Special polyester film slitting device for bus duct

A technology of polyester film and busway, which is applied in the field of special polyester film cutting device for busway, which can solve the problems of large proportion of waste materials, hidden dangers of busway product quality, and irregular product sizes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

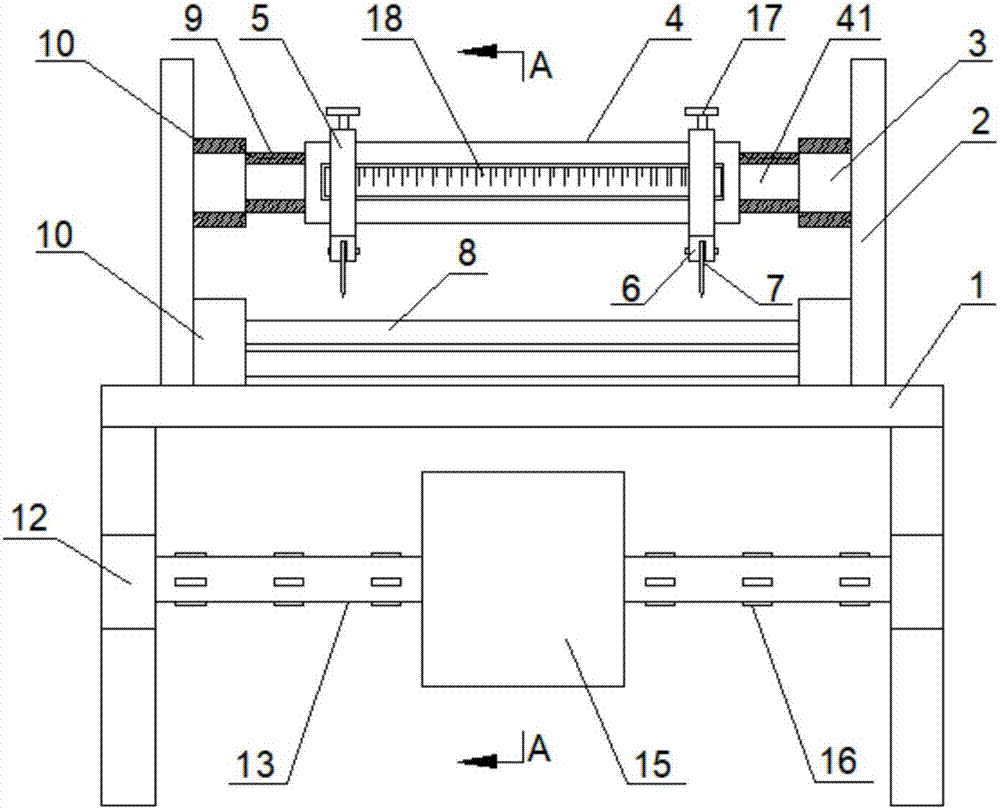

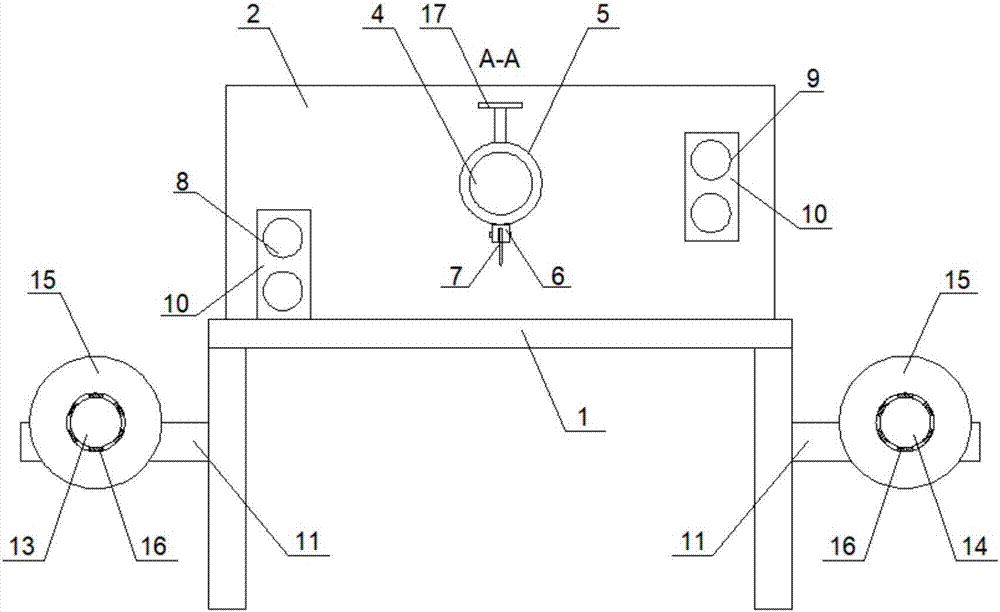

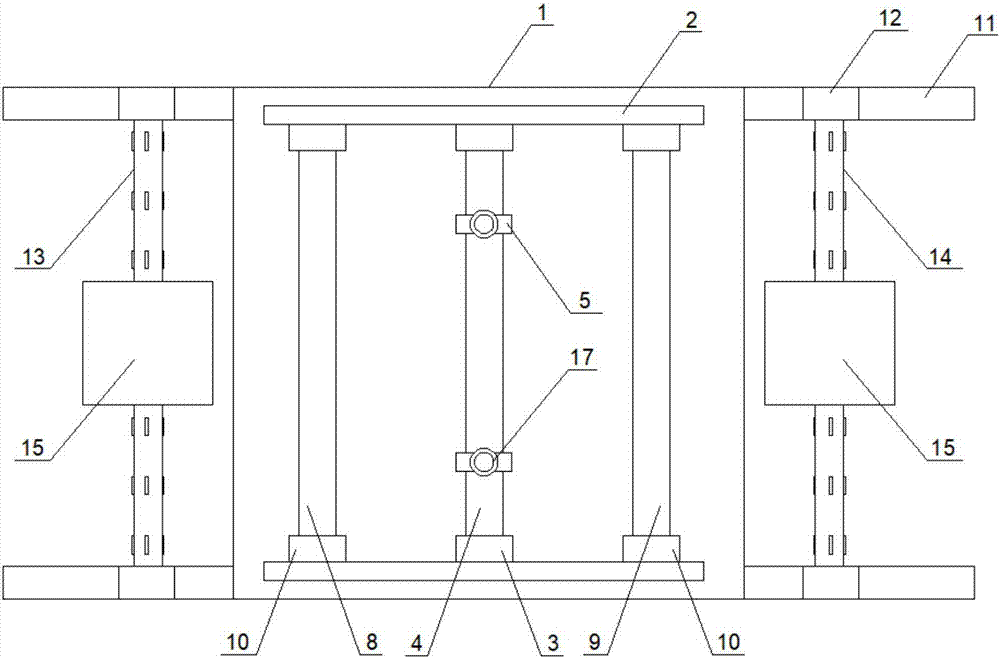

[0018] Such as Figure 1-4 As shown, the specific embodiment of the present invention: a special polyester film slitting device for bus duct, comprising: slitting table 1, vertical plates 2 arranged on both sides of slitting table 1, and legs arranged on slitting table 1 On the support frame 11 protruding forward on both sides, the cutting shaft 4 is arranged directly above the middle position of the cutting table 1, and the shaft ends 41 on both sides of the cutting shaft 4 are fixedly installed in the fixed seat 3, so that Said fixing seat 3 is fixedly installed on the vertical boards 2 on both sides.

[0019] Two sliding sleeve blocks 5 are installed by sliding assembly on the said cutting shaft 4, and the spacing is set between the two described sliding sleeve blocks 5, and said sliding sleeve block 5 is provided with a lock that pushes against the outer wall of the cutting shaft 4. Tightening bolt 17 is used to lock and position the adjusted sliding sleeve block 5, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com