Water holding controlled release fertilizer special for tobacco and method for producing the same

A water control and fertilizer technology, applied in the directions of inorganic fertilizers, nitrate fertilizers, fertilizer mixtures, etc., can solve the problems that the function of water-retaining agents is difficult to fully exert, and there is no technology for combining water-retention with fertilizers and controlled release in tobacco leaf production, so as to reduce farmland. Pollution and water pollution, reducing fertilizer fixation and leaching, and improving the effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

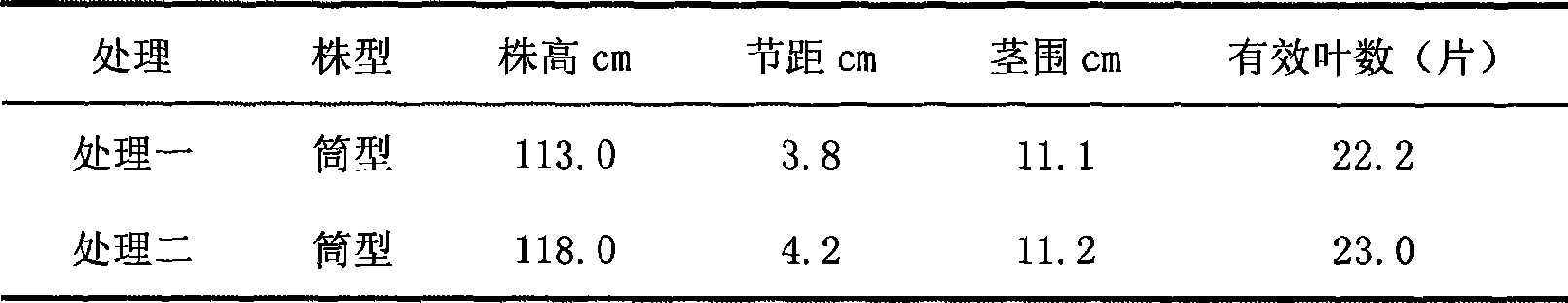

Embodiment 1

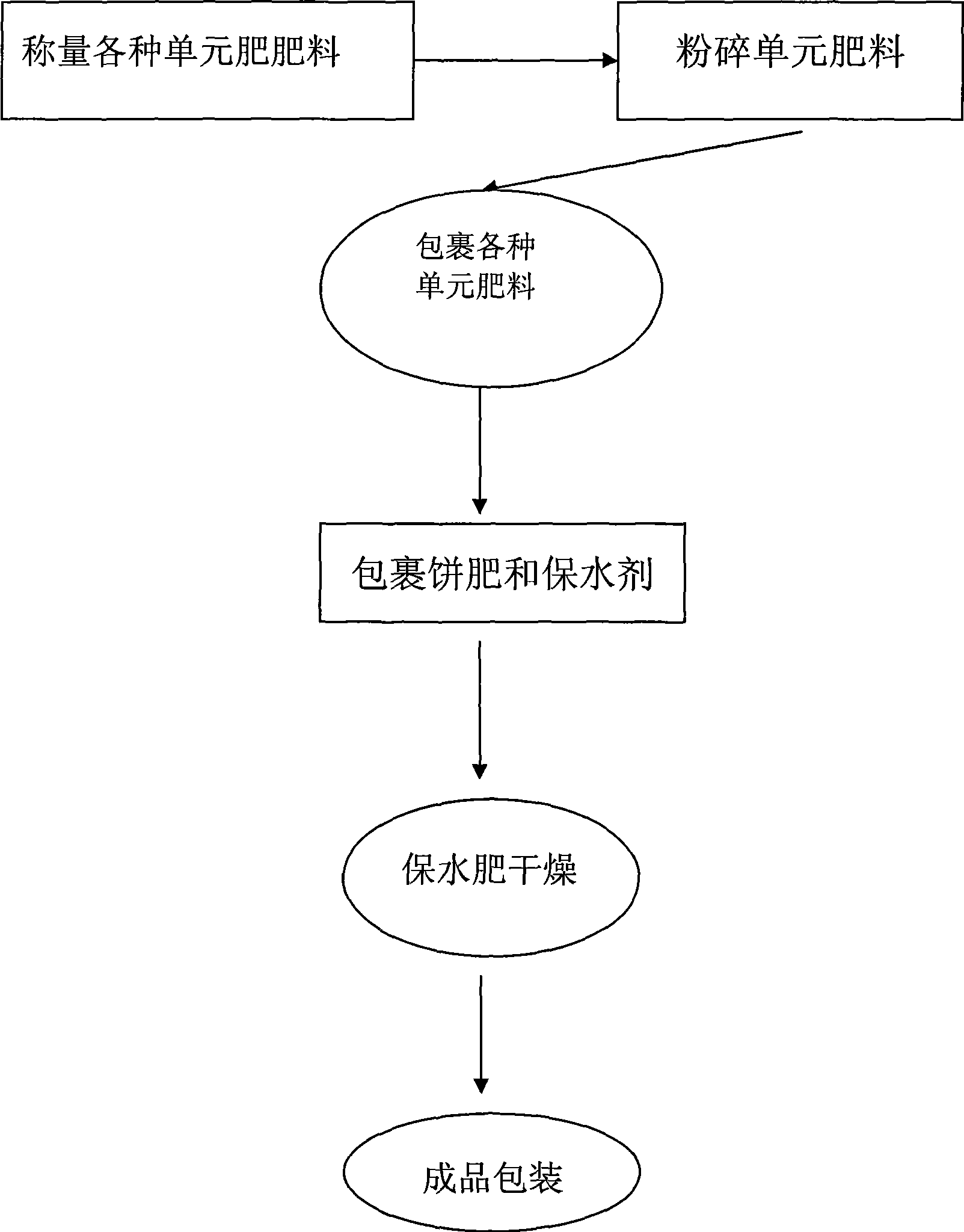

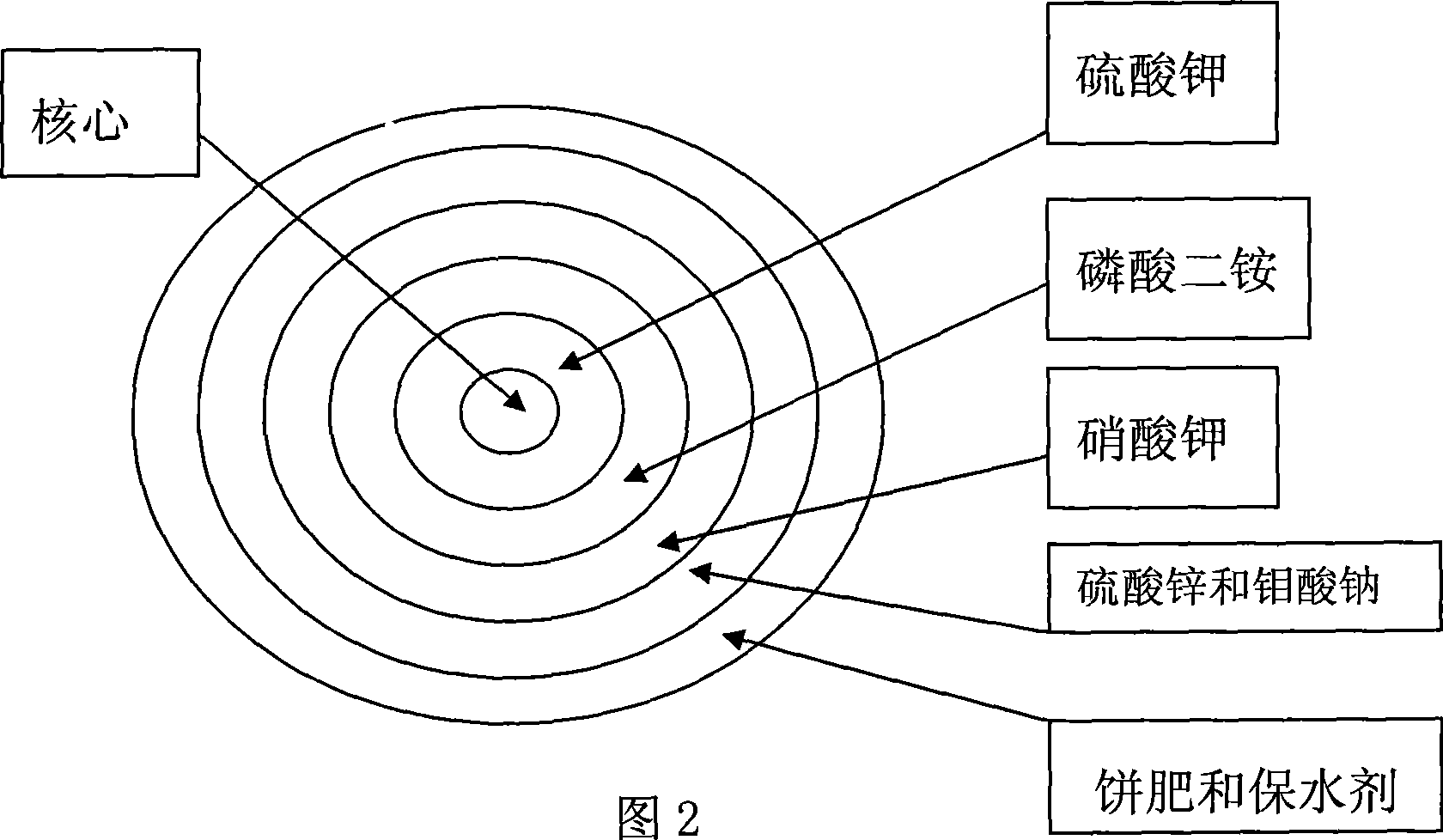

[0033] Firstly, the above-mentioned raw materials (not including sand grains) were pulverized into powder (through a 60-mesh sieve); 2.93% of the sand grains between 