Cutting device for solar cell piece

A technology for solar cells and cutting devices, which is applied in auxiliary devices, welding/cutting auxiliary equipment, laser welding equipment, etc., can solve the problems of affecting the cutting quality of cells, affecting the cutting positioning accuracy, and increasing the working hours of cutting. The positioning accuracy is limited, the effect of saving production man-hours and increasing the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

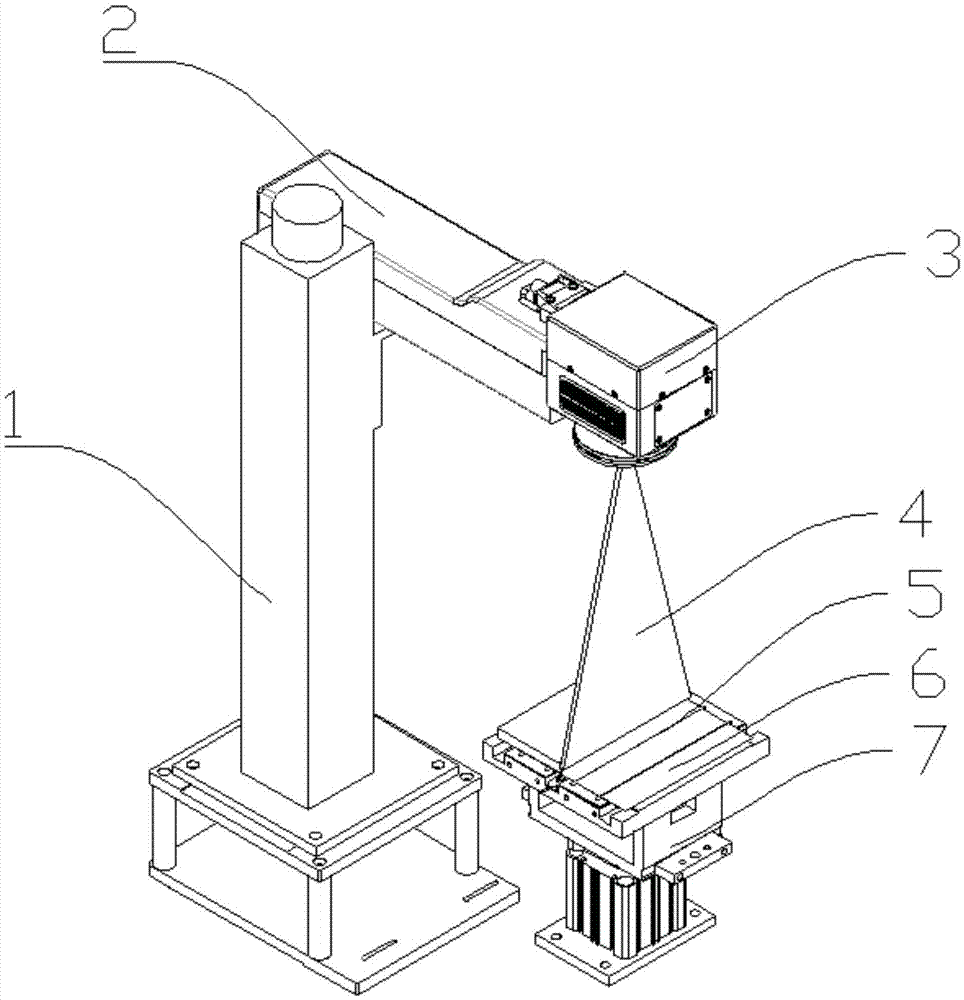

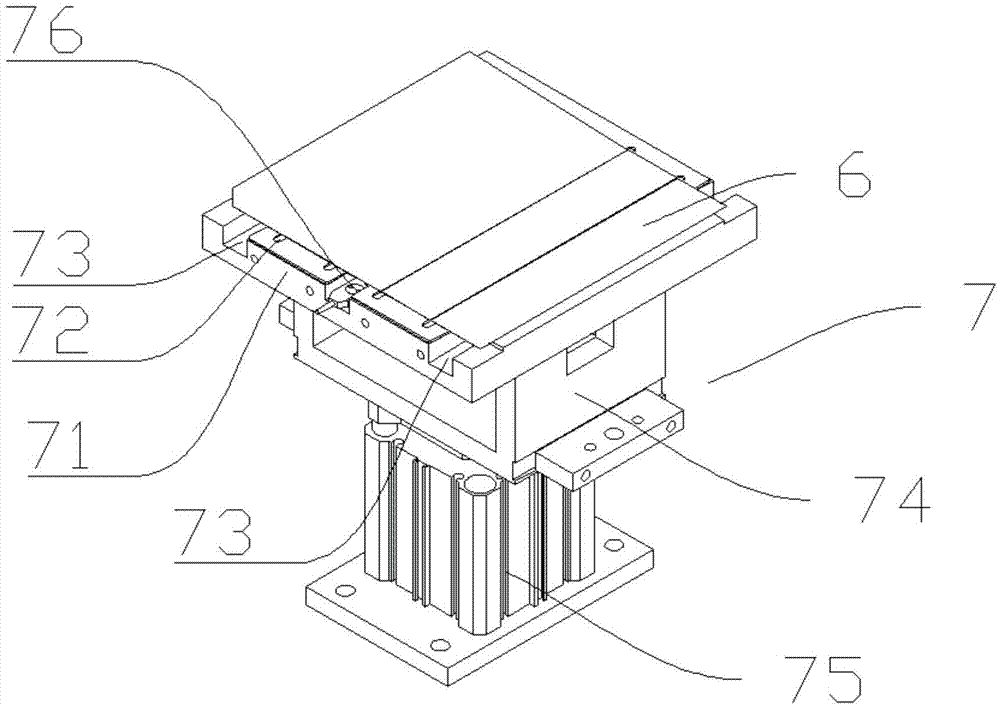

[0047] In order to achieve the purpose of the present invention, as Figure 1-4 As shown, some embodiments of a solar cell sheet cutting device in the present invention are: used to form a laser cutting line 5 on the surface of a solar cell sheet 6, including:

