A technical process of hanging tobacco drying with mechanical ribbing

A technological process and hanging technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that tobacco leaves cannot be protected, the workload of tobacco farmers is heavy, and the service life of tobacco folds is short, so as to achieve convenient and quick modulation process and good tobacco leaf modulation Function, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

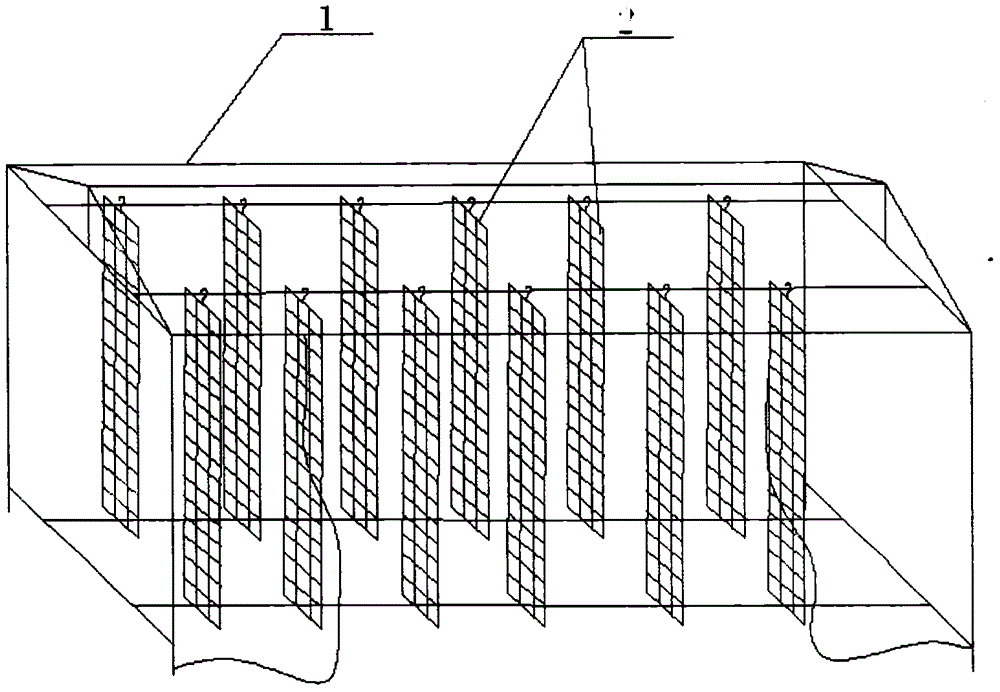

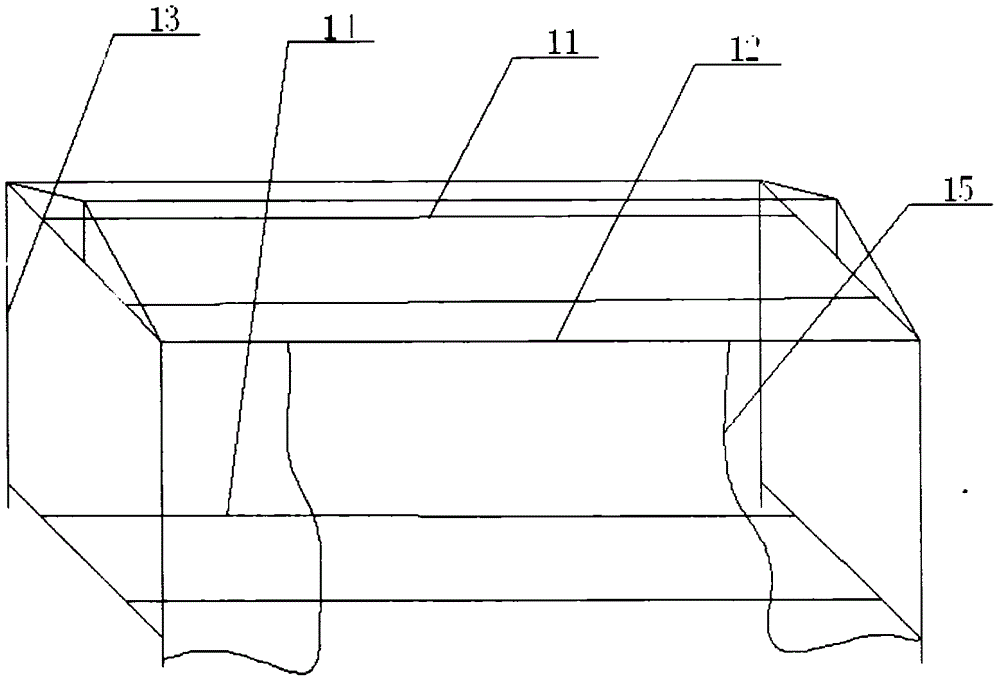

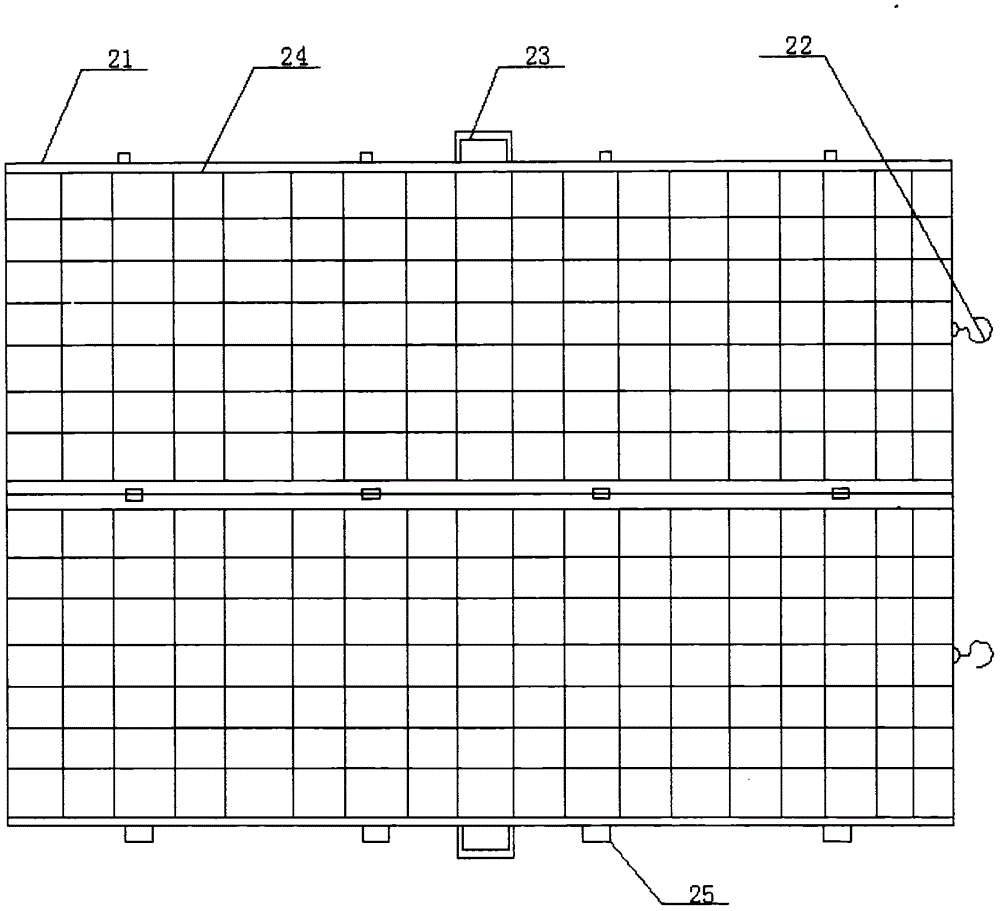

[0035] Such as Figure 1 to Figure 5 As shown, this specific embodiment adopts the following technical scheme: wherein the mechanically pressed bar hanging type tobacco drying device includes a hanging tobacco drying rack 1 and a hanging tobacco drying clip 2, and the hanging tobacco drying rack 1 includes a suspension rod 11, a movable curtain Installation rod 12, support rod 13, pressure bearing rod 14, movable curtain 15; two movable curtain installation rods 12 are arranged on the top of the four support rods 13, and several hanging curtains are arranged between the two movable curtain installation rods 12. The rod 11, the bottom of the support rod 13 is provided with a pressure rod 14, and the two sides of the movable curtain installation rod 12 are symmetrically provided with movable curtains 15; the hanging tobacco drying clip 2 includes two grids connected by a rotating shaft The block frame 24 realizes the integrated tobacco drying folder. The outer ring of the grid b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com