Rotating disc type vacuum heating setting machine for improving efficiency

A vacuum heating and turntable technology, which is applied to shoe uppers, clothing, footwear, etc., can solve the problems of unimproved production efficiency, multiple spaces, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

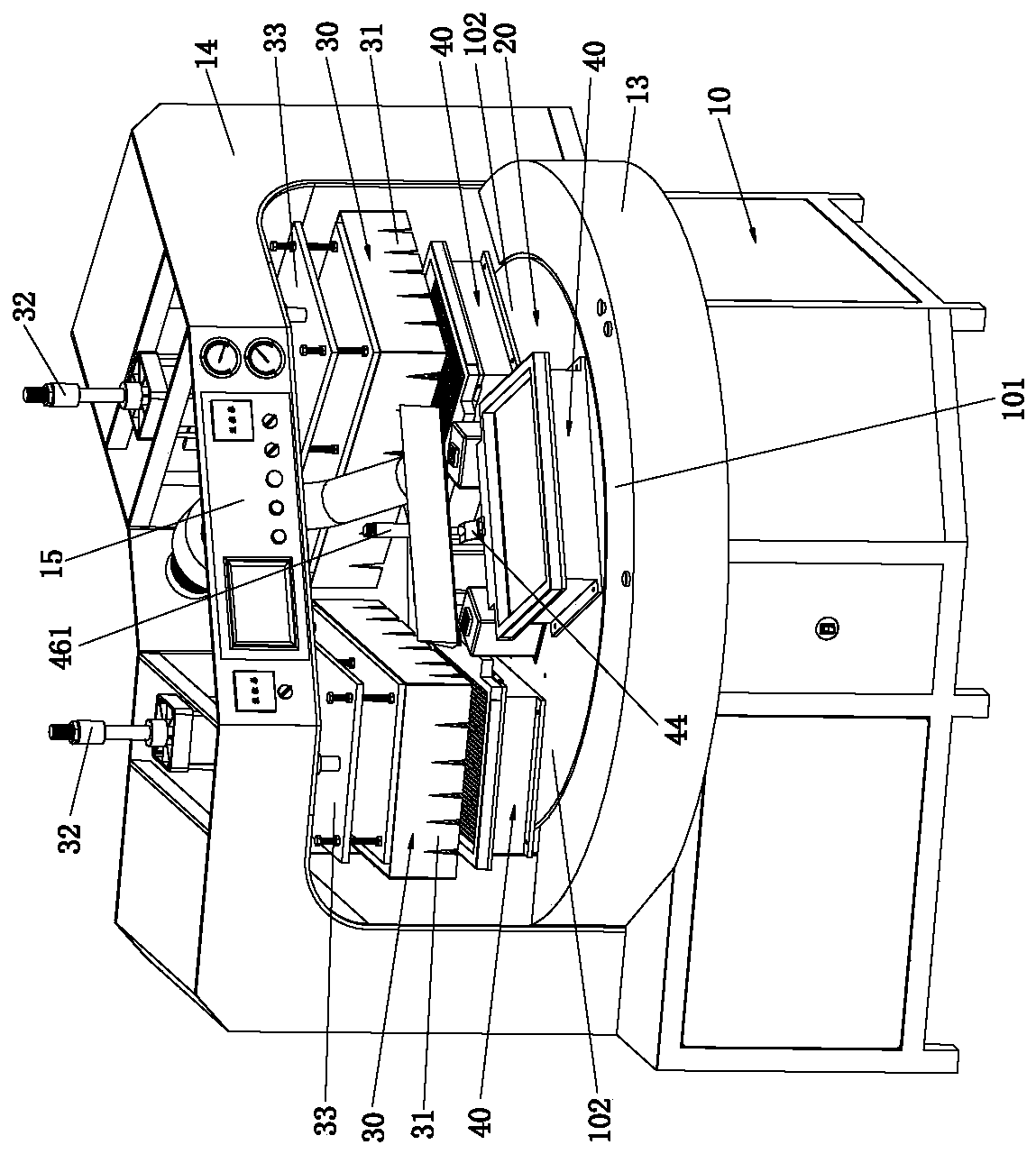

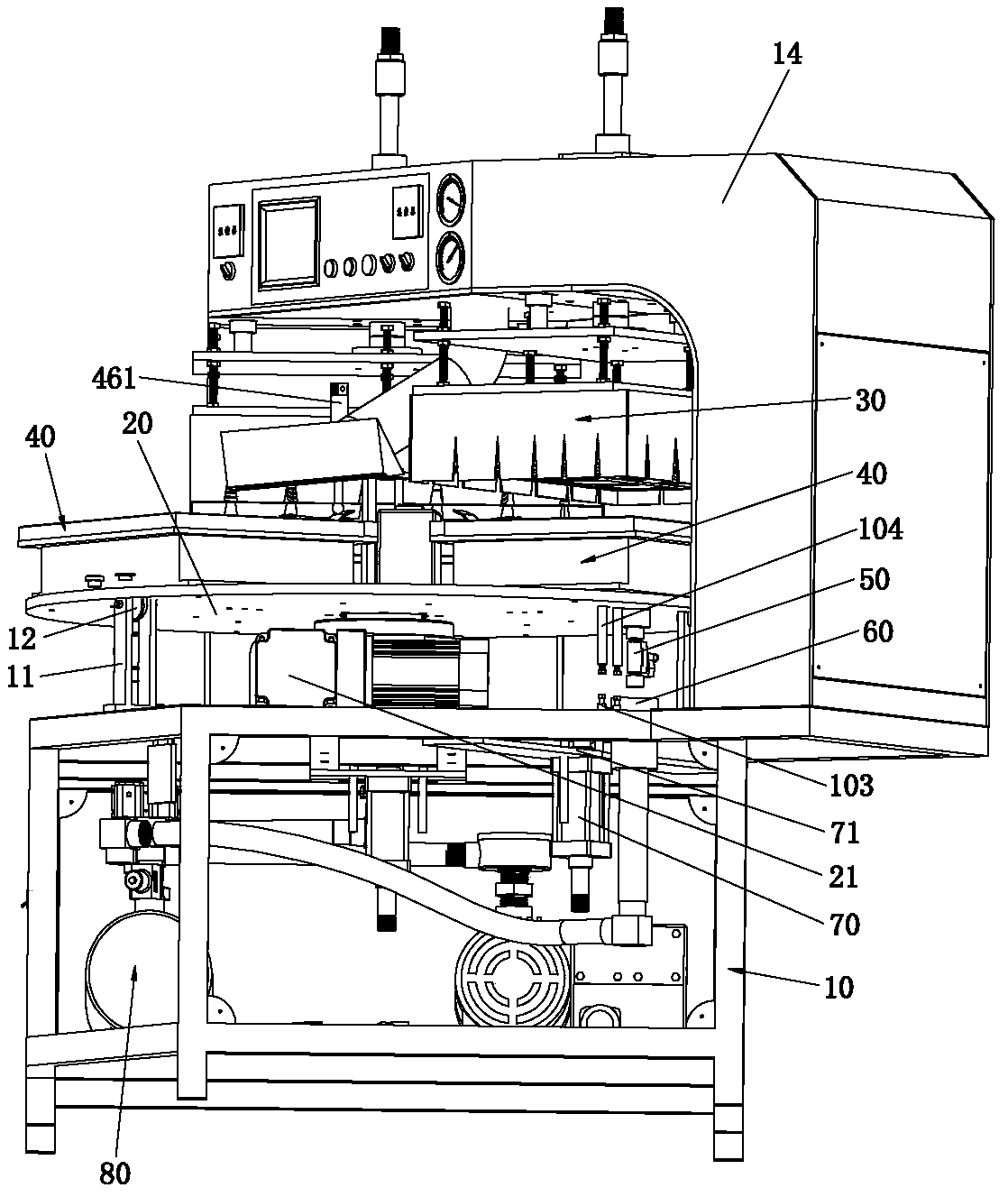

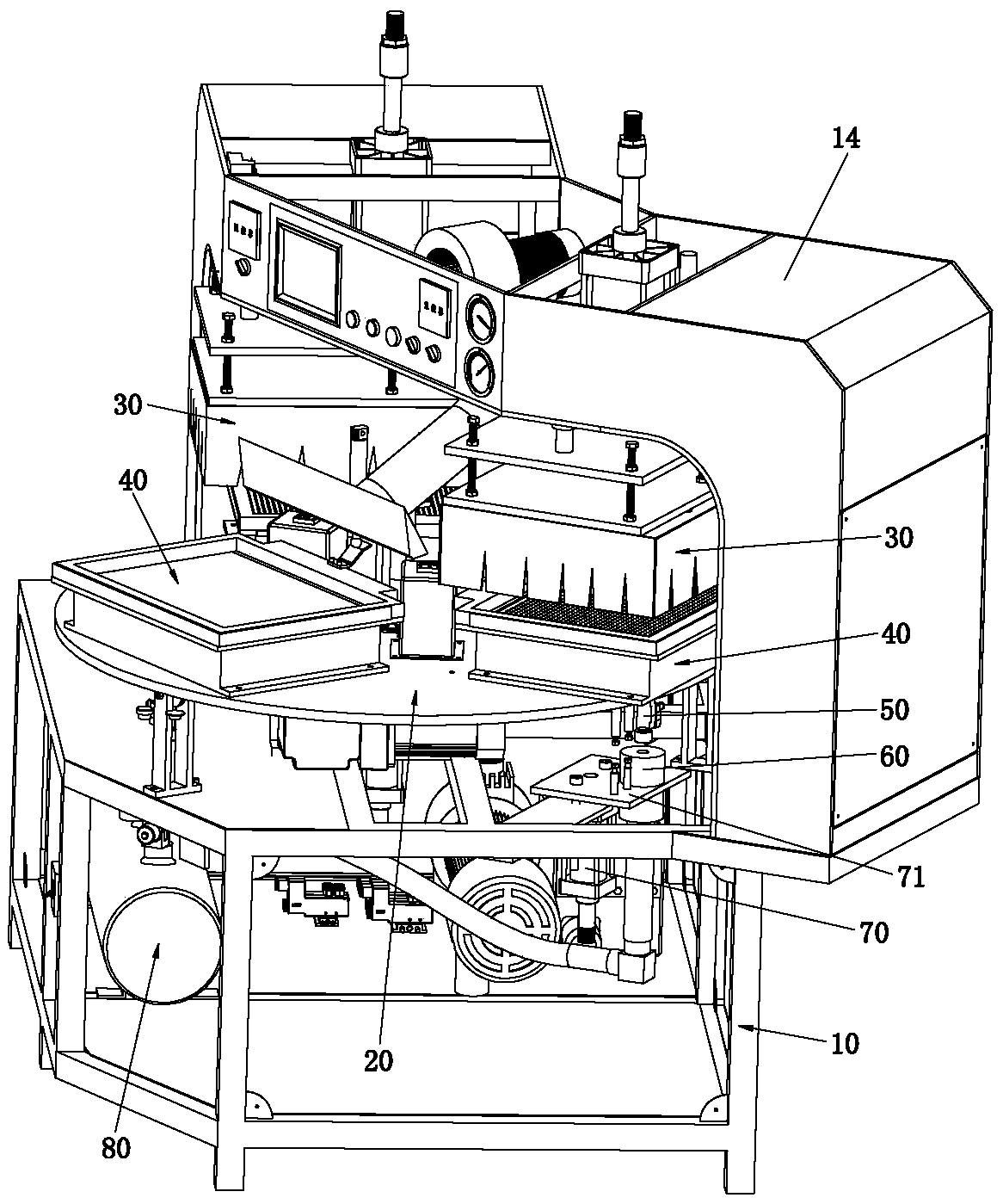

[0053] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the embodiment of the present invention.

[0054]The turntable vacuum heating and setting machine with improved efficiency includes a machine platform 10, a turntable 20 arranged on the machine platform 10, and at least two baking devices 30; the turntable 20 is connected with a turntable drive mechanism 21 for driving the turntable 20 to rotate; The machine table 10 has a first station 101 for loading and unloading and at least two second stations 102 for baking, which are arranged in sequence according to the process sequence. The first station 101, at least two second stations The positions 102 are arranged in an annular interval successively, and each baking device 30 is arranged above the corresponding second station 102; the turntable 20 is provided with at least three vacuum forming assemblies 40 arranged in an annular interval for carrying workpieces. The forming assembly 40 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com