Preparation of special high-tower water-retention long-acting fertilizer for improving wheat quality and application of fertilizer in wheat topdressing

A wheat and fertilizer technology, applied in the direction of application, inorganic fertilizer, ammonium salt fertilizer, etc., can solve the problems of difficulty in realizing the combination of agricultural machinery and agronomy, the shortage of high-quality wheat, and the increase in cost of top dressing, so as to facilitate the synthesis of protein and improve the quality of wheat , The effect of improving nitrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

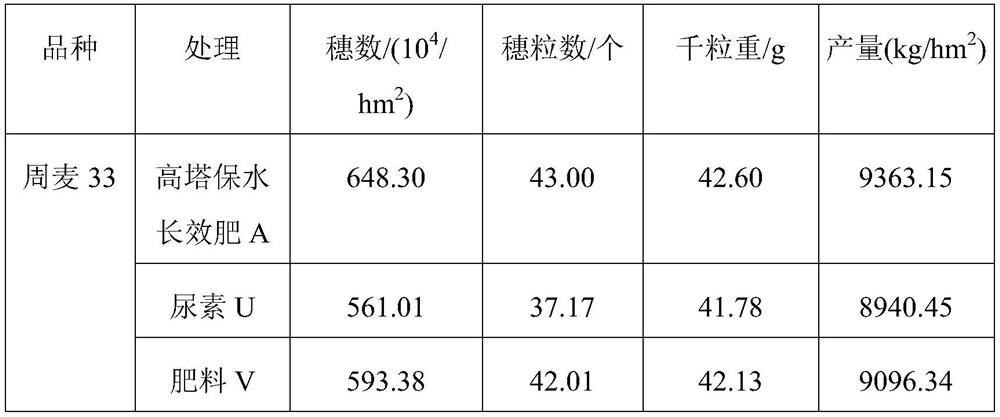

Embodiment 1

[0036] In this embodiment, a special high-tower water-retaining long-acting wheat fertilizer 30-0-5Cl and a preparation method thereof for improving the quality of wheat are provided, as follows:

[0037] (1) Melt 500kg of urea (with N content of 230kg) in a urea melter with steam at 135°C to form a urea melt, then transport the urea melt to the urine insulation tank, and add 2kg of water at the same time agent (modified polyacrylamide) and 1kg nitrification inhibitor (3,4-dimethylpyrazole phosphate, referred to as DMPP), and mix evenly under the action of high-speed shearing machine;

[0038] (2) 80kg ammonium sulfate (S content is 19.4kg), 210kg ammonium chloride (N content is 52.5kg), 85kg potassium chloride (K content is 51kg), 2kg amino acid, 20kg ammonium polyphosphate chelated zinc (zinc Content is 2.6kg), 10kg sodium octaborate tetrahydrate (boron content is 2kg), 20kg amino acid chelated manganese (manganese content is 2.6kg) and 70kg filler, heat and mix in the powde...

Embodiment 2

[0041] In this embodiment, a special high-tower water-retaining long-acting fertilizer 28-5-6cl and a preparation method thereof for improving wheat quality are provided, as follows:

[0042] (1) Melt 500kg of urea (with N content of 230kg) in a urea melter with steam at 135°C to form a urea melt, then transport the urea melt to the urine insulation tank, and add 2kg of water at the same time Agent (modified polyacrylamide) and 0.5kg nitrification inhibitor (DMPP), mix under the effect of high-speed shearing machine;

[0043] (2) 110kg diammonium phosphate (50.6kg phosphorus content), 100kg ammonium sulfate (24.2kg S content), 40kg ammonium chloride (10kg N content), 100kg potassium chloride (60kg K content), 1kg amino acid , 10kg ammonium polyphosphate chelated zinc (zinc content is 1.3kg), 10kg sodium octaborate tetrahydrate (boron content is 2kg), 15kg amino acid chelated manganese (manganese content is 1.95kg) and 111.5kg filler, heated in powder Heating and mixing in the...

Embodiment 3

[0046] In this embodiment, a special high-tower water-retaining long-acting fertilizer 32-0-8Cl and a preparation method thereof for improving wheat quality are provided, as follows:

[0047] (1) Melt 600kg of urea (with N content of 276kg) in a urea melter with steam at 135°C to form a urea melt, then transport the urea melt to the urine insulation tank, and add 1kg of water at the same time Agent (modified polyacrylamide) and 1kg nitrification inhibitor (DMPP), mix under the effect of high-speed shearing machine;

[0048] (2) 60kg ammonium sulfate (S content is 14.5kg), 130kg ammonium chloride (N content is 32.5kg), 135kg potassium chloride (K content is 81kg), 1.5kg amino acid, 25kg ammonium polyphosphate chelated zinc ( Zinc content is 3.25kg), 15kg sodium octaborate tetrahydrate (boron content is 3kg), 10kg amino acid chelated manganese (manganese content is 1.3kg) and 21.5kg filler, heat and mix in the powder heater, the material The temperature was increased to 70°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com