Biomass pellet burner for flue-cured tobacco

A biomass particle, combustion furnace technology, applied in combustion methods, combustion equipment, applications, etc., to achieve the effects of improving baking quality, avoiding burn accidents, and improving the quality of flue-cured tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

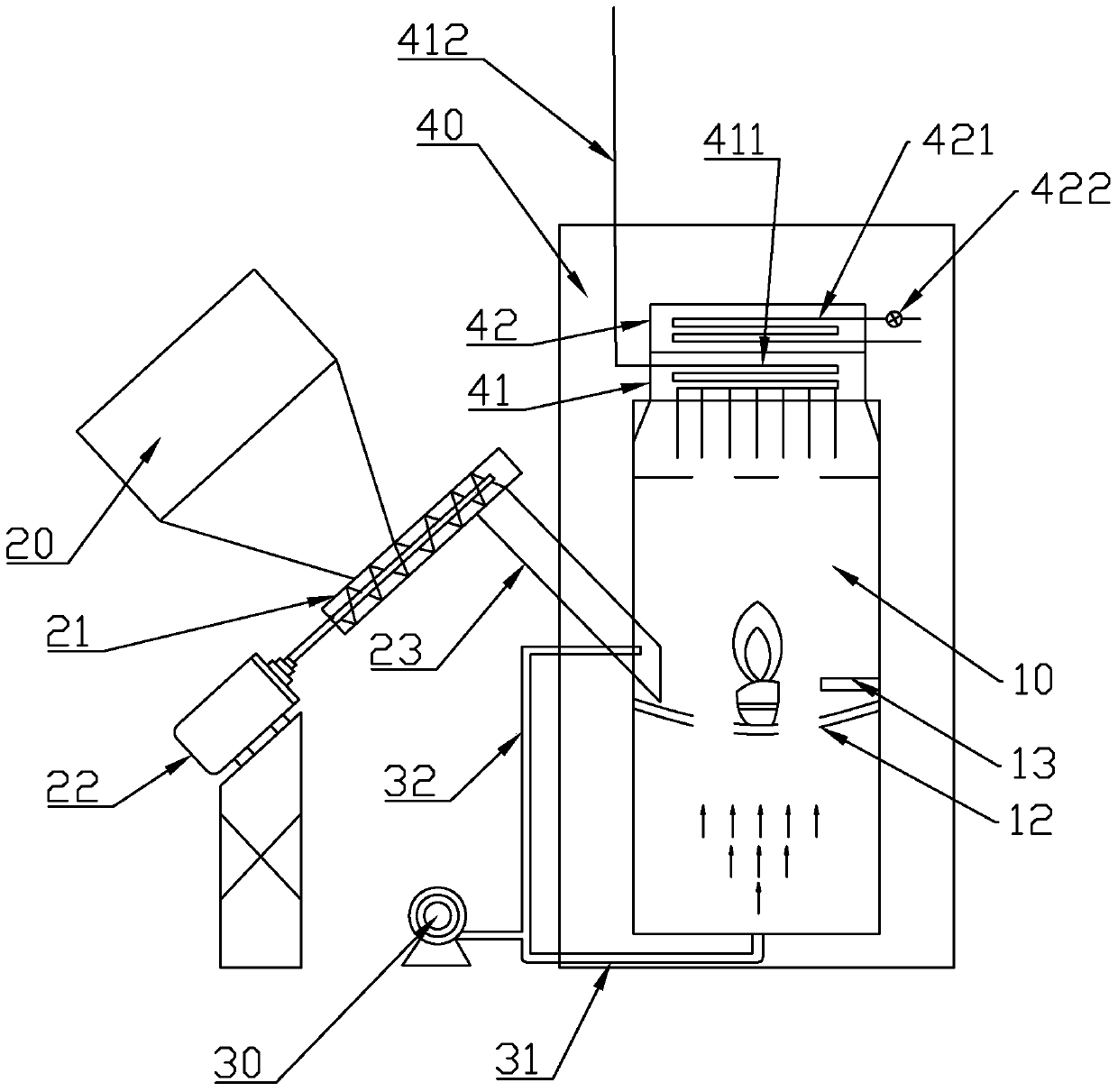

[0023] like figure 1 As shown, the biomass particle combustion furnace provided by the present invention includes a furnace body, a feeding device and an air supply device, wherein:

