A Tobacco Curing Room Using Multiple Heat Sources

A technology of flue-cured tobacco room and multiple heat sources, applied in the field of flue-cured tobacco room, can solve the problems of high construction cost and operating cost, low quality of tobacco leaf curing, high labor intensity of tobacco farmers, etc. The effect of reducing the comprehensive electricity cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

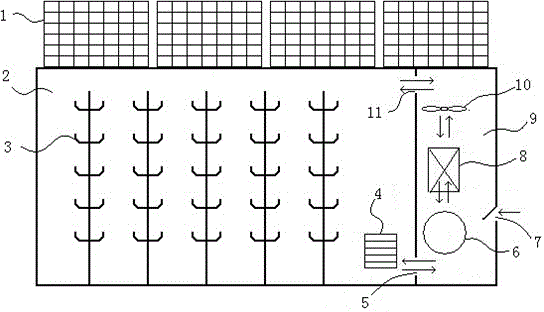

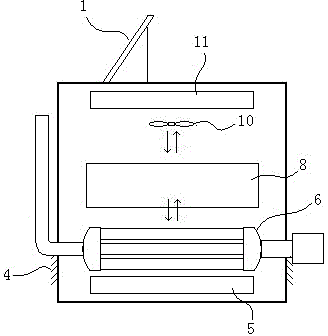

[0018] See figure 1 , figure 2 , adopt the flue-cured tobacco room of multi-heat source, comprise drying room 2, the top of drying room 2 is provided with solar power generation system 1, one end of drying room 2 is provided with heating chamber 9; Ventilation port 11, lower ventilating port 5, the lower part of the side of the drying room 2 is provided with a louver moisture discharge port 4, the drying room 2 is provided with a plurality of pole racks 3 for hanging tobacco leaves; the lower part of the heating chamber 9 is provided with a methanol burner 6, An electric heater 8 is provided in the middle, and a fan 10 is provided in the upper part, and the electric heater 8 and the fan 10 are electrically connected to the power grid and the solar power generation system; the heating chamber 2 is provided with an air volume regulating port 7 .

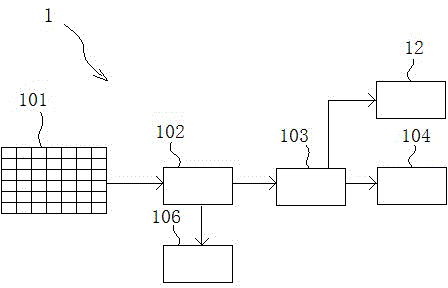

[0019] The solar power generation system 1 such as image 3 As shown, it includes a photovoltaic panel 101, a charging and dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com