Mechanical synchronous crank labor-saving torque-increasing mechanism

A mechanical synchronization and crank technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problem of not being able to increase torque at the same speed, and achieve the effects of reducing input power, reducing pollution emissions, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

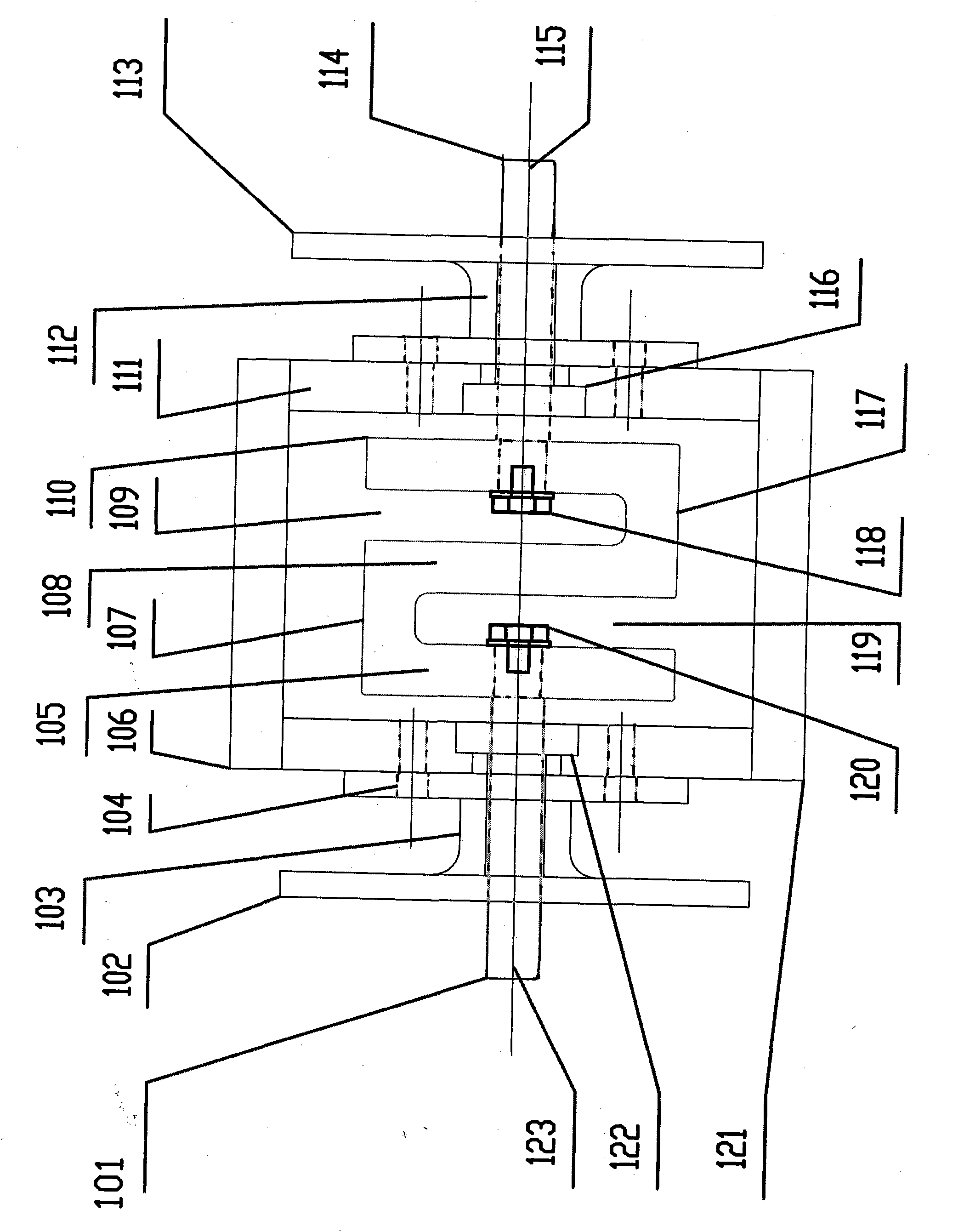

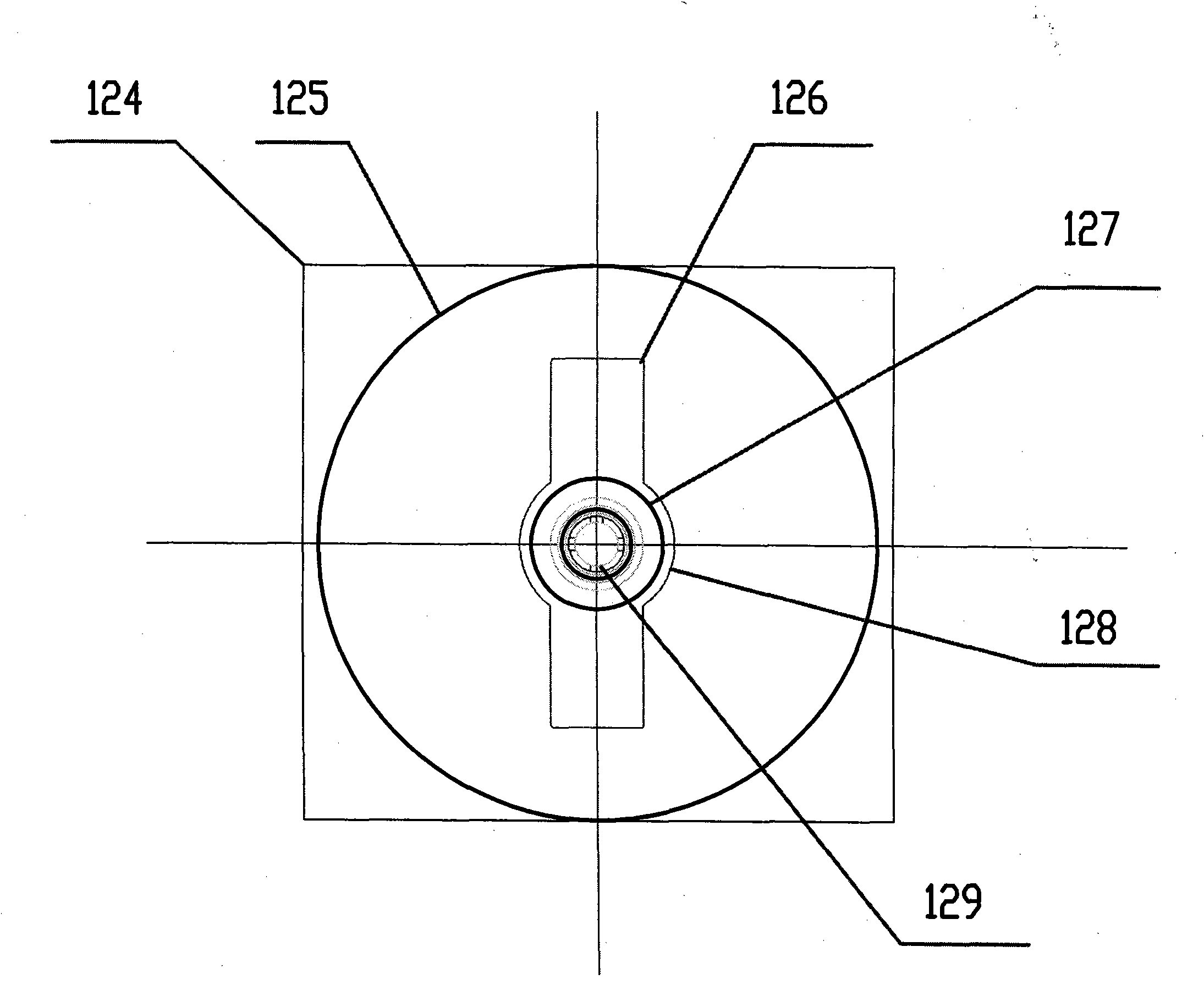

[0041] Specific implementation plan 1: Basic single-stage coaxial input and output mechanical synchronous crank labor-saving torque increasing mechanism The basic single-stage coaxial input and output mechanical synchronous crank torque increasing mechanism consists of six basic mechanisms, fixed mechanism, input mechanism, torque increasing mechanism, transmission Mechanism, dynamic balance mechanism, output mechanism. The input and output terminals of this basic scheme are not divided, that is, the input and output can be connected casually, which is also a major advantage of this scheme.

[0042] If 101 is the input shaft, then 123 is just the input connection keyway. The input connection of this structural diagram is a coaxial connection, the connection is fixed flange 102 (namely 125), 103 is the sealing groove of the input shaft 101, and 104 is the crimping bolt hole between the input connecting flange and the input fixing plate. The input shaft 101 is connected with th...

