Dehumidification method of heat pump curing equipment and heat pump curing equipment

A technology of curing equipment and heat pump, applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of reducing the quality of tobacco leaf curing, achieve the effects of shortening the curing cycle, reducing operating costs, and improving the curing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

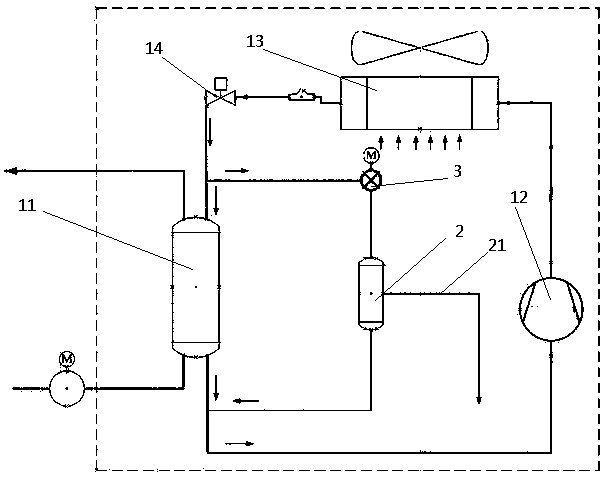

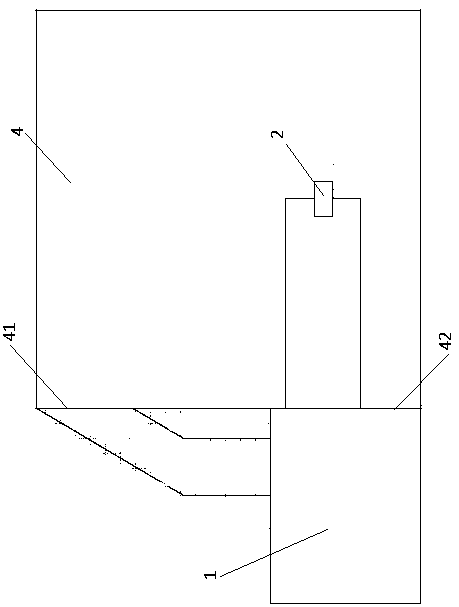

[0018] like figure 1 , figure 2 As shown, the present invention proposes a heat pump drying heat pump baking equipment, including: a barn 4, a heat pump unit 1, a humidity sensor and a condensation device 2, wherein the humidity sensor can also be a temperature and humidity sensor, and the heat pump unit 1 includes Compressor 12, condenser 13, electronic expansion valve 14, and evaporator 11 connected in sequence to increase the temperature in the barn 4, the barn 4 is a closed barn 4, and the heat exchange through the condenser 13 can continuously improve the temperature of the barn The temperature in the barn 4 is baked, and the humidity sensor can monitor the humidity information in the barn 4 in real time. When the monitored humidity value exceeds the preset humidity value, the condensation device 2 is turned on, and the condensation device 2 is connected to the heat pump unit through the pipeline. The heat exchanger connected in parallel with the evaporator 11 of 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com