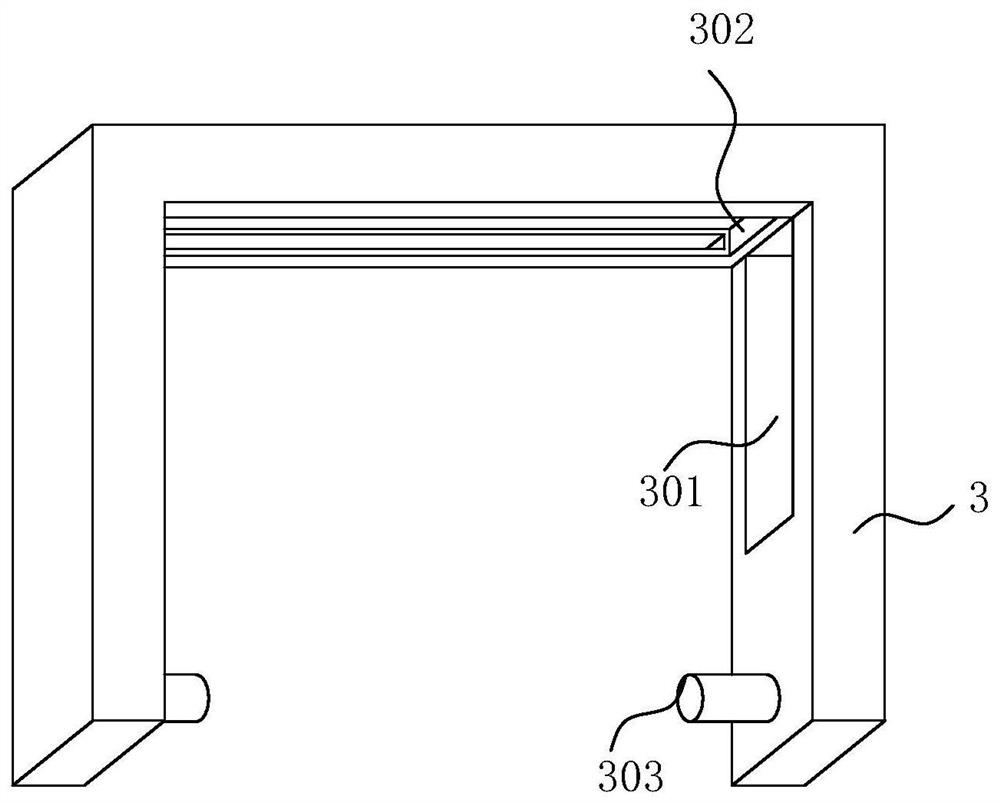

[0060] Such as Figure 1-Figure 6 Shown, on the basis of above-mentioned embodiment 1 technical scheme, increase following technical scheme:

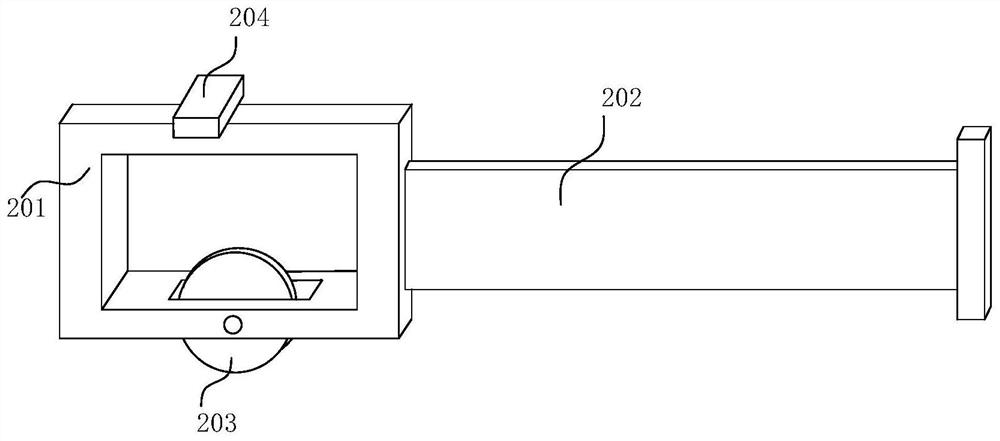

[0061] In a specific embodiment of the present invention, a cutter shaft 205 is fixed in the middle of the slitting hob 203, an installation cavity is provided at the bottom of the installation frame 201, and the slitting hob 203 is located in the installation cavity, And the two ends of the cutter shaft 205 are rotatably matched with the installation frame 201, and the cutter shaft 205 located in the installation cavity is sleeved with an annular air bag 207, and the outer end of the cutter shaft 205 is fixed with a cam 206, and the outer wall of the installation frame 201 A baffle 212 is fixed on the top, and an inflatable balloon 208 is fixed on the side of the baffle 212 , and a pipeline 209 is connected to the inflatable balloon 208 , and the pipeline 209 is connected to the annular airbag 207 .

[0062] In a specific embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com