18-mesh sieves and 24-mesh sieves were weighed by weight percentage, put into a granulation tray, and 4.4 % Binder A granulation; Weigh 11.74% potassium sulfate, mix with 2.93% Binder A and 2.93% Binder B, gradually add to the granulation pan, wrap around the core granules to form the first layer Fertilizer wrapping layer: Weigh 11.74% potassium nitrate, mix with 2.93% binder A and 2.93% binder B, gradually add to the granulation pan after mixing, and wrap it outside the first layer of fertilizer wrapping layer to form the second Layer fertilizer coating layer; weigh 11.74% diammonium phosphate, mix it with 5.87% binder A, gradually add it to the granulation pan, and wrap it outside the second layer of fertilizer coating layer to form the third layer of fertilizer coating layer; weigh Take 3.12% zinc sulfate and 0...

Embodiment 2

[0035] First above-mentioned raw material (not including grain of sand) is pulverized into powder respectively (passes 60 mesh sieves); The sand grain 3.04% that crosses 18 mesh~24 mesh sieves is put into granulation tray by weight percentage, and then Add 4.56% binder A to the granulation pan for granulation; weigh 12.16% potassium sulfate, mix it with 3.04% binder A and 3.04% binder B, and gradually add it to the granulation pan after mixing, and wrap it in the core Extragranular, forming the first layer of fertilizer coating layer; weigh 12.16% potassium nitrate, mix with 3.04% binder A and 3.04% binder B, gradually add to the granulation pan after mixing, wrap in the first layer of fertilizer Outside the wrapping layer, a second layer of fertilizer wrapping layer is formed; 12.16% diammonium phosphate is weighed, mixed with 6.08% binder A, gradually added to the granulation pan, and wrapped outside the second layer of fertilizer wrapping layer to form the second layer of fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com