Compact repetitive high-voltage charging power supply with low input electric power

A high-voltage charging and electric power technology, which is applied in battery circuit devices, electric pulse generator circuits, current collectors, etc., can solve problems such as compression on the time scale of energy supply, low electric power supplied by the power supply system, and inability to apply in applications. , to achieve the effect of compact power supply, light weight and low input electrical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

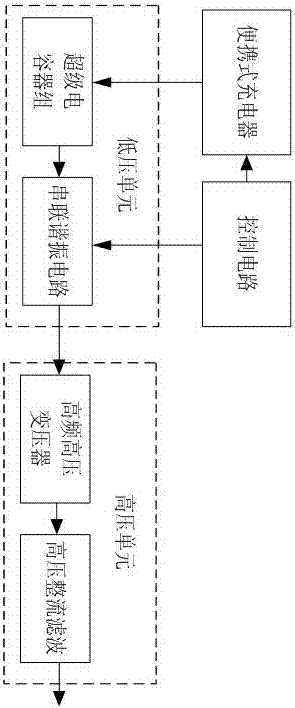

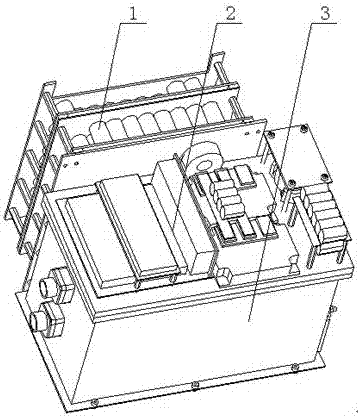

[0028] Such as figure 1 As shown, the low-input power compact heavy-frequency high-voltage charging power supply includes two parts: a low-voltage unit and a high-voltage unit. The low-voltage unit is composed of a super capacitor bank and a series resonant circuit. The high-voltage unit is composed of a high-frequency high-voltage transformer and a high-voltage rectifier filter. The input end of the high-voltage charging power supply (the actual electrical connection is the positive and negative terminals of the supercapacitor bank) is externally connected to a portable charger, and the charger is connected to the power supply terminal of the power supply system; the output end of the high-voltage charging power supply (the actual electrical connection is the high-voltage rectification and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com