Method for improving baking quality of frozen dough through magnetic field assisted freezing storage

A magnetic field-assisted, dough-based technology, applied in cold storage, radiation storage, etc., can solve problems such as high cost, achieve low cost, reduce hardness, and improve baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 500g of high-gluten flour, 300g of water, 45g of sugar, 6g of salt and 8g of yeast, mix well and pour into a blender to stir until the dough can pull out the glove film; stir at a slow speed of 18r / min for 5min, and then Stir rapidly at 40r / min for 20min. Cut the kneaded dough into small pieces of 50g / piece, and knead by hand to deflate and round.

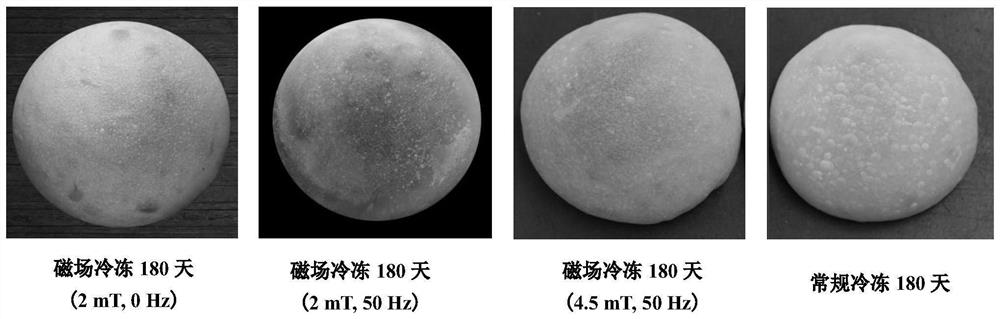

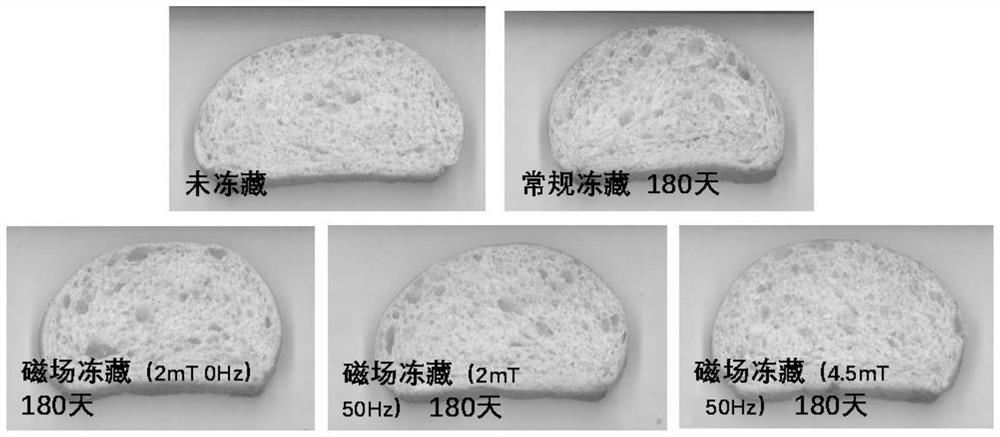

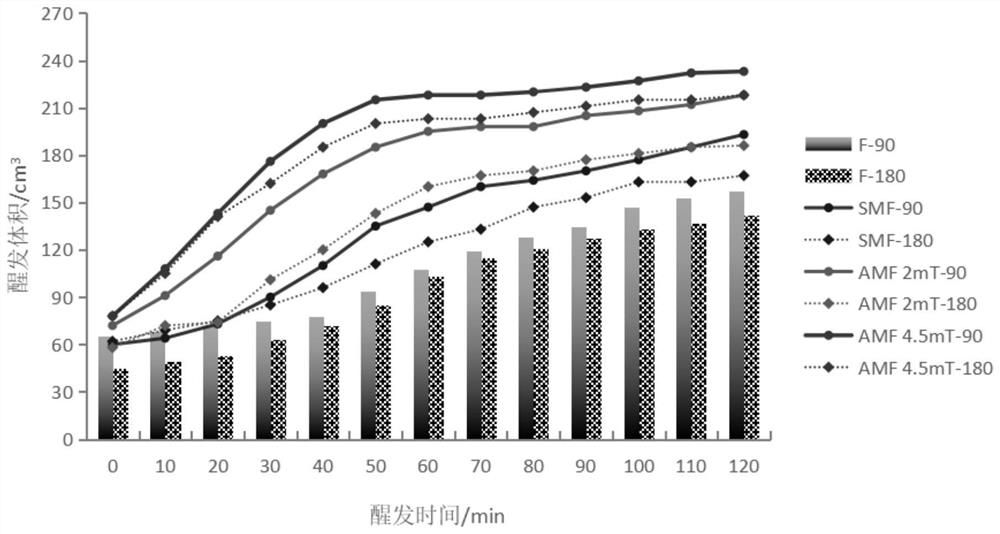

[0037] Wrap the divided and rounded frozen dough with plastic wrap, and put it into a No. 8.5 ziplock bag (specification: length × width × height = 270mm × 180mm × 0.05mm), and each bag is filled with 5 pieces of frozen dough . Place the frozen dough sealed in a ziplock bag in a magnetic field low-temperature test box, and set the magnetic field preservation parameters: the magnetic field strength is 2mT, the frequency is 0Hz, the temperature is -20°C, and the storage time is 0 to 180 days. The test chamber is equipped with corresponding temperature and humidity sensors and automatically controlled heating and humidi...

Embodiment 2

[0040] Weigh 500g of high-gluten flour, 300g of water, 45g of sugar, 6g of salt and 8g of yeast, mix well and pour into a blender to stir until the dough can pull out the glove film; stir at a slow speed of 18r / min for 5min, and then Stir rapidly at 40r / min for 20min. Cut the kneaded dough into small pieces of 50g / piece, and knead by hand to deflate and round.

[0041] Wrap the divided and rounded frozen dough with plastic wrap, and put it into a No. 8.5 ziplock bag (specification: length×width×height=270mm×180mm×0.05mm), wherein each bag is filled with 5 pieces of frozen dough. Place the frozen dough sealed in a ziplock bag in a magnetic field low-temperature test box, and set the magnetic field preservation parameters: magnetic field freezing storage mode: magnetic field strength is 2mT, frequency is 50Hz, temperature is -20°C, and the storage time is up to 180°C. sky. The test chamber is equipped with corresponding temperature and humidity sensors and automatically contro...

Embodiment 3

[0044] Weigh 500g of high-gluten flour, 300g of water, 45g of sugar, 6g of salt and 8g of yeast, mix well and pour into a blender to stir until the dough can pull out the glove film; stir at a slow speed of 18r / min for 5min, and then Stir rapidly at 40r / min for 20min. Cut the kneaded dough into small pieces of 50g / piece, and knead by hand to deflate and round.

[0045] Wrap the divided and rounded frozen dough with plastic wrap, and put it into a No. 8.5 ziplock bag (specification: length×width×height=270mm×180mm×0.05mm), wherein each bag is filled with 1 piece of frozen dough. Place the frozen dough sealed with a ziplock bag in a magnetic field low-temperature test box, and set the magnetic field preservation parameters: the magnetic field strength is 4.5mT, the frequency is 50Hz, the temperature is -20°C, and the storage time is 0 to 180 days. The test chamber is equipped with corresponding temperature and humidity sensors and automatically controlled heating and humidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com