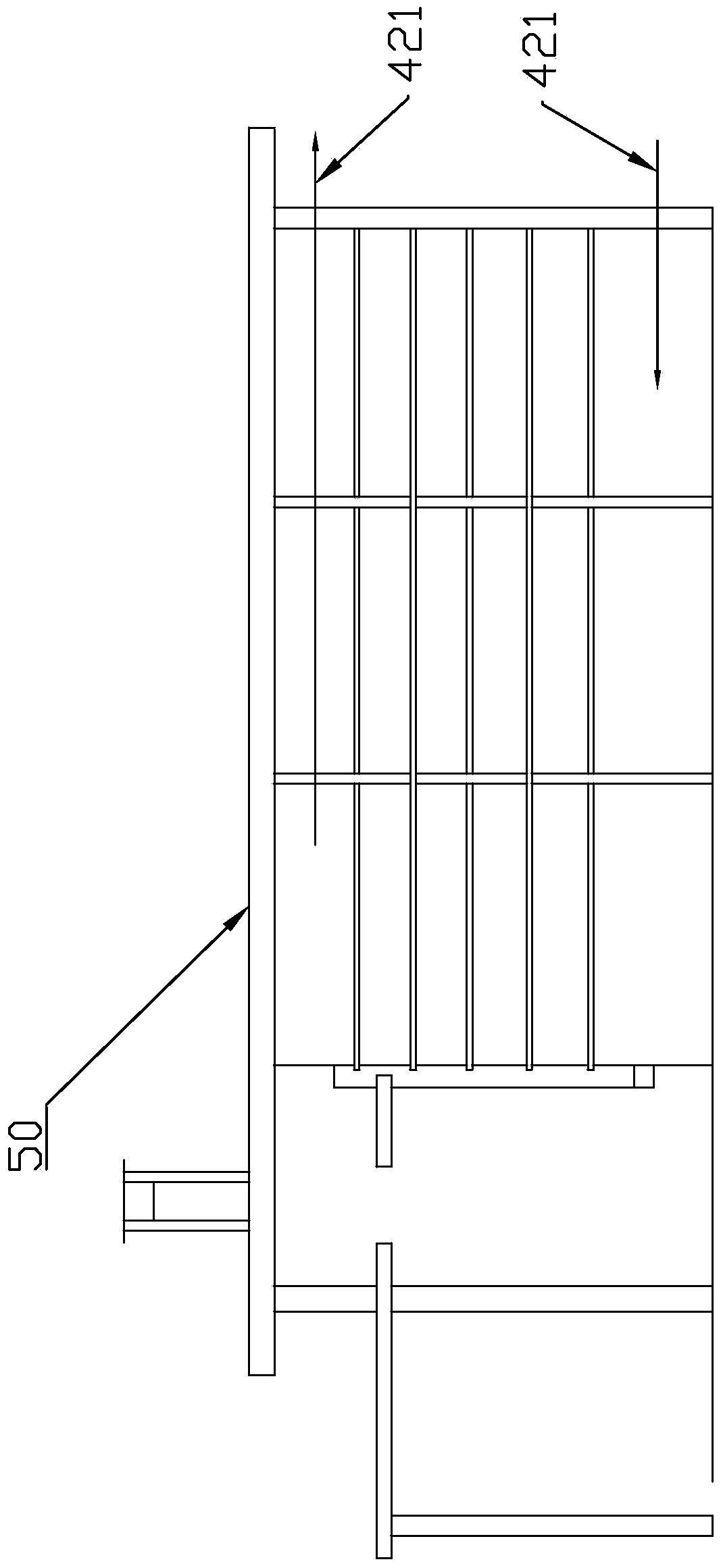

[0024] The hearth 10 of the furnace body is provided with a fire grate 12, the center of the fire grate 12 is provided with a basin-shaped depression, an igniter 13 is arranged at the basin-shaped depression, and a heat exchange chamber 40 is arranged above the furnace hearth 10 ;

[0025] The feeding device comprises a feed bin 20, a screw feeder 21, a variable frequency motor 22 and a feeding pipe 23, the inlet end of the screw feeder 21 is connected with the discharge port of the feed bin 20, and the screw feeder 21 is connected to one end of the feed pipe 23, and the other end of the feed pipe 23 is obliquely connected to the top of the basin-shaped depression, and the frequency conversion motor 22 is connected to the screw feeder 21. Power connection, conveying the material in the screw fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com