Method for controlling rotating speed of steam turbine on basis of self-adaptive inverse control

An adaptive inverse and speed control technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of difficult measurement of steam turbine power signals and great differences in the influence of control system dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

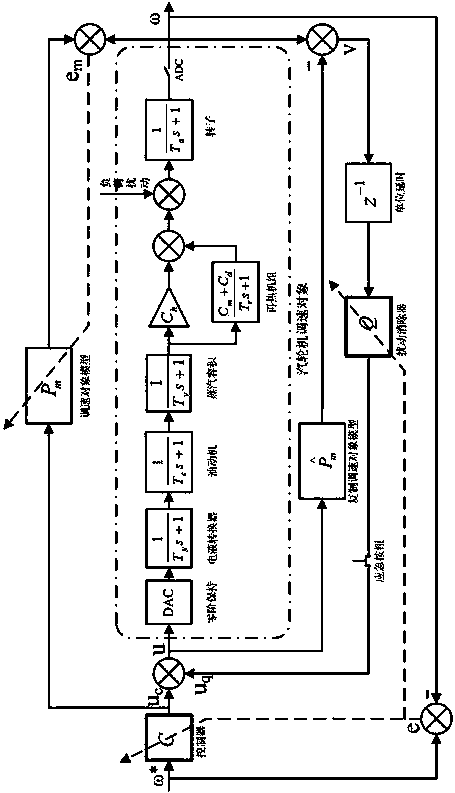

[0062] This publication proposes a steam turbine speed adaptive inverse control method (reference figure 1 ), the control method includes the following steps:

[0063] On-line identification of steam turbine speed control object model.

[0064] The steam turbine speed control object is a nonlinear object with dead zone, inertia and time-varying parameters, and its differential equation can be expressed as:

[0065] y(k+1)=g[u(k),u(k-1),Lu(k-m+1),y(k),y(k-1)L,y(k-n+1 )] (1)

[0066] In the formula, u and y are the control input signal of the steam turbine speed regulation object and the output speed ω of the steam turbine, respectively, and m and n are the corresponding orders respectively.

[0067] according to figure 1 Object model P for steam turbine speed regulation m To identify the structural requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com