Method for controlling magnetic monopole through DC to rotate to conduct segmented arc control

A DC control and magnetic monopole technology, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of poor control of arc shape, arc trajectory, high requirements, and difficult welding seam information, etc., so as to achieve easy stress Analysis and control, improved weld formation, precise weld seam tracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

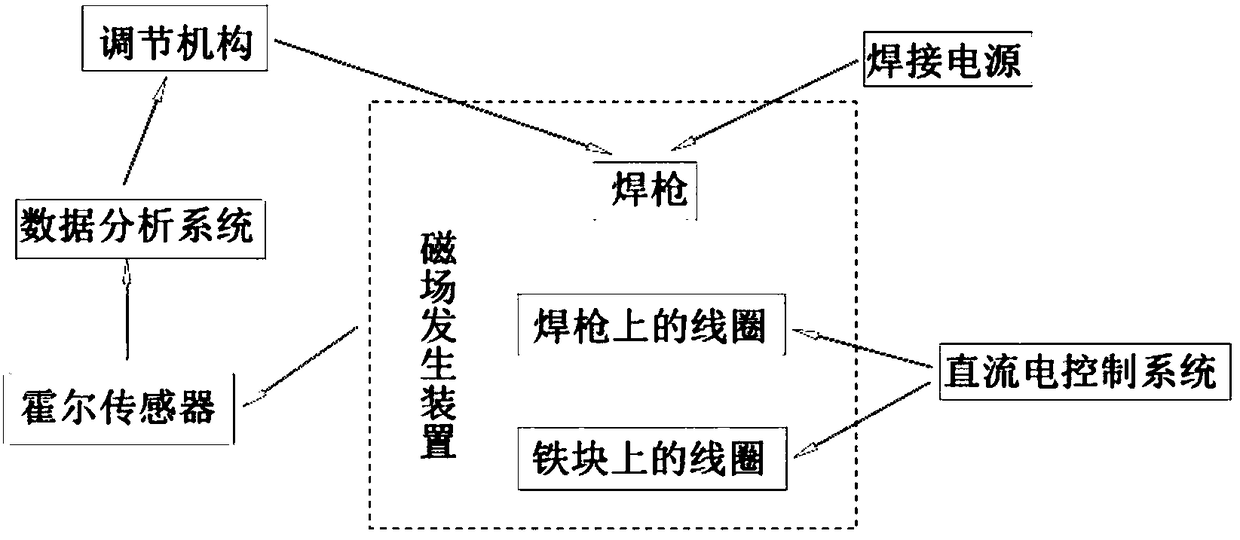

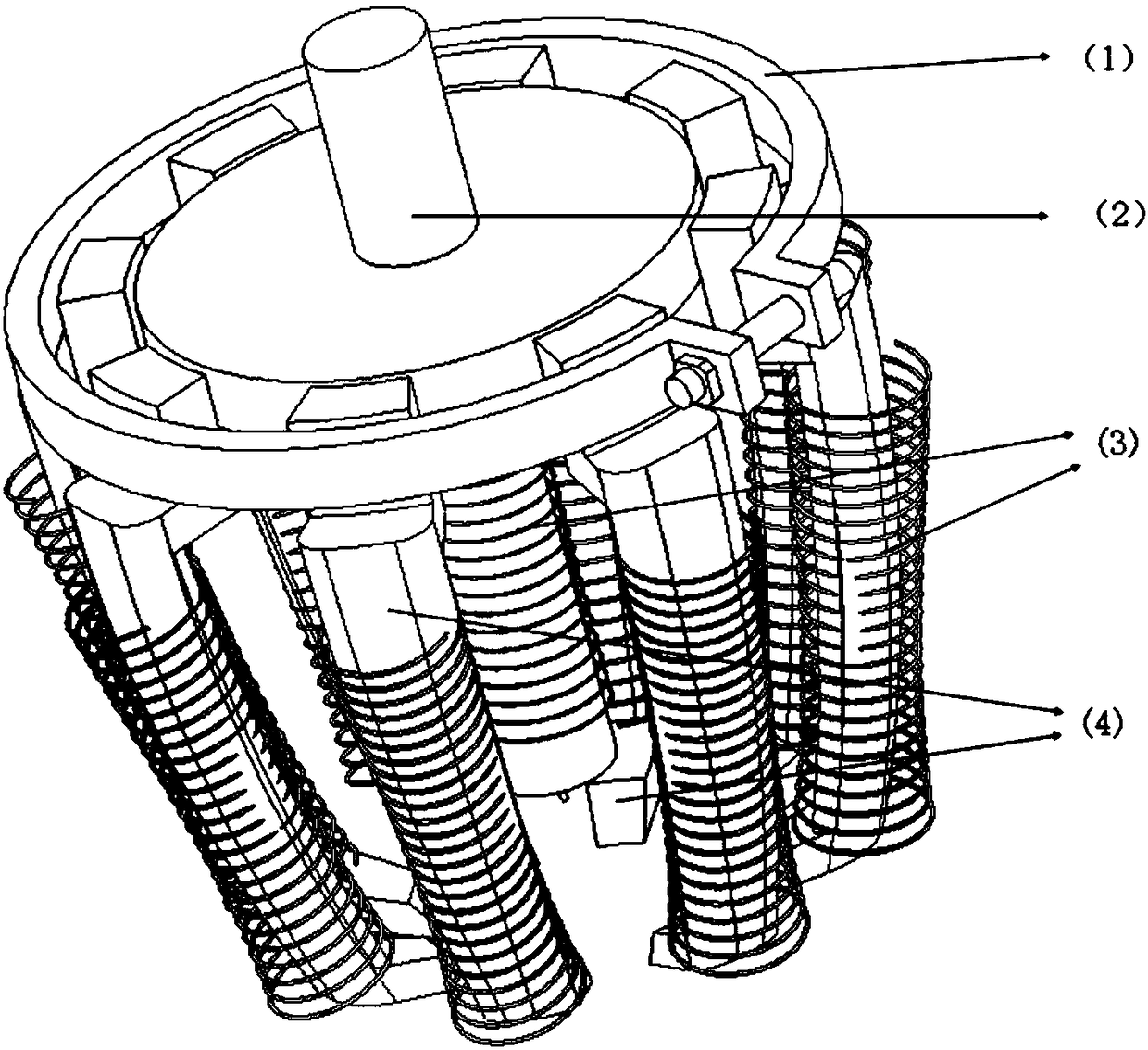

[0025] Implementation case 1, scan and track the weld seam. See figure 1 , figure 2 and Figure 4, made into a magnetic monopole rotary subsection arc control sensor. The direct current control system outputs a specific direct current to the conductive coil in the magnetic field generating device to rotate the single pole of the magnetic field to generate a longitudinal magnetic field with a deflection angle and swing along the center circle of the welding torch shaft. In each small arc interval, the traction The arc moves regularly, and the movements in the small arc intervals are combined to complete the circular swinging movement. During the entire circular movement of the arc, some required positions are taken, and the Hall sensor receives the change of the welding current when the arc moves to these positions to obtain corresponding data, and these data are input into the data analysis system for analysis. Corresponding welding parameters, these parameters are input ...

