Prestress steel purlin-concrete combined continuous rigid frame bridge and construction method thereof

A technology of prestressed steel and rigid frame bridges, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of concrete shrinkage, creep and prestress loss difficult to grasp, unstable concrete material properties, and excessive long-term deflection. , to achieve the effect of easy control of construction links and quality, reliable long-term structural performance, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

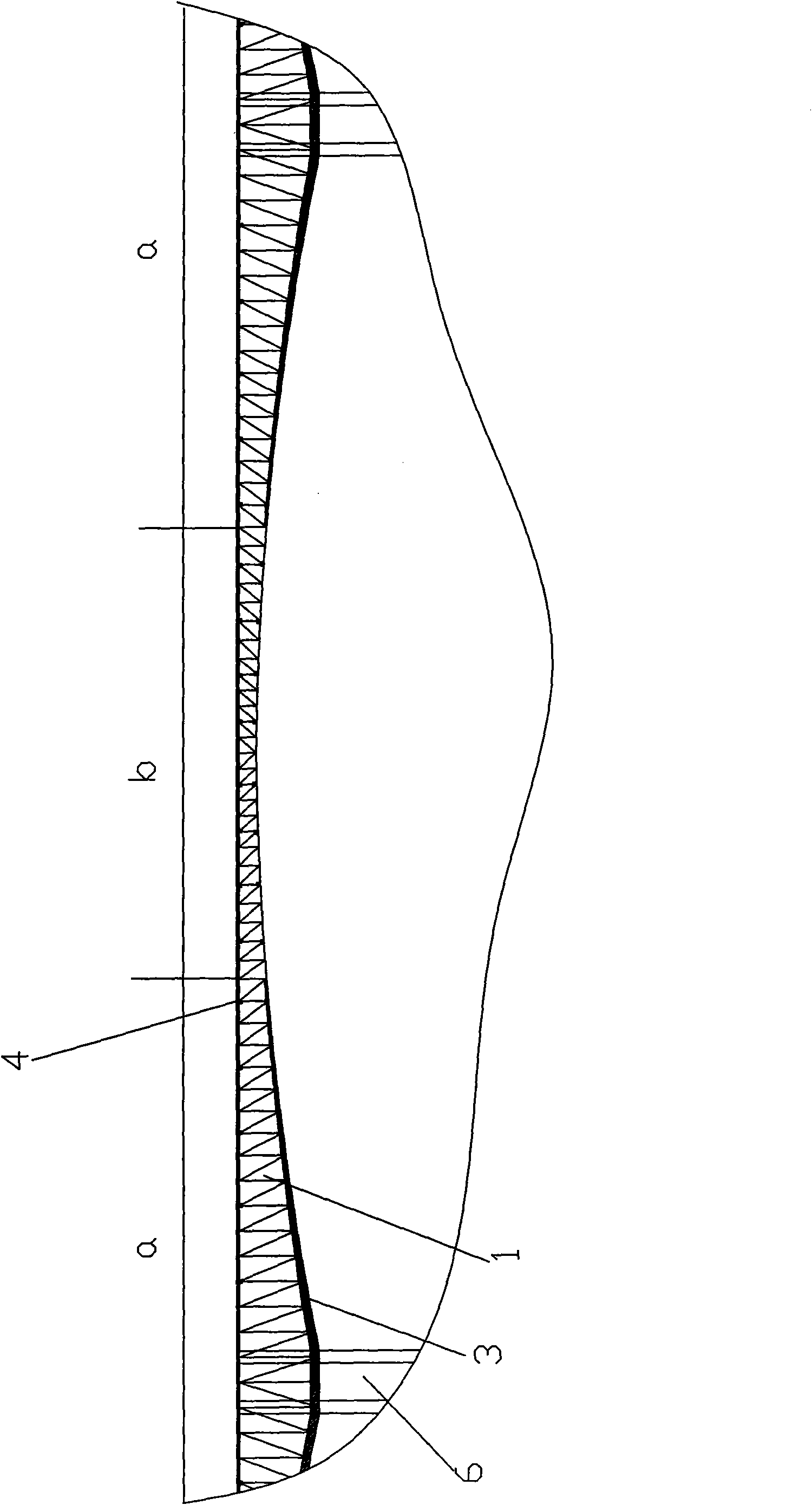