[0048] The laser adjustment platform 1 is used to adjust the installation position of the following laser 2;

[0049] A laser 2, connected to the laser adjustment platform 1, for emitting laser light;

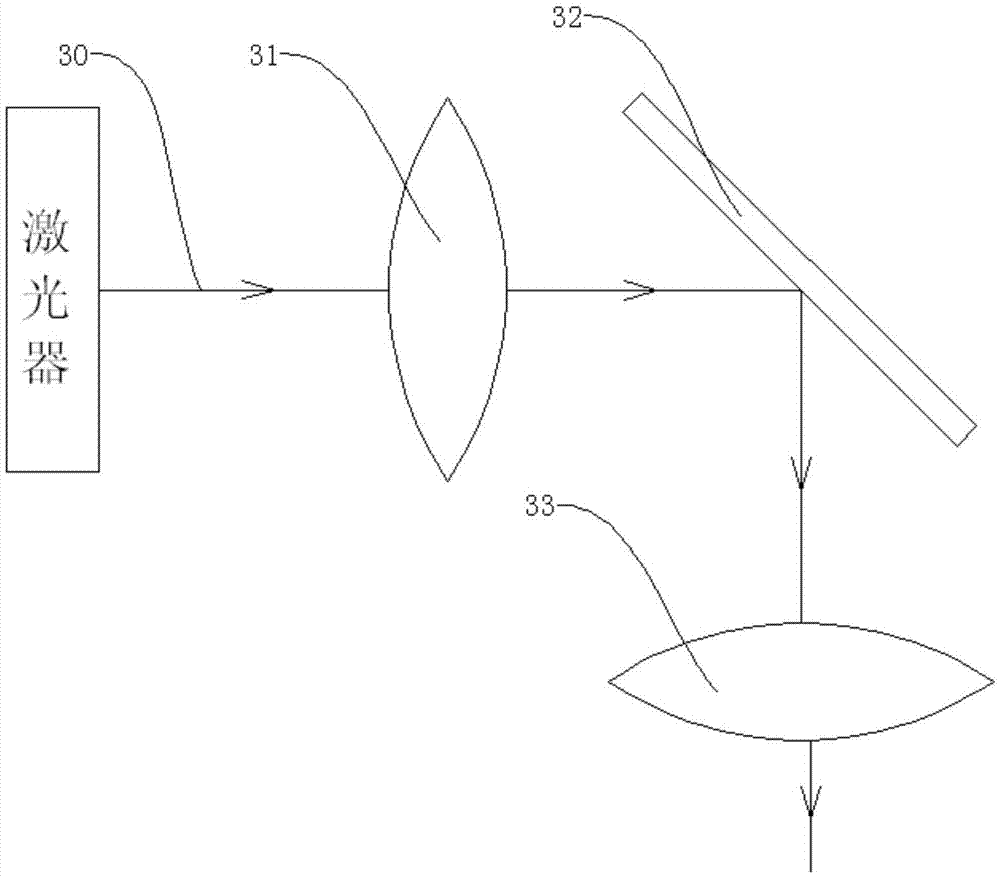

[0050] The spot generation device 3 is connected with the laser device 2 and includes a beam expander, a scanning galvanometer and a scanning field mirror arranged in sequence, and the laser light passes through the beam expander, the scanning galvanometer and the scanning field mirror in sequence; the beam expander It is used to enlarge the diameter of the laser and obtain a laser beam with high co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com