High-precision automatic fan cover production equipment

A production equipment and fan cover technology, applied in the field of high-precision fan cover automatic production equipment, can solve problems such as difficult to accurately position winding and welding, arc module shaking, positioning center point deviation, etc., to achieve high operation stability , Overcoming inertia, precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

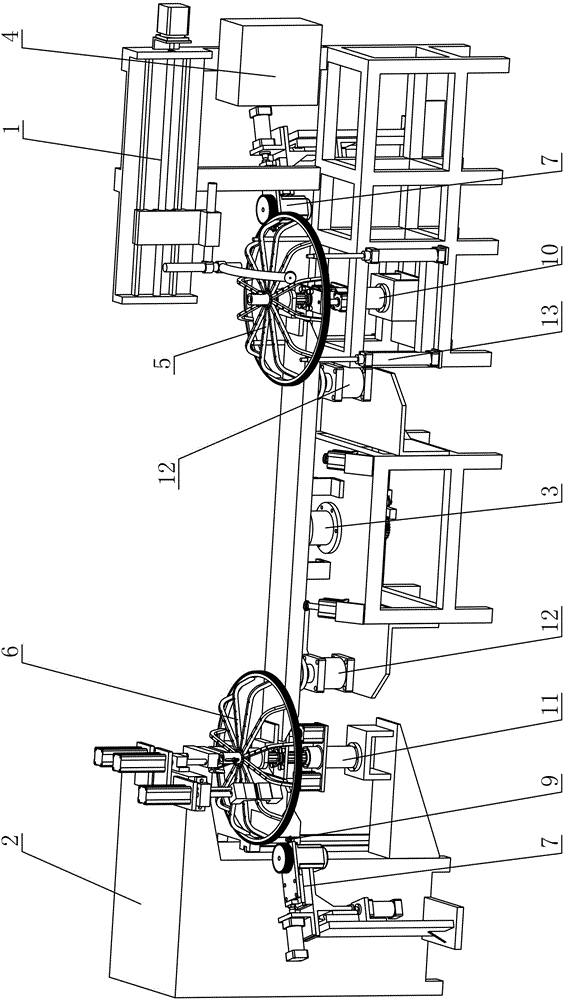

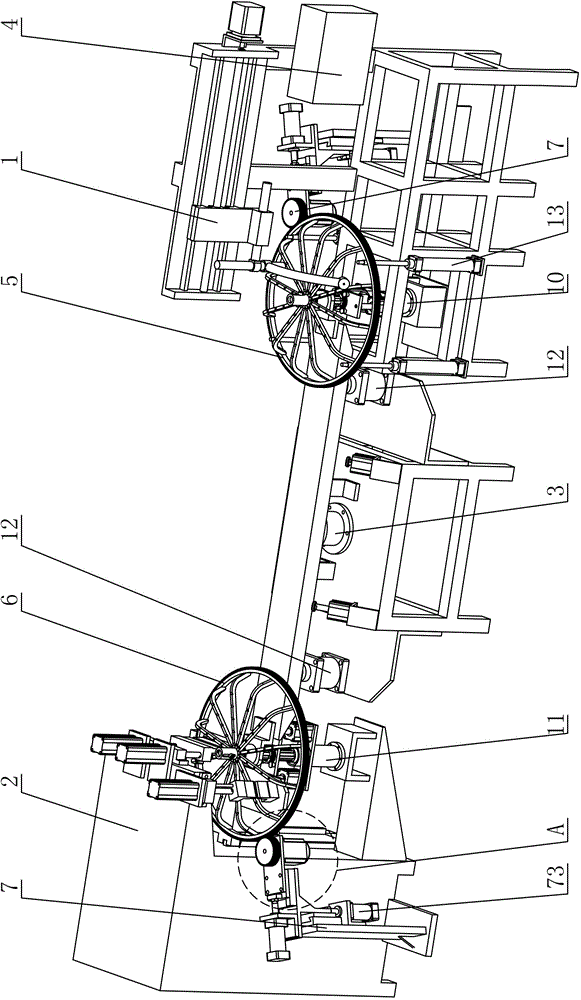

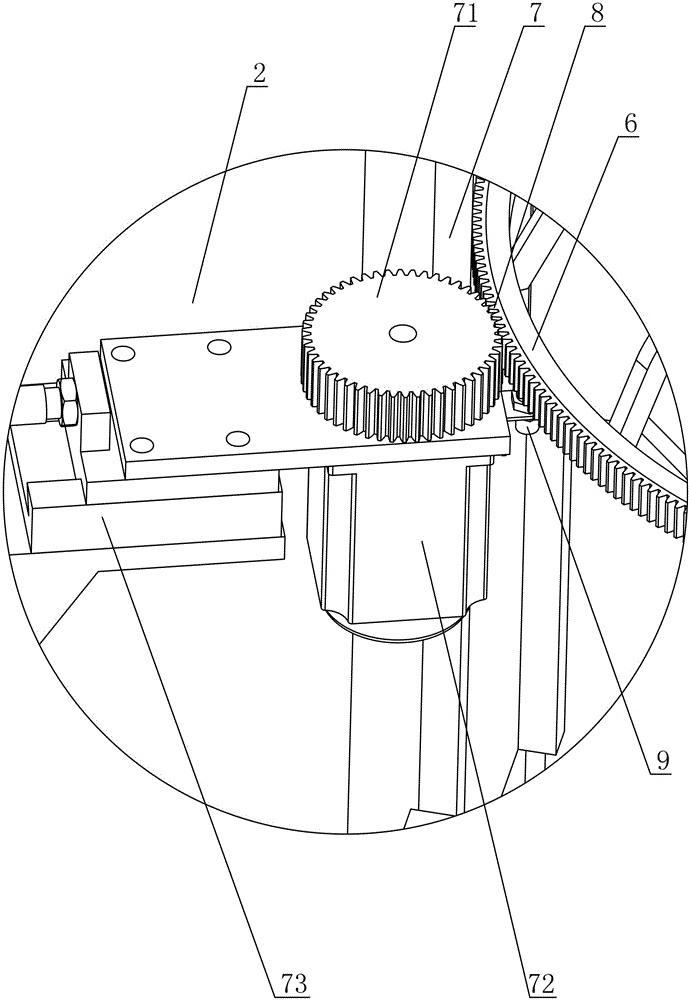

[0020] Below in conjunction with accompanying drawing, the present invention will be further described, Figure 1 to Figure 3 Shows a preferred embodiment of the present invention, which is mainly used for the manufacture of fan covers or other circular screen covers, which includes winding parts 1, welding parts 2, rotating drive parts 3 and control monitoring parts 4, control monitoring parts 4 are respectively connected with the winding part 1, the welding part 2, and the rotation driving part 3 and drive them to run sequentially. Wherein, the first processing module 5 and the second processing module 6 for installing workpieces are arranged on the two ends of the said rotating driving part 3, and the first processing module 5 and the second processing module 6 pass through the rotating driving part. 3 Rotate onto the winding part 1 or the welding part 2, the winding part 1 and the welding part 2 are respectively provided with an external meshing drive part 7 connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com