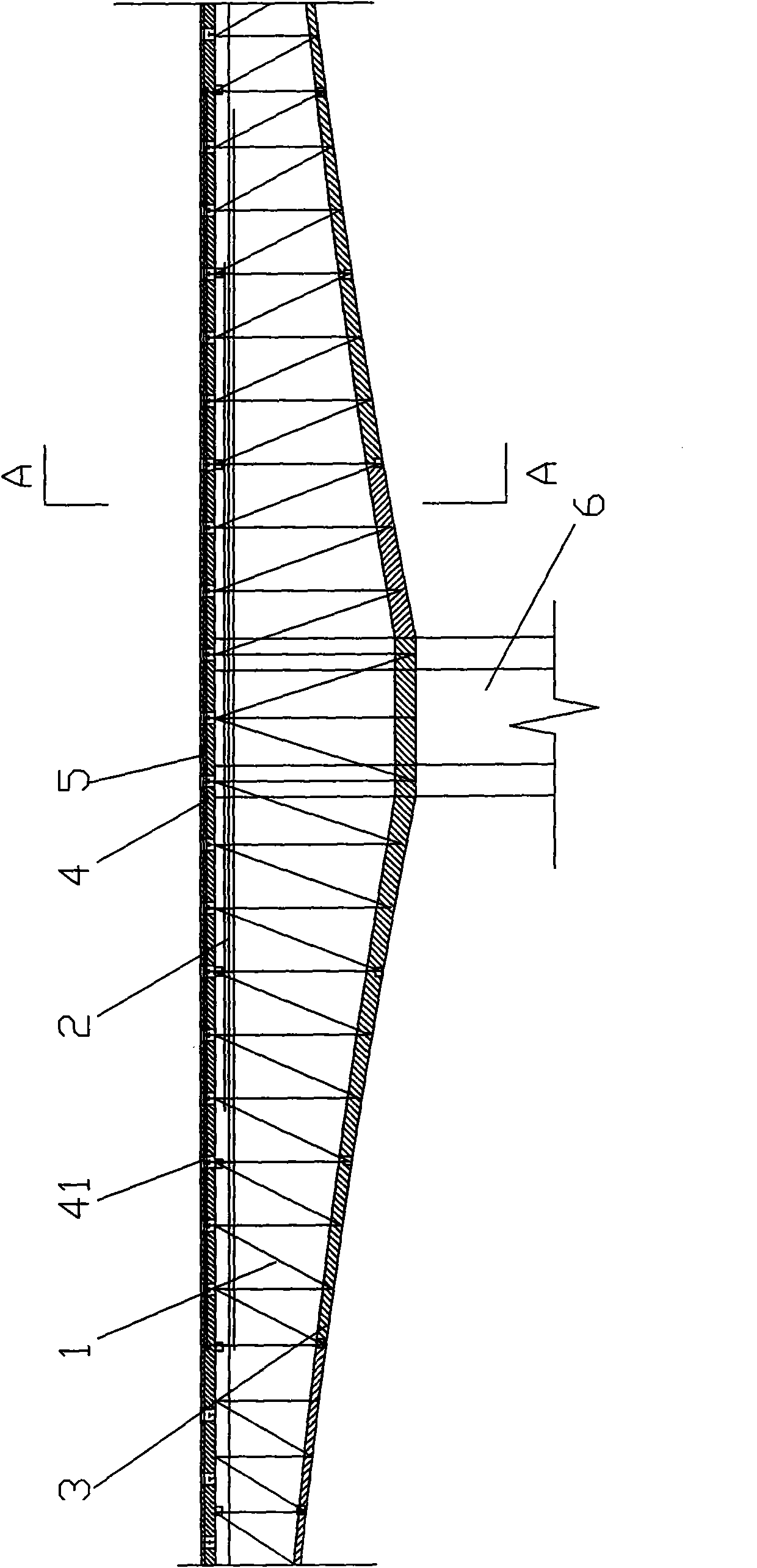

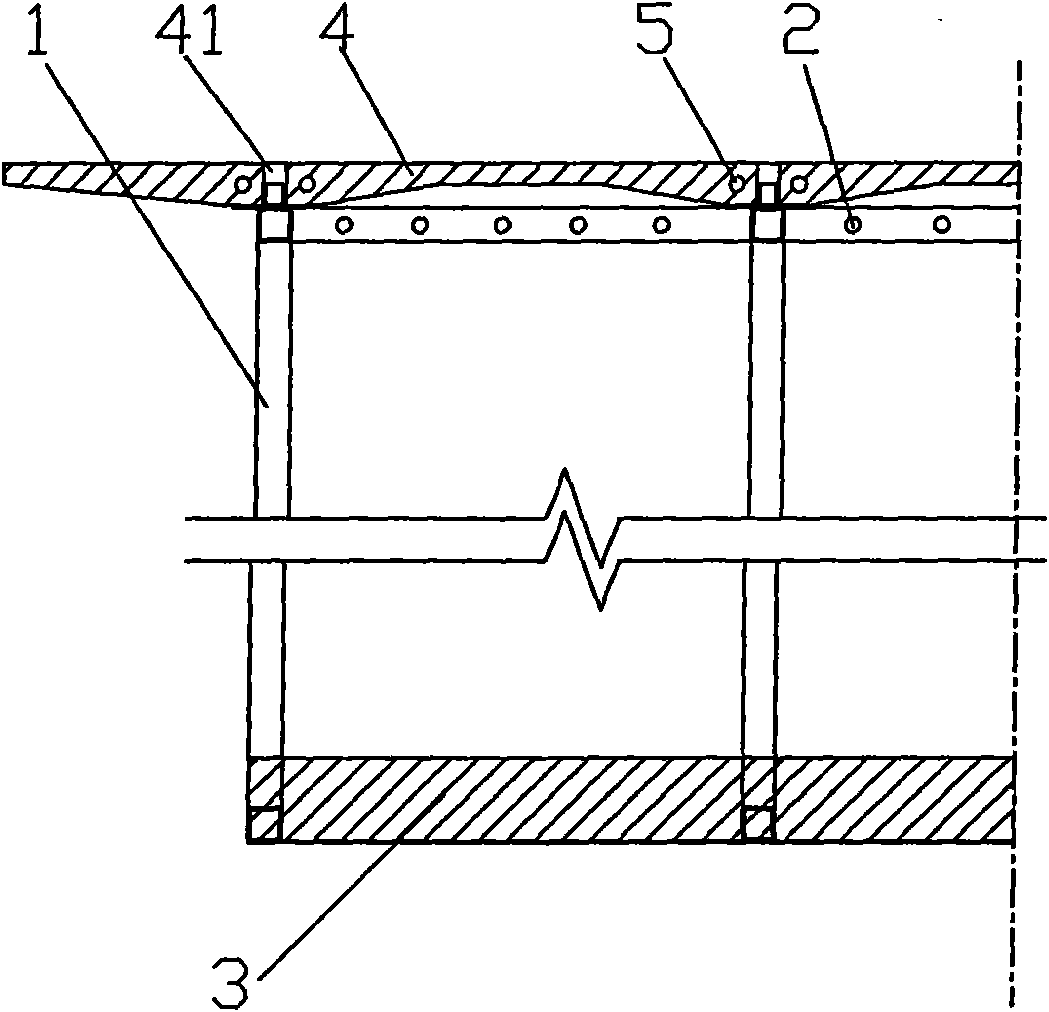

[0036] figure 1 It is a structural schematic diagram of the main girder of the bridge of the present invention, figure 2 Schematic diagram of the section of the main girder bearing negative bending moment, image 3 for figure 2 Sectional view along A-A direction, Figure 4 Schematic diagram of the section of the main beam bearing positive bending moment, Figure 5 for Figure 4 The cross-sectional view along the B-B direction shows that the prestressed steel truss-concrete composite continuous rigid frame bridge of this embodiment includes a main girder. The distance between the bars is provided with horizontal connections and diagonal braces; the top surface of each steel truss beam 1 is fixedly connected with the longitudinal steel plate to form the upper wing steel plate, and the bottom surface of all steel truss beams 1 is fixedly connected with steel plates to form the overall lower wing steel plate;

[0037] In the section of the main girder close to the pier 6 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com