Cable cutting machine

A wire cutting machine and frame technology, applied in the field of wire cutting machines, can solve the problems of affecting cutting quality, time-consuming and labor-intensive, and poor control of length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

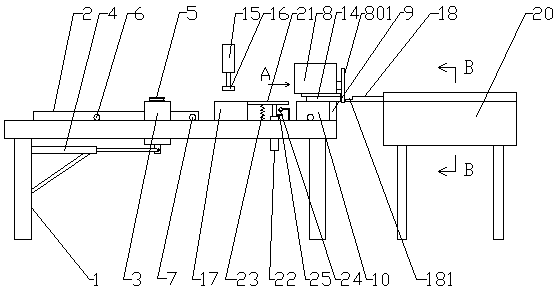

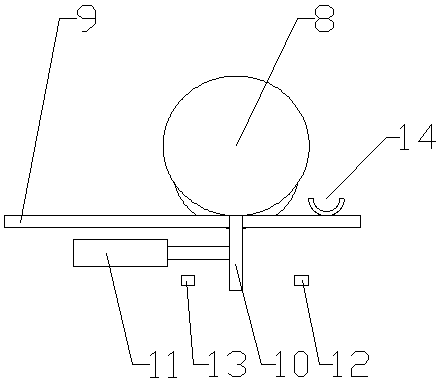

[0023] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 6 As shown, this thread cutting machine includes a frame 1 and a PLC control system, and the PLC control system controls the operation of the entire device. On the frame 1, a conveying system, a cutting system and a discharging system are installed in sequence, wherein:

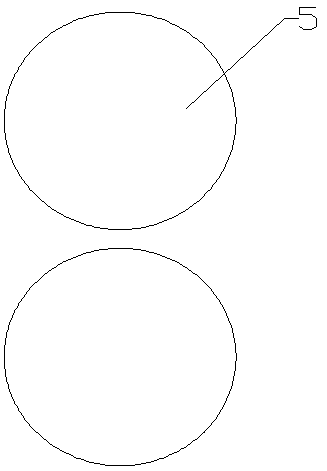

[0024] The conveying system includes: a slide rail 2 is installed on the frame 1, and there is a slide block 3 on the slide rail 2. The slide block 3 is fixed on the output end of the conveying cylinder 4, and the conveying cylinder 4 is installed under the slide rail 2. There are two ratchets 5 placed flat on the sliding block 3, and the two ratchets 5 are arranged front and back, that is to say, the line connecting the centers of the two ratchets 5 is perpendicular to the slide rail 2, and the rotation directions of the two ratchets 5 are opposite. The circumferential direction of 5 is inwardly rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com