Embodiment example 2

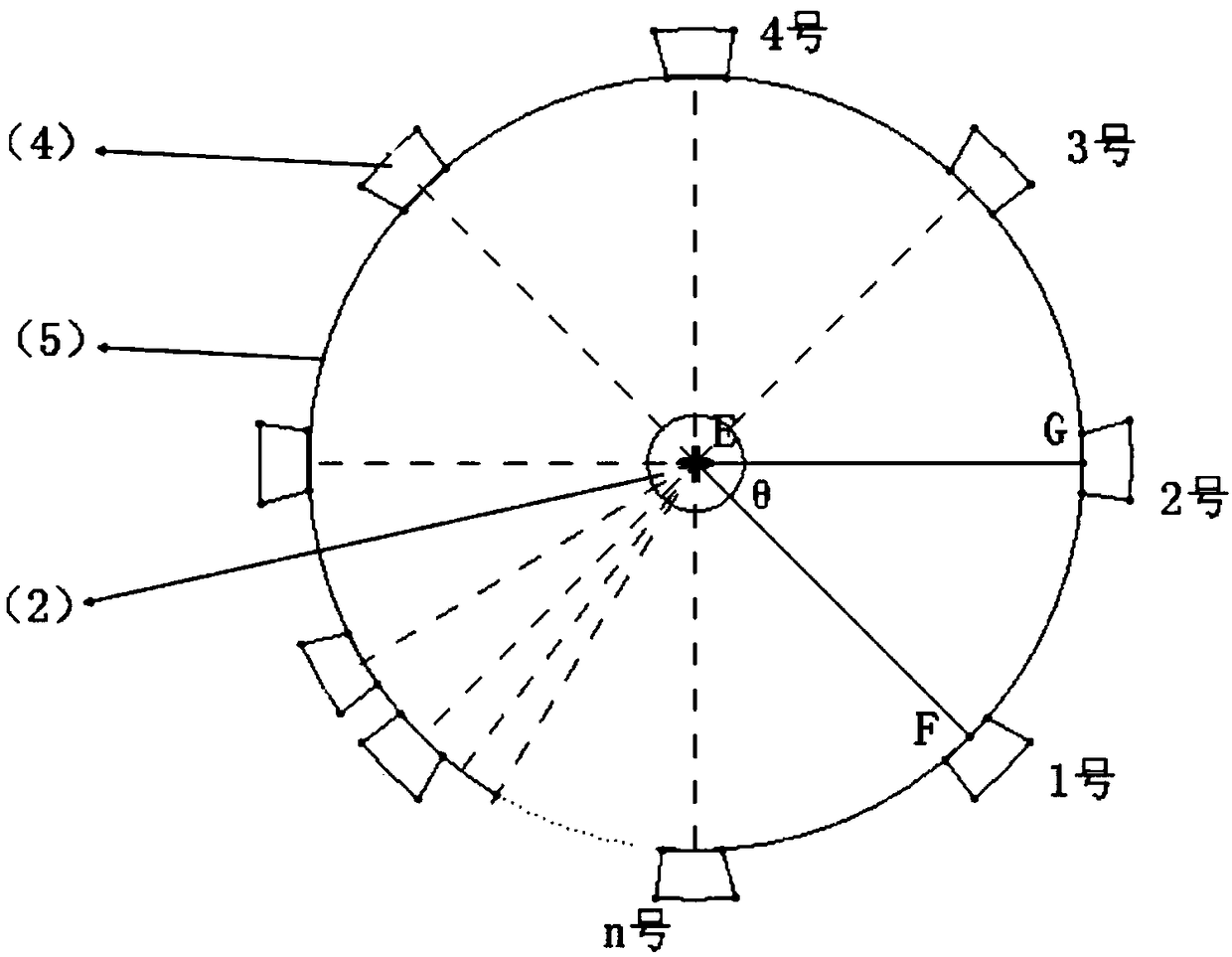

[0026] Implementation Case 2, improving weld formation. According to relevant literature and experiments, it can be known that a certain degree of stirring of the arc to the molten pool can improve the weld formation. The present invention divides the predetermined trajectory of the arc into equal segments, determines the positions of the electromagnets at the same time, and controls the magnetic presence and size of each iron block and the sequence of generating magnetism through direct current, thereby controlling the rotation and stirring area of the arc. See image 3 and Figure 4 , The value of n represents the number of electromagnets, if n is 5, it means that there are 5 electromagnets that form 72 degrees with each other. During welding, the molten pool plane is divided into 5 regions, that is, the force can be applied to the arc in each region in sequence, or the force can be applied between any number of regions in any order. When only one electromagnet is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com