specific Embodiment approach 2

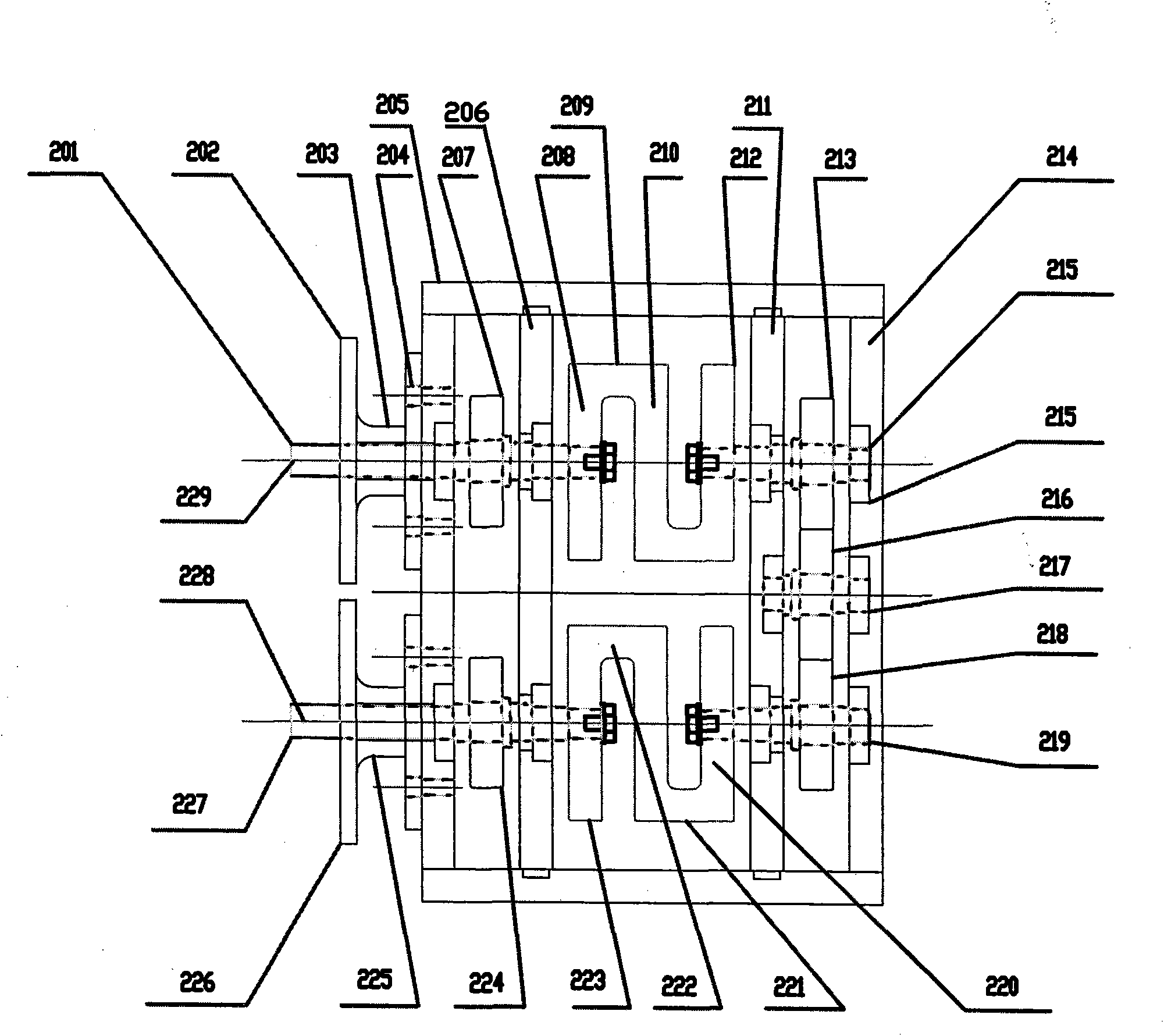

[0047] Specific implementation plan 2: double-stage series connection input and output mechanical synchronous crank labor-saving and torque-increasing mechanism

[0048] The two-stage series series input and output mechanical synchronous crank torque increasing mechanism is composed of eight basic mechanisms, the fixed mechanism, the input mechanism, the first-level torque increasing mechanism, the second-level torque increasing mechanism, the transposition transmission mechanism, the power transmission mechanism, the dynamic balance mechanism, output mechanism. In the structural diagram of this scheme, the input and output are in the same direction, that is, the input and output shafts 201 and 228 are in the same direction. This structure can reduce the length of the torque increasing mechanism and save the length space. It is especially suitable for output power equipment and demand power in practical applications. The equipment is a combination of upper and lower conjoined ...

specific Embodiment approach 3

[0057] Specific implementation plan three: three-stage series connection input and output mechanical synchronous crank torque increasing mechanism

[0058] The three-stage series connection input and output mechanical synchronous crank torque increasing mechanism is composed of nine basic mechanisms, the fixed mechanism, the input mechanism, the first-level torque increasing mechanism, the second-level torque increasing mechanism, the third-level torque increasing mechanism, the transposition transmission mechanism, the power Transmission mechanism, dynamic balance mechanism, output mechanism. In the structural diagram of this scheme, the input and output of the same horizontal axis are in different directions, that is, the input and output shafts 325 and 335 are in the same axis and different directions. This structure can reduce the length of the torque increasing mechanism, save the length space, and further amplify the increased torque. . In practical applications, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com