Baking method of sun-cured tobacco filial generation

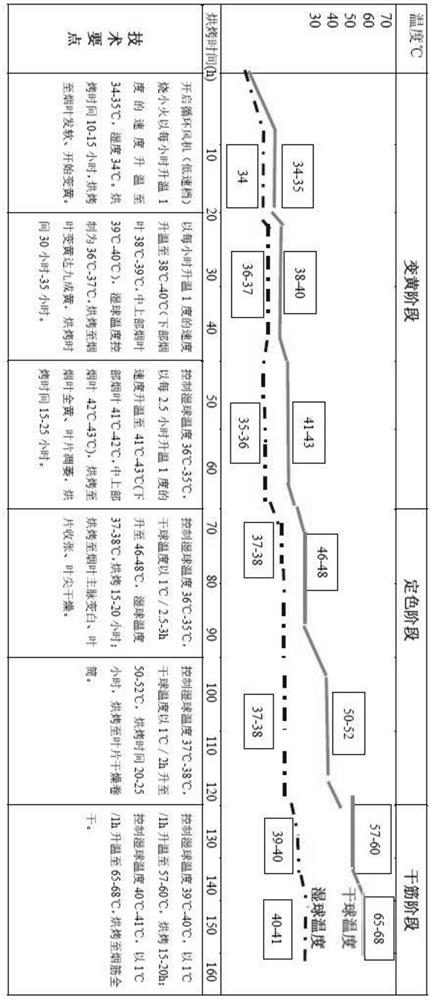

A curing method and flue-cured tobacco technology are applied in the fields of tobacco, tobacco preparation, climate change adaptation, etc., which can solve the problem that the intensive curing technology of flue-cured tobacco is not suitable for curing the hybrid descendants of sun-cured tobacco and flue-cured tobacco, so as to improve the quality of flue-cured tobacco and reduce the loss of aroma. , reduce the effect of brown flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using the above roasting methods, Y28 tobacco leaves were roasted in Huishui in 2016. The quality of the roasted tobacco leaves is as follows:

[0038] Appearance quality: The color of the lower tobacco leaves of Y28 is mainly yellow-golden, with good maturity, slightly negative oil content, thin identity, loose leaf structure, and medium-strong chroma; the color of the middle tobacco leaves is mainly golden-yellow, Good maturity, slightly oily, moderate identity-slightly thin, loose-sparse leaf structure, strong color-medium; the color of the upper tobacco leaves is mainly orange-golden, good maturity, oily content, moderate identity, leaves The structure is loose, and the color performance is strong-medium.

[0039] Main chemical components: the nicotine content of Y28 lower tobacco leaves is 1.2%, the total sugar content is 39.6%, the reducing sugar content is 27.1%, the total nitrogen content is 1.3%, the potassium content is 2.36%, and the chlorine content is 0.08%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com